sensor SSANGYONG TURISMO 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 233 of 796

03-26

The engine ECU calculates the accelerator pedal based on the input signals from various sensors, and

controls the overall operation of the vehicle.

The ECU receives the signals from various sensor through data line, and performs effective air-fuel ratio

control based on these signals.

The crankshaft speed (position) sensor measures the engine speed, and the camshaft speed (position)

sensor determines the order of injections, and the ECU detects the amount of the accelerator pedal

depressed (driver's will) by receiving the electrical signals from the accelerator pedal sensor.

The mass air flow sensor detects the volume of intake air and sends the value to the ECU.

The major function of the ECU is controlling air-fuel ratio to reduce the emission level (EGR valve

control) by detecting instantaneous air flow change with the signals from the mass air flow sensor.

Also, the ECU uses the signals from the coolant temperature & air temperature sensors, booster

pressure sensor, atmospheric pressure sensor to: a) determine injection starting point and set value for

pilot injection, and b) deal with various operations and variable conditions.

Page 237 of 796

04-6

1. OVERVIEW

The intake system for D20DTR engine is equipped with a throttle body which includes a flap. This flap

is controlled by an electrical signal to cut off the intake air entering to the engine when the ignition

switch is turned off. Because of this, the shape of the intake manifold has been changed and improved

HFM sensor is newly adopted to control the intake air volume more precisely.

2. COMPONENT

2330-01 Intercooler assembly

2313-15 HFM sensor

HFM sensor, version 7

*For more information, refer to Chapter "Engine

Control".

2313-01 Air cleaner assembly

Page 250 of 796

06-51914-01

2) Inspection of Turbocharger

When problem occurs with the turbocharger, it could cause engine power decline, excessive discharge

of exhaust gas, outbreak of abnormal noise and excessive consumption of oil.

On-board Inspection 1.

Check the bolts and nuts foe looseness or missing

Check the intake and exhaust manifold for looseness or damage

Check the oil supply pipe and drain pipe for damages

Check the housing for crack and deterioration -

-

-

-

Inspection of turbine 2.

Remove the exhaust pipe at the opening of the turbine and check, with a lamp, the existence of

interference of housing and wheel, oil leakage and contamination (at blade edge) of foreign materials.

Interference: In case where the oil leak sign exists, even the small traces of interferences on the

turbine wheel mean, most of times, that abrasion has occurred on the journal bearing. Must

inspect after overhauling the turbocharger.

Oil Leakage: Followings are the reasons for oil leakage condition -

-

Problems in engine: In case where the oil is smeared on inner wall section of the exhaust gas

opening.

Problems in turbocharger: In case where the oil is smeared on only at the exhaust gas

outlet section. *

*

Idling for long period of time can cause oil leakage to the turbine side due to low pressure of exhaust

gas and the rotation speed of turbine wheel. Please note this is not a turbocharger problem.

Oil Drain Pipe Defect

In case where oil flow from the turbocharger sensor housing to the crank case is not smooth

would become the reason for leakage as oil builds up within the center housing. Also, oil thickens

(sludge) at high temperature and becomes the indirect reason of wheel hub section. In such case,

clogging and damage of the oil drain pipe and the pressure of blow-by gas within the crank case

must be inspected.

Damages due to Foreign Materials.

When the foreign materials get into the system, it could induce inner damage as rotating balance

of the turbocharger gets out of alignment. -

-

-

Page 264 of 796

06-191914-01

2. COMPONENTS

Atmospheric pressure, RPM

signal * For details about control logic, refer to Chapter “Engine Control”.

E-VGT turbocharger

Improves engine powerAccelerator pedal position

sensor

Transfers driver's will to

accelerate to ECUEngine ECU (D20DTR)

E-VGT duty control

Coolant temperature sensor

Operates the VGT according to

engine warm-upT-MAP sensor

Improves the engine powerHFM sensor

Booster pressure and

temperature

Page 270 of 796

07-51543-00

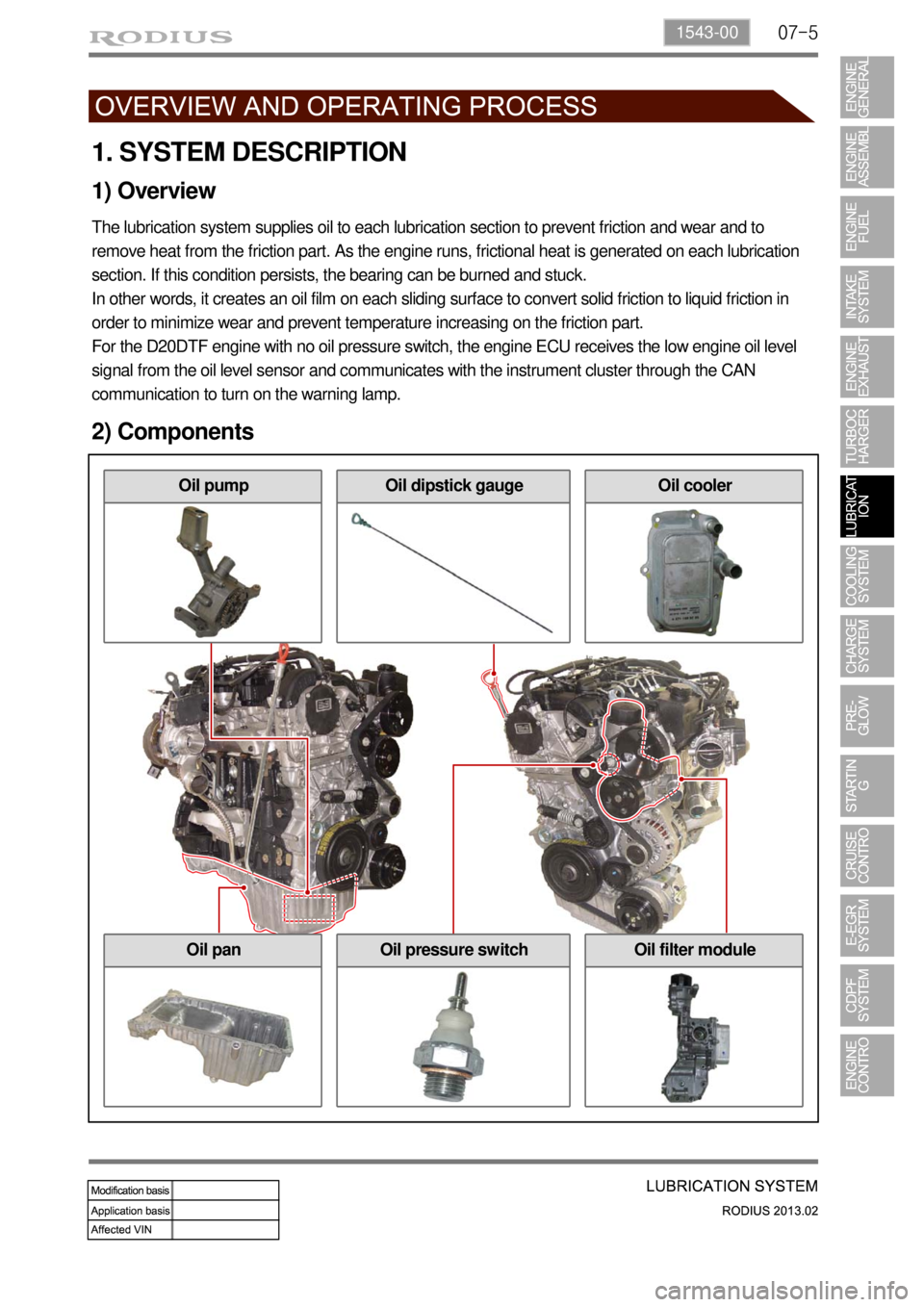

1. SYSTEM DESCRIPTION

1) Overview

The lubrication system supplies oil to each lubrication section to prevent friction and wear and to

remove heat from the friction part. As the engine runs, frictional heat is generated on each lubrication

section. If this condition persists, the bearing can be burned and stuck.

In other words, it creates an oil film on each sliding surface to convert solid friction to liquid friction in

order to minimize wear and prevent temperature increasing on the friction part.

For the D20DTF engine with no oil pressure switch, the engine ECU receives the low engine oil level

signal from the oil level sensor and communicates with the instrument cluster through the CAN

communication to turn on the warning lamp.

2) Components

Oil coolerOil dipstick gaugeOil pump

Oil filter moduleOil pressure switchOil pan

Page 273 of 796

08-4

2. INSPECTION

Possible Cause Action

Coolant level

is

too low- Leak from the radiator

- Leak from the coolant auxiliary tank

- Leak from the heater core- Change the radiator

- Change the coolant auxiliary tank

- Change the heater

- Leak from the coolant hose

connections

- Damaged coolant hose - Reconnect the hose or replace

the clamp

- Change the hose

- Leak from the water pump gasket

- Leak from the water pump internal

seal- Change the gasket

- Change the water pump

- Leak from the water inlet cap

- Leak from the thermostat housing- Change the water inlet cap

gasket

- Change the thermostat sealing

- Incorrect tightening torque of the

cylinder head bolts

- Damaged cylinder head gasket- Tighten the bolts to the specified

torque

- Change the cylinder head gasket

Coolant

temperature is

too high- Coolant leakage (Coolant level is low)

- Improper coolant mixture ratio

- Kinked coolant hose- Add coolant

- Check the coolant concentration

(Anti-freeze)

- Repair or replace the hose

- Defective thermostat

- Defective water pump

- Defective radiator

- Defective coolant auxiliary tank or tank

cap- Change the thermostat

- Change the water pump

- Change the radiator

- Change the coolant auxiliary tank

or tank cap

- Cracks on the cylinder block or

cylinder head

- Clogged coolant passages in the

cylinder block or cylinder head- Change cylinder block or cylinder

head

- Clean the coolant passage

- Clogged radiator core - Clean the radiator core

- Improper operation of cooling fan - Replace the cooling fan or repair

the related circuit

- Defective temperature sensor or

faulty wiring- Replace the sensor or repair the

related wiring

Coolant

temperature is

too low- Thermostat is stuck open - Change the thermostat

- Improper operation of cooling fan - Replace the cooling fan or repair

the related circuit

- Defective temperature sensor or faulty

wiring- Replace the sensor or repair the

related wiring

Page 278 of 796

08-91520-00

Coolant temperature sensor

Measures the coolant

temperature and sends the

result to the engine ECU.

Electric fan

Circulates the fresh air forcibly to exchange heat

with the radiator core fin.

Radiator

Releases heat through fins and cools down the hot

coolant as the coolant passes through the tube of the

radiator core.

MT - 400W , AT- 600W

Page 310 of 796

13-31793-00

1. SPECIFICATION

Item Specification

E-EGR valve Motor EGR response time 50 ms

Driven by DC motor

Valve EGR gas flow rate 120 Kg/h

Position sensor Sensing type Hole sensor

Supplied voltage5V ± 10%

Maximum signal

range5% ~ 95%

Maximum power

consumption<15mA

E-EGR cooler Cooling capacity 8.3 kW or more

Cooling fin type Wavy fin

Cooler type U-shaped

E-EGR bypass valve Driven by Vacuum

(Solenoid valve)

Page 311 of 796

13-4

1. SYSTEM DESCRIPTION

1) Overview

The EGR (Electric-Exhaust Gas Recirculation) valve reduces the NOx emission level by recirculating

some of the exhaust gas to the intake system.

To meet Euro-V regulation, the capacity and response rate of E-EGR valve in D20DTR engine have

been greatly improved. The EGR cooler with high capacity reduces the Nox, and the bypass valve

reduces the CO and HC due to EGR gas before warming up.

Also, the engine ECU adjusts the E-EGR opening by using the air mass signal through HFM sensor. If

the exhaust gas gets into the intake manifold when the EGR valve is open, the amount of fresh air

through HFM sensor should be decresed.

Benefits of E-EGR valve ▶

Improved accuracy and response through electric control

Feedback function (Potentiometer)

Preventing chattering of EGR valve and improved durability

Self-cleaning function -

-

-

-

Page 312 of 796

13-51793-00

EGR pipe

Transports the exhaust gas from the EGR cooler

and EGR bypass valve to the intake duct.E-EGR valve

Receives the electric signal from the ECU to

control the valve.

E-EGR cooler and bypass valve

The cooler lowers the high temperature of the

exhaust gas and the bypass valve directly

supplies the exhaust gas to the intake duct

without passing through the EGR cooler to

reduce the emission of exhaust gas before

warming up the engine.HFM sensor

Used as a main map value to control the EGR.

The coolant temperature, engine rpm, engine

load, intake air temperature (HFM: decreased at

60˚C or more), atmospheric pressure

(atmospheric pressure sensor: altitude

compensation) are used as auxiliary map values.

2) Location and Components

See the section "Engine control" for E-EGR

valve control logic.EGR coolerEGR bypass

For details, see the section "Engine control".

*