sensor SSANGYONG TURISMO 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 167 of 796

02-8

4. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value ▶

Compression ratio16.5 : 1

Test conditionat normal operating temperature (80˚C)

Compression

pressureStandard32 bar

Minimum18 bar

Differential limit between cylindersMaximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston ring,

intake and exhaust vale, cylinder head gasket). This test provides current engine operating status.

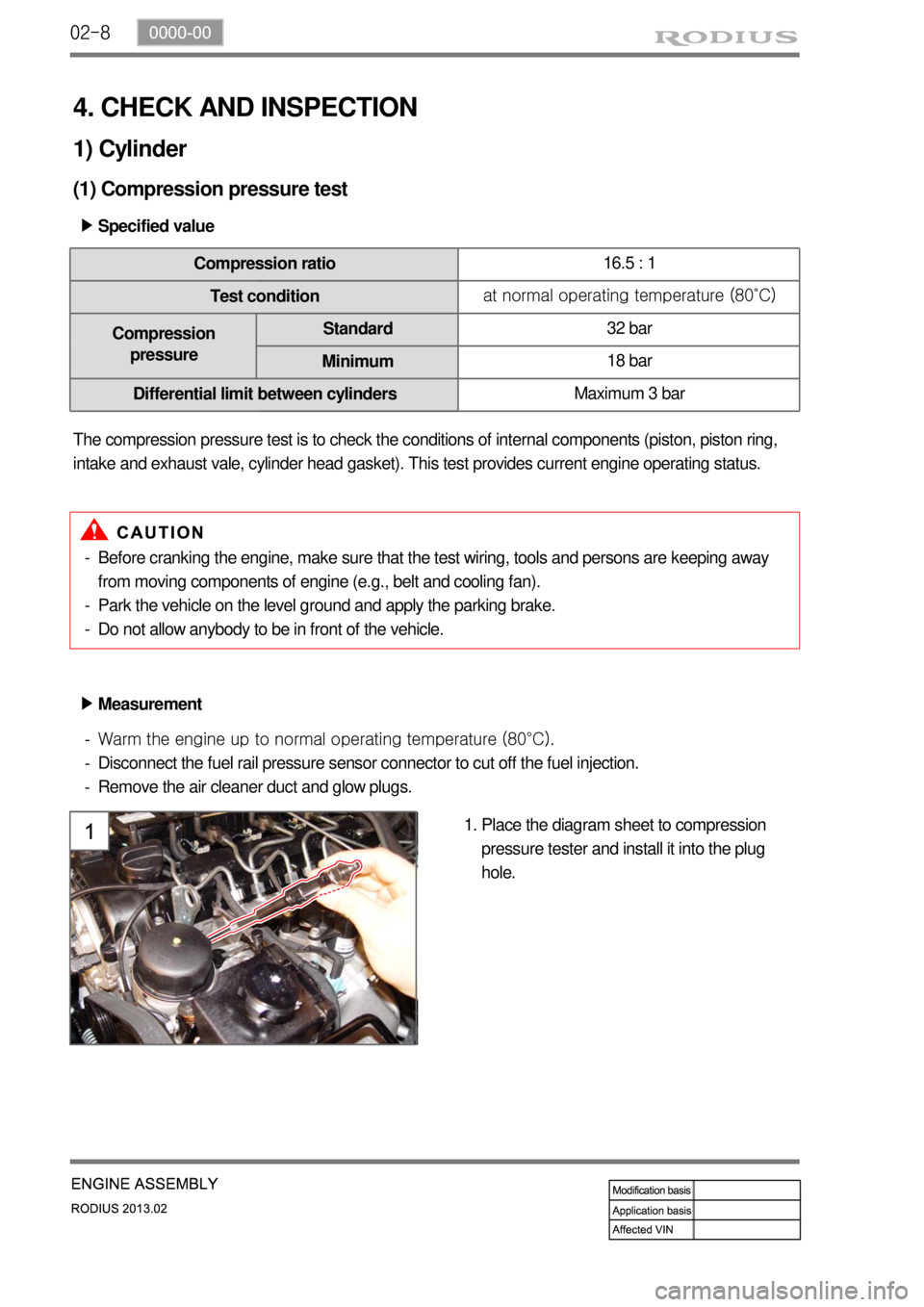

Measurement ▶

Warm the engine up to normal operating temperature (80°C).

Disconnect the fuel rail pressure sensor connector to cut off the fuel injection.

Remove the air cleaner duct and glow plugs. -

-

-

Place the diagram sheet to compression

pressure tester and install it into the plug

hole. 1. Before cranking the engine, make sure that the test wiring, tools and persons are keeping away

from moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle. -

-

-

Page 184 of 796

02-250000-00

Vacuum pump driveHP pump drive gear

Cylinder head gasket

Camshaft position sensor

Components ▶

Cylinder head

Cylinder head contains cam position sensor, vacuum pump, intake manifold, exhaust manifold and valve

assembly. Vacuum pump and the high pressure (HP) pump are driven by Camshaft and valves are install

in vertical direction. This enables the compact layout in cylinder head assembly.

6. CYLINDER HEAD

Finger follower & HLACamshaft sprocketIntake/exhaust Camshafts

Page 207 of 796

02-48

4) Cylinder Block

(1) Overview

The major dimensions in D20DTR are similar to

D20DTR engine. It has two mounting

bosses for knock sensor and meets the

requirements for EURO5 regulation.

(2) Layout

Right sideCylindrical pin

Expansion plug

Screw plug

Page 219 of 796

03-12

(5) High Pressure System Pressure Test

Fuel rail pressure test ▶

Disconnect the pressure sensor connector

(A) and IMV connector (B) from the fuel rail. 1.

Connect the pressure tester to the fuel rail

pressure sensor connector. 2.

Crank the engine 2 times for 5 seconds.

3.

Read the highest pressure value displayed

on the tester display.

If the highest pressure value is 1,050 bar

or less, refer to the section "Fuel System

Check Process". -

-

Page 222 of 796

03-152210-01

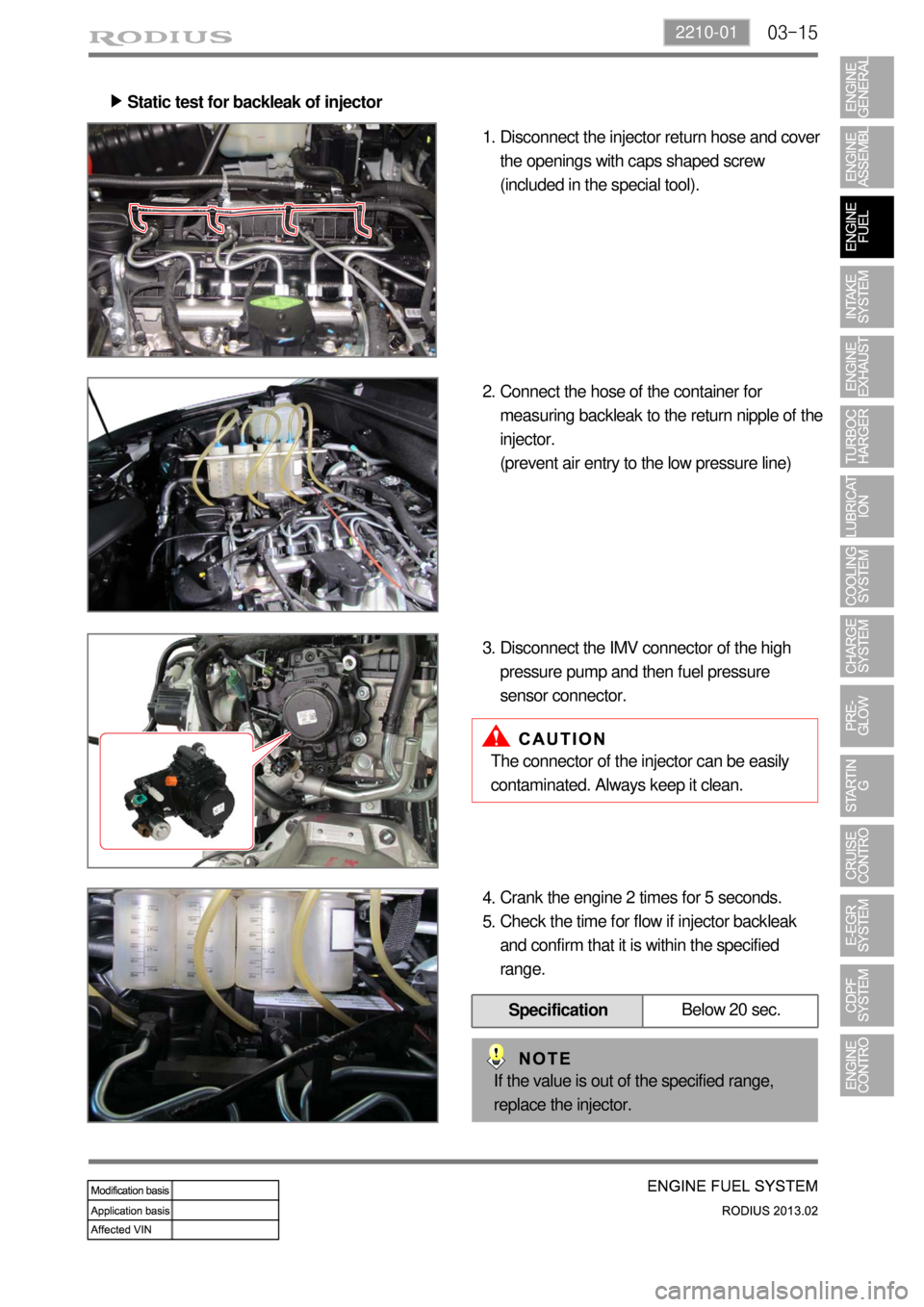

Static test for backleak of injector ▶

Disconnect the injector return hose and cover

the openings with caps shaped screw

(included in the special tool). 1.

Connect the hose of the container for

measuring backleak to the return nipple of the

injector.

(prevent air entry to the low pressure line) 2.

Disconnect the IMV connector of the high

pressure pump and then fuel pressure

sensor connector. 3.

The connector of the injector can be easily

contaminated. Always keep it clean.

Crank the engine 2 times for 5 seconds.

Check the time for flow if injector backleak

and confirm that it is within the specified

range. 4.

5.

If the value is out of the specified range,

replace the injector.

SpecificationBelow 20 sec.

Page 224 of 796

03-172210-01

HP pump pressure test ▶

Prepare a special tool for high pressure test

and clean it thoroughly to prevent foreign

materials from entering. 1.

Disconnect the high pressure fuel supply pipe

on the HP pump and install the close rail in the

tool kit. 2.

Connect the other end of the close rail to the

fuel rail for test. 3.

Disconnect the return hose for HP pump and

connect the clear hose and connect its the

other end to the return port of the fuel rail for

test. 4.

Connect the digital tester connector to the

sensor connector of the fuel rail for test.

Crank the engine 2 times for 5 seconds after

removing the IMV connector and fuel rail

pressure sensor connector.

Read the pressure value displayed on the

tester display is within the specified. 5.

6.

7.

Specification1,050 bar or more

Page 228 of 796

03-212210-01

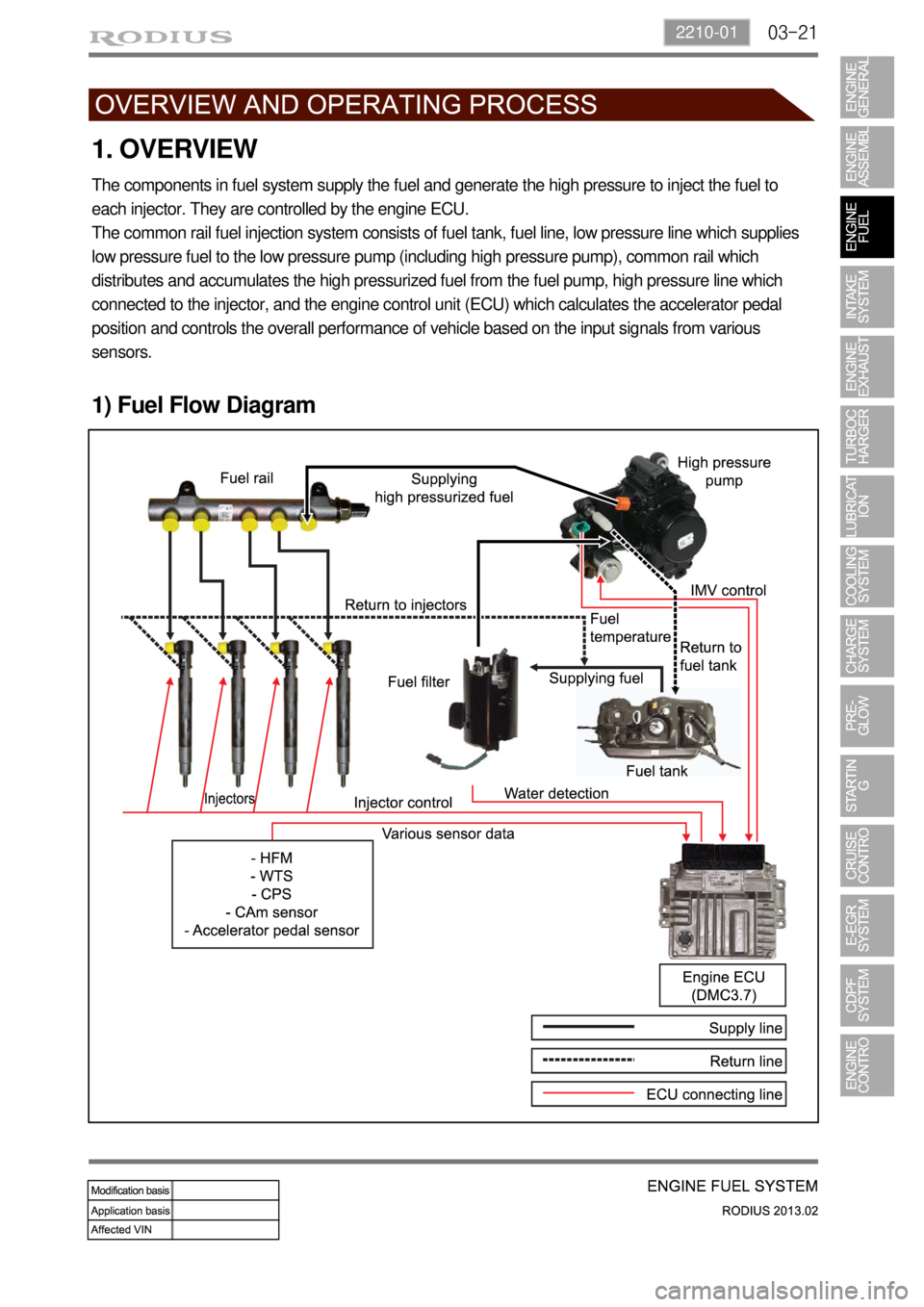

1. OVERVIEW

The components in fuel system supply the fuel and generate the high pressure to inject the fuel to

each injector. They are controlled by the engine ECU.

The common rail fuel injection system consists of fuel tank, fuel line, low pressure line which supplies

low pressure fuel to the low pressure pump (including high pressure pump), common rail which

distributes and accumulates the high pressurized fuel from the fuel pump, high pressure line which

connected to the injector, and the engine control unit (ECU) which calculates the accelerator pedal

position and controls the overall performance of vehicle based on the input signals from various

sensors.

1) Fuel Flow Diagram

Page 229 of 796

03-22

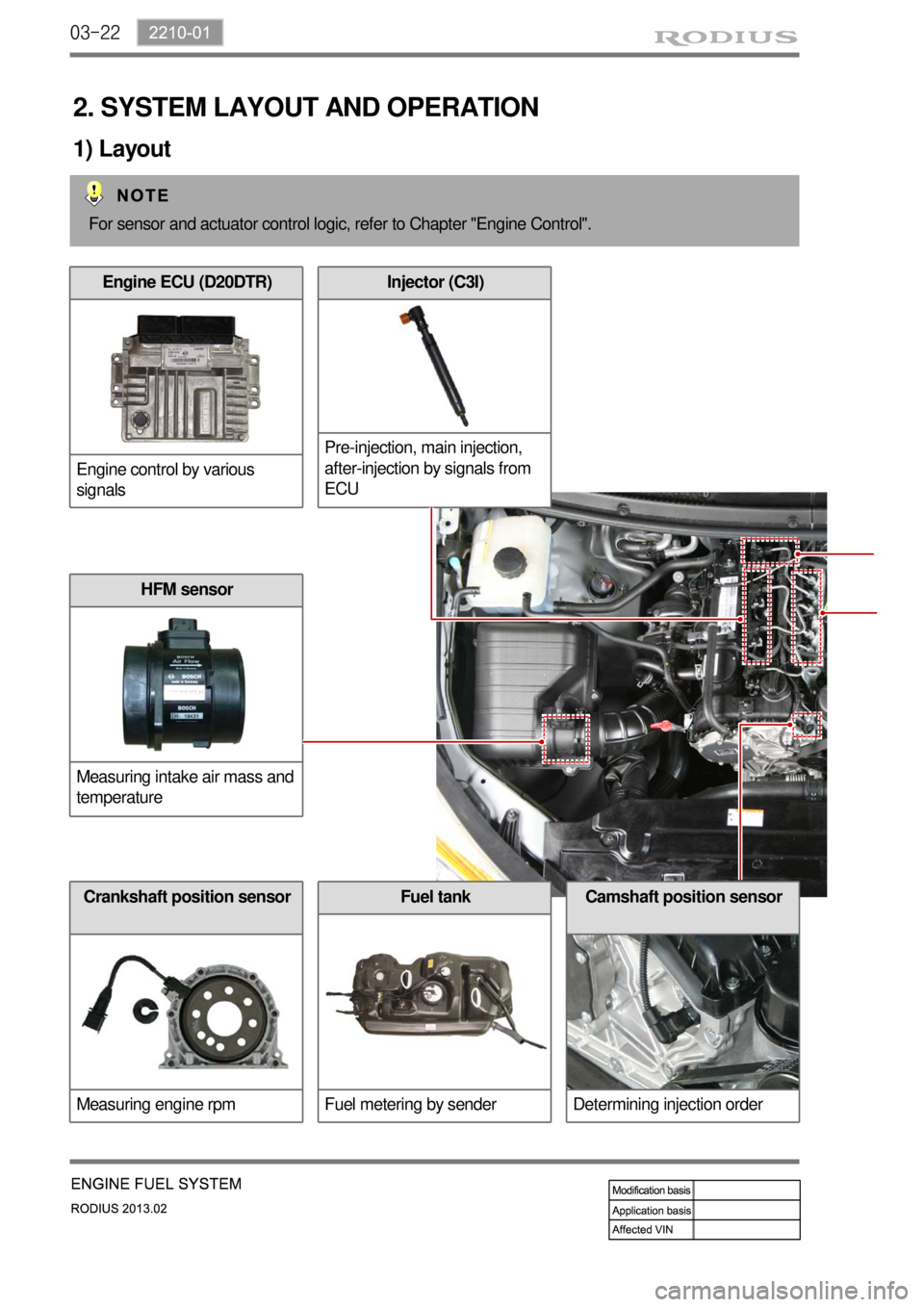

Camshaft position sensor

Determining injection orderFuel tank

Fuel metering by sender

2. SYSTEM LAYOUT AND OPERATION

1) Layout

For sensor and actuator control logic, refer to Chapter "Engine Control".

Engine ECU (D20DTR)

Engine control by various

signalsInjector (C3I)

Pre-injection, main injection,

after-injection by signals from

ECU

HFM sensor

Measuring intake air mass and

temperature

Crankshaft position sensor

Measuring engine rpm

Page 230 of 796

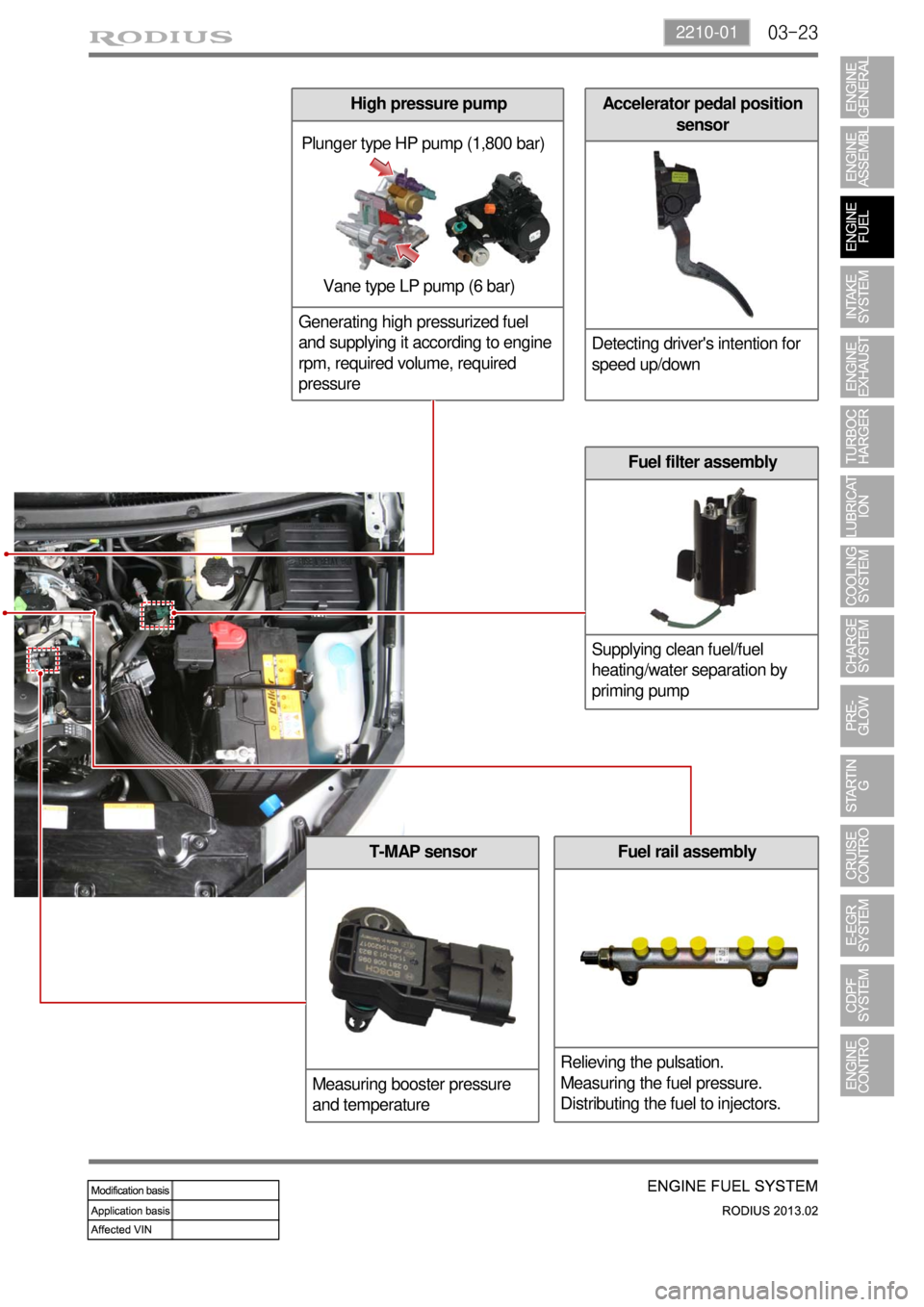

03-232210-01

T-MAP sensor

Measuring booster pressure

and temperatureFuel rail assembly

Relieving the pulsation.

Measuring the fuel pressure.

Distributing the fuel to injectors.

Plunger type HP pump (1,800 bar)

Vane type LP pump (6 bar)

Accelerator pedal position

sensor

Detecting driver's intention for

speed up/down

Fuel filter assembly

Supplying clean fuel/fuel

heating/water separation by

priming pump

High pressure pump

Generating high pressurized fuel

and supplying it according to engine

rpm, required volume, required

pressure

Page 231 of 796

03-24

2) Fuel System Flow Diagram

The fuel from the fuel tank is supplied to the fuel heater of fuel filter/priming pump and then low

pressure generated by the low pressure pump (built into HP pump) is transmitted to the HP pump.

The fuel pressure at the HP pump is controlled by the IMV valve, and the maximum allowed pressure

is 1,800 bar. The compressed fuel at the fuel pump is delivered to the rail, and injected by the injectors

according to the injection signals. The injection method is the same with the conventional method; Fuel

return by backleak which operates the needle valve.

The major difference is that the fuel return line is connected to the fuel filter inlet port, not the HP pump

venturi.

The pressure from the high pressure pump is increased to 1,800 bar from 1,600 bar, and the pump is

now installed to the cylinder head (cylinder block for previous model). The fuel pressure is generated

by the operation of intake camshaft and gears. The specifications for the IMV valve and the fuel

temperature sensor are not changed.