lock SSANGYONG TURISMO 2013 Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 651 of 796

09-54891-01

2. FUNCTION

1) Term Definition

ABS: Anti-Lock Brake System ▶

When the brake pedal is abruptly depressed, the HECU calculates the slip ratio of each wheel based

on information received from the wheel speed sensors and controls the hydraulic module data quickly

and precisely in order to maintain the friction between the road surface and tire optimal (static friction).

Therefore, by keeping the friction between the road surface and tire optimal, it is possible to obtain

following effects: Enhanced steering stability, improved direction stability, reduced stopping distance

and etc.

EBD: Electronic brake-Force Distribution ▶

This is to detect the tire speed from the wheel speed sensor in order to supply the braking pressure to

the rear tires individually. In other words, the HECU measures the tire deceleration speed continuously

and controls the rear inlet valve on the hydraulic modulator to obtain optimal braking force as much as

possible. Thereby, stopping distance, braking effect and straight stability are improved.

ESP: Electronic Stability Program ▶

This is used to make the vehicle stabilized to recognize the emergency driving conditions, and to

control the brake for each wheels and the engine power when the brake system or acceleration will not

work any more in dangerous circumstances.

TCS: Traction Control System ▶

When the wheel is slipping due to an excessive engine torque while starting off or driving, this controls

the driving force (braking force + engine torque) in order to prevent the wheel from slipping through the

engine or brake control.

AYC: Active Yaw Control ▶

This has been developed to help a driver avoid danger of losing control of the vehicle stability due to

understeer or oversteer during cornering, which is a part of the ESP function.

HBA: Hydraulic Brake Assistant ▶

Developed based on the fact that elderly drivers depress the brake pedal too soft even when hard

braking is necessary, this an assist system to operate the HECU drive motor immediately and apply

high braking force to the wheels when the brake pedal is depressed softly and the vehicle should be

braked in emergency.

ARP: Active Rollover Protection ▶

This is a supplementary device for safety in ESP system and can help minimize the rollover accidents

by detecting a potential rollover situation through the brake and engine control when making sudden

lane change or turning sharply by adding only the software, without any separate device or switch.

Page 658 of 796

09-12

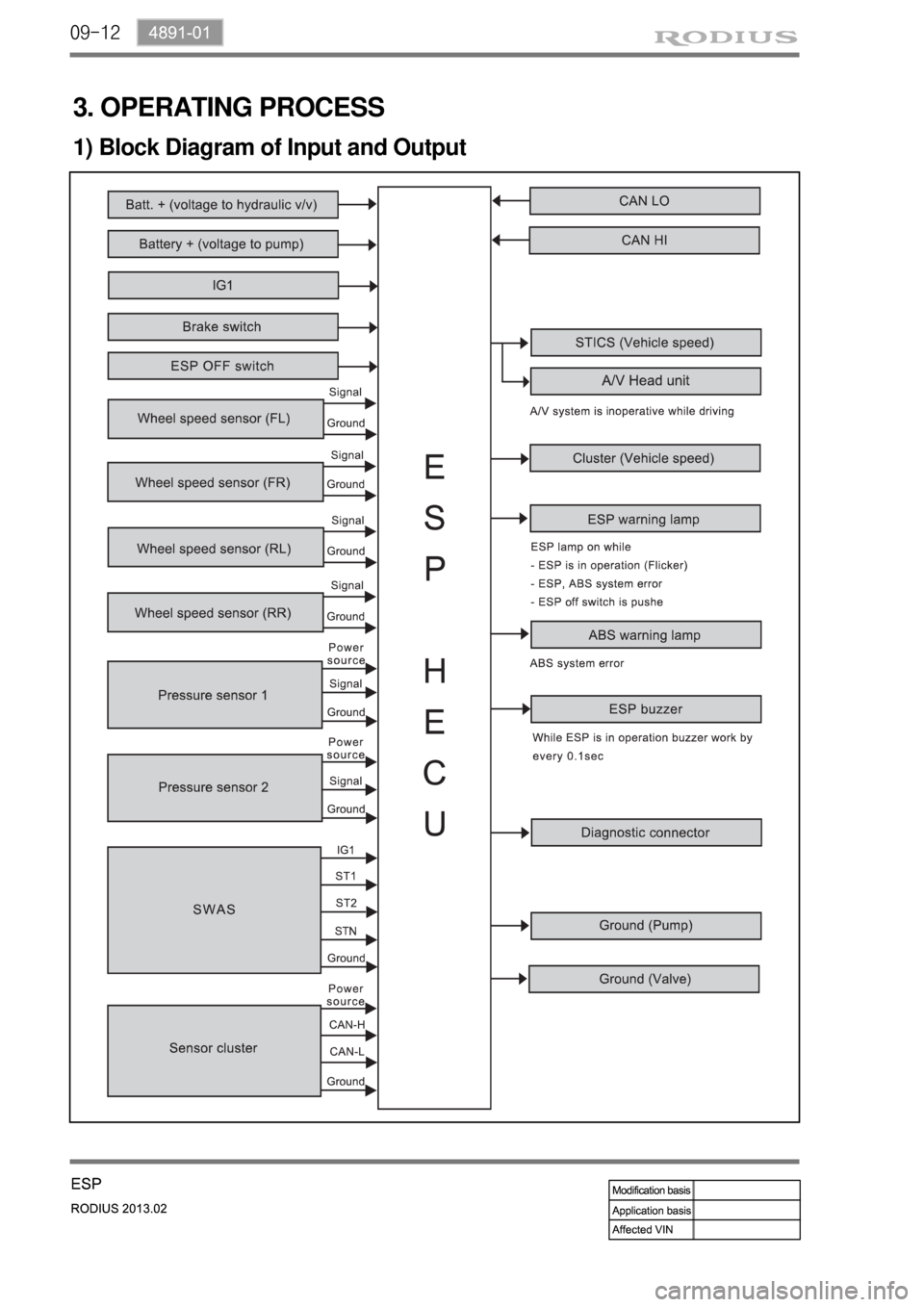

3. OPERATING PROCESS

1) Block Diagram of Input and Output

Page 669 of 796

09-234891-01

(2) Hydraulic Circuit of HBA

The above figure shows one front and one rear wheel and the same hydraulic circuit forms as in the

ESP operation. When HECU recognizes that it is an emergency and it is required for hard braking,

depending on the pressure value of the brake pressure sensor and pressure changes caused by the

pressure sensor timing, it operates the pump immediately to apply the brake pressure at the wheels.

Then, the pressure in the pump increases until just before the corresponding wheel gets locked. The

motor still keeps rotating and the outlet valve and the separation valve will stay closed. When the wheel

starts to lock, the HBA function cancels and switches to ABS operation.

Page 671 of 796

09-254891-01

▶DUMP (ESP is working) Mode

The pressure decreases just before the wheel speed drops and the wheels are locked.

The inlet valve closes and the outlet valve opens as in the ESP HECU and the oil is gathered at the

low pressure chamber while no additional oil is being supplied. Then the pump operates to allow fast oil

drainage. The shuttle valve and the separation valve do not operate while decompression.

Page 673 of 796

09-274891-01

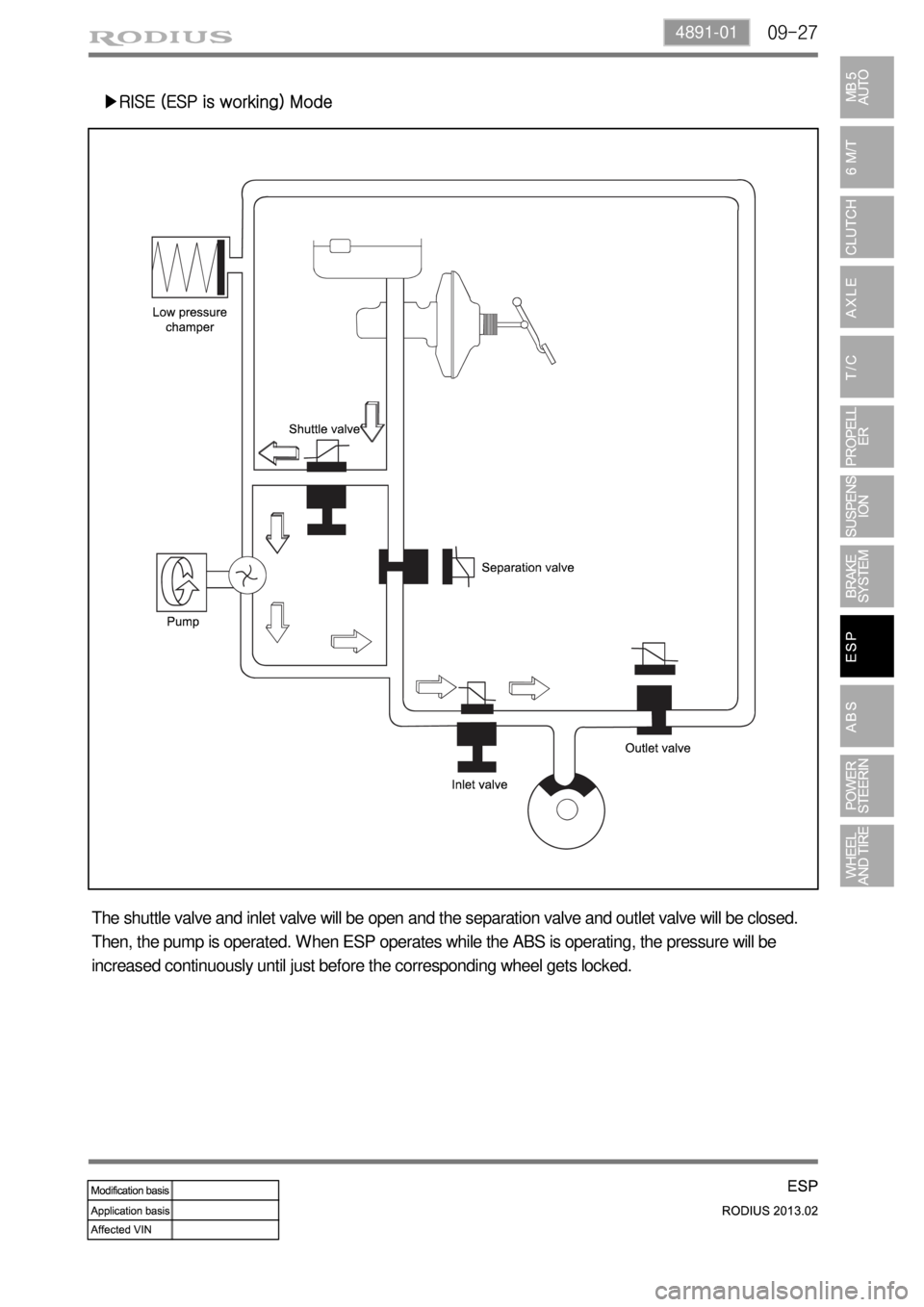

▶RISE (ESP is working) Mode

The shuttle valve and inlet valve will be open and the separation valve and outlet valve will be closed.

Then, the pump is operated. When ESP operates while the ABS is operating, the pressure will be

increased continuously until just before the corresponding wheel gets locked.

Page 676 of 796

10-34891-01

1. SYSTEM OVERVIEW

When braking suddenly or braking on slippery roads, the vehicle keeps moving forward but the wheels

are locking and not rotating. If these happen, the vehicle may lose stability or rotate resulting in an

accident. ABS helps to maintain directional stability and control of the vehicle. ABS is designed to

secure more safety and increase the control of steering wheel during emergency braking situation.

But, ABS does not guarantee perfect safety beyond its physical limit. ABS in this vehicle contains EBD

function. In normal driving conditions, the brake system operates without ABS function.

1) Basic Theory of ABS Function

To give you a better understanding of the tasks and functions of ABS, we will first look at the physics

principles.

▶Stopping distance

The stopping distance depends on the vehicle weight and initial speed when braking starts. This also

applies for vehicle with ABS, where ABS always tries to set an optimum brake force on each wheel. As

great forces are exerted between the tires and the carriageway when braking, even with ABS the

wheels may scream and rubber is left on the road. With an ABS skid mark one may be able to clearly

recognize the tire profile. The skid mark of an ABS vehicle does not however leave any hint of the

speed of the vehicle in the case of an accident, as it can only be clearly drawn at the start of braking.

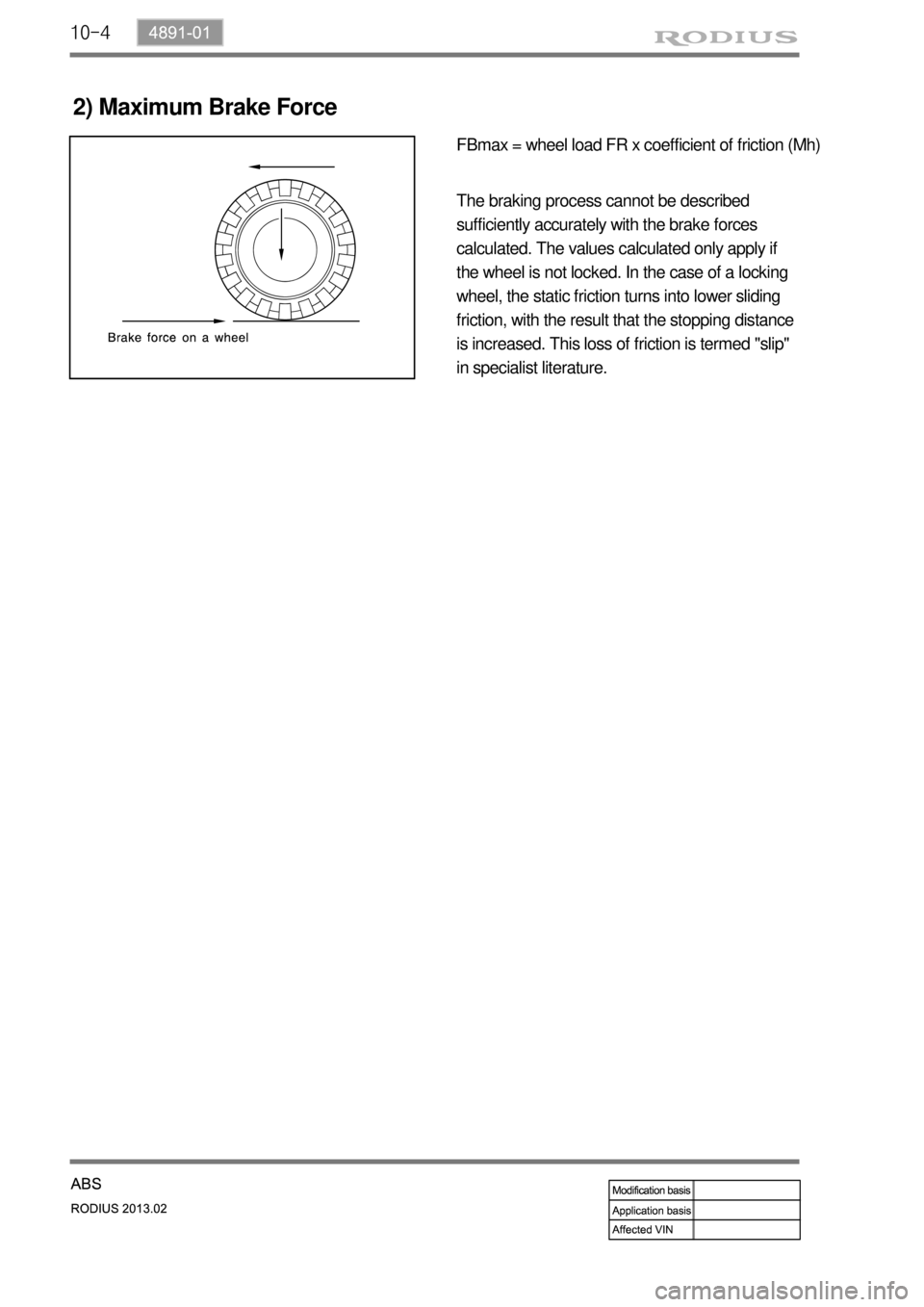

▶Brake force on a wheel

The maximum possible brake force on a wheel depends on the wheel load and the adhesion

coefficient between tire and carriageway. With a low adhesion coefficient the brake force, which can be

obtained is very low. You are bound to know the result already from driving on winter roads. With a

high adhesion coefficient on a dry road, the brake force, which can be obtained, is considerably higher.

The brake force, which can be obtained, can be calculated from below formula:

Page 677 of 796

10-4

2) Maximum Brake Force

FBmax = wheel load FR x coefficient of friction (Mh)

The braking process cannot be described

sufficiently accurately with the brake forces

calculated. The values calculated only apply if

the wheel is not locked. In the case of a locking

wheel, the static friction turns into lower sliding

friction, with the result that the stopping distance

is increased. This loss of friction is termed "slip"

in specialist literature.

Page 679 of 796

10-6

3. ABS SYSTEM OPERATION

1) Block Diagram

Page 682 of 796

10-94891-01

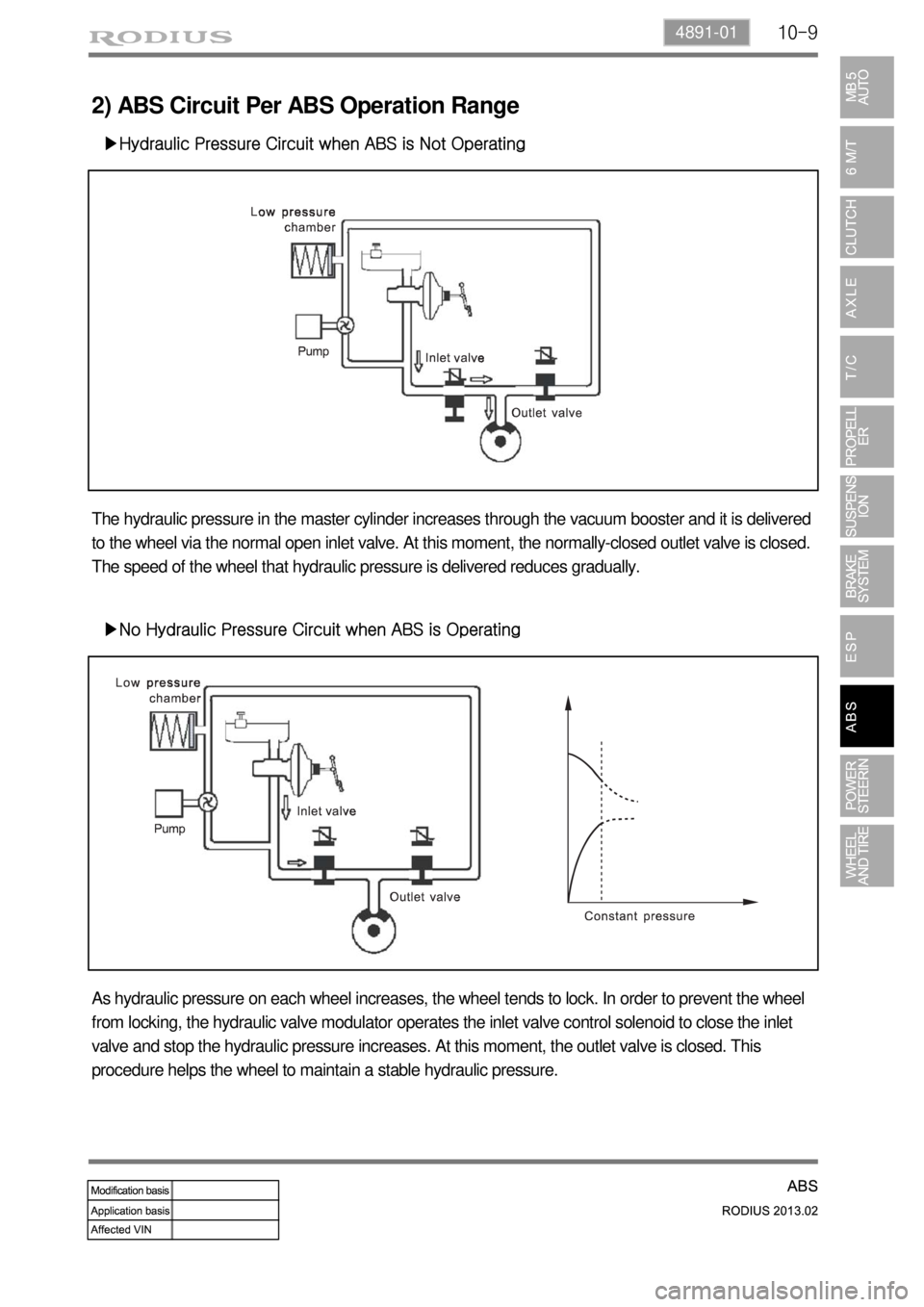

2) ABS Circuit Per ABS Operation Range

▶Hydraulic Pressure Circuit when ABS is Not Operating

The hydraulic pressure in the master cylinder increases through the vacuum booster and it is delivered

to the wheel via the normal open inlet valve. At this moment, the normally-closed outlet valve is closed.

The speed of the wheel that hydraulic pressure is delivered reduces gradually.

▶No Hydraulic Pressure Circuit when ABS is Operating

As hydraulic pressure on each wheel increases, the wheel tends to lock. In order to prevent the wheel

from locking, the hydraulic valve modulator operates the inlet valve control solenoid to close the inlet

valve and stop the hydraulic pressure increases. At this moment, the outlet valve is closed. This

procedure helps the wheel to maintain a stable hydraulic pressure.

Page 683 of 796

10-10

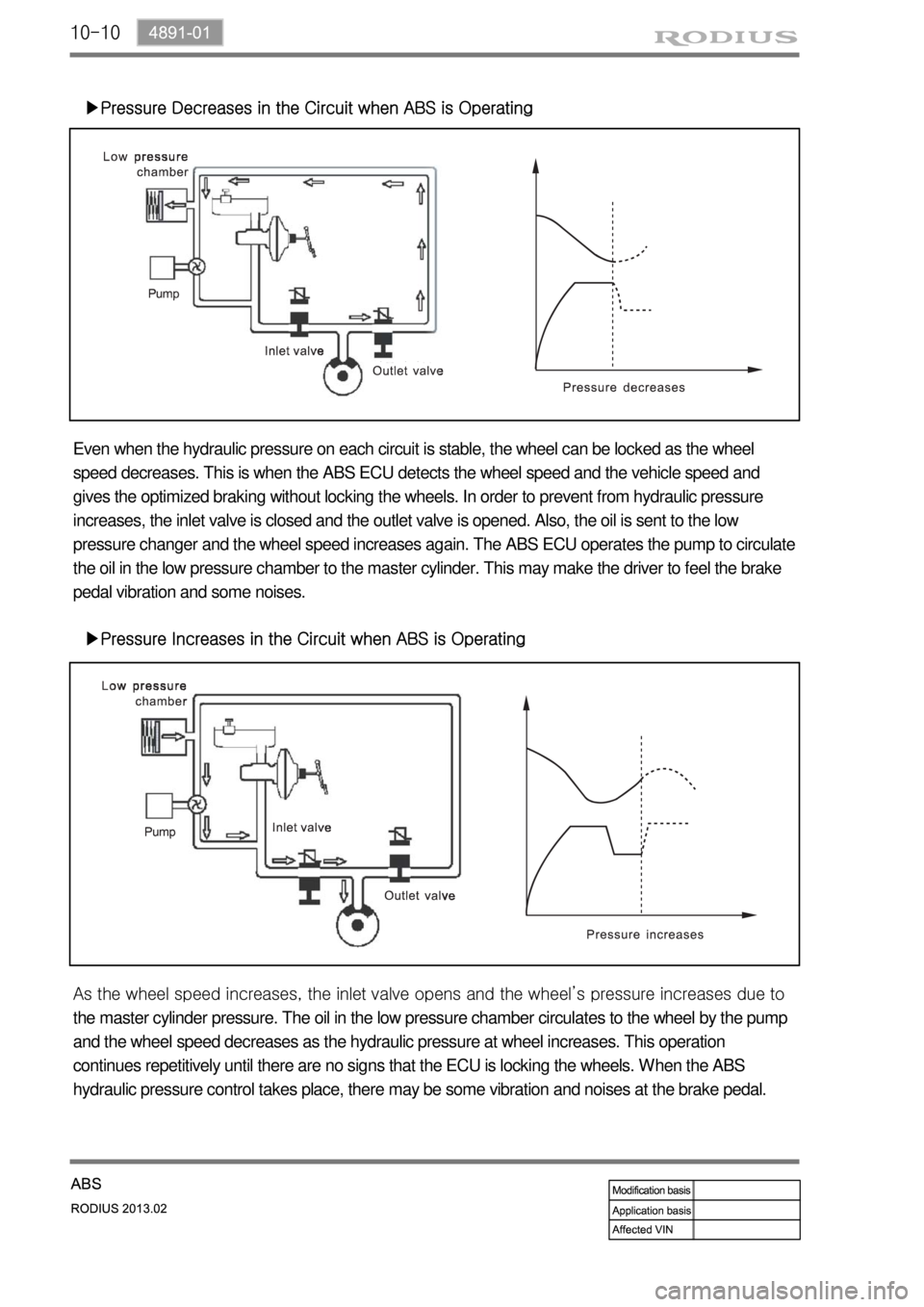

▶Pressure Decreases in the Circuit when ABS is Operating

Even when the hydraulic pressure on each circuit is stable, the wheel can be locked as the wheel

speed decreases. This is when the ABS ECU detects the wheel speed and the vehicle speed and

gives the optimized braking without locking the wheels. In order to prevent from hydraulic pressure

increases, the inlet valve is closed and the outlet valve is opened. Also, the oil is sent to the low

pressure changer and the wheel speed increases again. The ABS ECU operates the pump to circulate

the oil in the low pressure chamber to the master cylinder. This may make the driver to feel the brake

pedal vibration and some noises.

▶Pressure Increases in the Circuit when ABS is Operating

As the wheel speed increases, the inlet valve opens and the wheel’s pressure increases due to

the master cylinder pressure. The oil in the low pressure chamber circulates to the wheel by the pump

and the wheel speed decreases as the hydraulic pressure at wheel increases. This operation

continues repetitively until there are no signs that the ECU is locking the wheels. When the ABS

hydraulic pressure control takes place, there may be some vibration and noises at the brake pedal.