air filter SSANGYONG RODIUS 2005 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2005, Model line: RODIUS, Model: SSANGYONG RODIUS 2005Pages: 502, PDF Size: 70.43 MB

Page 155 of 502

09-9

ENGINE CONTROL SYSTEM

RODIUS 2005.07

0452-01

2. FUEL SYSTEM

The function of the fuel metering system is to deliver the correct amount of fuel to the engine

under all operating conditions.

The fuel is delivered to the engine by the individual fuel injectors mounted into the intake

manifold near each cylinder.

The main fuel control sensors are the Mass Air Flow (MAF) sensor and the oxygen (O2)

sensors.

The MAF sensor monitors the mass flow of the air being drawn into the engine.

An electrically heated element is mounted in the intake air stream, where it is cooled by the

flow of incoming air.

Engine Control Module (ECM) modulates the flow of heating current to maintain the

temperature

differential between the heated film and the intake air at a constant level. The amount o

f

heating current required to maintain the temperature thus provides an index for the mass ai

r

flow.

This concept automatically compensates for variations in air density, as this is one of the

factors that determines the amount of warmth that the surrounding air absorbs from the heated

element. MAF sensor is located between the air filter and the throttle valve.

Under high fuel demands, the MAF sensor reads a high mass flow condition, such as wide

open throttle.

The ECM uses this information to enrich the mixture, thus increasing the fuel injector on?time,

to provide the correct amount of fuel. When decelerating, the mass flow decreases.

This mass flow change is sensed by the MAF sensor and read by the ECM, which then

decreases the fuel injector on?time due to the low fuel demand conditions.

The O2 sensors are located in the exhaust pipe before catalytic converter.

The O2 sensors indicate to the ECM the amount of oxygen in the exhaust gas, and the ECM

changes the air/fuel ratio to the engine by controlling the fuel injectors.

The best air/fuel ratio to minimize exhaust emissions is 14.7 to 1, which allows the catalytic

converter to operate most efficiently. Because of the constant measuring and adjusting of the

air/fuel ratio, the fuel injection system is called a “closed loop” system.

The ECM uses voltage inputs from several sensors to determine how much fuel to provide to

the engine.

The fuel is delivered under one of several conditions, called ‘‘modes”.

Page 234 of 502

0-7

BRAKS SYSTEM

RODIUS 2005.07

4830-01

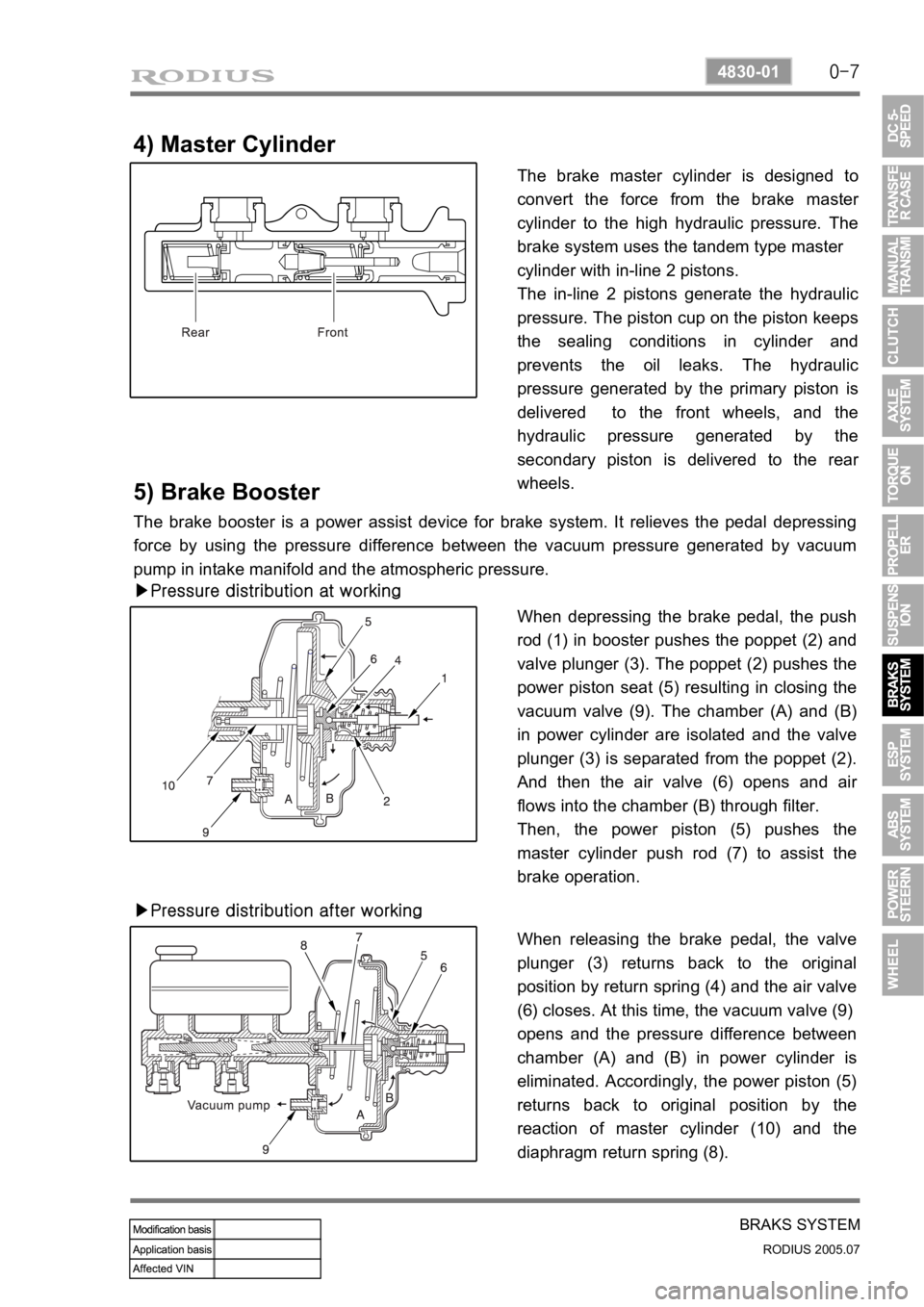

4) Master Cylinder

The brake master cylinder is designed to

convert the force from the brake maste

r

cylinder to the high hydraulic pressure. The

brake system uses the tandem type master

cylinder with in-line 2 pistons.

The in-line 2 pistons generate the hydraulic

pressure. The piston cup on the piston keeps

the sealing conditions in cylinder and

prevents the oil leaks. The hydraulic

pressure generated by the primary piston is

delivered to the front wheels, and the

hydraulic pressure generated by the

secondary piston is delivered to the rea

r

wheels.

5) Brake Booster

The brake booster is a power assist device for brake system. It relieves the pedal depressing

force by using the pressure difference between the vacuum pressure generated by vacuum

pump in intake manifold and the atmospheric pressure.

▶Pressure distribution at working

When depressing the brake pedal, the push

rod (1) in booster pushes the poppet (2) and

valve plunger (3). The poppet (2) pushes the

power piston seat (5) resulting in closing the

vacuum valve (9). The chamber (A) and (B)

in power cylinder are isolated and the valve

plunger (3) is separated from the poppet (2).

And then the air valve (6) opens and ai

r

flows into the chamber (B) through filter.

Then, the power piston (5) pushes the

master cylinder push rod (7) to assist the

brake operation.

▶Pressure distribution after working

When releasing the brake pedal, the valve

plunger (3) returns back to the original

position by return spring (4) and the air valve

(6) closes. At this time, the vacuum valve (9)

opens and the pressure difference between

chamber (A) and (B) in power cylinder is

eliminated. Accordingly, the power piston (5)

returns back to original position by the

reaction of master cylinder (10) and the

diaphragm return spring (8).

Page 419 of 502

0-10

RODIUS 2005.07

6810-20

AIR CONDITIONING SYSTEM

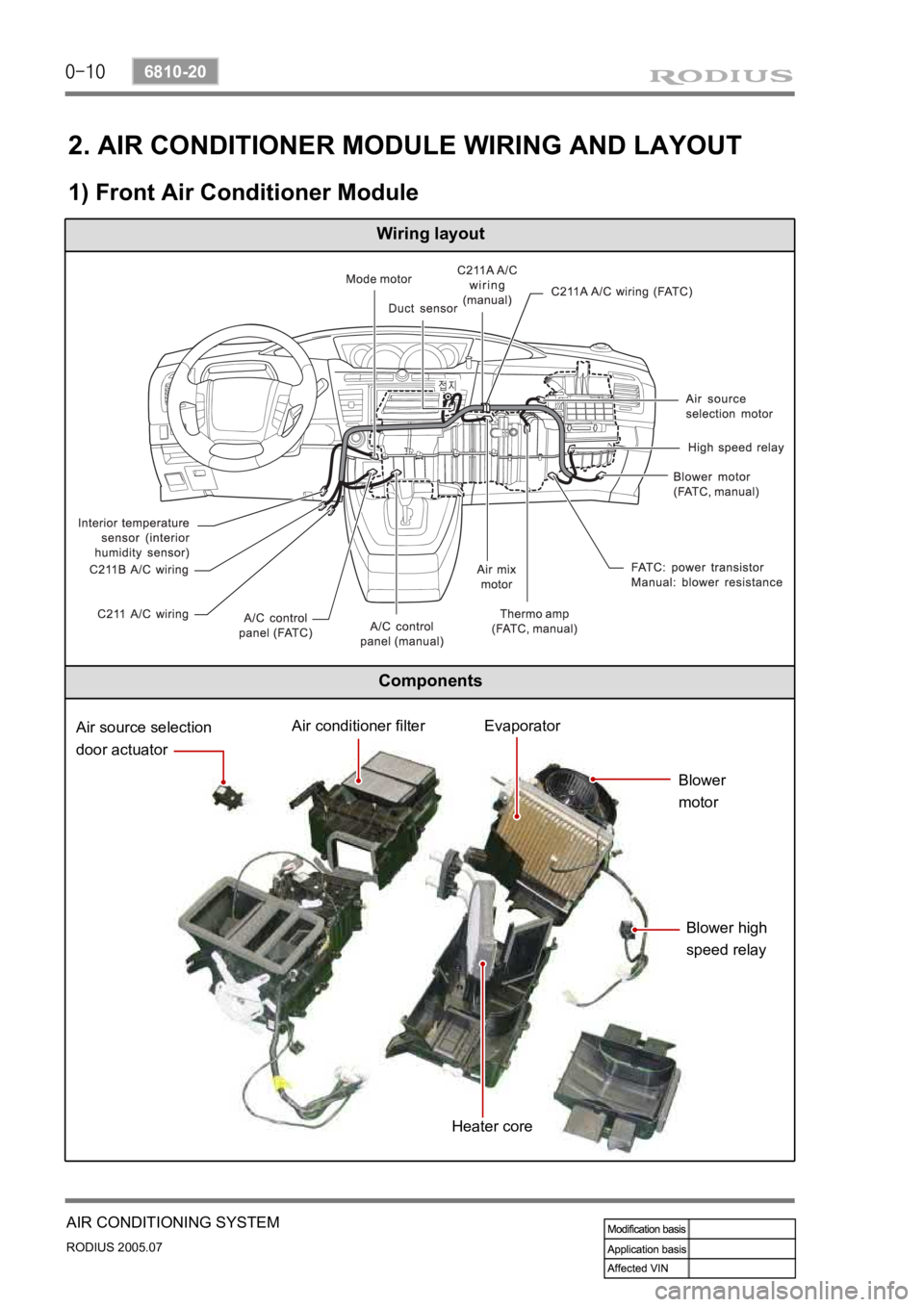

2. AIR CONDITIONER MODULE WIRING AND LAYOUT

1) Front Air Conditioner Module

Wiring layout

Components

Air source selection

door actuatorAir conditioner filterEvaporator

Blower

motor

Blower high

speed relay

Heater core