ECU SSANGYONG RODIUS 2005 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2005, Model line: RODIUS, Model: SSANGYONG RODIUS 2005Pages: 502, PDF Size: 70.43 MB

Page 47 of 502

CIRCUIT

1461-01/2820-01/1491-01/1491-01/8210-01/3670-01/3670-03/3410-01/4891-01/4920-01/4480-01/8810-01/8010-01/8610-04/8610-11/7421-60/8510-52/8610-17/8510

-

20

/

8710-03/8510-03/8710-03/8510-12/8610-09/7630-02/7340-03/8310-01/8510-00/8320-01/8510-26/8510-24/4810-10/8610-01/7770-07/8910-01/8730-01/6810-21/6910

-

01

/

6810-30/6810-30

CIRCUIT

ENGINE

8910-01 AUDIO (MULTI VISION)................

8910-01 AUDIO..........................................

8730-01 PARKING AID CIRCUIT................

6810-21 PTC HEATER (POSITIVE

TEMPERATURE

COEFFICIENT).............................

6910-01 FFH (FUEL FIRED HEATER).........

6810-30 FATC (FULL AUTO TEMP.

CONTROL) CIRCUIT....................

6810-30 AIR-CON (MANUAL).....................

CHASSIS3670-01 TCU (5-SPEED)............................

3670-03 TOD.............................................

3410-01 TCCU...........................................

4891-01 ABS/ESP......................................

4920-01 EPB..............................................

4480-01 EAS..............................................ELECTRIC

8610-17 DEFFOGER (FRT GLASS, RR

GLASS, OUTSIDE MIRROR)........

8510-20 FRT SEAT WARMER...................

8510-20 AUTO LIGHT CORTROL CIRC.....

8710-03 STICS..........................................

8510-03 POWER WINDOW CIRCUIT.........

8710-03 CENTRAL DOOR LOCKING

CIRCUIT.......................................

8510-12 RR WIPER & WASHER

CIRCUIT.......................................

8610-09 HORN...........................................

7630-02 CIGAR LIGHTER, POWER

OUTLET......................................

7340-03 SUN ROOF CIRCUIT....................

8310-01 HEAD LAMP & DRL (DAY TIME

RUNNING LIGHT) UNIT

CIRCUIT.......................................

8510-00 HEAD LAMP LEVELING DEVICE

CIRCUIT.......................................

8320-01 TAIL LAMP CIRCUIT...................

8510-26 TURN SIGNAL & HAZARD LAMP

CIRCUIT.......................................

8510-24 FOG LAMP CIRCUIT....................

4810-10 STOP & BACK-UP LAMP

CIRCUIT.......................................

8610-01 INTERIOR LAMP(ROOM,

G/HENDLE, DOOR COURTESY)

CIRCUIT......................................

7770-07 AUTO DIMMING ROOM MIRROR

CIRCUIT....................................... 8810-01 AIR-BAG.......................................

8010-01 CLUSTER.....................................

8610-04 MULTI METER.............................

8610-11 RAIN SENSING WIPER

CIRCUIT.......................................

7421-60 DRIVER POWER SEAT

CIRCUIT.......................................

8510-52 ELECTRIC OUTSIDE MIRROR &

FOLDING CIRCUIT.......................49

52

53

54

55

56

59

12

14

15

16

18

19

20

21

24

25

26

2728

29

30

31

35

36

37

38

39

40

41

42

43

44

45

46

47

48 1461-01 STARTING & CHARGING............

2820-01 PREHEATING UNIT CIRCUIT

(XDi))............................................

1491-01 ECU (ENGINE CONTROL UNIT -

XDi)..............................................

1491-01 ECU (GSL G32)............................

8210-01 DIAGNOSIS CIRCUIT...................3

4

5

8

11

Page 51 of 502

0-5

CIRCUIT

RODIUS 2005.07

1491-01

1491-01

ECU (ENGINE CONTROL UNIT - XDi)

1) ENG MAIN RELAY, PEDAL MODULE, HAN SENSORS, VALVE

(1) CONNECTOR INFORMATION

(2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION (1) TRUBO CHARGER BOOSTER, EGR VACUUM MODULE,

INLETMETERING VALVE

Page 54 of 502

0-8RODIUS 2005.07

1491-01

CIRCUIT1491-01

ECU (GSL G32)

1)

(1) CONNECTOR INFORMATION

(2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

IGN COIL, CPS, AIR FLOW SENSOR, THROTTLE SENSOR,

TPS

Page 128 of 502

04-5

ENGINE INTAKE SYSTEM

RODIUS 2005.07

1715-01

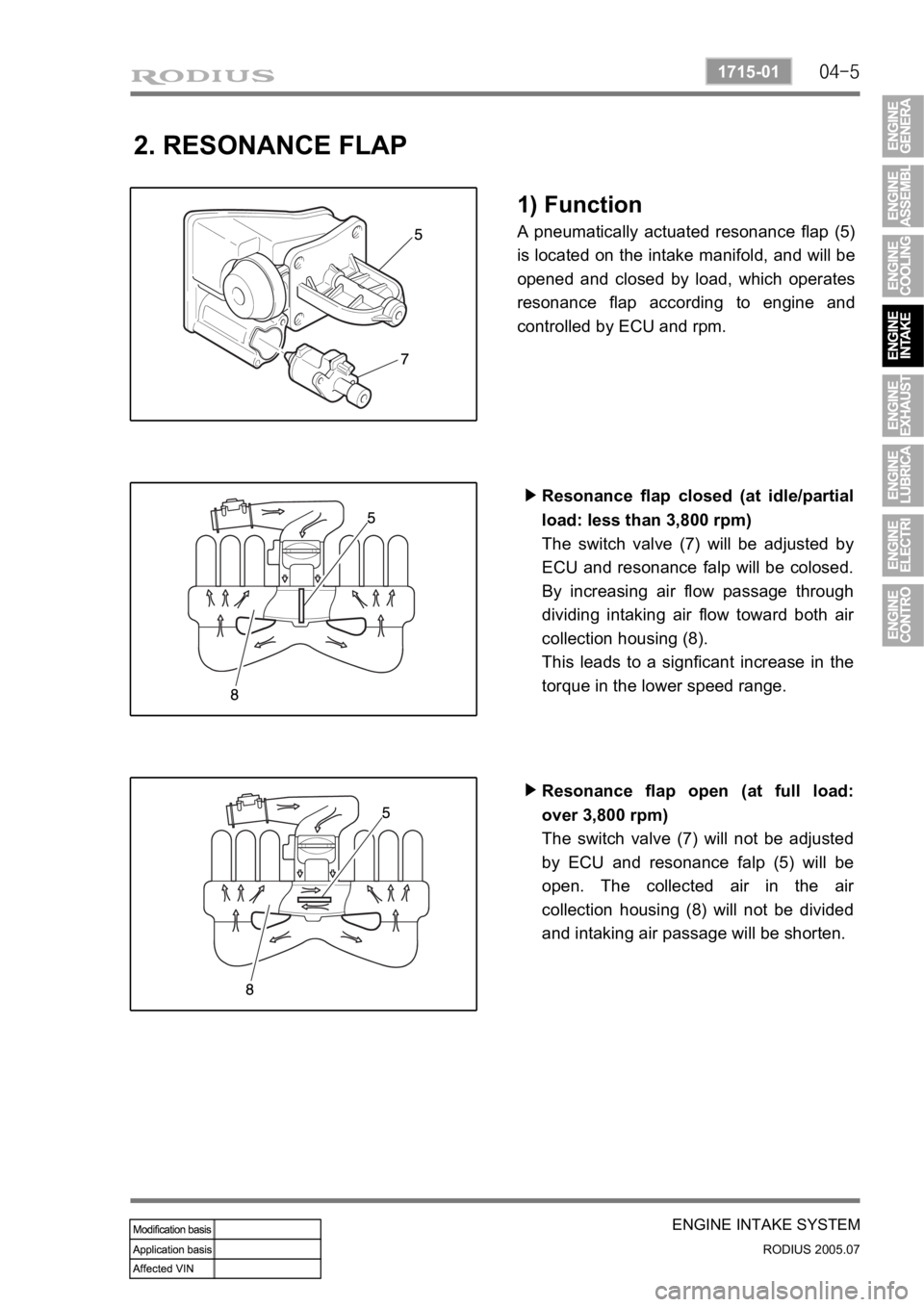

2. RESONANCE FLAP

1) Function

A pneumatically actuated resonance flap (5)

is located on the intake manifold, and will be

opened and closed by load, which operates

resonance flap according to engine and

controlled by ECU and rpm.

Resonance flap closed (at idle/partial

load: less than 3,800 rpm)

The switch valve (7) will be adjusted by

ECU and resonance falp will be colosed.

By increasing air flow passage through

dividing intaking air flow toward both ai

r

collection housing (8).

This leads to a signficant increase in the

torque in the lower speed range. ▶

Resonance flap open (at full load:

over 3,800 rpm)

The switch valve (7) will not be adjusted

by ECU and resonance falp (5) will be

open. The collected air in the ai

r

collection housing (8) will not be divided

and intaking air passage will be shorten. ▶

Page 161 of 502

09-15

ENGINE CONTROL SYSTEM

RODIUS 2005.07

0452-01

2) ECU (GSL G32)

IGN COIL, CPS, AIR FLOW SENSOR, THROTTLE SENSOR, TPS ▶

Page 213 of 502

0-6

RODIUS 2005.07

3240-01

TORQUE ON DEMAND

When turning on the road with low friction rate ▶

During cornering on roads such as unpaved, snowy, icy and muddy, ground grab capacity is

increased by distributing required torque and, at the same time, comfortable steering operation

is maintained by controlling the ground grab capacity at high level.

Distribution ratio: 30 % for front wheels and 70 % for rear wheels.

When climbing or starting off on the road with low friction rate ▶

In order to secure the maximum ground grab capacity and driving force during climbing o

r

starting off on the roads such as unpaved, snowy and icy road, the system controls the driving

force to distribute properly in full 4WD mode.

Distribution ratio: 44 % for front wheels and 56 % for rear wheels.

Page 237 of 502

0-4

RODIUS 2005.07

4892-01

ESP SYSTEM

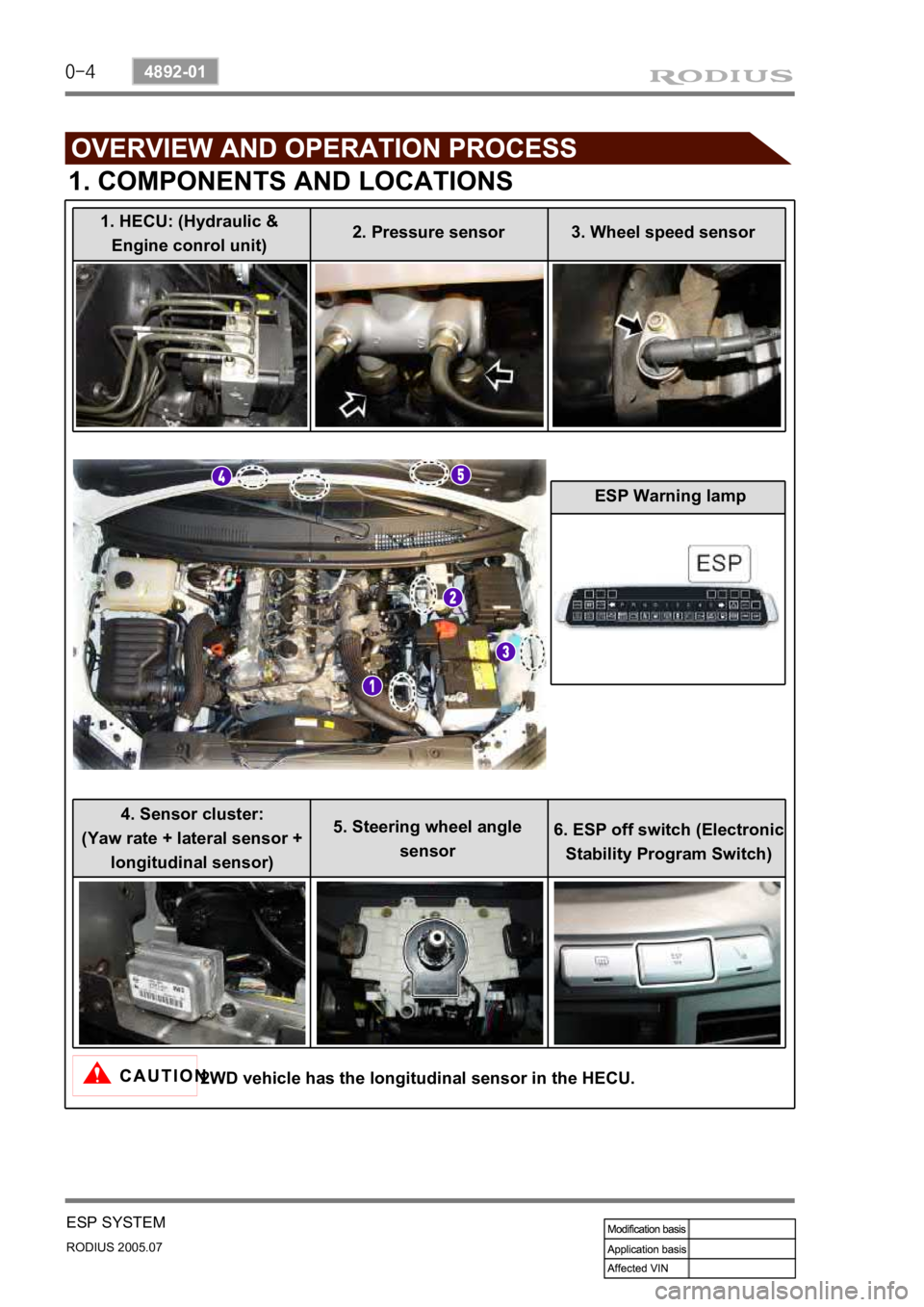

1. COMPONENTS AND LOCATIONS

2WD vehicle has the longitudinal sensor in the HECU.

1. HECU: (Hydraulic &

Engine conrol unit) 2. Pressure sensor 3. Wheel speed sensor

4. Sensor cluster:

(Yaw rate + lateral sensor + longitudinal sensor) 5. Steering wheel angle

sensor 6. ESP off switch (Electronic

Stability Program Switch) ESP Warning lamp

Page 239 of 502

0-6

RODIUS 2005.07

4892-01

ESP SYSTEM

3. ESP SYSTEM DESCRIPTION

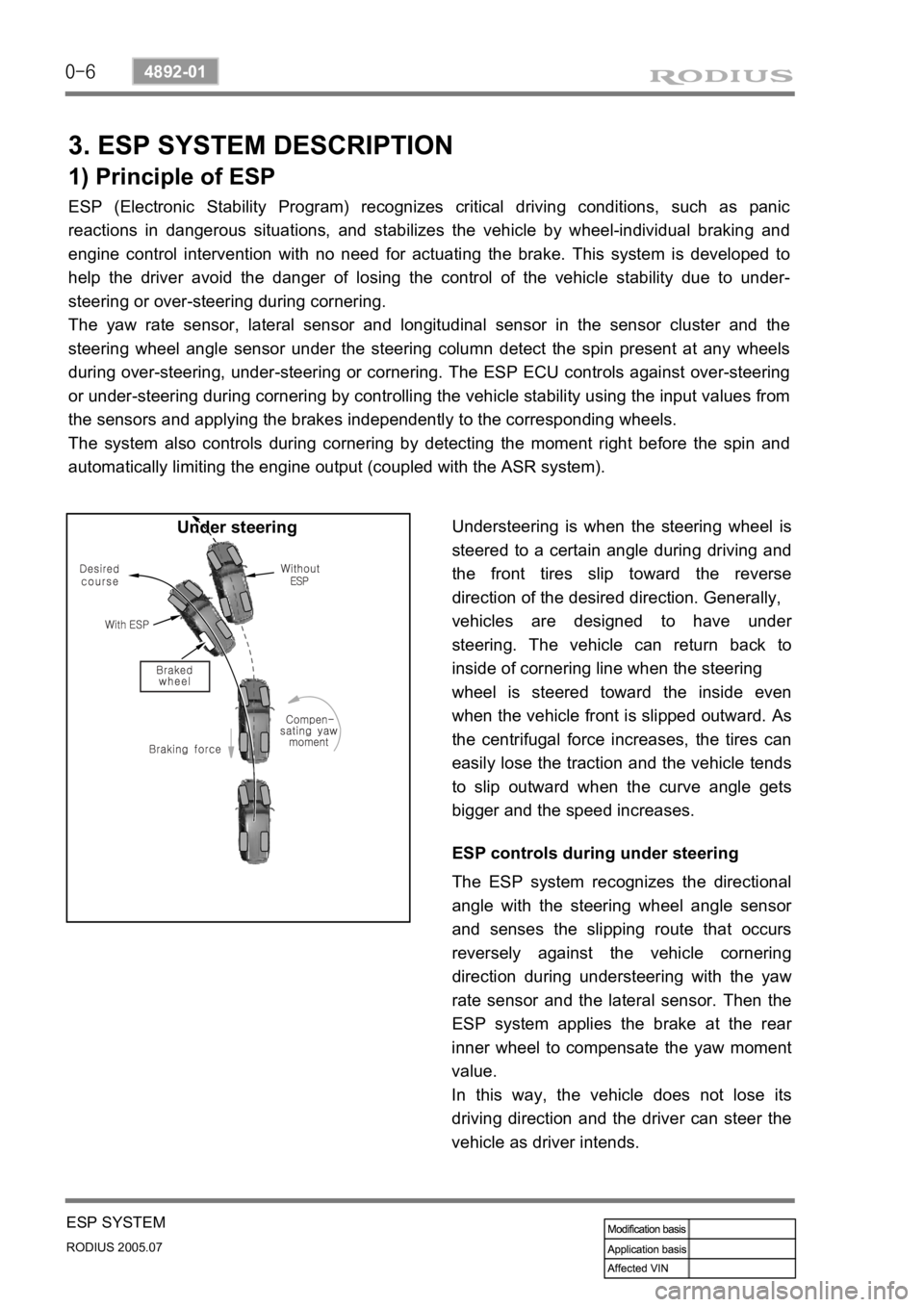

1) Principle of ESP

ESP (Electronic Stability Program) recognizes critical driving conditions, such as panic

reactions in dangerous situations, and stabilizes the vehicle by wheel-individual braking and

engine control intervention with no need for actuating the brake. This system is developed to

help the driver avoid the danger of losing the control of the vehicle stability due to under-

steering or over-steering during cornering.

The yaw rate sensor, lateral sensor and longitudinal sensor in the sensor cluster and the

steering wheel angle sensor under the steering column detect the spin present at any wheels

during over-steering, under-steering or cornering. The ESP ECU controls against over-steering

or under-steering during cornering by controlling the vehicle stability using the input values from

the sensors and applying the brakes independently to the corresponding wheels.

The system also controls during cornering by detecting the moment right before the spin and

automatically limiting the engine output (coupled with the ASR system).

Understeering is when the steering wheel is

steered to a certain angle during driving and

the front tires slip toward the reverse

direction of the desired direction. Generally,

vehicles are designed to have unde

r

steering. The vehicle can return back to

inside of cornering line when the steering

wheel is steered toward the inside even

when the vehicle front is slipped outward.

As

the centrifugal force increases, the tires can

easily lose the traction and the vehicle tends

to slip outward when the curve angle gets

bigger and the speed increases. Under steering

ESP controls during under steering

The ESP system recognizes the directional

angle with the steering wheel angle senso

r

and senses the slipping route that occurs

reversely against the vehicle cornering

direction during understeering with the yaw

rate sensor and the lateral sensor. Then the

ESP system applies the brake at the rea

r

inner wheel to compensate the yaw moment

value.

In this way, the vehicle does not lose its

driving direction and the driver can steer the

vehicle as driver intends.

Page 243 of 502

0-10

RODIUS 2005.07

4892-01

ESP SYSTEM

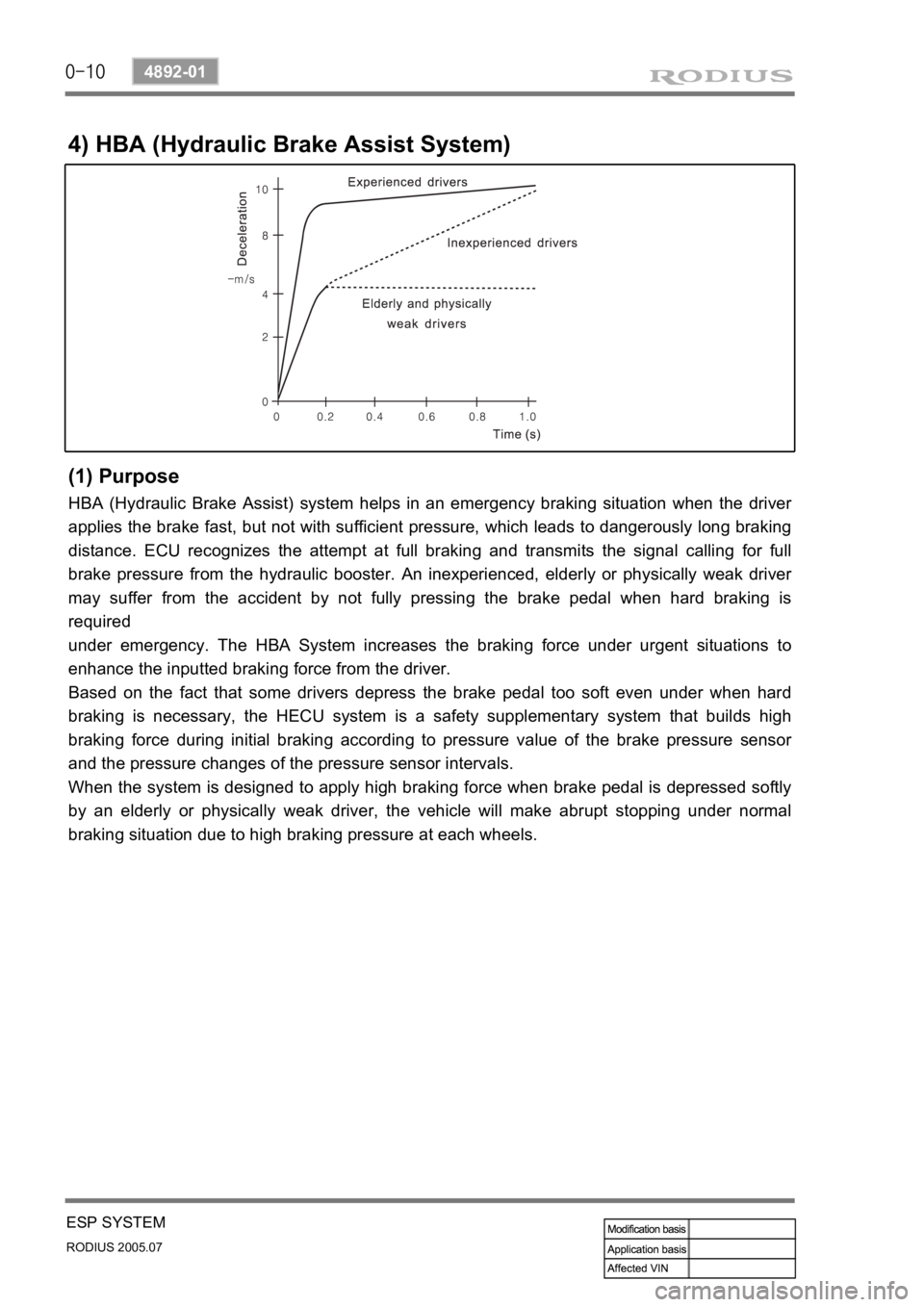

4) HBA (Hydraulic Brake Assist System)

(1) Purpose

HBA (Hydraulic Brake Assist) system helps in an emergency braking situation when the driver

applies the brake fast, but not with sufficient pressure, which leads to dangerously long braking

distance. ECU recognizes the attempt at full braking and transmits the signal calling for full

brake pressure from the hydraulic booster. An inexperienced, elderly or physically weak drive

r

may suffer from the accident by not fully pressing the brake pedal when hard braking is

required

under emergency. The HBA System increases the braking force under urgent situations to

enhance the inputted braking force from the driver.

Based on the fact that some drivers depress the brake pedal too soft even under when hard

braking is necessary, the HECU system is a safety supplementary system that builds high

braking force during initial braking according to pressure value of the brake pressure senso

r

and the pressure changes of the pressure sensor intervals.

When the system is designed to apply high braking force when brake pedal is depressed softly

by an elderly or physically weak driver, the vehicle will make abrupt stopping under normal

braking situation due to high braking pressure at each wheels.

Page 244 of 502

0-11

ESP SYSTEM

RODIUS 2005.07

4892-01

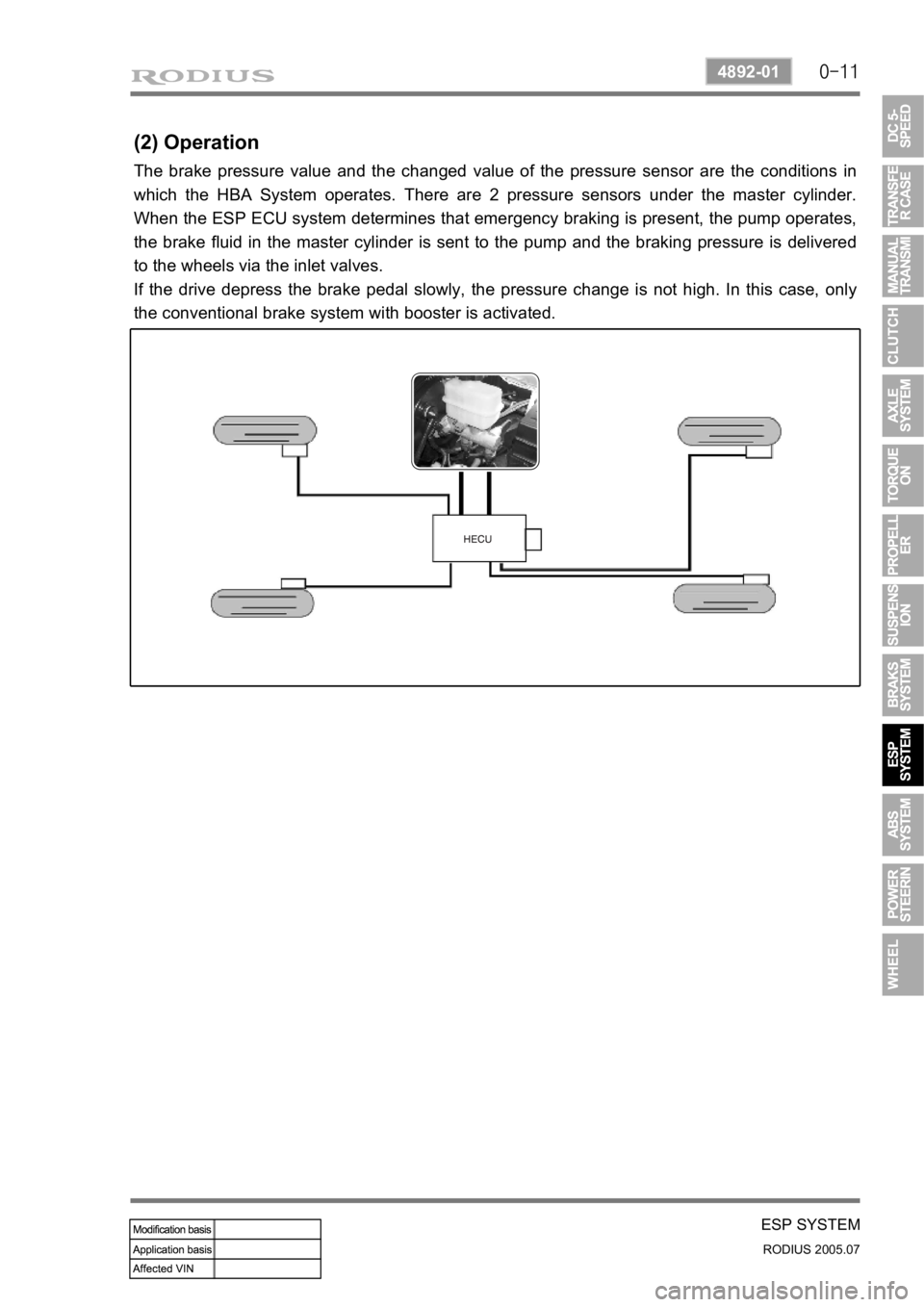

(2) Operation

The brake pressure value and the changed value of the pressure sensor are the conditions in

which the HBA System operates. There are 2 pressure sensors under the master cylinder.

When the ESP ECU system determines that emergency braking is present, the pump operates,

the brake fluid in the master cylinder is sent to the pump and the braking pressure is delivered

to the wheels via the inlet valves.

If the drive depress the brake pedal slowly, the pressure change is not high. In this case, only

the conventional brake system with booster is activated.