steering SSANGYONG TURISMO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 148 of 796

01-4

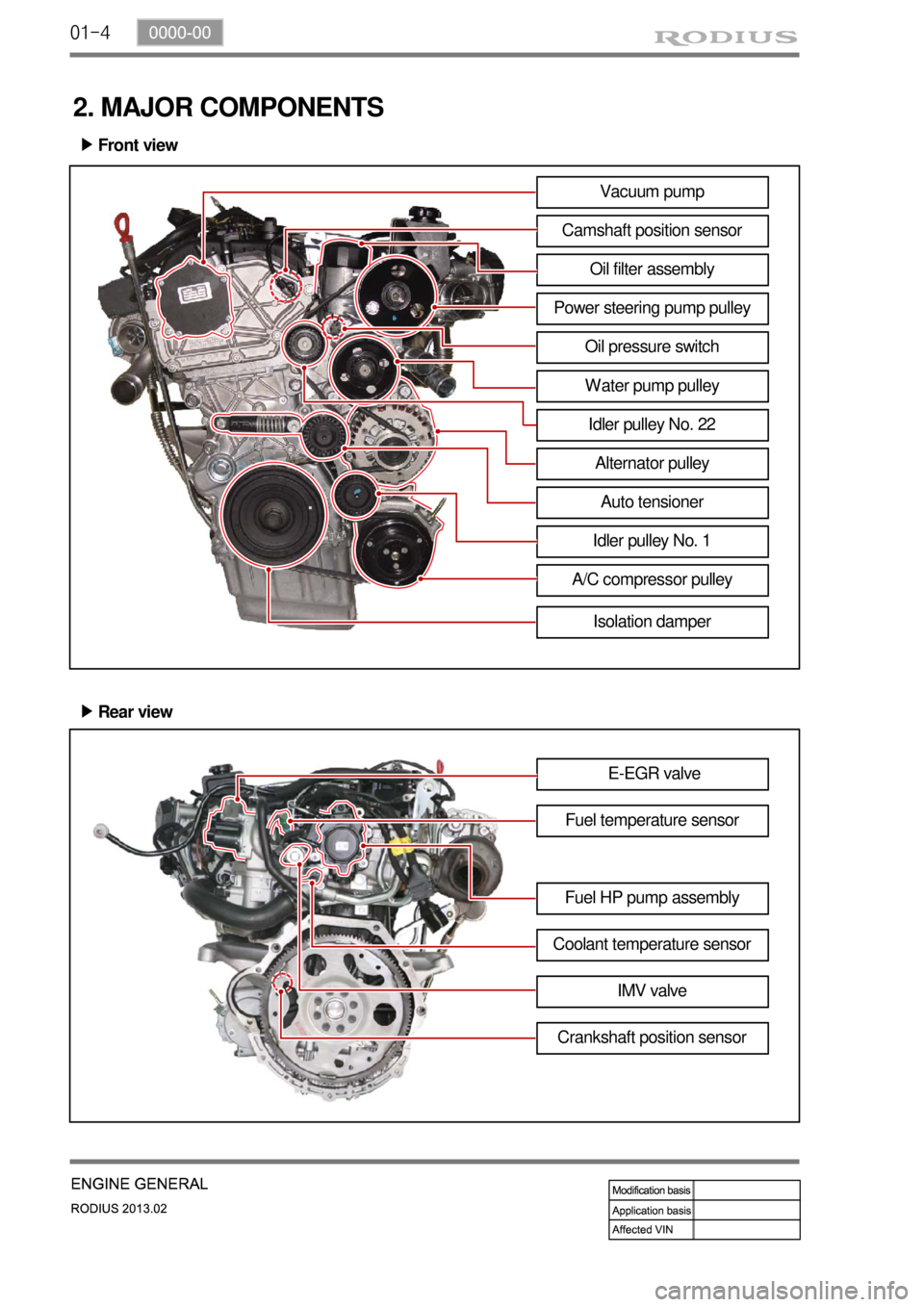

2. MAJOR COMPONENTS

Front view ▶

Vacuum pump

Camshaft position sensor

Oil filter assembly

Power steering pump pulley

Oil pressure switch

Water pump pulley

Idler pulley No. 22

Alternator pulley

Auto tensioner

Idler pulley No. 1

A/C compressor pulley

Rear view ▶

E-EGR valve

Fuel temperature sensor

Fuel HP pump assembly

Coolant temperature sensor

Crankshaft position sensorIMV valve

Isolation damper

Page 150 of 796

01-6

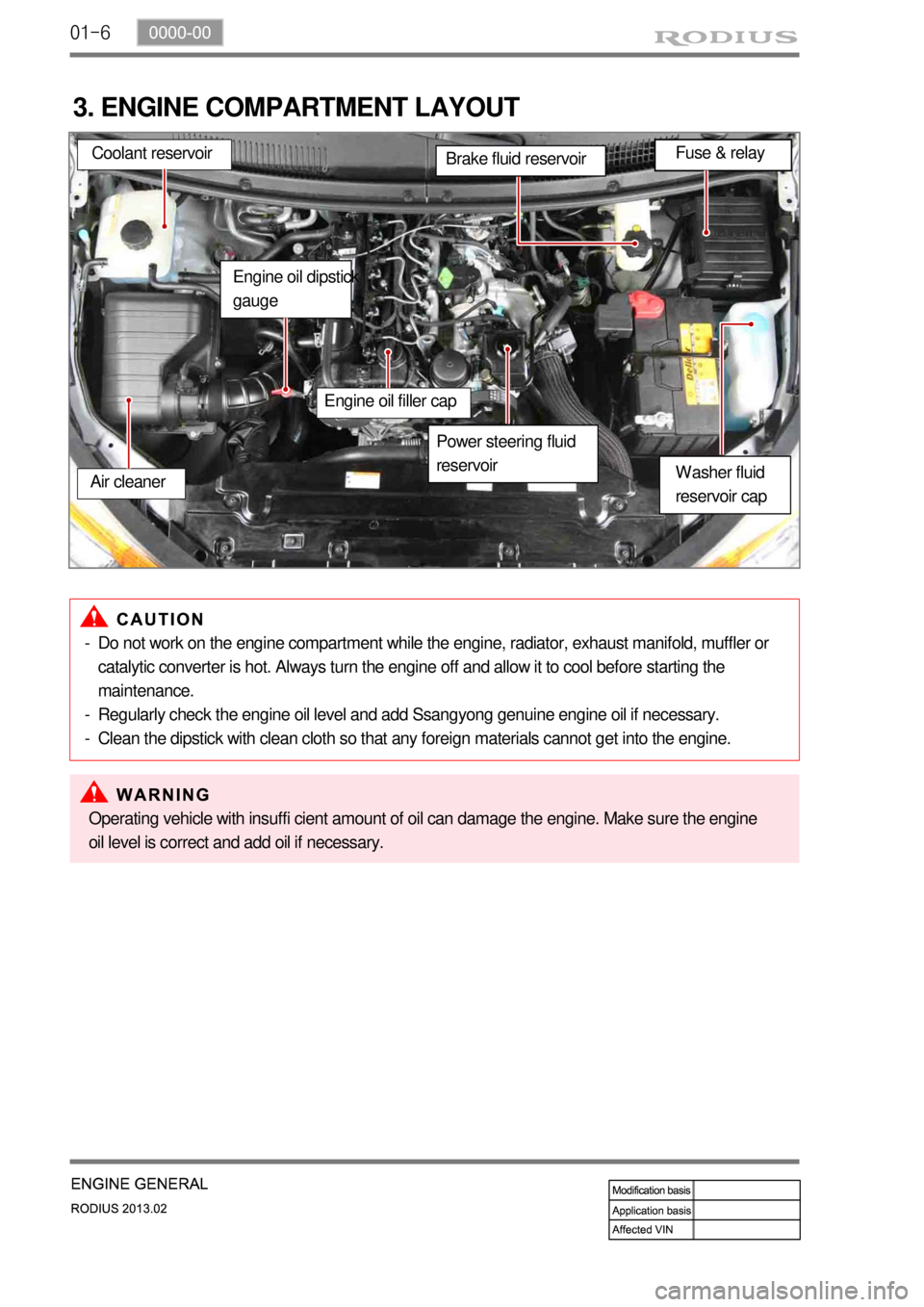

3. ENGINE COMPARTMENT LAYOUT

Do not work on the engine compartment while the engine, radiator, exhaust manifold, muffler or

catalytic converter is hot. Always turn the engine off and allow it to cool before starting the

maintenance.

Regularly check the engine oil level and add Ssangyong genuine engine oil if necessary.

Clean the dipstick with clean cloth so that any foreign materials cannot get into the engine. -

-

-

Power steering fluid

reservoirBrake fluid reservoir

Engine oil dipstick

gauge

Washer fluid

reservoir cap Engine oil filler cap

Air cleaner

Operating vehicle with insuffi cient amount of oil can damage the engine. Make sure the engine

oil level is correct and add oil if necessary.

Coolant reservoirFuse & relay

Page 158 of 796

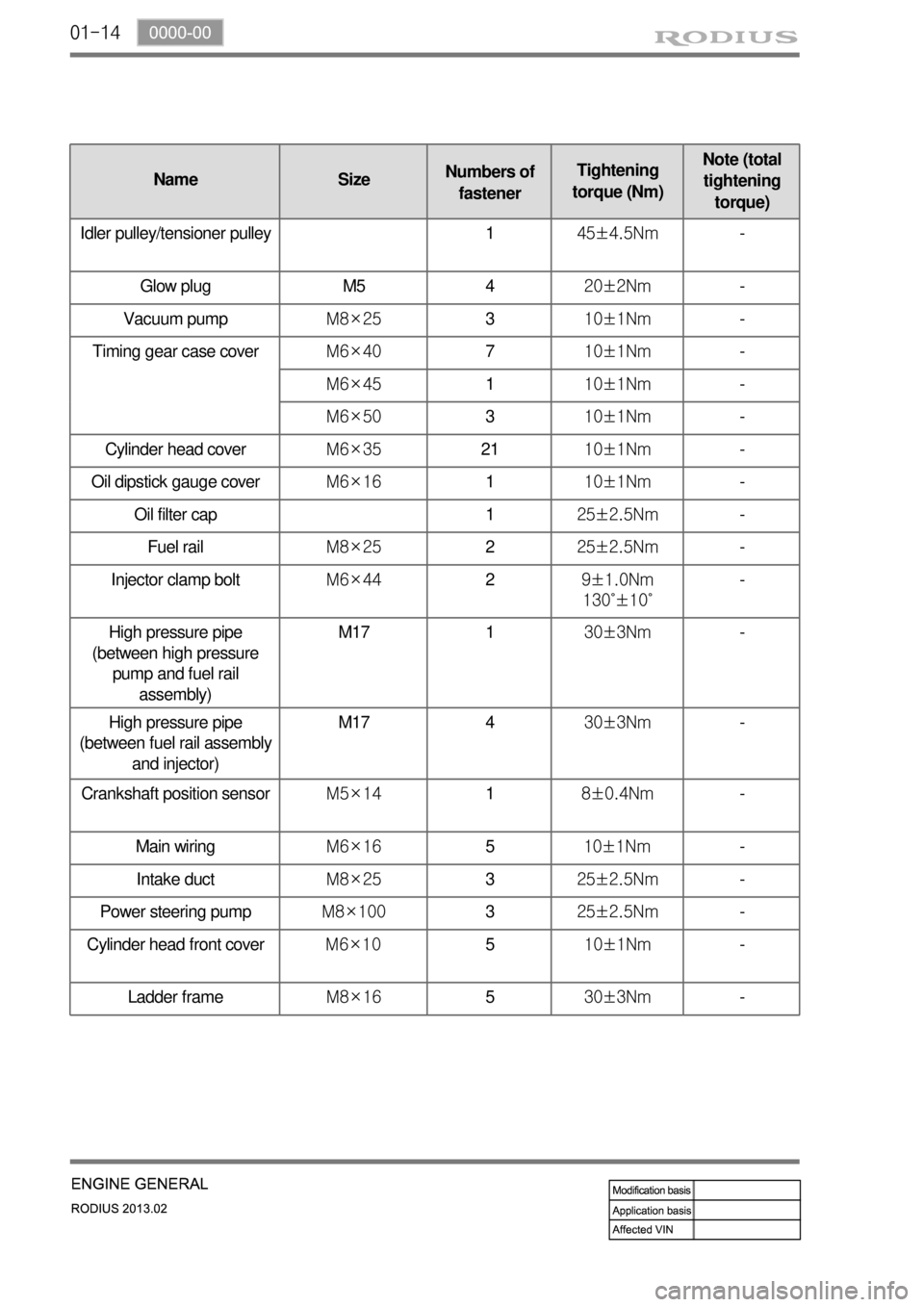

01-14

Name SizeNumbers of

fastenerTightening

torque (Nm)Note (total

tightening

torque)

Idler pulley/tensioner pulley 1 45±4.5Nm -

Glow plug M5 4 20±2Nm -

Vacuum pumpM8×25 3 10±1Nm -

Timing gear case coverM6×40 7 10±1Nm -

M6×45 1 10±1Nm -

M6×50 3 10±1Nm -

Cylinder head coverM6×35 21 10±1Nm -

Oil dipstick gauge coverM6×16 1 10±1Nm -

Oil filter cap 1 25±2.5Nm -

Fuel railM8×25 2 25±2.5Nm -

Injector clamp boltM6×44 2 9±1.0Nm

130˚±10˚ -

High pressure pipe

(between high pressure

pump and fuel rail

assembly)M17 1 30±3Nm -

High pressure pipe

(between fuel rail assembly

and injector)M17 4 30±3Nm -

Crankshaft position sensorM5×14 1 8±0.4Nm -

Main wiringM6×16 5 10±1Nm -

Intake ductM8×25 3 25±2.5Nm -

Power steering pumpM8×100 3 25±2.5Nm -

Cylinder head front coverM6×10 5 10±1Nm -

Ladder frameM8×16 5 30±3Nm -

Page 166 of 796

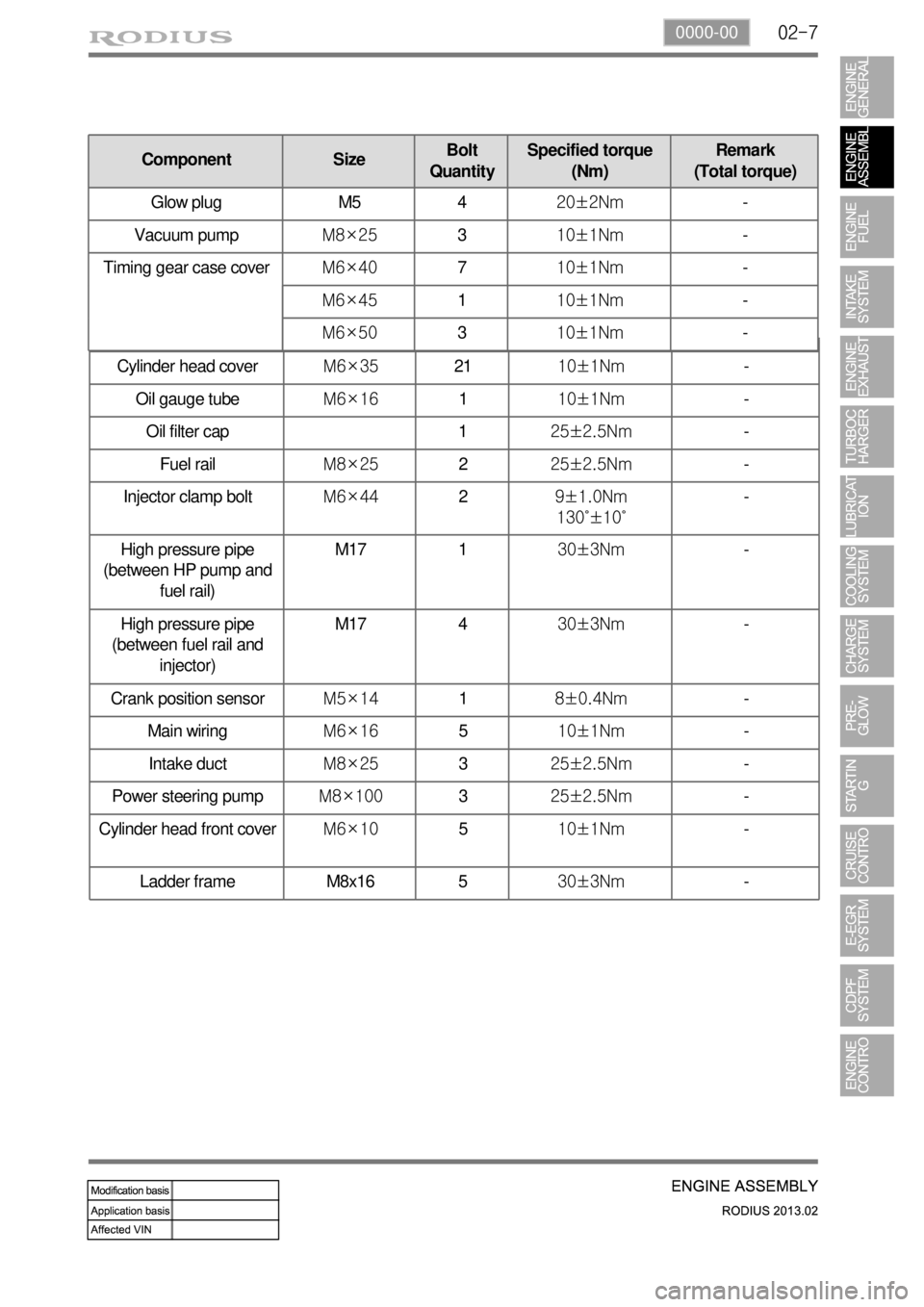

02-70000-00

Cylinder head coverM6×352110±1Nm-

Oil gauge tubeM6×16110±1Nm-

Oil filter cap 125±2.5Nm-

Fuel railM8×25225±2.5Nm-

Injector clamp boltM6×4429±1.0Nm

130˚±10˚-

High pressure pipe

(between HP pump and

fuel rail)M17 130±3Nm-

High pressure pipe

(between fuel rail and

injector)M17 430±3Nm-

Crank position sensorM5×1418±0.4Nm-

Main wiringM6×16510±1Nm-

Intake ductM8×25325±2.5Nm-

Power steering pumpM8×100325±2.5Nm-

Cylinder head front coverM6×10510±1Nm-

Ladder frame M8x16 530±3Nm-

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Glow plug M5 420±2Nm-

Vacuum pumpM8×25310±1Nm-

Timing gear case coverM6×40710±1Nm-

M6×45110±1Nm-

M6×50310±1Nm-

Page 173 of 796

02-14

D20DTR Engine

1. BELT LAYOUT

It is single drive type and uses FEAD (Front End Accessories Drive) design to make a compact layout.

Components ▶

HPS

(Hydraulic Power Steering)

1 Crankshaft pulley (DDU)

2 Auto tensioner

3 Tensioner pulley

4 Vacuum pump

5 A/C compressor pulley

6 Alternator pulley

7 Water pump pulley

8 Idle pulley #1

9 Idle pulley #2

10 Power steering pump pulley

Page 346 of 796

15-18

C. Idle Speed Controller

The idle speed controller consists of 2 principal modules:

The first module determines the required idle speed according to:

* The operating conditions of the engine (coolant temperature, gear engaged)

* Any activation of the electrical consumers (power steering, air conditioning, others)

* The battery voltage

* The presence of any faults liable to interface with the rail pressure control or the injection control.

In this case, increase the idle speed to prevent the engine from stalling.

The second module is responsible for providing closed loop control of the engine's idle speed by

adapting the minimum fuel according to the difference between the required idle speed and the

engine speed. -

-

D. Flow Limitation

The flow limitation strategy is based on the following strategies:

The flow limitation depending on the filling of the engine with air is determined according to the

engine speed and the air flow. This limitation allows smoke emissions to be reduced during

stabilized running.

The flow limitation depending on the atmospheric pressure is determined according to the

engine speed and the atmospheric pressure. It allows smoke emissions to be reduced when

driving at altitude.

The full load flow curve is determined according to the gear engaged and the engine speed. It

allows the maximum torque delivered by the engine to be limited.

A performance limitation is introduced if faults liable to upset the rail pressure control or the

injection control are detected by the system. In this case, and depending on the gravity of the

fault, the system activates: -

-

-

-

Reduced fuel logic 1: Guarantees 75 % of the performance without limiting the engine speed.

Reduced fuel logic 2: Guarantees 50 % of the performance with the engine speed limited to

3,000 rpm.

Reduce fuel logic 3: Limits the engine speed to 2,000 rpm.

The system chooses the lowest of all values.

A correction depending on the coolant temperature is added to the flow limitation. This correction

makes it possible to reduce the mechanical stresses while the engine is warming up.

The correction is determined according to the coolant temperature, the engine speed and the time

which has passed since starting.

E. Superchager Flow Demand

The supercharge flow is calculated according to the engine speed and the coolant temperature. A

correction depending on the air temperature and the atmospheric pressure is made in order to

increase the supercharge flow during cold starts. It is possible to alter the supercharge flow value by

adding a flow offset with the aid of the diagnostic tool

Page 419 of 796

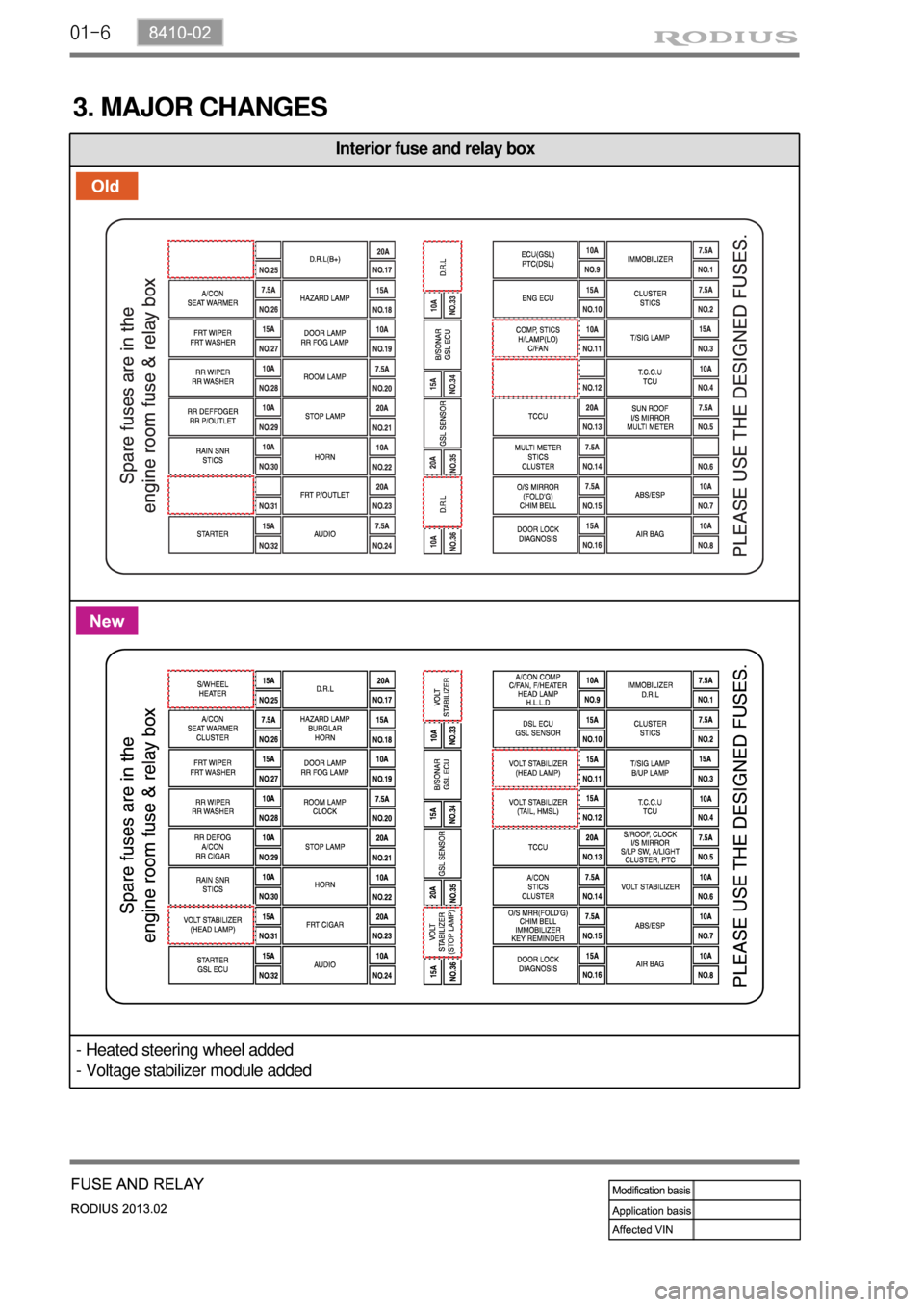

01-6

3. MAJOR CHANGES

Interior fuse and relay box

- Heated steering wheel added

- Voltage stabilizer module added

Page 503 of 796

06-38510-00

1. SPECIFICATIONS

1) Center Fascia Switch

Item Specifications

Center fascia switch &

bezel assemblyHazard warning flasher switch DC 12 V 10 A(lamp load)

Windshield heated glass switch

DC 12 V 1 A(inductive load) Rear heated glass switch

ESP OFF switch

Driver/front passenger seat warmer

switch

Fog lamp switch

2) 4WD Switch & HLLD Switch & Rear Wiper Operation Switch

Item Specifications

4WD switch &

HLLD switch &

rear wiper operation

switch assemblyWasher switch DC 12 V 3.8 A(lamp load)

Wiper switch DC 12 V 3.0 A (max. 10 A)

4WD switch DC 12 V 300 mA

HLLD switch DC 12 V 1 A (inductive load)

3) Steering Wheel Switch

Item Specifications

Steering wheel switch Rated voltage DC 5 V 0.1 A(rated load)

Operation temperature-30℃~+80℃

Page 505 of 796

06-58510-00

2. MAJOR CHANGES

Center fascia switch

- Design changed

Steering wheel switch assembly

- Power button deleted, steering wheel heating (option) switch added

- Design changed

Multifunction switch assembly

- Connector pin layout changed due to newly added steering wheel heating (option) circuit

- Contact coil and steering wheel angle sensor changed

Page 508 of 796

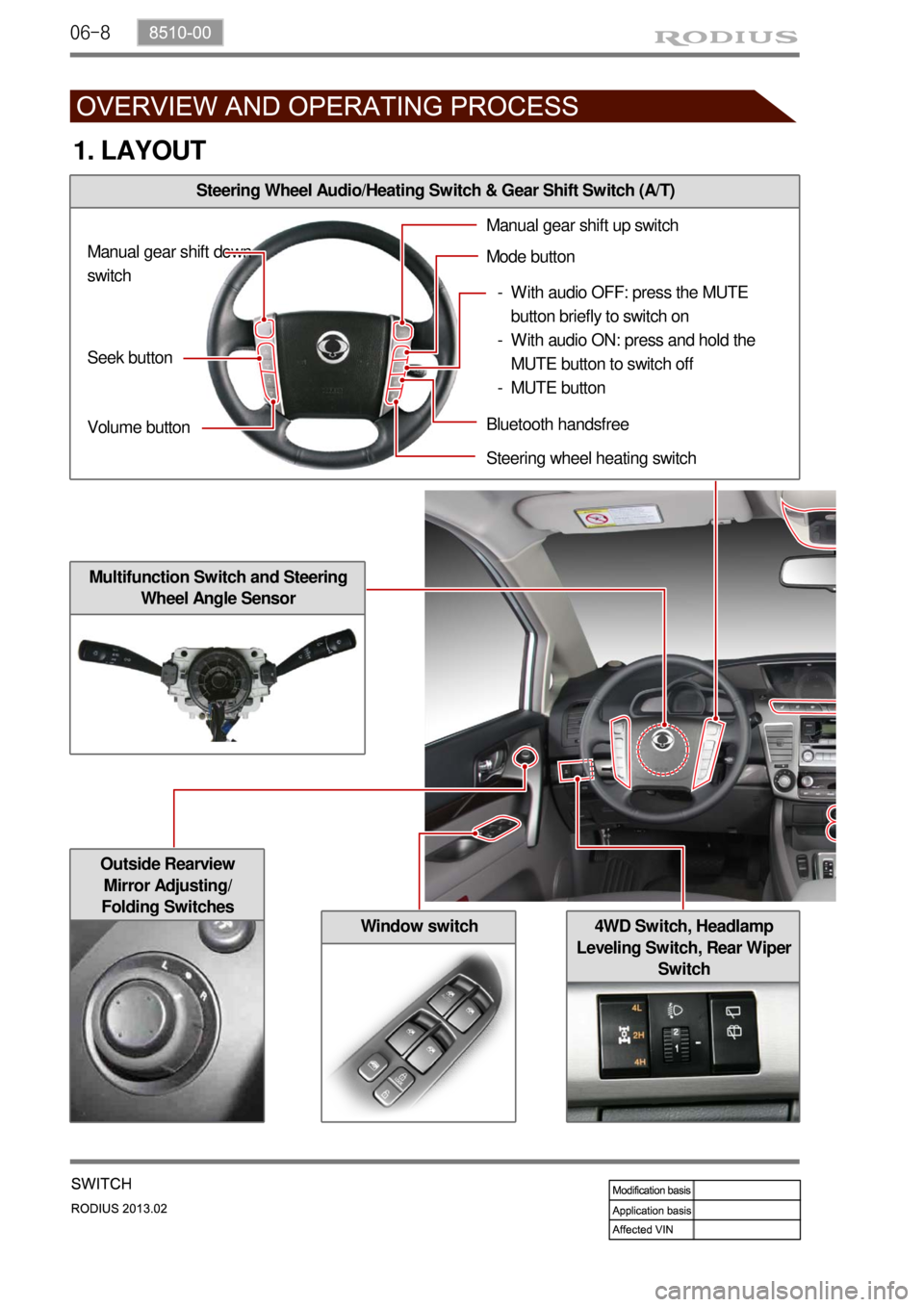

06-8

Outside Rearview

Mirror Adjusting/

Folding Switches

Window switch

Steering Wheel Audio/Heating Switch & Gear Shift Switch (A/T)

Multifunction Switch and Steering

Wheel Angle Sensor

4WD Switch, Headlamp

Leveling Switch, Rear Wiper

Switch

1. LAYOUT

Seek button

Volume button Manual gear shift down

switchManual gear shift up switch

Mode button

Bluetooth handsfree

Steering wheel heating switch

With audio OFF: press the MUTE

button briefly to switch on

With audio ON: press and hold the

MUTE button to switch off

MUTE button -

-

-