check engine SSANGYONG NEW ACTYON SPORTS 2013 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 562 of 751

09-134850-01

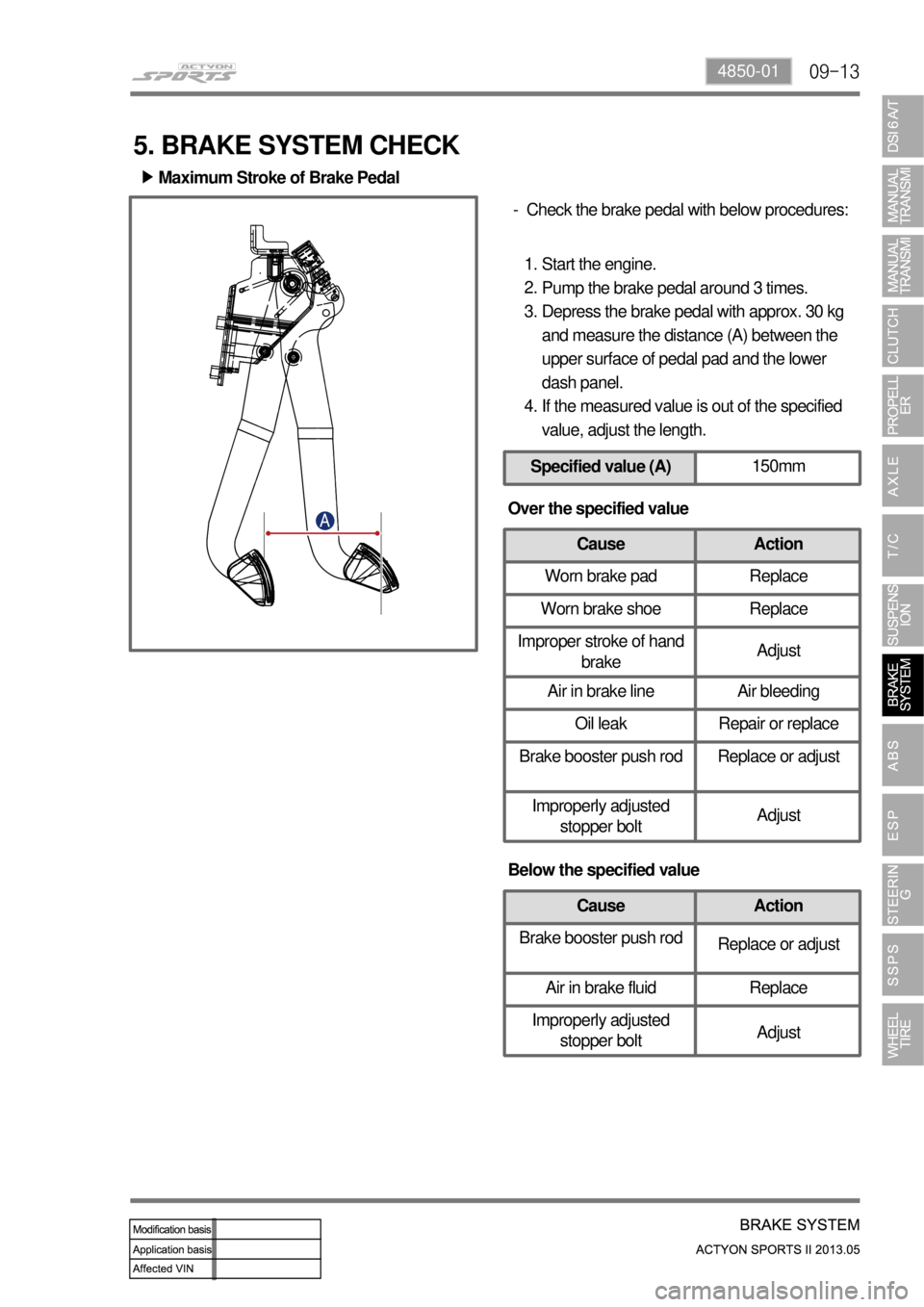

Maximum Stroke of Brake Pedal ▶

Check the brake pedal with below procedures: -

Start the engine.

Pump the brake pedal around 3 times.

Depress the brake pedal with approx. 30 kg

and measure the distance (A) between the

upper surface of pedal pad and the lower

dash panel.

If the measured value is out of the specified

value, adjust the length. 1.

2.

3.

4.

Specified value (A)150mm

5. BRAKE SYSTEM CHECK

Over the specified value

Cause Action

Worn brake pad Replace

Worn brake shoe Replace

Improper stroke of hand

brakeAdjust

Air in brake line Air bleeding

Oil leak Repair or replace

Brake booster push rod Replace or adjust

Improperly adjusted

stopper boltAdjust

Below the specified value

Cause Action

Brake booster push rod

Replace or adjust

Air in brake fluid Replace

Improperly adjusted

stopper boltAdjust

Page 563 of 751

09-14

Specified value (B)155mm

Push rod

Stop lamp

switch Pedal Height ▶

Check the pedal height with below procedures: -

Start the engine and measure the length (A)

between floor mat and pedal.

If the measured value is out of the specified

value, adjust the length. 1.

2.

Adjust the pedal height with below procedures: -

Disconnect the stop lamp switch connector.

Unscrew the lock nut and remove the stop

lamp switch assembly.

Loosen the lock nut on the pedal push rod.

Turn the pedal push rod to adjust the pedal

height.

Tighten the lock nut.

Install the stop lamp switch assembly.

Connect the stop lamp switch connector.

Check if the stop lamps come on when

pressing the brake pedal around 5 mm.

If the stop lamp dpes not come on, adjust the

stop lamp switch assembly again.

If the stop lamps come on, tighten the lock nut

and measure the pedal height again. 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Page 564 of 751

09-154850-01

Specified value (A)3 ~ 10mm

Connect the multimeter to stop lamp switch

connector and check if the continuity exists

when pushing in the plunger. If the continuity

doesn't exist, the stop lamp switch is normal. - Pedal Free Play ▶

Stop Lamp Switch ▶Check the pedal free play with below

procedures: -

Stop the engine.

Depress the brake pedal several times to

discharge the vacuum pressure of the brake

booster.

Depress the brake pedal until you feel the

resistance, and measure the movement (A). 1.

2.

3.

Below the specified value: Check if the

distance between the outer case of stop lamp

switch and the brake pedal.

Over the specified value: It may be caused by

bigger clearance between the clevis pin and

the brake pedal arm. Replace the

components if necessary. -

-

Page 565 of 751

09-16

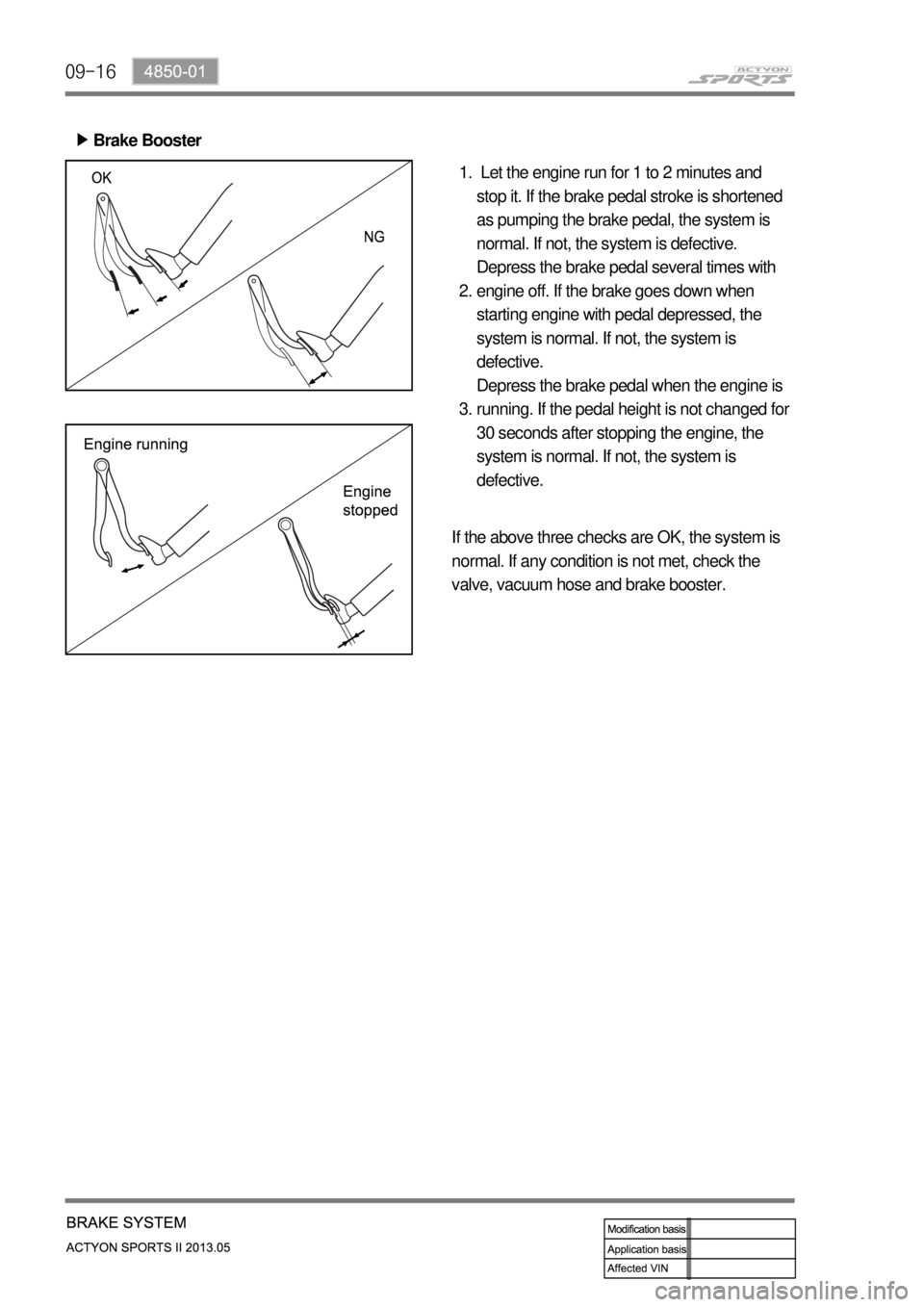

Let the engine run for 1 to 2 minutes and

stop it. If the brake pedal stroke is shortened

as pumping the brake pedal, the system is

normal. If not, the system is defective.

Depress the brake pedal several times with

engine off. If the brake goes down when

starting engine with pedal depressed, the

system is normal. If not, the system is

defective.

Depress the brake pedal when the engine is

running. If the pedal height is not changed for

30 seconds after stopping the engine, the

system is normal. If not, the system is

defective. 1.

2.

3.

If the above three checks are OK, the system is

normal. If any condition is not met, check the

valve, vacuum hose and brake booster. Brake Booster ▶

Page 644 of 751

12-154610-01

Adjusting Plug

Gear Preload Check ▶

Preload is the term used in mechanical engineering to describe the load applied to a fastener merely as

a result of being fastened (and before any external loads are applied)

5. INSPECTION AND MAINTENANCE

Place the wheels at straight ahead direction.

Lift up the vehicle with a lift.

Unscrew the adjusting plug lock nut.

Measure the torque of the adjusting plug. 1.

2.

3.

4.

If the torque is excessive or too low, adjust to

the specified torque. 5.

Place the rack gear to the center position.

Tighten the adjusting plug to 10.2 Nm.

Turn the pinion gear so that the rack gear is

turned to lock to lock 5 times.

Unscrew the adjusting plug.

Tighten the adjusting plug to 4.6 to 5.6 Nm.

Unscrew the adjusting plug to 67.5°. -

-

-

-

-

-

Lock nut

Adjusting Plug

Bushing

Rack support yokeRack support spring

Yoke plugLock nut

Page 645 of 751

12-16

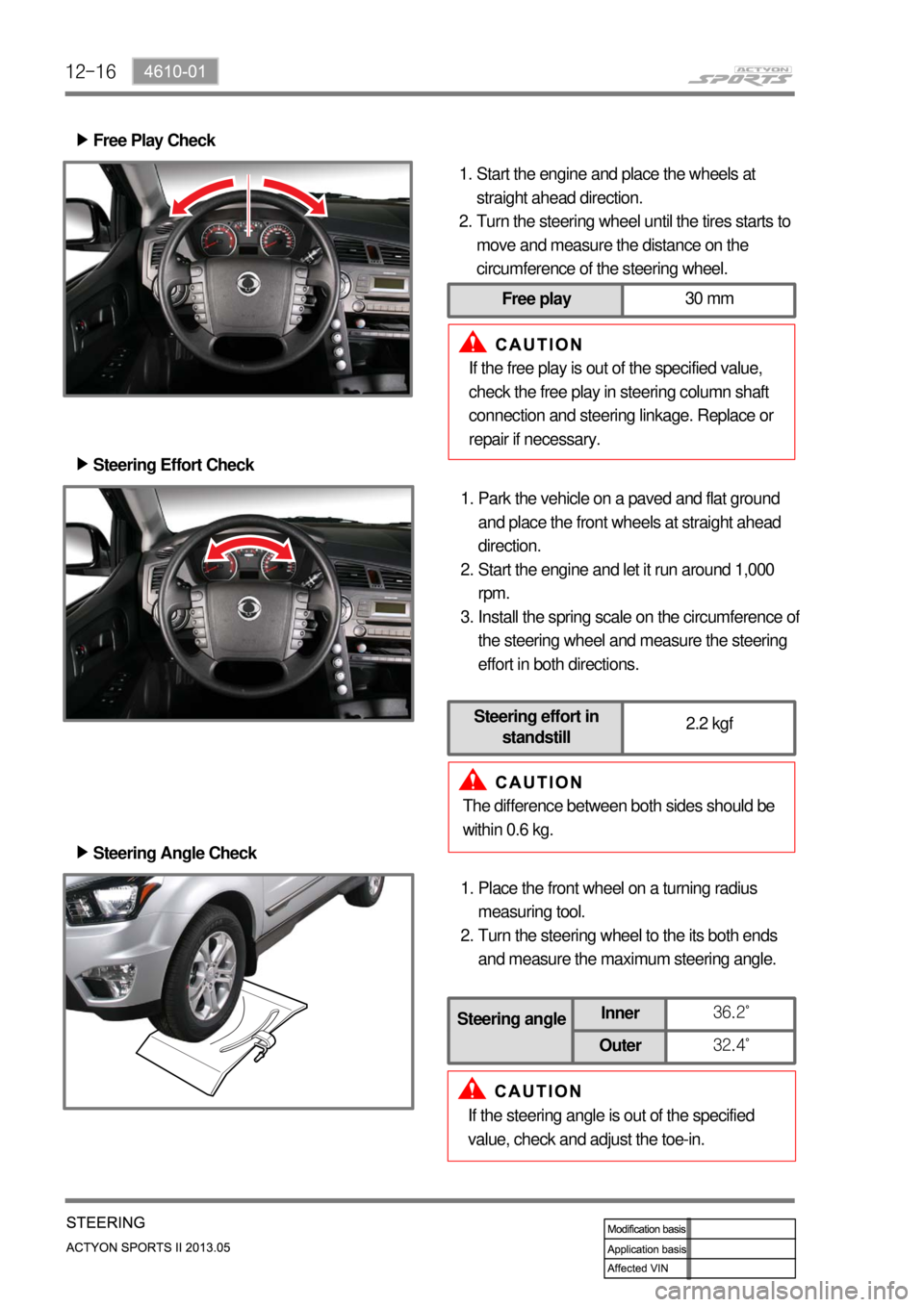

The difference between both sides should be

within 0.6 kg.Park the vehicle on a paved and flat ground

and place the front wheels at straight ahead

direction.

Start the engine and let it run around 1,000

rpm.

Install the spring scale on the circumference o

f

the steering wheel and measure the steering

effort in both directions. 1.

2.

3. Steering Effort Check ▶

Steering Angle Check ▶

Place the front wheel on a turning radius

measuring tool.

Turn the steering wheel to the its both ends

and measure the maximum steering angle. 1.

2.

If the steering angle is out of the specified

value, check and adjust the toe-in.

Steering angleInner36.2˚

Outer32.4˚

Free Play Check ▶

Start the engine and place the wheels at

straight ahead direction.

Turn the steering wheel until the tires starts to

move and measure the distance on the

circumference of the steering wheel. 1.

2.

If the free play is out of the specified value,

check the free play in steering column shaft

connection and steering linkage. Replace or

repair if necessary.

Free play30 mm

Steering effort in

standstill2.2 kgf

Page 646 of 751

12-174610-01

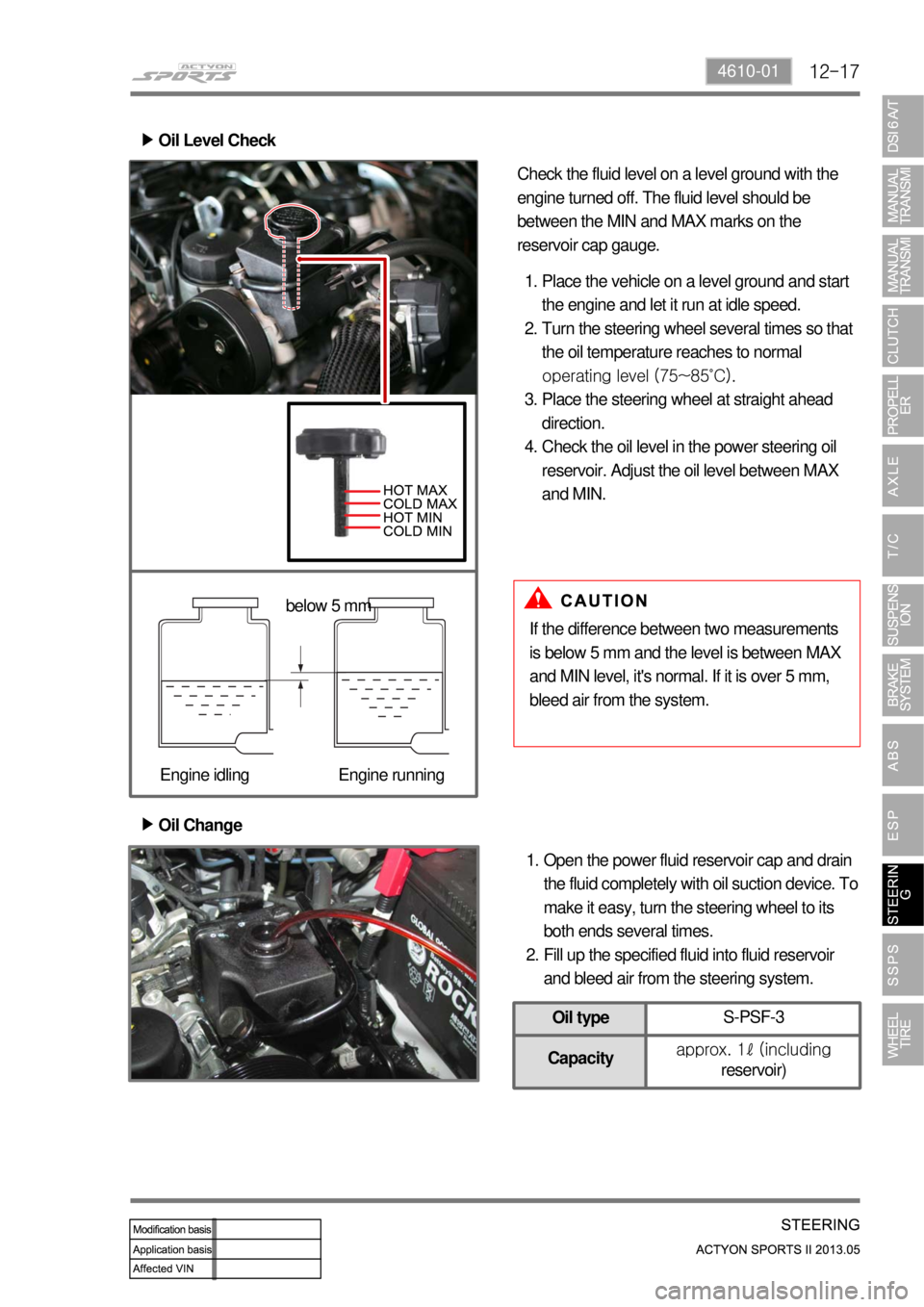

Oil Change ▶

Open the power fluid reservoir cap and drain

the fluid completely with oil suction device. To

make it easy, turn the steering wheel to its

both ends several times.

Fill up the specified fluid into fluid reservoir

and bleed air from the steering system. 1.

2. Oil Level Check ▶

Place the vehicle on a level ground and start

the engine and let it run at idle speed.

Turn the steering wheel several times so that

the oil temperature reaches to normal

operating level (75~85˚C).

Place the steering wheel at straight ahead

direction.

Check the oil level in the power steering oil

reservoir. Adjust the oil level between MAX

and MIN. 1.

2.

3.

4.

If the difference between two measurements

is below 5 mm and the level is between MAX

and MIN level, it's normal. If it is over 5 mm,

bleed air from the system. Check the fluid level on a level ground with the

engine turned off. The fluid level should be

between the MIN and MAX marks on the

reservoir cap gauge.

below 5 mm

Engine idling Engine running

Oil typeS-PSF-3

Capacityapprox. 1ℓ (including

reservoir)

Page 647 of 751

12-18

Air Bleeding ▶

Lift up the vehicle very carefully.

Turn the steering wheel to its both ends

several times and add the oil up to MAX line

in the steering oil reservoir.

Periodically crank the starting motor and turn

the steering wheel to its both ends without

any interruption.

Check the oil level again. If the oil level is

fluctuated, repeat the procedures from step 3

to step 5.

Start the engine.

Turn the steering wheel to its both ends until

any bubble can be found in the steering oil

reservoir.

Perform the test drive and check the steering

wheel for normal operation and noise.

If the oil level abruptly goes up, bleed the air

from the system again. 1.

2.

3.

4.

5.

6.

7.

8.

The air bleeding should be done after servicing

the power steering system and when the

difference between two measurements (cooled

and normal temperature) is prominent.

Max

Min

Normal Abnormal

If the air bleeding is not properly performed,

the life span of the power steering pump

may be shortened. -

Page 648 of 751

12-194610-01

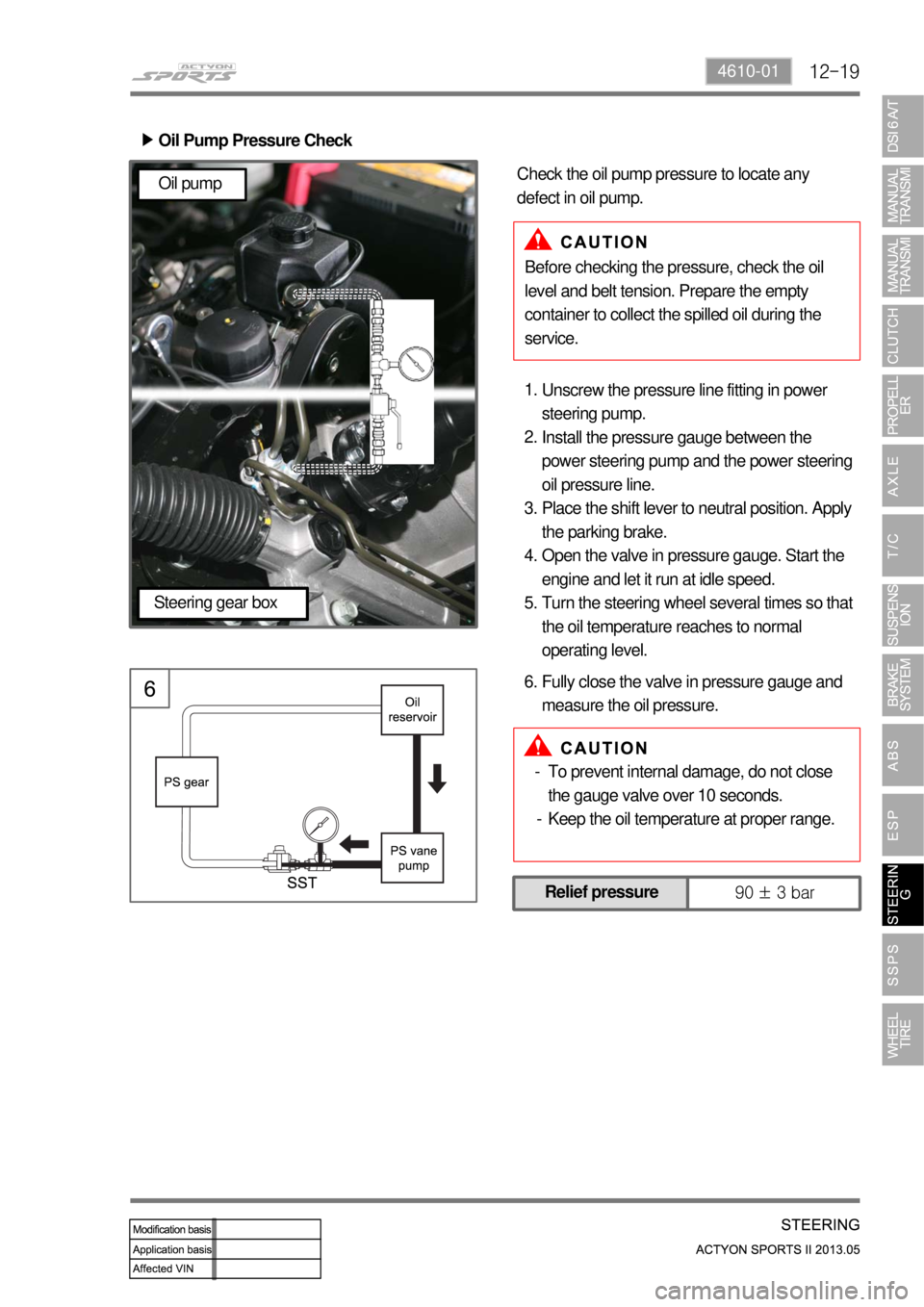

Oil Pump Pressure Check ▶

Unscrew the pressure line fitting in power

steering pump.

Install the pressure gauge between the

power steering pump and the power steering

oil pressure line.

Place the shift lever to neutral position. Apply

the parking brake.

Open the valve in pressure gauge. Start the

engine and let it run at idle speed.

Turn the steering wheel several times so that

the oil temperature reaches to normal

operating level. 1.

2.

3.

4.

5.

Before checking the pressure, check the oil

level and belt tension. Prepare the empty

container to collect the spilled oil during the

service. Check the oil pump pressure to locate any

defect in oil pump.

Fully close the valve in pressure gauge and

measure the oil pressure. 6.

Relief pressure

90 ± 3 bar

Oil pump

Steering gear box

To prevent internal damage, do not close

the gauge valve over 10 seconds.

Keep the oil temperature at proper range. -

-

Page 730 of 751

03-6

3. WARNINGS FOR POWER SEAT

Adjust the driver's seat before driving.

Make sure that the seat is firmly secured after adjusting.

Never drive the vehicle with the head restraint removed or lowered excessively. Otherwise, your neck,

spine or other parts of the body can be severely injured in the event of an accident.

If you recline the seatback excessively, you could slide under the seat belt and be injured severely in a

collision.

Do not put any object that could damage the seat on the seat.

The front and rear seats are equipped with the heated wire (seat warmer) system. Using the seat

warmer system excessively may cause minor burns. The following occupants should exercise special

care when using the heated wire seat. 1.

2.

3.

4.

5.

6.

Infant, child, old or handicapped person

Person with sensitive skin

Exhausted person

Persons who is drunk or took medicine which causes drowsiness such as sleeping pills, cold

tablets, etc. -

-

-

-

Do not place anything on the seat that insulates against the heat, such as a blanket or cushion.

Make sure that the head restraints are in place and secured properly. Never drive the vehicle with the

head restraint removed.

To minimize the injuries in a collision or an abrupt stop, make sure the seatback is in the upright

position before driving. If the seatback is reclined too much, the occupant could slide under the seat

belt in a collision or an abrupt stop and cannot be protected properly by the airbag system. 7.

5.

9.

4. CAUTIONS FOR POWER SEAT

You can operate the power seat with the ignition switch OFF. However, frequent operation of the seat

switch with the engine stopped can result in battery becoming discharged.

Operating more than one seat adjustment switch at the same time can cause damage to the seat

motor. Therefore, operate the seat switch only one at a time.

Do not use organic solvents such as benzene, thinner, alcohol or gasoline to prevent the seat cover

from being damaged while cleaning.

Do not operate the seat position adjustment switch forcefully when the seat does not move or it

contacts an object.

If the power seat is not operated, check and correct the problem before driving off. 1.

2.

3.

4.

5.