engine SSANGYONG TURISMO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 591 of 796

03-53010-00

3. INSPECTION

Pedal stroke and height ▶

Pedal stroke (A)

A.

Stop the engine.

Measure the current pedal position.

Depress the clutch pedal all the way and

measure the pedal stroke (A). 1)

2)

3)

Stroke (A)150 ± 3 mm

Pedal height (B) B.

Stop the engine.

Remove the floor mat from the driver’s

footwall.

Measure the pedal height (B). 1)

2)

3)

Height (B)95.2 ± 3 mm

Adjustment-

Release the lock nut (D) on stopper bolt (C).

Turn the stopper bolt to adjust the pedal

height.

Tighten the lock nut to the specified tightening

torque. 1)

2)

3)

Page 592 of 796

03-6

Pedal free play ▶

Pedal free play (A) A.

Stop the engine.

Measure the current pedal position.

Lightly depress the clutch pedal until you feel

the resistance from the pedal and measure

the distance. 1)

2)

3)

Free play (A)5 ~ 15 mm

Adjustment-

Release the lock nut (B) from the master

cylinder.

Turn the push rod (C) to adjust the pedal

free play.

Tighten the lock nut to the specified

tightening torque. 1)

2)

3)

Page 593 of 796

03-73010-00

1. OVERVIEW

The hydraulic clutch transmits the force required to operate the clutch pedal to the concentric slave

cylinder fitted to the clutch housing as a hydraulic pressure.

(The hydraulic pressure is transmitted in the following order: Clutch pedal - Clutch master cylinder -

Clutch pipe - Clutch damper - Clutch pipe and hose - Concentric slave cylinder - Pressure plate -

Flywheel.)

If a driver depress the clutch pedal, the hydraulic pressure is generated in the master cylinder. It is

transmitted to the concentric slave cylinder through the pipe, resulting in the cylinder being forced out.

At this time, the clutch disc is forced against the cylinder by pushing the cover. This, in turn, remove the

flywheel from the pressure plate. As a consequence, the power from the engine will be cut off and the

gear change can be carried out.

Page 595 of 796

03-93010-00

2) Overview

Driving elements ▶

The driving elements consist of two flat surfaces machined to a smooth finish.

One of these is the rear face of the engine flywheel and the other is the clutch pressure plate. The

clutch pressure plate is fitted into a clutch steel cover, which is bolted to the flywheel.

Driven elements ▶

The driven element is the clutch disc with a splined hub which is free to slide lengthwise along the

splines of the input shaft.

The driving and driven elements are held in contact by spring pressure. This pressure is exerted by a

diaphragm spring in the clutch cover pressure plate assembly.

Operating Elements ▶

The clutch "release" system consists of the clutch pedal and clutch release cylinder.

This system directly releases the clutch by using hydraulic pressure while the conventional clutch

system releases the clutch by using release lever and release fork. This system provides higher

efficiency than conventional clutch system, and its durability is superior.

Clutch master cylinder (mounted on clutch pedal)

Concentric slave cylinder pipe (mounted inside of transmission) -

-

Page 597 of 796

03-113010-00

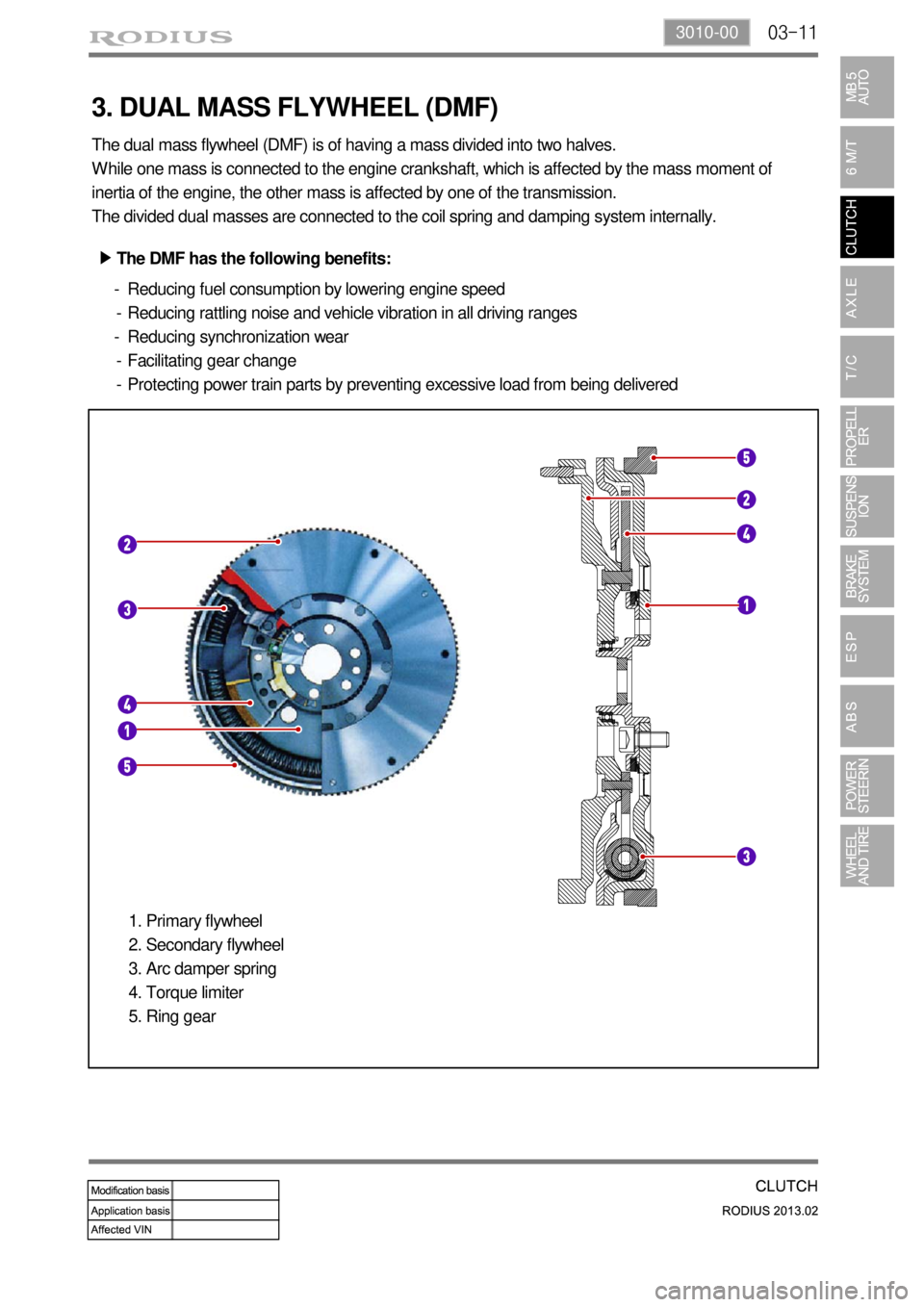

3. DUAL MASS FLYWHEEL (DMF)

The dual mass flywheel (DMF) is of having a mass divided into two halves.

While one mass is connected to the engine crankshaft, which is affected by the mass moment of

inertia of the engine, the other mass is affected by one of the transmission.

The divided dual masses are connected to the coil spring and damping system internally.

The DMF has the following benefits: ▶

Reducing fuel consumption by lowering engine speed

Reducing rattling noise and vehicle vibration in all driving ranges

Reducing synchronization wear

Facilitating gear change

Protecting power train parts by preventing excessive load from being delivered -

-

-

-

-

Primary flywheel

Secondary flywheel

Arc damper spring

Torque limiter

Ring gear 1.

2.

3.

4.

5.

Page 598 of 796

04-34120-01

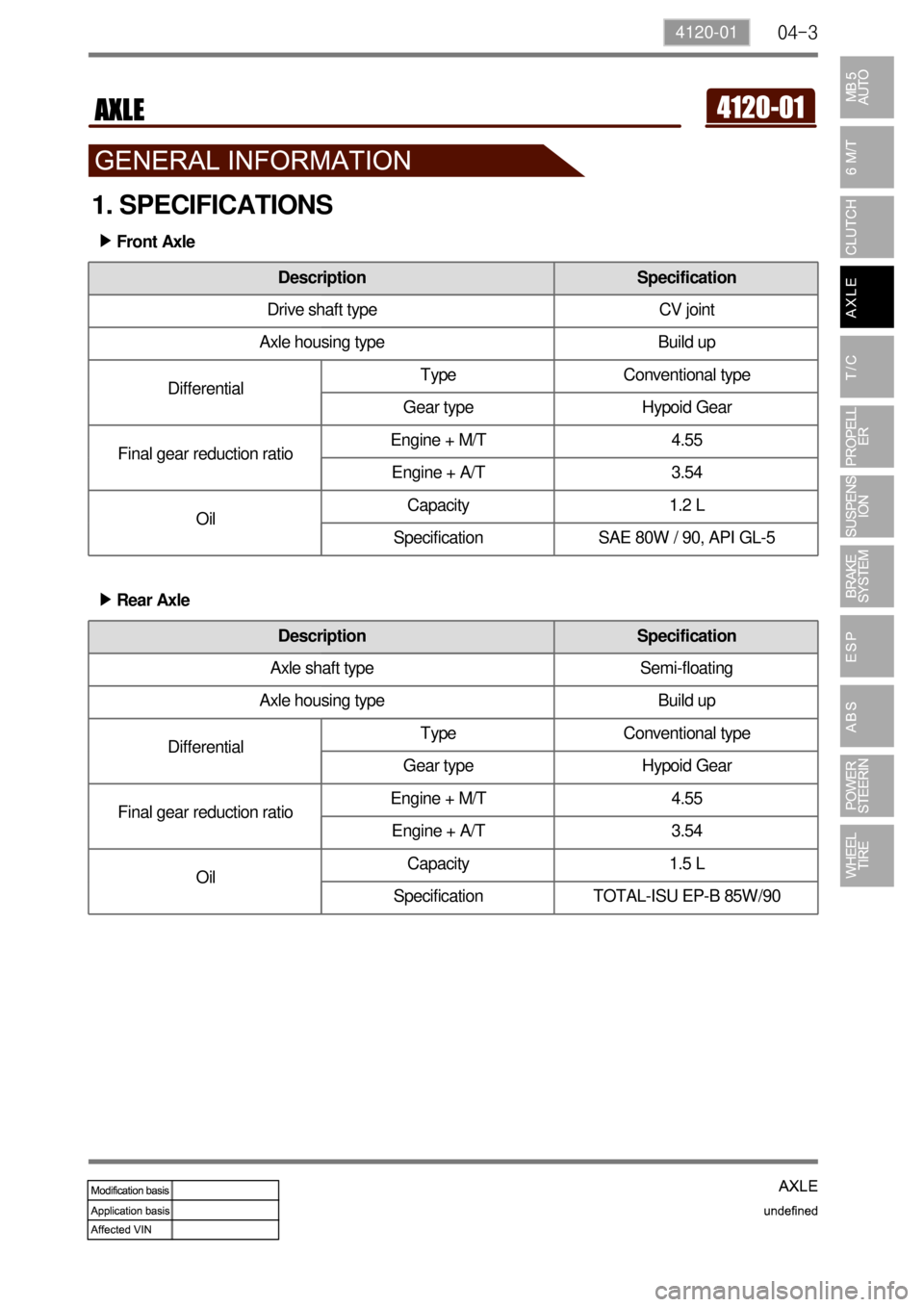

1. SPECIFICATIONS

Front Axle ▶

Rear Axle ▶

Description Specification

Drive shaft type CV joint

Axle housing type Build up

DifferentialType Conventional type

Gear type Hypoid Gear

Final gear reduction ratioEngine + M/T 4.55

Engine + A/T 3.54

OilCapacity 1.2 L

Specification SAE 80W / 90, API GL-5

Description Specification

Axle shaft type Semi-floating

Axle housing type Build up

DifferentialType Conventional type

Gear type Hypoid Gear

Final gear reduction ratioEngine + M/T 4.55

Engine + A/T 3.54

OilCapacity 1.5 L

Specification TOTAL-ISU EP-B 85W/90

Page 600 of 796

04-54120-01

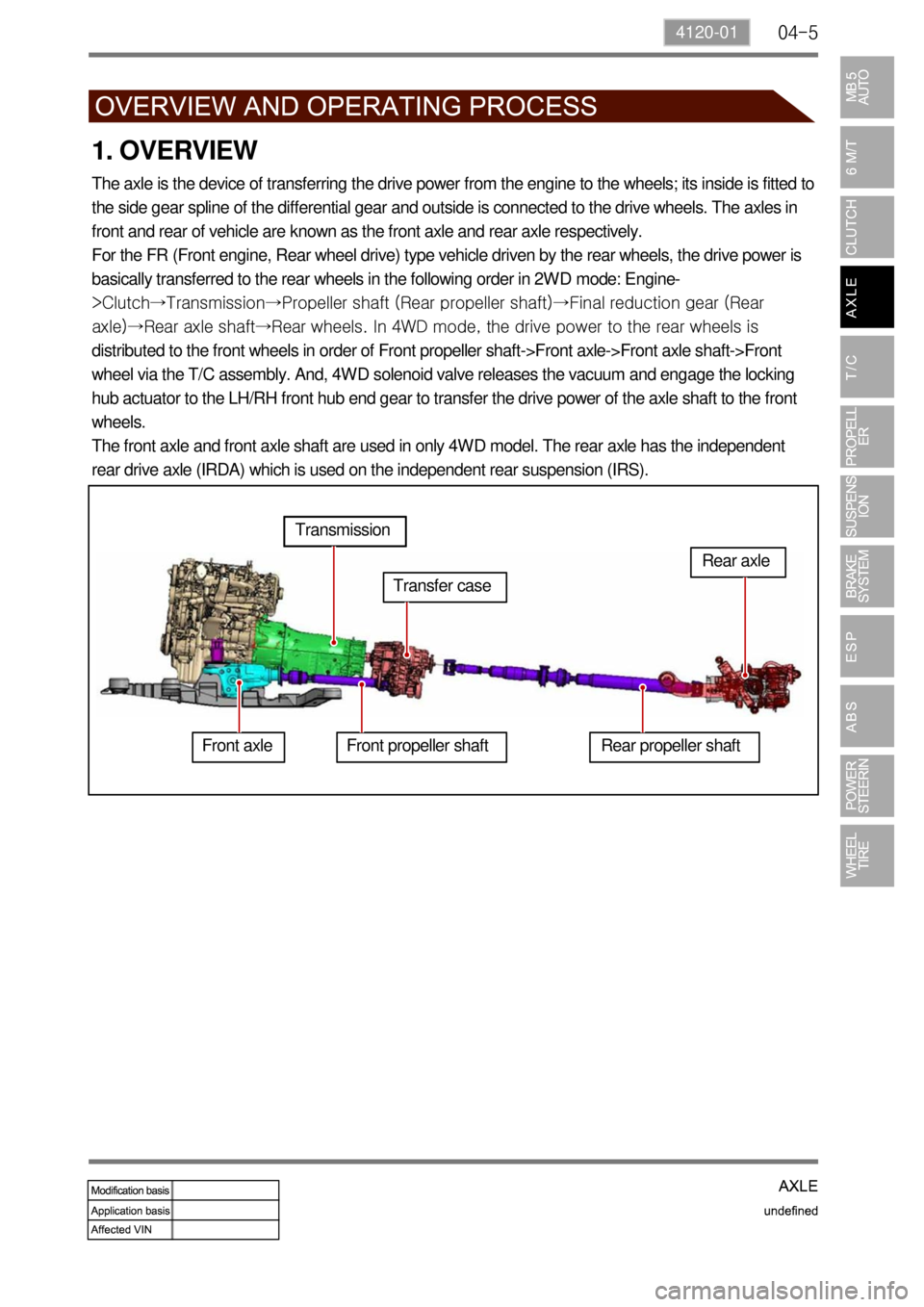

1. OVERVIEW

The axle is the device of transferring the drive power from the engine to the wheels; its inside is fitted to

the side gear spline of the differential gear and outside is connected to the drive wheels. The axles in

front and rear of vehicle are known as the front axle and rear axle respectively.

For the FR (Front engine, Rear wheel drive) type vehicle driven by the rear wheels, the drive power is

basically transferred to the rear wheels in the following order in 2WD mode: Engine-

>Clutch→Transmission→Propeller shaft (Rear propeller shaft)→Final reduction gear (Rear

axle)→Rear axle shaft→Rear wheels. In 4WD mode, the drive power to the rear wheels is

distributed to the front wheels in order of Front propeller shaft->Front axle->Front axle shaft->Front

wheel via the T/C assembly. And, 4WD solenoid valve releases the vacuum and engage the locking

hub actuator to the LH/RH front hub end gear to transfer the drive power of the axle shaft to the front

wheels.

The front axle and front axle shaft are used in only 4WD model. The rear axle has the independent

rear drive axle (IRDA) which is used on the independent rear suspension (IRS).

Front axleTransmission

Transfer case

Front propeller shaft Rear propeller shaftRear axle

Page 621 of 796

07-6

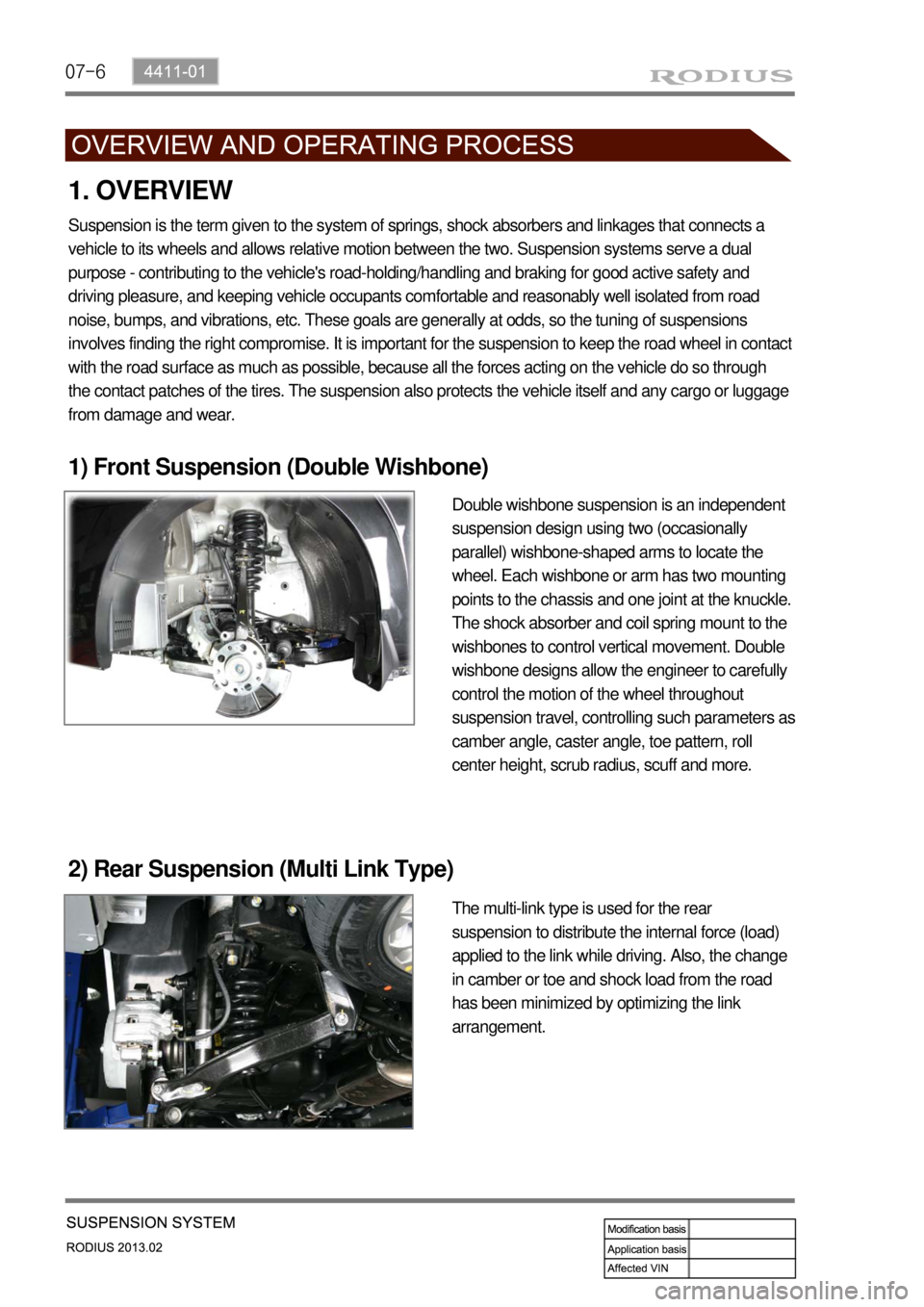

1) Front Suspension (Double Wishbone)

Suspension is the term given to the system of springs, shock absorbers and linkages that connects a

vehicle to its wheels and allows relative motion between the two. Suspension systems serve a dual

purpose - contributing to the vehicle's road-holding/handling and braking for good active safety and

driving pleasure, and keeping vehicle occupants comfortable and reasonably well isolated from road

noise, bumps, and vibrations, etc. These goals are generally at odds, so the tuning of suspensions

involves finding the right compromise. It is important for the suspension to keep the road wheel in contac

t

with the road surface as much as possible, because all the forces acting on the vehicle do so through

the contact patches of the tires. The suspension also protects the vehicle itself and any cargo or luggage

from damage and wear.

2) Rear Suspension (Multi Link Type)

1. OVERVIEW

Double wishbone suspension is an independent

suspension design using two (occasionally

parallel) wishbone-shaped arms to locate the

wheel. Each wishbone or arm has two mounting

points to the chassis and one joint at the knuckle.

The shock absorber and coil spring mount to the

wishbones to control vertical movement. Double

wishbone designs allow the engineer to carefully

control the motion of the wheel throughout

suspension travel, controlling such parameters as

camber angle, caster angle, toe pattern, roll

center height, scrub radius, scuff and more.

The multi-link type is used for the rear

suspension to distribute the internal force (load)

applied to the link while driving. Also, the change

in camber or toe and shock load from the road

has been minimized by optimizing the link

arrangement.

Page 635 of 796

08-8

Problem Cause Action

Burning smell

around tireToo frequent braking in high driving speed Reduce the use of

foot brake/use

engine brake

properly Use only foot brake during downhill driving

Driving with foot on brake pedal Get off the foot from

pedal

Foreign materials such as dirt or sand in brake system Replace: caliper,

wheel cylinder,

master cylinder,

return spring

Broken return spring in shoe assembly Replace

Incorrectly adjusted parking brake cable Adjust

Incorrect wheel or wheel cover

(generating the heat)Replace

Page 639 of 796

08-12

Let the engine run for 1 to 2 minutes and

stop it. If the brake pedal stroke is shortened

as pumping the brake pedal, the system is

normal. If not, the system is defective. 1.

Depress the brake pedal several times with

engine off. If the brake goes down when

starting engine with pedal depressed, the

system is normal. If not, the system is

defective. 2.

If the above three checks are OK, the system is

normal. If any condition is not met, check the

valve, vacuum hose and brake booster.

3) Brake Booster

OK

NG

Engine stopped

Engine running

Depress the brake pedal when the engine is

running. If the pedal height is not changed

for 30 seconds after stopping the engine, the

system is normal. If not, the system is

defective. 3.