wheel SSANGYONG RODIUS 2006 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2006, Model line: RODIUS, Model: SSANGYONG RODIUS 2006Pages: 444, PDF Size: 56.32 MB

Page 278 of 444

0-5

TORQUE ON DEMAND

RODIUS 2007.07

3240-01

2. GENERAL DESCRIPTION

TOD system means the full time 4WD system and the registered trade mark of Borg Warner.

TOD is an abbreviation of Torque On Demand.

TOD (Torque On Demand) system, which is superior than existing Full Time 4WD, checks the

road surface and vehicle conditions via various sensors and, subsequently, according to the

situations and conditions, distributes the most optimal driving force to front wheels and rea

r

wheels by activating the electro-magnetic clutch located inside of TOD Transfer Case.

TOD receives the speed signals from speed sensors installed in front axle and rear axle, the

TPS signals from engine, and the operating signals from ABS control unit via CAN.

Based on these data, TOD control unit controls the electro-magnetic clutch to distribute the

3:97 ~ 44:56 of driving force to front wheels and rear wheels.

The conventional system uses “FR driving” (theoretically, the 100 % of driving force is

transferred to rear wheels) on normal paved road.

When the system detects a slip in the rear wheels, a proper percentage of driving force is

transferred to front wheels.

TOD control unit receives the wheel speed signals from the speed sensors in propeller shaft o

f

transfer case and engine output information from the engine control unit.

TOD control unit changes the pressure force of the electromagnetic clutch based on the

analyzed data.

1) Distribution of Driving Force According to Road Surface

On normal road surface ▶

In vehicle with existing part time transfer case, when a driver turns the steering wheel to park in

the 4WD mode, the vehicle may halt sensation of tight corner braking phenomena. However, in

vehicle with TOD system, this phenomena does not occur and the driving force is properly and

automatically distributed.

On paved road with high speed ▶

Driving at high speed on roads such as highway mainly uses rear wheels as driving wheel.

At this moment, some of torques is also distributed to front wheels so that the vehicle could

maintain safe ground grab capacity against side winds and rain.

Distribution ratio: 15 % for front wheels and 85% for rear wheels.

Page 279 of 444

0-6

RODIUS 2007.07

3240-01

TORQUE ON DEMAND

When turning on the road with low friction rate ▶

During cornering on roads such as unpaved, snowy, icy and muddy, ground grab capacity is

increased by distributing required torque and, at the same time, comfortable steering operation

is maintained by controlling the ground grab capacity at high level.

Distribution ratio: 30 % for front wheels and 70 % for rear wheels.

When climbing or starting off on the road with low friction rate ▶

In order to secure the maximum ground grab capacity and driving force during climbing o

r

starting off on the roads such as unpaved, snowy and icy road, the system controls the driving

force to distribute properly in full 4WD mode.

Distribution ratio: 44 % for front wheels and 56 % for rear wheels.

Page 280 of 444

0-7

TORQUE ON DEMAND

RODIUS 2007.07

3240-01

2) Transfer Case

(1) Planetary gear set

Planetary Gear set consists of sun gear, ring gear and carrier. It is engaged with the gear in

“HIGH-LOW” collar to increase the driving force by reducing vehicle speed.

Sun gear is connected to input shaft and ring gear is fixed into the transfer case.

Splined rear output shaft is able to slide on the “HIGH - LOW” collar.

The inside and outside ends of “HIGH - LOW” collar have machined gear. The input

shaft transmits the power to driving wheels by engaging with sun gear and carrier gear.

If the 4WD switch is at “4WD HIGH”, the TOD control unit operates the shift motor to

engage “HIGH - LOW” collar directly with input shaft for transmitting the driving force

to front and rear propeller shafts.

When a driver selects “4WD LOW”, the TOD control unit controls the electro-

magnetic clutch and operates the shift motor to engage “HIGH - LOW” collar with

carrier.

The power from transmission is increased up to 2.48:1 by reduction ratio from planetary

gear, and then is sent to front and rear propeller shafts. null

(2) Ball type slant cam and clutch

disc pack

If the speed sensors installed on front and

rear propeller shafts detect the slips at front

and rear wheels, and these slips exceed

the specified range, TOD control unit

controls electromagnetic clutch to transmit

driving force to front wheels.

At this time, ball slant cam is moved to

compress multi-disc located in clutch disc to

transmit driving force to front wheels.

Page 281 of 444

0-8

RODIUS 2007.07

3240-01

TORQUE ON DEMAND

(3) Electro Magnetic Clutch (EMC)

EMC consists of coil and housing. TOD control unit controls EMC by controlling duty cycle

according to the road and driving conditions. These controls use the continuity time and amount

of electric current to determine the torque to be transmitted to front wheels.

Basic controls in EMC ▶

Page 286 of 444

0-13

TORQUE ON DEMAND

RODIUS 2007.07

3240-01

2) 4WD Operation Overview

To make the mode shift easier, stop the vehicle, depress the brake pedal, select the mode

switch, and move the selector lever with the sequence of [N-P-N].

3) Mode Switch

Selection Mode ▶

The TOD system has 2 selectable mode, 4H and 4L.

4H is the normal operating mode when drive of which gear ratio is 1:1 and 4L mode distributes

power to front and rear wheels 50:50 of which gear ratio is 2.48:1.

4L Mode ▶

When selecting 4L mode, EMC is locked to apply maximum torque into front and rear propelle

r

shafts (when the wheel speed is more than 87Hz).

Shift motor rotates also 4L position by rotation of cam thus propeller shaft torque changes from

1:1 to 2.48:1 by planetary gear set.

Releasing the 4L Mode ▶

When selecting 4H mode, 4L drive mode is

released and 4H mode is resumed.

“4H” switch: Self-return type

“4L” switch: Push lock type ·

·

Page 299 of 444

0-6

RODIUS 2007.07

4830-01

BRAKS SYSTEM

2. BRAKE SYSTEM OPERATION PROCESS

1) Brake System

Even though a driver cuts off the power, while driving, the vehicle continues to move due to the

law of inertia. Therefore, a braking device is needed to stop the vehicle. The brake system

normally uses the frictional discs that converts the kinetic energy to the thermal energy by

frictional operation.

The brake system consists of the brake disc (front wheel), brake disc or drum (rear wheel),

parking brake (mechanical type), master cylinder, booster, pedal and supply lines (pipes and

hoses).

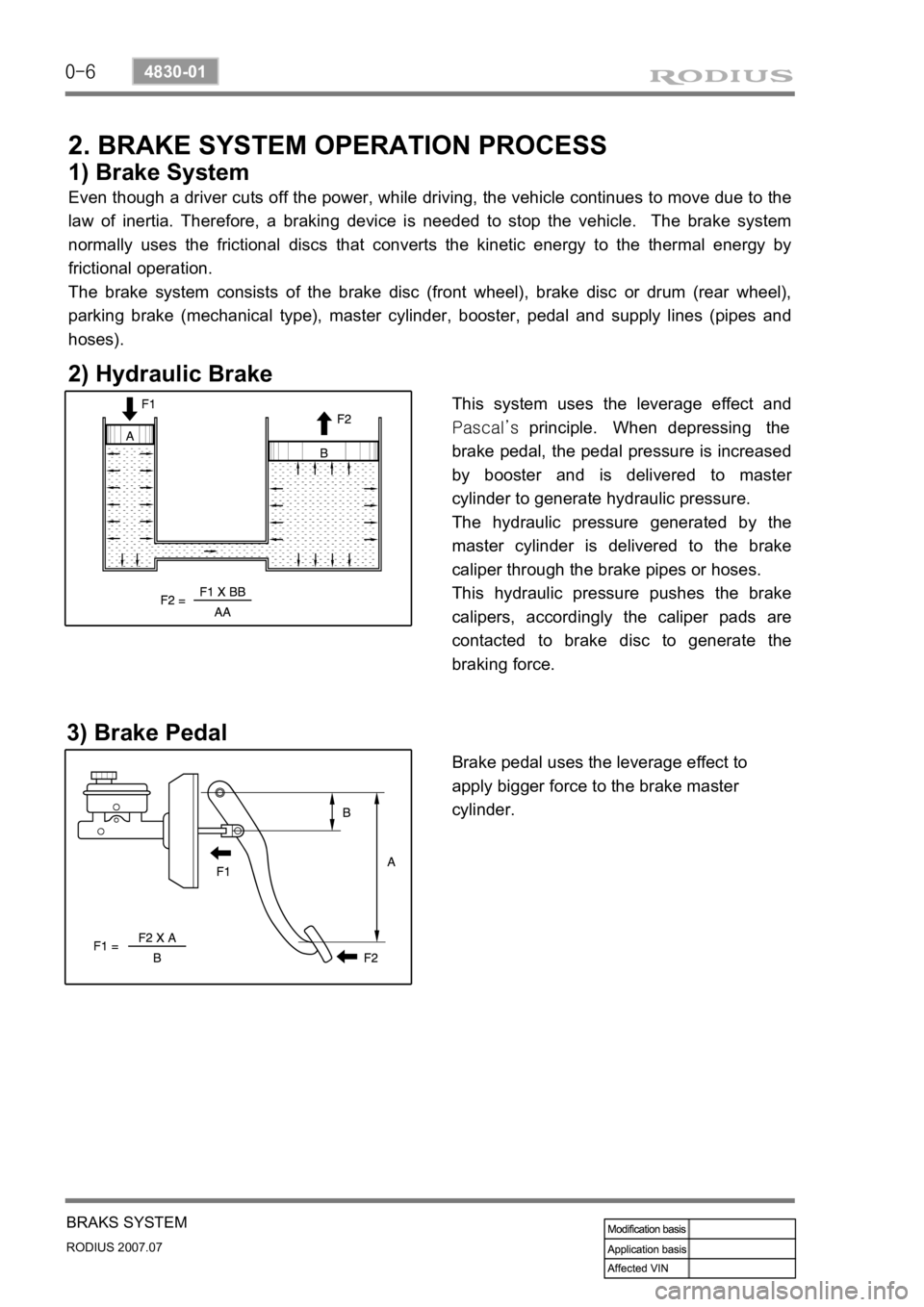

2) Hydraulic Brake

This system uses the leverage effect and

Pascal’s principle. When depressing the

brake pedal, the pedal pressure is increased

by booster and is delivered to maste

r

cylinder to generate hydraulic pressure.

The hydraulic pressure generated by the

master cylinder is delivered to the brake

caliper through the brake pipes or hoses.

This hydraulic pressure pushes the brake

calipers, accordingly the caliper pads are

contacted to brake disc to generate the

braking force.

3) Brake Pedal

Brake pedal uses the leverage effect to

apply bigger force to the brake master

cylinder.

Page 300 of 444

0-7

BRAKS SYSTEM

RODIUS 2007.07

4830-01

4) Master Cylinder

The brake master cylinder is designed to

convert the force from the brake maste

r

cylinder to the high hydraulic pressure. The

brake system uses the tandem type master

cylinder with in-line 2 pistons.

The in-line 2 pistons generate the hydraulic

pressure. The piston cup on the piston keeps

the sealing conditions in cylinder and

prevents the oil leaks. The hydraulic

pressure generated by the primary piston is

delivered to the front wheels, and the

hydraulic pressure generated by the

secondary piston is delivered to the rea

r

wheels.

5) Brake Booster

The brake booster is a power assist device for brake system. It relieves the pedal depressing

force by using the pressure difference between the vacuum pressure generated by vacuum

pump in intake manifold and the atmospheric pressure.

▶Pressure distribution at working

When depressing the brake pedal, the push

rod (1) in booster pushes the poppet (2) and

valve plunger (3). The poppet (2) pushes the

power piston seat (5) resulting in closing the

vacuum valve (9). The chamber (A) and (B)

in power cylinder are isolated and the valve

plunger (3) is separated from the poppet (2).

And then the air valve (6) opens and ai

r

flows into the chamber (B) through filter.

Then, the power piston (5) pushes the

master cylinder push rod (7) to assist the

brake operation.

▶Pressure distribution after working

When releasing the brake pedal, the valve

plunger (3) returns back to the original

position by return spring (4) and the air valve

(6) closes. At this time, the vacuum valve (9)

opens and the pressure difference between

chamber (A) and (B) in power cylinder is

eliminated. Accordingly, the power piston (5)

returns back to original position by the

reaction of master cylinder (10) and the

diaphragm return spring (8).

Page 302 of 444

0-3

ESP SYSTEM

RODIUS 2007.07

4892-01

8510-56ABS/ESP System

1. SPECCIFICATIONS OF ESP SYSTEM

1) Specifications Of Pressure Sensor

2) Specifications Of Sensor Cluster

(sensor cluster: yaw rate sensor + lateral acceleration sensor + Longitudinal acceleration sensor)

3) Specifications Of Wheel Speed Sensor

4) Specifications Of Steering Wheel Angle sensor

Page 303 of 444

0-4

RODIUS 2007.07

4892-01

ESP SYSTEM

1. COMPONENTS AND LOCATIONS

2WD vehicle has the longitudinal sensor in the HECU.

1. HECU: (Hydraulic &

Engine conrol unit) 2. Pressure sensor 3. Wheel speed sensor

4. Sensor cluster:

(Yaw rate + lateral sensor + longitudinal sensor) 5. Steering wheel angle

sensor 6. ESP off switch (Electronic

Stability Program Switch) ESP Warning lamp

Page 305 of 444

0-6

RODIUS 2007.07

4892-01

ESP SYSTEM

3. ESP SYSTEM DESCRIPTION

1) Principle of ESP

ESP (Electronic Stability Program) recognizes critical driving conditions, such as panic

reactions in dangerous situations, and stabilizes the vehicle by wheel-individual braking and

engine control intervention with no need for actuating the brake. This system is developed to

help the driver avoid the danger of losing the control of the vehicle stability due to under-

steering or over-steering during cornering.

The yaw rate sensor, lateral sensor and longitudinal sensor in the sensor cluster and the

steering wheel angle sensor under the steering column detect the spin present at any wheels

during over-steering, under-steering or cornering. The ESP ECU controls against over-steering

or under-steering during cornering by controlling the vehicle stability using the input values from

the sensors and applying the brakes independently to the corresponding wheels.

The system also controls during cornering by detecting the moment right before the spin and

automatically limiting the engine output (coupled with the ASR system).

Understeering is when the steering wheel is

steered to a certain angle during driving and

the front tires slip toward the reverse

direction of the desired direction. Generally,

vehicles are designed to have unde

r

steering. The vehicle can return back to

inside of cornering line when the steering

wheel is steered toward the inside even

when the vehicle front is slipped outward.

As

the centrifugal force increases, the tires can

easily lose the traction and the vehicle tends

to slip outward when the curve angle gets

bigger and the speed increases. Under steering

ESP controls during under steering

The ESP system recognizes the directional

angle with the steering wheel angle senso

r

and senses the slipping route that occurs

reversely against the vehicle cornering

direction during understeering with the yaw

rate sensor and the lateral sensor. Then the

ESP system applies the brake at the rea

r

inner wheel to compensate the yaw moment

value.

In this way, the vehicle does not lose its

driving direction and the driver can steer the

vehicle as driver intends.