wheel SSANGYONG RODIUS 2006 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2006, Model line: RODIUS, Model: SSANGYONG RODIUS 2006Pages: 444, PDF Size: 56.32 MB

Page 33 of 444

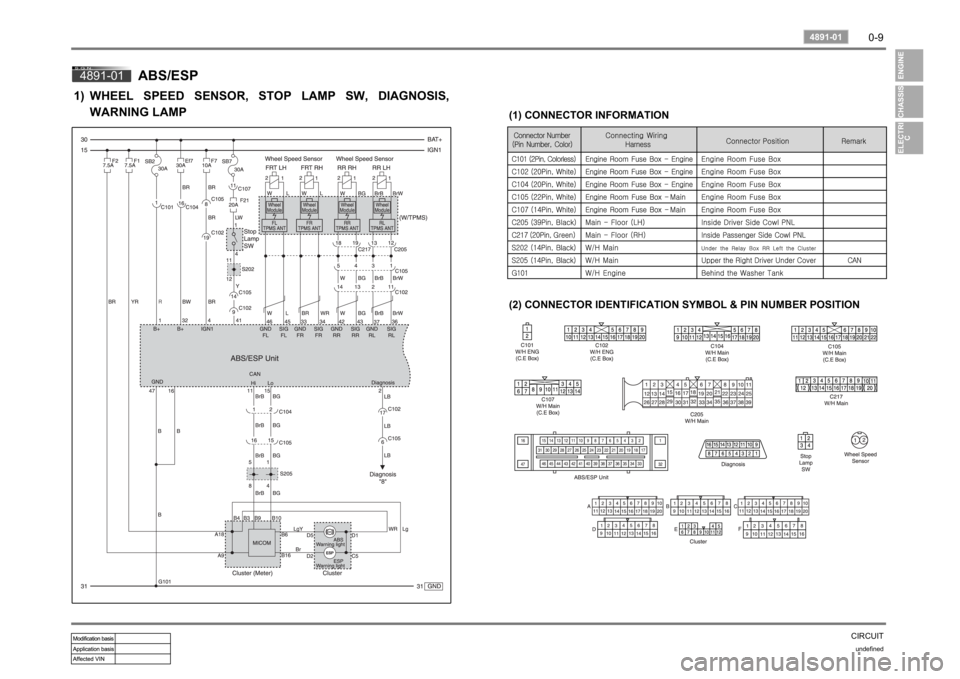

0-9

CIRCUITundefined

4891-01

4891-01

ABS/ESP

WHEEL SPEED SENSOR, STOP LAMP SW, DIAGNOSIS,

WARNING LAMP

1)

(1) CONNECTOR INFORMATION

(2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

Page 66 of 444

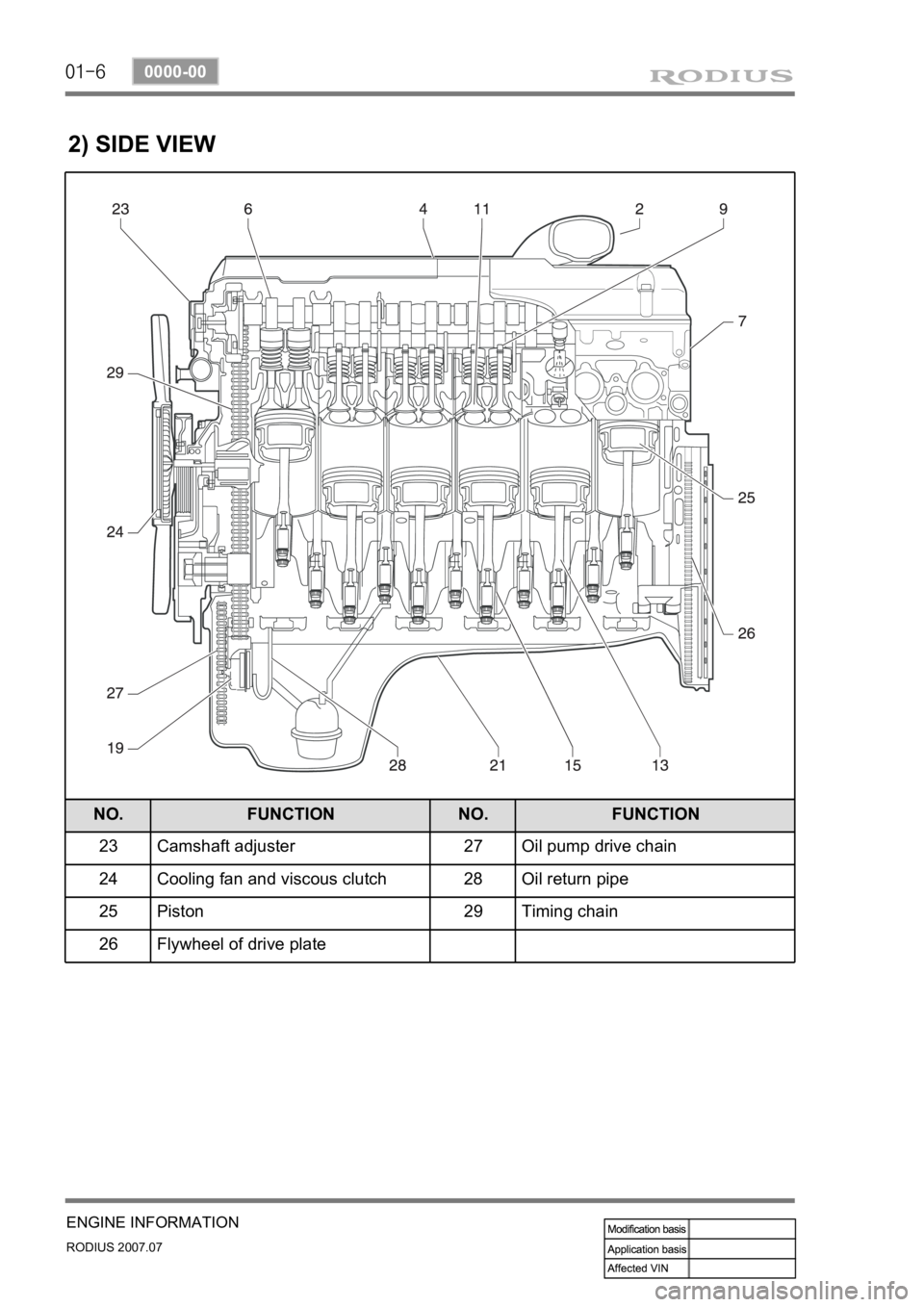

01-6

RODIUS 2007.07

0000-00

ENGINE INFORMATION

2) SIDE VIEW

NO. FUNCTION NO. FUNCTION

23 Camshaft adjuster 27 Oil pump drive chain

24 Cooling fan and viscous clutch 28 Oil return pipe

25 Piston 29 Timing chain

26 Flywheel of drive plate

Page 170 of 444

0-8

RODIUS 2007.07

0000-00

ELECTRIC GENERAL

Window switches

Outside

rearview

mirror

adjusting

and folding

switch

4WD switch and rear

washer/wiper switch

3. SWITCHES IN PASSENGER COMPARTMENT

Audio remote control switch on the steering wheel

Page 221 of 444

0-9

CLUSTER

RODIUS 2007.07

8010-10

2) Speedometer

The speedometer indicates the vehicle speed by calculating the signals from the rear right

wheel speed sensor through ABS or ESP unit.

If the speedometer pointer vibrates, stands at a certain range or sounds abnormal noise, there

could be defectives in speedometer. However, these symptoms also could be appeared when

the tire has uneven wear, different tire inflation pressures or different tire specifications.

Perform the speedometer test regarding the tolerance as described. However, it is not simila

r

simple work in field due to lack of measuring conditions such as test equipment and

preciseness.

Check the allowable tolerance of the speedometer and operations of the trip odometer by

using a tester.

Check if the speedometer pointer is shaking and the abnormal noise sounds.

Eliminate the hysteresis by tapping the speedometer. 1.

2.

3.

The allowable tolerance increases when the tires are worn or the tire pressure is out of

specified range. -

Page 252 of 444

0-4

RODIUS 2007.07

3410-01

TRANSFER CASE

1. PART TIME TRANSFER CASE OVERVIEW

By using the planetary gear sets, two-gears shift type part time transfer case achieves direct

connection when selecting 4WD “HIGH” and 2.48 of reduction gear ratio when selecting

4WD “LOW”.

The silent chain in transfer case transfers the output power to front wheels.

Simple operation of switches on instrument panel allows to shift to “2H”, “4H” and “4L”

easily while driving.

The warning lamp alarms the driver when the system is defective.

Page 257 of 444

0-9

TRANSFER CASE

RODIUS 2007.07

3410-01

Ring, snap

Ring, snap

Ring, snap

Bearing

Hub, circular

Asm. -shaft, input

Plate, thrust

Gear, sun

Snap ring

Asm. -carrier (complete)

Hub reduction

Asm. -shaft, main

Clamp hose

Hose

Filter

Asm. -coil, electric

Asm. -cam/coil hsg.

Ring, snap

Armature

Hub, lockup

Spring, sleeve return

Collar, lockup

Sprocket, driving

Spring, return

Rail, shift

Fork, shift

Asm. -fork, shift

Cam, electric shift

Spring, torsion

Spacer

Shaft, shift

Ring, retaining

Asm. -case, transfer

Barb, breather 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.Decal

Shaft, output

Deflector, dust

Magnet

Ring snap

Sprocket lower

Spacer

Chain

Ring retaining

Bearing

Bearing

Cover

Bendable clip

Bolt, Metric

Seal, oil

Washer

Nut, Metric

Flange, companion

Seal, oil

Spacer

Tone wheel (upper)

Nut, Metric

Clip, “J”

Bolt, hex head

Bracket, relay mounting

Locking clip

Connector

Bolt, hex head

Capscrew, hex head

Asm. -motor, electric

Seal, oil

Plug, pipe

Sealing Compound 35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

66.

Page 259 of 444

0-11

TRANSFER CASE

RODIUS 2007.07

3410-01

1) 2H Mode (Rear Wheel Drive)

Power Flow ▶

Page 265 of 444

0-17

TRANSFER CASE

RODIUS 2007.07

3410-01

8. SYSTEM OPERATION

1) Transfer Case Control Unit (Tccu)

(1) 4WD Operation

TCCU is located under the front left seat and

permits the vehicle to shift from two-wheel

drive to four-wheel drive (and back shift)

according to drivers switch operation during

driving (For the shifting between 4WD HIGH

and 4WD LOW, stop the vehicle).

2H → 4H ▶

Change the 4WD switch in instrument panel from 2H to 4H.

This shift is available during driving.

“4WD HIGH” indicator in meter cluster comes on. -

-

-

When the system is defective

“4WD CHECK” warning lamp comes

on -

Change the 4WD switch in instrument panel from 4H to 2H.

This shift is available during driving.

“4WD HIGH” indicator in meter cluster goes out.

“4WD CHECK” warning lamp comes on when the system is defective. -

-

-

- 4H → 2H ▶

Page 271 of 444

0-4

RODIUS 2007.07

3010-01

CLUTCH

1. OVERVIEW

1) Driving Elements

The driving elements consist of two flat surfaces machined to a smooth finish.

One of these is the rear face of the engine flywheel and the other is the clutch cover pressure

plate. The clutch pressure plate is fitted into a clutch steel cover, which is bolted to the flywheel.

2) Driven Elements

The driven element is the clutch disc with a splined hub which is free to slide lengthwise along

the splines of the input shaft. The driving and driven elements are held in contact by spring

pressure. This pressure is exerted by a diaphragm spring in the clutch cover pressure plate

assembly.

3) Operating Elements

The clutch control system consists of the clutch pedal, clutch master cylinder, concentric slave

cylinder. This system directly releases the clutch by using hydraulic pressure while the

conventional clutch system releases the clutch by using release lever and release fork. This

system provides higher efficiency than conventional clutch system, and its durability is superior.

Adaptor (mounted on transmission case) Concentric slave cylinder pipe (mounted inside o

f

transmission) Concentric slave cylinder (mounted inside of transmission)

Page 272 of 444

0-5

CLUTCH

RODIUS 2007.07

3010-01

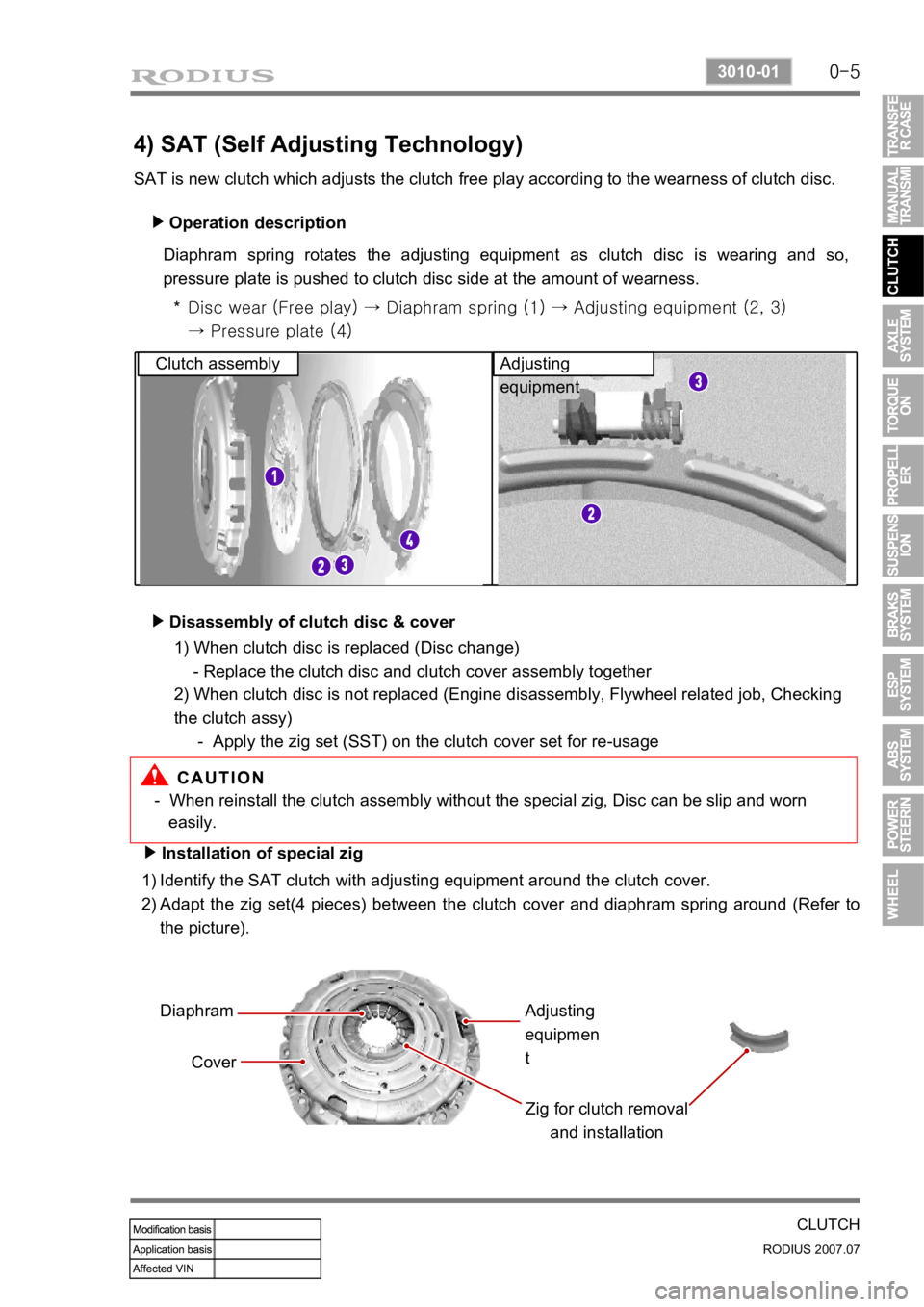

4) SAT (Self Adjusting Technology)

SAT is new clutch which adjusts the clutch free play according to the wearness of clutch disc. Operation description

▶

Diaphram spring rotates the adjusting equipment as clutch disc is wearing and so,

pressure plate is pushed to clutch disc side at the amount of wearness.

Disc wear (Free play) → Diaphram spring (1) → Adjusting equipme nt (2, 3)

→ Pressure plate (4)

*

Clutch assembly Adjusting

equipment

Disassembly of clutch disc & cover

▶

- When reinstall the clutch assembly without the special zig, Disc can be slip and worn

easily.

Installation of special zig

▶

Identify the SAT clutch with adjusting equipment around the clutch cover.

Adapt the zig set(4 pieces) between the clutch cover and diaphram spring around (Refer to

the picture).

1)

2)

Diaphram

Cover Zig for clutch removal and installationAdjusting

equipmen

t

1) When clutch disc is replaced (Disc change)

- Replace the clutch disc and clutch cover assembly together

2) When clutch disc is not replaced (Engine disassembly, Flywheel related job, Checking

the clutch assy)

- Apply the zig set (SST) on the clutch cover set for re-usage