sensor SSANGYONG NEW REXTON 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 213 of 600

0000-00

HP PumpFuel Line

Injector (7-way Injection and C3I Coding)Fuel filter Priming Pump

Common Rail

2. COMPONENTS OF FUEL SYSTEM

Fuel nozzle

holes (7)

Injector

Fuel pipe

High pressure fuel pip Fuel rail pressure sensor

Fuel filter

Connector

Priming

pump

Fuel from

HP pumpFuel filter

HP pumpFuel tank

Fuel tank

Common rail

Fuel return

port

Low pressure

fuel supply port

Venturi

High pressure

fuel supply port

(orifice included)

Fuel

temperature

sensor

IMV valve

Fuel return

port

IMV

connector

Page 216 of 600

HFM Sensor (ver. 6.0)VGT Turbo Chargera

Uncompressed air

Air coeaner Turbo

charger

Temperature

sensor

Pretension

graph

Ambient air

Air cleaner

Compressed air

1. INTAKE SYSTEM LAYOUT

The intake system is equipped with an electric throttle body which includes a flap. This flap is controlled

by an electrical signal to cut off the intake air entering to the engine when the ignition switch is turned off.

And, the improved HFM sensor has been adopted to control the intake air volume more precisely.

Exhaust manifold

Air coeaner

Intercooler Exhaust gas

VGT control actuator

Page 217 of 600

0000-00

Intercooler

Booster Pressure SensorIntake Manifold

Ground Supply power

Output

voltageTo corresponding

cylinders Coolant

port

Compressed

air

EGR gas

Engine stopped:

flap closed Normal: flap open

Intake duct

Intake duct

Intake manifold

(Throttle body)

Turbo charger

Throttle body

Page 221 of 600

1533-01

1. OVERVIEW FOR CDPF (EURO IV)

The CDPF (Catalyst & Diesel Particulate Filter) was installed to the Rexton II D27DTP engine previously.

However, it is now installed to the all 2009 DI engine models, except the Actyon Sports. The DI engine

type sinstalled to Rexton are D27DTP, D27DT and D20DT, and their CDPF, related sensor and

operation logic are the same.This section describes the CDPF system (based on Euro IV) which is

installed to the Rexton II D27DTPengine (older model).

1) General Description

2) Compatibility of CDPF System by Vehicle Model

Rexton II: Same CDPF system for D27DTP and D27DT engines (including its components)

Kyron & Actyon: Same CDPF system for D27DT and D20DT engines (including its components)

The CDPF assemblies installed to the Euro IV D27DTP Rexton II and 2009 Rexton II are

different in their mounting layout, but their front/rear exhaust temperature sensors and

differential pressure sensors are same. -

3) System Met with EURO IV Regulations

The Ssangyong vehicles installed with the D27DT engine manufactured from July 2007 to December

2007 comply with the EURO IV regulations. Modified components from the old engine model are as

follow:

- E-EGR valve

- EGR cooler

- Engine ECU (Ver. 3.2)

- HFM senso

- C3I injector

- Electronic throttle valve (body)

- Other engine mounting components

For details about the modified components and system related to the EURO IV regulations, refer to the

2008 Rodius engine service manual.

Page 222 of 600

Under air cleaner in right side

of engine compartment

2. CDPF (EURO IV) SYSTEM

The CDPF system is only installed to the D27DT engine, and the major changes comparing to the

previous D27DT engine is as follows:

CDPF (Catalyst & Diesel Particulate Filter) and Sensors

Front exhaust gas

temperature sensor

CDPF Exhaust Gas Temperature Sensor

The two temperature sensors

in-side the CDPF are installed

inexhaust manifold (front

exhaustgas temperature

sensor) and inDOC (rear

exhaust gas tempera-ture

sensor), and perform the fol-

lowing functions.Front Exhaust Gas Tempera-ture

Sensor:

Measures the exhaust gas tem-

perature of the exhaust manifold. As it

is installed in front of the VGT

turbocharger, it also monitors the

exhaust gas tempera-ture coming to

the turbocharger. If the temperature of

the exhaust gas flowing to the

turbocharger is higher than the

specification, the engine lowers the

exhaust gas temperature.Rear Exhaust Gas Tempera-

ture Sensor:

Measures the increased ex-

haust gas temperature after

the oxidation process of DOC.

If the temperature is below

amount is increased to

increase the temperature.

As the soot is filtered in the CDPF, the pressure between the front side and the rear side of the filter is

different from each other. If the amount of soot is over 28 g, the soot is burnt in the CDPF. The

combustion is determined depending on the pressure difference, temperature of exhaust gas and

Page 223 of 600

1533-01

Throttle Body

CDPF system controls the amount of intake air by controlling the

electronic throttle body. The electronic throttle body has the

following main functions.

CDPF control - added a function that increases the exhaust gas

temperature by closing the throttle valve flap to minimize the intake

air amount by the fuel injection amount during the CDPF

regeneration range with the low engine load range.

ON/OFF control - prevents the engine from turning off with

vibration and noise by closing the throttle body flap to block the

intake air when the engine is stopped.

Duty control - controls the valve inside the throttle body to burn

more EGR gas in the EGR valve operating range.

VGT Turbocharger and Front Exhaust Gas Temperature Sensor

Turbocharger may become weaker if high tem-

perature exhaust gas passes through the tur-

bocharger for DPF regeneration process.

The front exhaust gas temperature sensor moni-tors

the temperature of the exhaust gas that flows into the

turbocharger.

If the temperature of the exhaust gas that passes

through the exhaust manifold is higher than the

specification, the ECU decreases the fuel injection

amount and increases the EGR gas intake amount to

decrease the exhaust gas temperature.Front exhaust gas

temperature sensor

Page 225 of 600

1533-01

2.CDPF (EURO IV) SYSTEM CONTROL

1) General Description

As the soot is filtered in the CDPF, it is burnt and removed, and the CDPF is returned to the initial state to

collect the soot. Therefore, the burning procedures in the CDPF can be called as regeneration.

The CDPF assembly is integrated with DOC (at front side) and DPF (at rear side).

The DPF burns the soot with high-temperature exhaust gas (over

The rear exhaust gas

temperature sensor monitors the temperature of DPF section. If this temperature is below the

regeneration temperature, the ECU increases the post injection period to increase the fuel injection

amount, and consequently to increase the exhaust gas temperature.

Front exhaust gas temperature sensor

(Measuring temperature of exhaust gas in

exhaust manifold)

Rear exhaust gas temperature sensor

(Measuring temperature of exhaust gas

escaping DOC)

Normally, when the vehicle is driven for 600 ~ 1,200 km, the enough amount of soot to be burnt is

filtered and accumulated in the CDPF. The ECU increase the amount of post injection to increase

the tempeature of exhaust gas up to

so that the soot is burnt. The soot is burnt for

15 ~ 20 minutes. -

Page 226 of 600

2) System Composition for Soot Combustion

When the engine is running in low load range, the temperature of exhaust gas is decreased as the

amount of fuel supplied is decreased. To burn the soot filtered in the CDPF, the control system should

be installed to check the operating range and increase the temperature of exhaust gas by controlling the

amount of fuel supplied and intake air.

Two temperature sensors and one differential pressure sensor monitor the CDPF's operating range.

According to these sensors' information, the throttle flap decreases the intake air entered to the throttle

body. Also, the fuel injection pattern is added to increase the temperature of exhaust gas for soot

combustion.

There are three fuel injection patterns (pilot injection, pre-injection and main injection). As the CDPF is

installed, the post injection pattern is added.

3) Post Injection and Air Mass Control

When the differential pressure sensor detects the pressure difference between the front and the rear

side of CDPF, the sensor sends signal indicating the soot is acumulated and the post injection is

performed to raise the temperature of exhaust gas. The amount of fuel injected is determined according

to the temperature of exhaust gas detected by the rear temperature sensor. If the temperature is below

the amount of fuel injected is increased to raise the temperature. If the temperature is over

the amount of fuel injected is decreased or not controlled.

When the engine is running in low load range, the amount of post injection and the amount of intake ai

r

are controlled. It is to raise the temperature by increasing the amount of fuel while decreasing the

amount of intake air.

Page 228 of 600

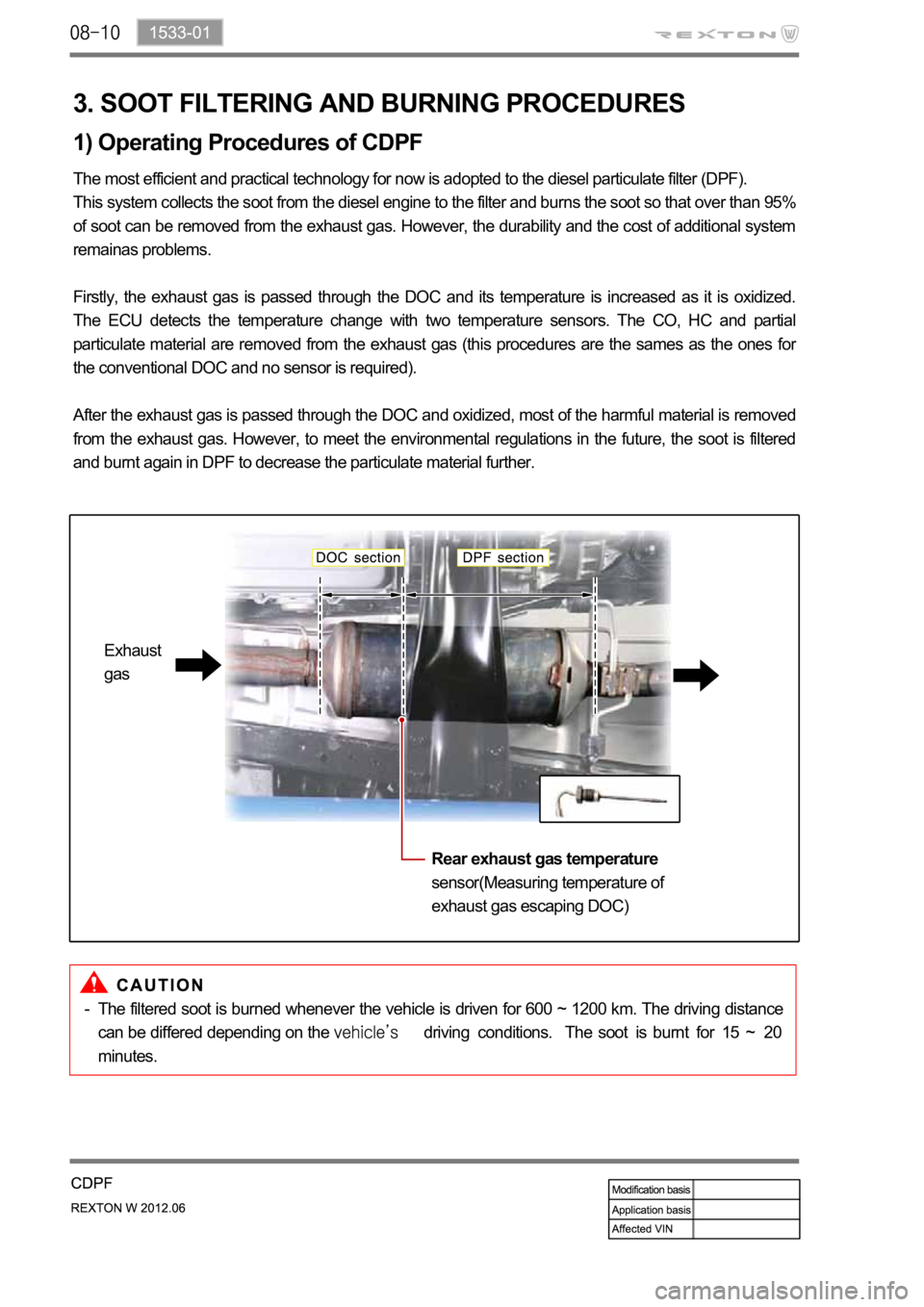

3. SOOT FILTERING AND BURNING PROCEDURES

1) Operating Procedures of CDPF

The most efficient and practical technology for now is adopted to the diesel particulate filter (DPF).

This system collects the soot from the diesel engine to the filter and burns the soot so that over than 95%

of soot can be removed from the exhaust gas. However, the durability and the cost of additional system

remainas problems.

Firstly, the exhaust gas is passed through the DOC and its temperature is increased as it is oxidized.

The ECU detects the temperature change with two temperature sensors. The CO, HC and partial

particulate material are removed from the exhaust gas (this procedures are the sames as the ones fo

r

the conventional DOC and no sensor is required).

After the exhaust gas is passed through the DOC and oxidized, most of the harmful material is removed

from the exhaust gas. However, to meet the environmental regulations in the future, the soot is filtered

and burnt again in DPF to decrease the particulate material further.

The filtered soot is burned whenever the vehicle is driven for 600 ~ 1200 km. The driving distance

can be differed depending on the

driving conditions. The soot is burnt for 15 ~ 20

minutes. -Exhaust

gas

Rear exhaust gas temperature

sensor(Measuring temperature of

exhaust gas escaping DOC)

Page 229 of 600

1533-01

Front temperature sensor

(Measuring the temperature of

exhaust gas passedthrough

exhaust manifold)Rear temperature sensor

(Measuring the temperature of exhaust

gas passed through DOC)

Differrential pressure sensor

(Front pressure port)Differrential pressure sensor

(Rear pressure port)

The engine ECU detects the

amount of particulate material

colected by the information

from temperature sensors

and differential pressure

snesor. When the soot is

accumulated, the pressure

difference be-tween the front

and the rear side occurs.

Then, the engineECU

performs the post injec-tion to

raise the exhaust gas

temperature and burn the

collected soot at approx. The exhaust gas enters

intoCDPF assembly after

passing through the exhaust

manifold. (Normal

temperature of ex-haust gas: When the exhaust gas

enters into the CDPF

assembly, its CO, HC and

particulate mate-rial are

reduced as it is oxi-dized in

DOC. The remaining

particulate material is

filtered and collected in

DPF and the temperature

of exhaust gas is increased