AC Assembly SSANGYONG TURISMO 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 325 of 796

14-132412-02

Collecting PM

→ Regeneration

The engine ECU detects the

amount of PM collected by the

information from the

temperature sensors and

differential pressure sensor.

When the soot is accumulated,

the engine ECU performs post-

injection to increase the

exhaust gas temperature and

burns the collected PM at

approx. 600°C.Oxidation (DOC)

When the exhaust gas enters

into the CDPF assembly, its

CO, HC and PM are reduced

by the redox reaction of the

DOC. The remaining PM is

filtered and collected in CDPF,

and the temperature of the

exhaust gas is increased to

between 450 and 500°C.

5. OPERATING PROCESS

[Configuration and principle of operation]

The exhaust gas

passed through the

exhaust manifold

enters into the CDPF

assembly (at approx

250℃).

Page 382 of 796

01-70000-00

2. DESCRIPTION AND OPERATION

1) Cleanliness and Care

An automobile engine is a combination of many machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousandths of an inch. When any internal engine parts are

serviced, care and cleanliness are important. A liberal coating of engine oil should be applied to friction

areas during assembly, to protect and lubricate the surfaces on initial operation.

Proper cleaning and protection of machined surfaces and friction areas is part of the repair procedure.

This is considered standard shop practice even if not specifically stated.

Whenever valve train components are removed for service, they should be kept in order.

They should be installed in the same locations, and with the same mating surfaces, as when they were

removed. Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to wire harness or other electrical parts.

2) On-Engine Service

Disconnect the negative battery cable before removing or installing any electrical unit, or when a

tool or equipment could easily come in contact with exposed electrical terminals.

Disconnecting this cable will help prevent personal injury and damage to the vehicle.

The ignition must also be in LOCK unless otherwise noted.

Notice Any time the air cleaner is removed, the intake opening -

Any time the air cleaner is removed, the intake opening should be covered. This will protect

against accidental entrance of foreign material, which could follow the intake passage into the

cylinder and cause extensive damage when the engine is started. -

Page 391 of 796

05-32420-01

1. OVERVIEW OF EXHAUST SYSTEM

When you are inspecting or replacing exhaust system components, make sure there is adequate

clearance from all points on the underbody to avoid possible overheating of the floor panel and

possible damage to the passenger compartment insulation and trim materials.

Check the complete exhaust system and the nearby body areas and trunk lid for broken,

damaged, missing or mispositioned parts, open seams, holes, loose connections, or othe

r

deterioration which could permit exhaust fumes to seep into the trunk may be an indication of a

problem in one of these areas. Any defects should be corrected immediately. -

2. OVERVIEW OF MUFFLER

Aside from the exhaust manifold connection, the exhaust system uses a flange and seal joint design

rather than a slip joint coupling design with clamp and U-bolts.

If hole, open seams, or any deterioration is discovered upon inspection of the front muffler and pipe

assembly, the complete assembly should be replace, the complete assembly should be replaced.

The same procedure is applicable to the rear muffler assembly. Heat shields for the front and rea

r

muffler assembly and catalytic converter protect the vehicle and the environment from the high

temperatures that the exhaust system develops.

3. OVERVIEW OF CATALYTIC CONVERTER

When jacking or lifting the vehicle from the body side rails, be certain that the lift pads do not

contact the catalytic converter, as this could damage the catalytic converter. -

Use of anything other than unleaded fuel will damage the catalyst in the catalytic converter. -

The catalytic converter are emission-control devices added to the exhaust system to reduce

pollutants from the exhaust pipes.

The oxidation catalyst is coated with a catalytic material containing platinum and palladium,

which reduces levels of hydrocarbon (HC) and carbon monoxide (CO) from the exhaust gas.

The three-way catalyst has coatings which contain platinum and rhodium, which additionall

y

lower the levels of oxides of nitrogen (NOx). -

-

Page 404 of 796

08-6

3. IGNITION SYSTEM OPERATION

This ignition system does not use a conventional distributor and coil. It uses a crankshaft position

sensor input to the Engine Control Module (ECM).

The ECM then determines Electronic Spark Timing (EST) and triggers the electronic ignition system

ignition coil.

This type of distributor less ignition system uses a "waste spark" method of spark distribution. Each

cylinder is paired with the cylinder that is opposite it (2.3L DOHC: 2 - 3 or 1 - 4, 3.2L DOHC: 1 - 6 or 2 -

5 or 3 - 4).

The spark occurs simultaneously in the cylinder coming up on the compression stroke and in the

cylinder coming up on the exhaust stroke.

The cylinder on the exhaust stroke requires very little of the available energy to fire the spark plug.

The remaining energy is available to the spark plug in the cylinder on the compression stroke. These

systems use the EST signal from the ECM to control the EST.

The ECM uses the following information: Engine load (mass air flow sensor, manifold air pressure

sensor).

Engine coolant temperature.

Intake air temperature.

Crankshaft position.

Engine speed (rpm).

1) Electronic Ignition System Ignition Coil

The Electronic Ignition (EI) system ignition coil is located on the cylinder head cover.

The double ended coils receive the signal for the ECM which controls the spark advance. Each

EI system ignition coil provides the high voltage to two spark plugs simultaneously;

3.2L DOHC

T1/1: cylinder 2 and 5

T1/2: cylinder 3 and 4

T1/3: cylinder 1 and 6

The EI system ignition coil is not serviceable and must be replaced as an assembly.

Page 420 of 796

01-78410-02

1. OVERVIEW

The fuse and relay boxes consist of four boxes: Fuse & relay box, in engine room and Fuse and relay

box in left side of instrument panel.

2. LOCATION

▶Engine Room Fuse and Relay Box

▶Interior Fuse and Relay Box

PTC Box Assembly

Page 503 of 796

06-38510-00

1. SPECIFICATIONS

1) Center Fascia Switch

Item Specifications

Center fascia switch &

bezel assemblyHazard warning flasher switch DC 12 V 10 A(lamp load)

Windshield heated glass switch

DC 12 V 1 A(inductive load) Rear heated glass switch

ESP OFF switch

Driver/front passenger seat warmer

switch

Fog lamp switch

2) 4WD Switch & HLLD Switch & Rear Wiper Operation Switch

Item Specifications

4WD switch &

HLLD switch &

rear wiper operation

switch assemblyWasher switch DC 12 V 3.8 A(lamp load)

Wiper switch DC 12 V 3.0 A (max. 10 A)

4WD switch DC 12 V 300 mA

HLLD switch DC 12 V 1 A (inductive load)

3) Steering Wheel Switch

Item Specifications

Steering wheel switch Rated voltage DC 5 V 0.1 A(rated load)

Operation temperature-30℃~+80℃

Page 505 of 796

06-58510-00

2. MAJOR CHANGES

Center fascia switch

- Design changed

Steering wheel switch assembly

- Power button deleted, steering wheel heating (option) switch added

- Design changed

Multifunction switch assembly

- Connector pin layout changed due to newly added steering wheel heating (option) circuit

- Contact coil and steering wheel angle sensor changed

Page 517 of 796

08-58610-11

2. RAIN SENSOR OPERATION

The rain sensor is installed on the specific heat treated windshield that has minimum 13% of

transmittance rate with specified intensity of radiation. It is installed on the glass with a adhesive of

Sorepa.

It communicates with STICS and makes the wipers to operate automatically under the rain sensing

mode (multifunction switch wiper: AUTO mode).

The emitting section of the rain sensor unit emits infrared rays against the windshield and then detects

the amount of rain drops by receiving reflected rays with photodiode.

The sensing section on the windshield is located just above the center point between LED and

photodiode.

Components and functions of the rain sensor unit

Unit latch

Rain

sensor unit

PCB assembly and

emitter lens

Emitter lens

The LED emits the infrared

rays is located at bottom and

the lens guides the infrared

rays to target point.

Receiver lens

The receiver lens guides the

reflected infrared rays from

windshield to photodiode.

Housing and

receiver lens

Housing and PCB

Rear

Front

Rain sensor unit (including cover)

Page 542 of 796

11-58910-05

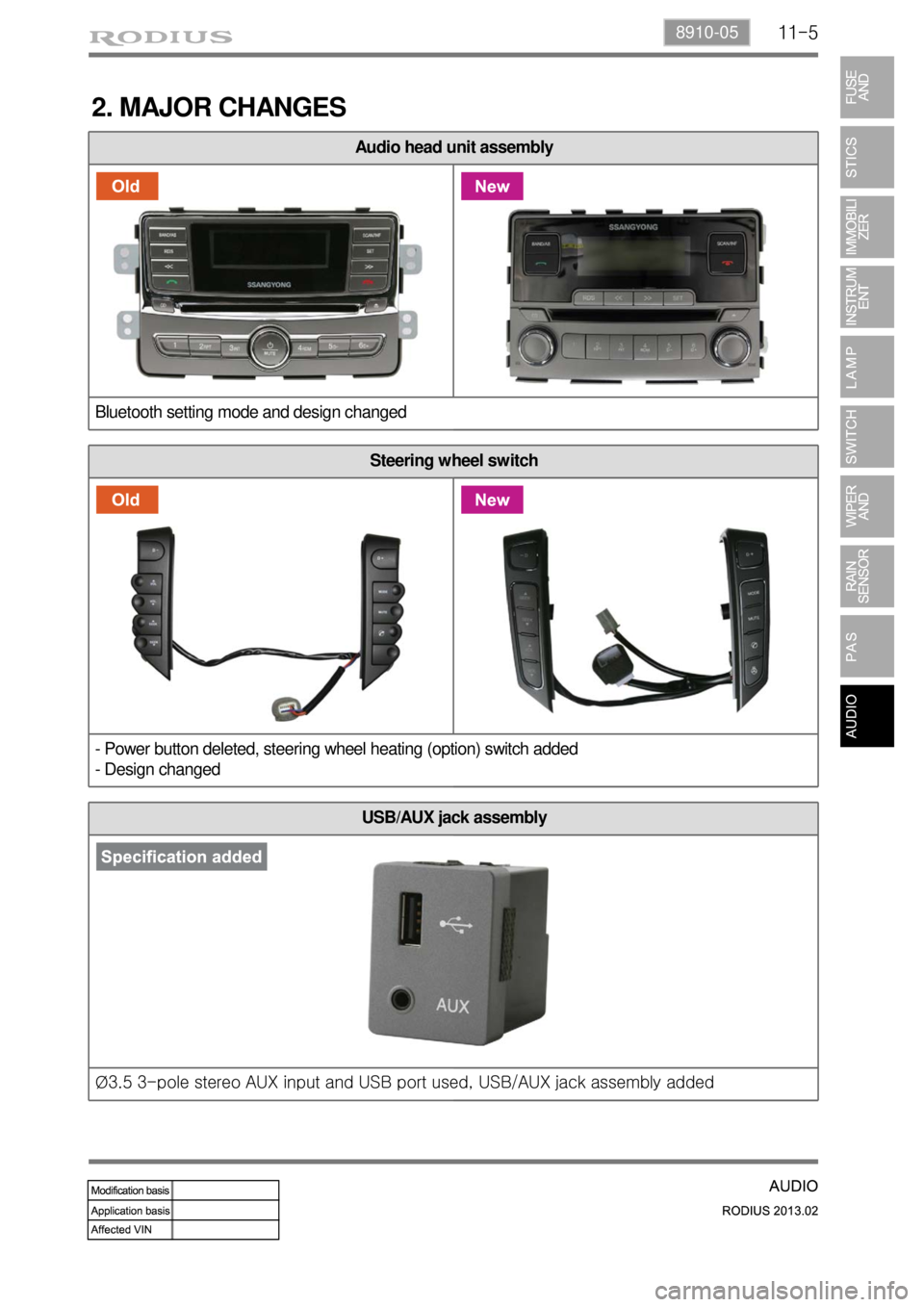

Audio head unit assembly

Bluetooth setting mode and design changed

Steering wheel switch

- Power button deleted, steering wheel heating (option) switch added

- Design changed

2. MAJOR CHANGES

USB/AUX jack assembly

Ø3.5 3-pole stereo AUX input and USB port used, USB/AUX jack assembly added

Page 545 of 796

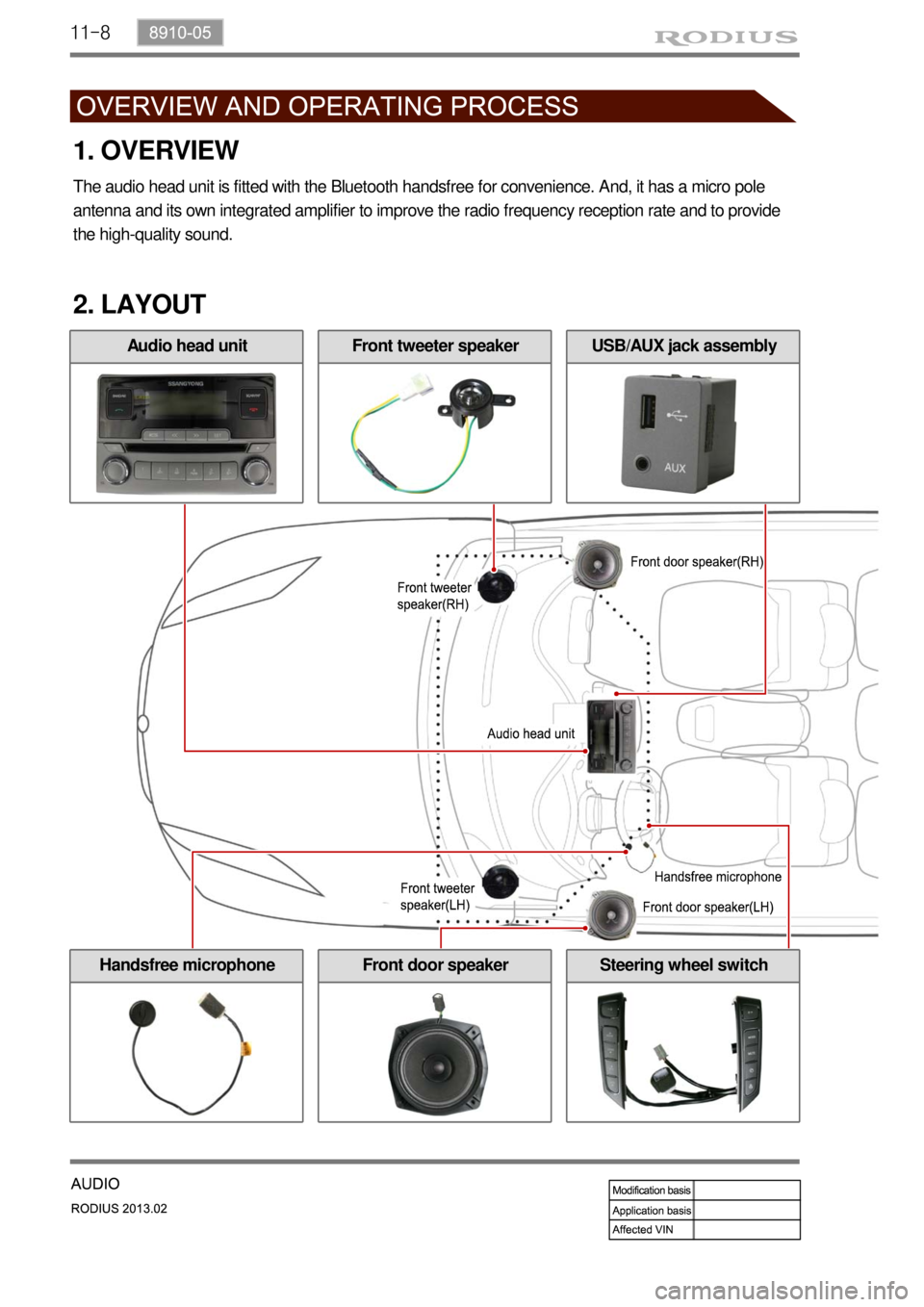

11-8

Front door speaker

2. LAYOUT

Handsfree microphoneSteering wheel switch

1. OVERVIEW

The audio head unit is fitted with the Bluetooth handsfree for convenience. And, it has a micro pole

antenna and its own integrated amplifier to improve the radio frequency reception rate and to provide

the high-quality sound.

Audio head unitFront tweeter speakerUSB/AUX jack assembly