oil SSANGYONG NEW REXTON 2012 Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 386 of 600

2. INSPECTION

1) Alternator Output Test

Item How to check DTC set value / Action

Output

current

B terminal

current

Rotor

coil

resistance

L terminal

voltage

Disconnect the cable connected to the B

terminal on the alternator. Connect one end

of the ammeter to the B terminal and the

other end to the cable connected to the B

terminal.

Measure the maximum output value.

(Maintain the engine speed between 2,500

and 3,000 rpm.)

(Turn the headlamp and all the electrical

switches on.) 1.

2.Pass: If the measured current is 45

A or higher.

Fail: If the measured current is less

than 45 A.

Check the current of the B terminal. -

-

-

Move the gear selector lever to the neutral

position.

Maintain the engine speed at 2,500 rpm

with the vehicle unloaded.

(Turn all the electrical switches off.) 1.

2.Open circuit: If the measured

current is 5 A or higher. -

Disconnect the negative cable from the

battery.

Remove the B terminal and turn off the

ignition switch.

Measure the resistance between the L and

F terminals with an ohmmeter. 1.

2.

3.Pass: If the measured resistance is

Faulty rotor coil or slip ring: If the

measured resistance is less than

-

-

Connect the B terminal wiring.

Measure the voltage with the engine running. 1.

2.Specification: 12.5 V to 14.5 V

Faulty IC regulator or field coil: If

the measured voltage is 14.5 V or

higher. -

-

Disconnect the negative battery cable.

Connect the negative cable again after connecting the ammeter. -

-

Page 426 of 600

2. CAUTIONS

Standard pattern of soot accumulation

(1) Abnormal Soot Accumulation (2) Normal Soot Combustion

Cautions to protect the catalyst filter

Use the designated fuel only.

Observe the recommended service intervals of engine oil.

Check the engine oil level frequently and add if necessary.

Do not idle the vehicle unnecessarily.

Do not turn off the engine while the vehicle is running.

Do not shift the gear selector lever to neutral when going downhill.

Do not use improper engine oil or fuel additives.

Do not drive for a long time when the warning lamp is illuminated.

Make sure no flammable material, such as dry grass or tissue paper, contacts with the catalyst filter

while the vehicle is parked.

For the vehicles used in urban traffic, driving on the expressways for more than 1 hour at least once

per week is needed so that the PM inside CDPF isn't collected to one side only. -

-

-

-

-

-

-

-

-

-

Page 440 of 600

7. CAUTIONS

1) Designated Engine Oil for CDPF (Low Ash Oil)

Need to use the designated engine oil for CDPF 1.

The smoke from the vehicle may generate the particle material in the ambient air. CDPF is the

device to reduce the smoke by collecting and recycling it. To ensure the performance of CDPF,

the designated engine oil should be used.

The smoke including combusted sulfur in fuel cannot be recycled in CDPF. This smoke

generates the ash, resulting in clogging the filter. -

-

Advantages when using the designated engine oil for CDPF 2.

Reduces the amount of ash

Improves the fuel economy and reduces the CO2

Increases the life span of engine oil

Available for all engines (diesel and gasoline) -

-

-

-

Problems when using non-designated engine oil for CDPF 3.

Decreases the life span of engine oil due to accumulated ash in DPF (around 30%)

Decreases the fuel economy due to friction resistance, exhaust gas resistance and frequent

recycling process of DPF -

-

The fuel containing high sulfur may cause the same problems.

2) Do Not Use the Fuel Containing High Sulfur

Producing white smoke during recycling 1.

The sulfur in exhaust gas is changed to sulfate gas during exhaust process. This sulfate gas is

shown as white smoke. -

Producing odor during recycling 2.

The sulfur after oxidation may produce the odor. -

Accumulation of ash 3.

The sulfur accumulated in DPF cannot be recycled. It reduces the life span of DPF. -

3) White Smoke

The white smoke can be generated when the exhaust gas is recycled in DPF. There are two reasons as

below.

Saturated vapor

Sulfate -

-

Page 476 of 600

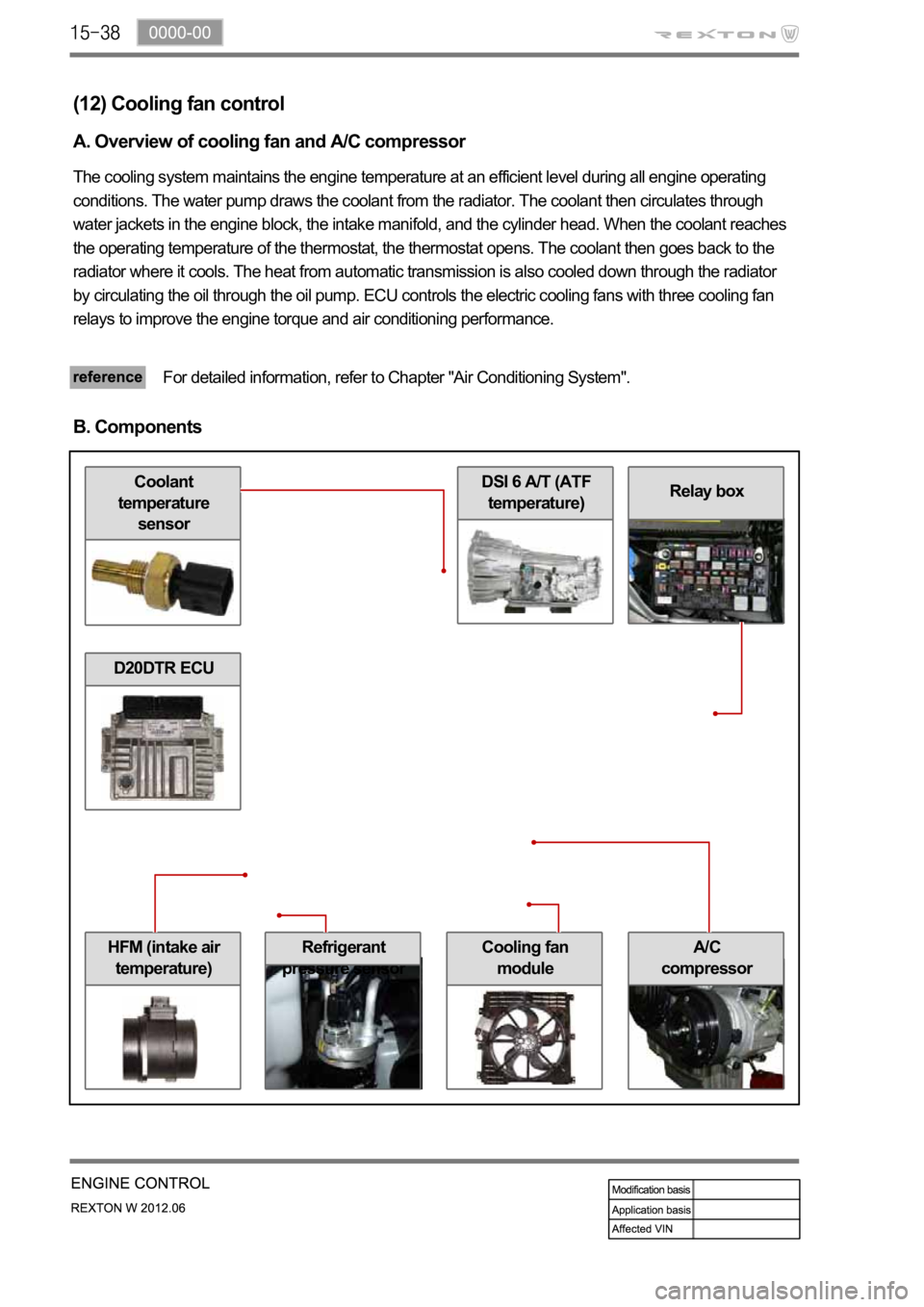

HFM (intake air

temperature)Cooling fan

module

DSI 6 A/T (ATF

temperature)Coolant

temperature

sensor

Refrigerant

pressure sensor

Relay box

(12) Cooling fan control

A. Overview of cooling fan and A/C compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transmission is also cooled down through the radiator

by circulating the oil through the oil pump. ECU controls the electric cooling fans with three cooling fan

relays to improve the engine torque and air conditioning performance.

For detailed information, refer to Chapter "Air Conditioning System".

B. Components

A/C

compressor

D20DTR ECU

Page 487 of 600

0000-00

E. Cautions

Use only specified Engine Oil (approved by MB Sheet 229.51) for CDPF. -

Use only specified engine oil (Low Ash Oil)

The vehicle equipped with CDPF should use specific engine oil to improve the engine performance

and fuel economy, and ensure the service life of CDPF. -

Issue with normal engine oil

Sulfur, one of the contents of engine oil is burned and generates soot that is not regenerated by the

DPF. This remains on the filter as ashes and keeps accumulating. Eventually, this ashes will block

the filter. -

Benefit for specified engine oil

Minimized the sulfur content of engine oil which reduces the service life.

Improved fuel economy and emission level of CO2 with high performance and low viscosity.

Increased service life of engine oil with high resistance to temperature. -

-

-

Problems when using unspecified engine oil

The service life of filter may be reduced by 30% or more by the ashes accumulated on the filter.

The fuel economy may be reduced because of engine rolling resistance, frequent regeneration of

DPF. -

-

These problems are also caused by oil with high sulfur content, such as tax exemption oil and

heating oil, etc. *

Page 494 of 600

2) D27DT Engine Performance Curve

(1) Output and Torque

(2) Oil Temperature/Pressure and Boost Pressure

Page 508 of 600

2) Cautions on Service Procedures

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the

tires. Position the jack under the frame and lift up the vehicle and then support with chassis

stand before service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to

electric systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace

them with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfaces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners with the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the

problem has been eliminated clearly. 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Page 509 of 600

0000-00

3) Guidelines on Engine Service

To prevent personal injuries and vehicle damages that can be caused by mistakes during engine

and unit inspection/repair and to secure optimum engine performance and safety after service

works, basic cautions and service work guidelines that can be easily forgotten during engine

service works are described in.

Cautions before service works

For safe and correct works, you must observe the working procedures and instructions in this

manual. And, use the designated tools as follow:

Engine stand / Heavy duty engine jack

To prevent the engine from starting abruptly, do not allow anybody to get in the vehicle while

servicing in engine compartment.

Before work on engine and electrical equipment, be sure to disconnect battery negative (-)

terminal.

Before service works, be sure to prepare the works by cleaning and aligning work areas.

Do not allow the foreign material get into the fuel injection system.

When removing the engine, use only the safety hook on engine and engine hanger. Do not

support the bottom of oil pan with a jack. -

-

-

-

-

Completely drain the engine oil, coolant and fuel from engine before removal.

Before disassembling/assembling the engine components, carefully read the working

procedures in this manual.

Make sure to keep the specified tightening torques during installation.

Clean and properly lubricate the parts before reassembly.

Carefully check that there is not any interference while servicing. -

-

-

-

-

Page 510 of 600

Do not allow the fluid and engine oil to make contact with the body paintwork and hoses.

If work on the fluid system such as fuel and oil, working area should be well ventilated and

smoking should be prohibited.

Gasket or seal on the fuel/lubrication system should be replaced with new ones and bolts and

nuts should be tightened as specified.

After removal/installation works, be sure to check whether there is leak on the connecting

section. -

-

-

-

If fine dust or foreign material enters into DI engine's fuel system, there can be serious

damages between HP pump and injectors. So, be sure to cover removed fuel system

components with cap and protect removed parts not to be contaminated with dirt. (Refer to

cleanness in this manual while working on DI engine fuel system)

When working on the fuel line between priming pump and injector (including return line),

always plug the openings with caps to prevent foreign materials or dust from entering to the

openings and connections.

The HP fuel supply pipe (HP pump to fuel rail) and HP fuel pipe (Fuel rail to injector) should

be replaced with new ones when removed. 1.

2.

3.

Electric devices should be handled more carefully.

Currently, the engine has a lot of electric devices. There could be poor engine performance,

incomplete combustion and other abnormal symptoms due to short circuit or poor contact.

Before work on engine and electrical equipment, be sure to disconnect battery negative (-)

terminal.

When replacing the electric device, use only genuine part and check the conditions of

connections and grounds. Loosened connection or ground makes cause a fire and personal

injury. -

-

Page 514 of 600

Engine Compartment Layout

Engine assembly

Engine oil dipstick

Vacuum pump

Oil filter and cooler

Fuel filter and priming pump

Brake booster

Brake oil tank

AQGS unit

Washer fluid filler cap

Engine compartment fuse box

PTC relay box

Battery

Vacuum modulator (for VGT turbo charger) 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.FFH Assembly (Only for vehicle with FFH)

Power steering oil tank

Engine oil filler cap

Fan shroud

E-EGR Valve

High-capacity PCV oil separator

HFM sensor (6.0)

VGT turbo charger

Air cleaner housing

2Coolant surge tank

ABS/ESP HECU (Including TPMS function:

optional)

Exhaust gas FRT Temp. sensor (T3) 14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.