torque SUBARU FORESTER 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: FORESTER, Model: SUBARU FORESTER 1999Pages: 345, PDF Size: 5.6 MB

Page 309 of 345

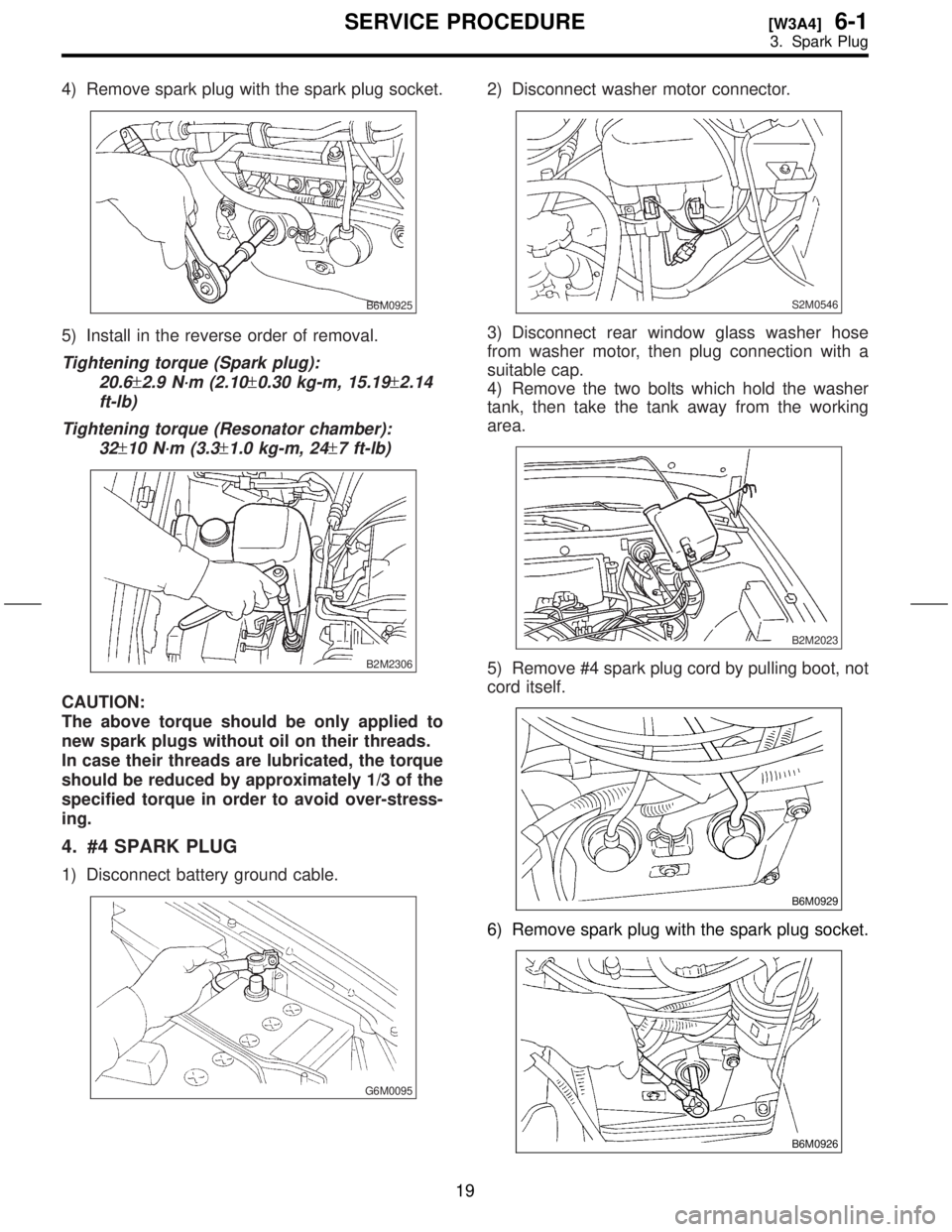

4) Remove spark plug with the spark plug socket.

B6M0925

5) Install in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

Tightening torque (Resonator chamber):

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

B2M2306

CAUTION:

The above torque should be only applied to

new spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approximately 1/3 of the

specified torque in order to avoid over-stress-

ing.

4. #4 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Disconnect washer motor connector.

S2M0546

3) Disconnect rear window glass washer hose

from washer motor, then plug connection with a

suitable cap.

4) Remove the two bolts which hold the washer

tank, then take the tank away from the working

area.

B2M2023

5) Remove #4 spark plug cord by pulling boot, not

cord itself.

B6M0929

6) Remove spark plug with the spark plug socket.

B6M0926

19

[W3A4]6-1SERVICE PROCEDURE

3. Spark Plug

Page 310 of 345

7) Install in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

CAUTION:

The above torque should be only applied to

new spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approximately 1/3 of the

specified torque in order to avoid over-stress-

ing.

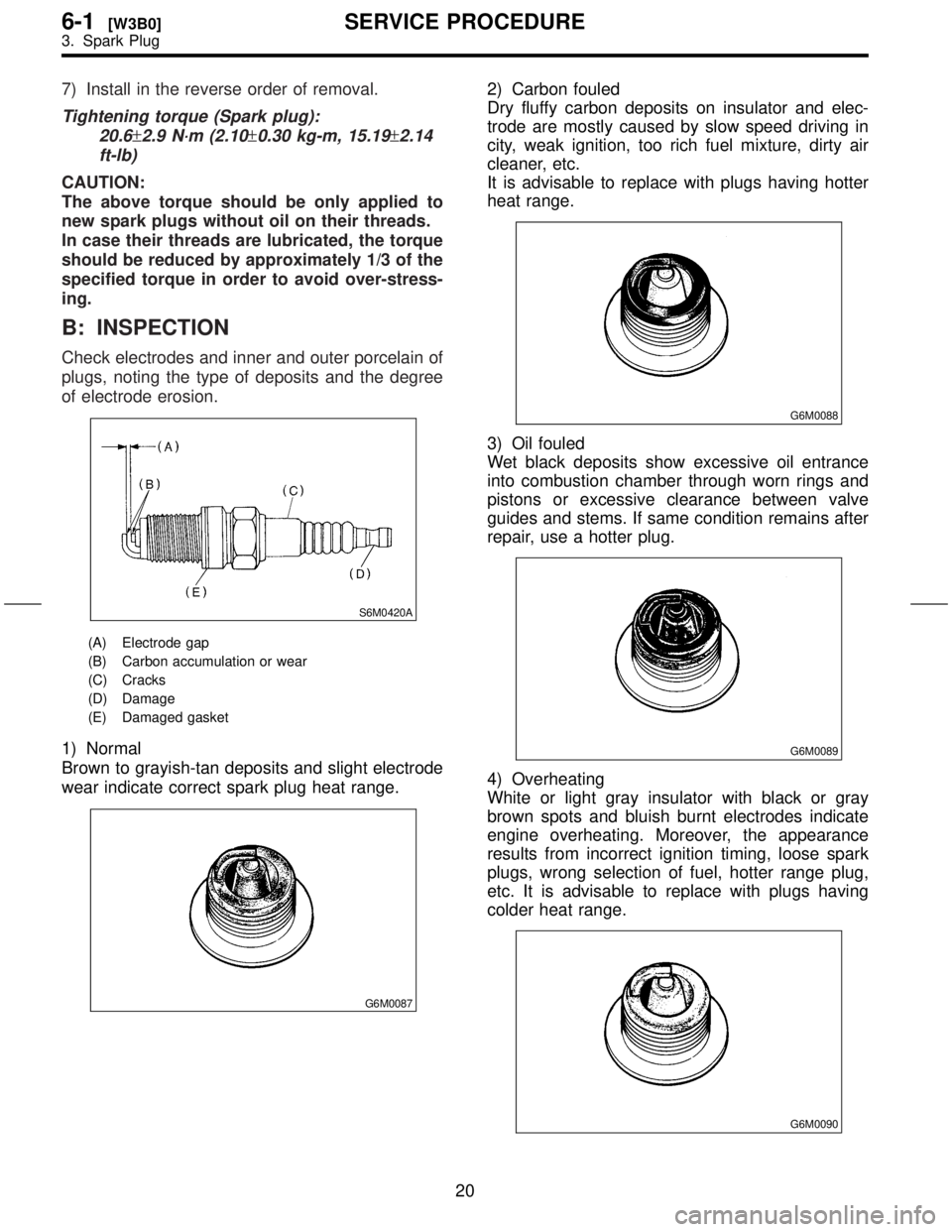

B: INSPECTION

Check electrodes and inner and outer porcelain of

plugs, noting the type of deposits and the degree

of electrode erosion.

S6M0420A

(A) Electrode gap

(B) Carbon accumulation or wear

(C) Cracks

(D) Damage

(E) Damaged gasket

1) Normal

Brown to grayish-tan deposits and slight electrode

wear indicate correct spark plug heat range.

G6M0087

2) Carbon fouled

Dry fluffy carbon deposits on insulator and elec-

trode are mostly caused by slow speed driving in

city, weak ignition, too rich fuel mixture, dirty air

cleaner, etc.

It is advisable to replace with plugs having hotter

heat range.

G6M0088

3) Oil fouled

Wet black deposits show excessive oil entrance

into combustion chamber through worn rings and

pistons or excessive clearance between valve

guides and stems. If same condition remains after

repair, use a hotter plug.

G6M0089

4) Overheating

White or light gray insulator with black or gray

brown spots and bluish burnt electrodes indicate

engine overheating. Moreover, the appearance

results from incorrect ignition timing, loose spark

plugs, wrong selection of fuel, hotter range plug,

etc. It is advisable to replace with plugs having

colder heat range.

G6M0090

20

6-1[W3B0]SERVICE PROCEDURE

3. Spark Plug

Page 323 of 345

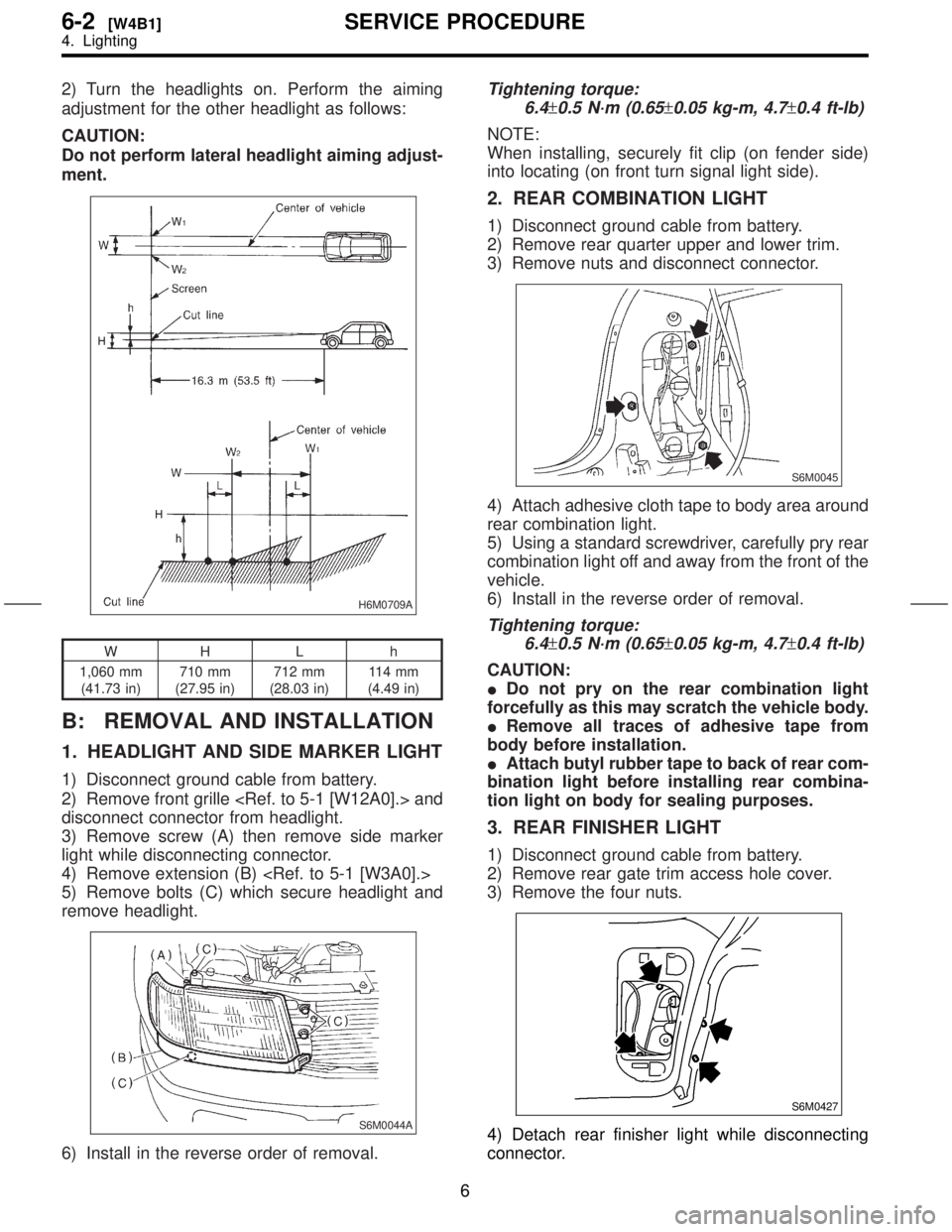

2) Turn the headlights on. Perform the aiming

adjustment for the other headlight as follows:

CAUTION:

Do not perform lateral headlight aiming adjust-

ment.

H6M0709A

WH L h

1,060 mm

(41.73 in)710 mm

(27.95 in)712 mm

(28.03 in)11 4 m m

(4.49 in)

B: REMOVAL AND INSTALLATION

1. HEADLIGHT AND SIDE MARKER LIGHT

1) Disconnect ground cable from battery.

2) Remove front grille

disconnect connector from headlight.

3) Remove screw (A) then remove side marker

light while disconnecting connector.

4) Remove extension (B)

5) Remove bolts (C) which secure headlight and

remove headlight.

S6M0044A

6) Install in the reverse order of removal.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

NOTE:

When installing, securely fit clip (on fender side)

into locating (on front turn signal light side).

2. REAR COMBINATION LIGHT

1) Disconnect ground cable from battery.

2) Remove rear quarter upper and lower trim.

3) Remove nuts and disconnect connector.

S6M0045

4) Attach adhesive cloth tape to body area around

rear combination light.

5) Using a standard screwdriver, carefully pry rear

combination light off and away from the front of the

vehicle.

6) Install in the reverse order of removal.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

CAUTION:

IDo not pry on the rear combination light

forcefully as this may scratch the vehicle body.

IRemove all traces of adhesive tape from

body before installation.

IAttach butyl rubber tape to back of rear com-

bination light before installing rear combina-

tion light on body for sealing purposes.

3. REAR FINISHER LIGHT

1) Disconnect ground cable from battery.

2) Remove rear gate trim access hole cover.

3) Remove the four nuts.

S6M0427

4) Detach rear finisher light while disconnecting

connector.

6

6-2[W4B1]SERVICE PROCEDURE

4. Lighting

Page 327 of 345

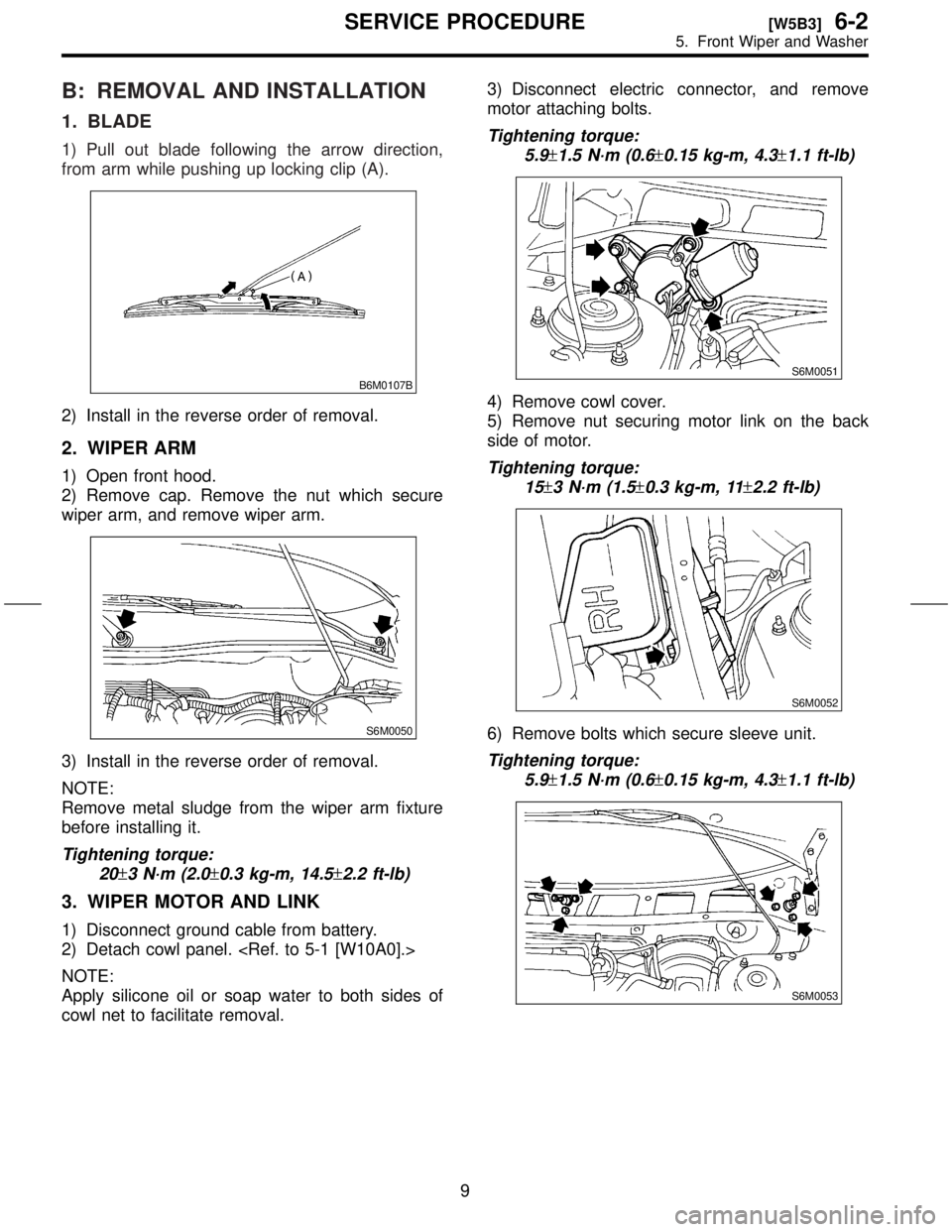

B: REMOVAL AND INSTALLATION

1. BLADE

1) Pull out blade following the arrow direction,

from arm while pushing up locking clip (A).

B6M0107B

2) Install in the reverse order of removal.

2. WIPER ARM

1) Open front hood.

2) Remove cap. Remove the nut which secure

wiper arm, and remove wiper arm.

S6M0050

3) Install in the reverse order of removal.

NOTE:

Remove metal sludge from the wiper arm fixture

before installing it.

Tightening torque:

20

±3 N´m (2.0±0.3 kg-m, 14.5±2.2 ft-lb)

3. WIPER MOTOR AND LINK

1) Disconnect ground cable from battery.

2) Detach cowl panel.

NOTE:

Apply silicone oil or soap water to both sides of

cowl net to facilitate removal.3) Disconnect electric connector, and remove

motor attaching bolts.

Tightening torque:

5.9

±1.5 N´m (0.6±0.15 kg-m, 4.3±1.1 ft-lb)

S6M0051

4) Remove cowl cover.

5) Remove nut securing motor link on the back

side of motor.

Tightening torque:

15

±3 N´m (1.5±0.3 kg-m, 11±2.2 ft-lb)

S6M0052

6) Remove bolts which secure sleeve unit.

Tightening torque:

5.9

±1.5 N´m (0.6±0.15 kg-m, 4.3±1.1 ft-lb)

S6M0053

9

[W5B3]6-2SERVICE PROCEDURE

5. Front Wiper and Washer

Page 330 of 345

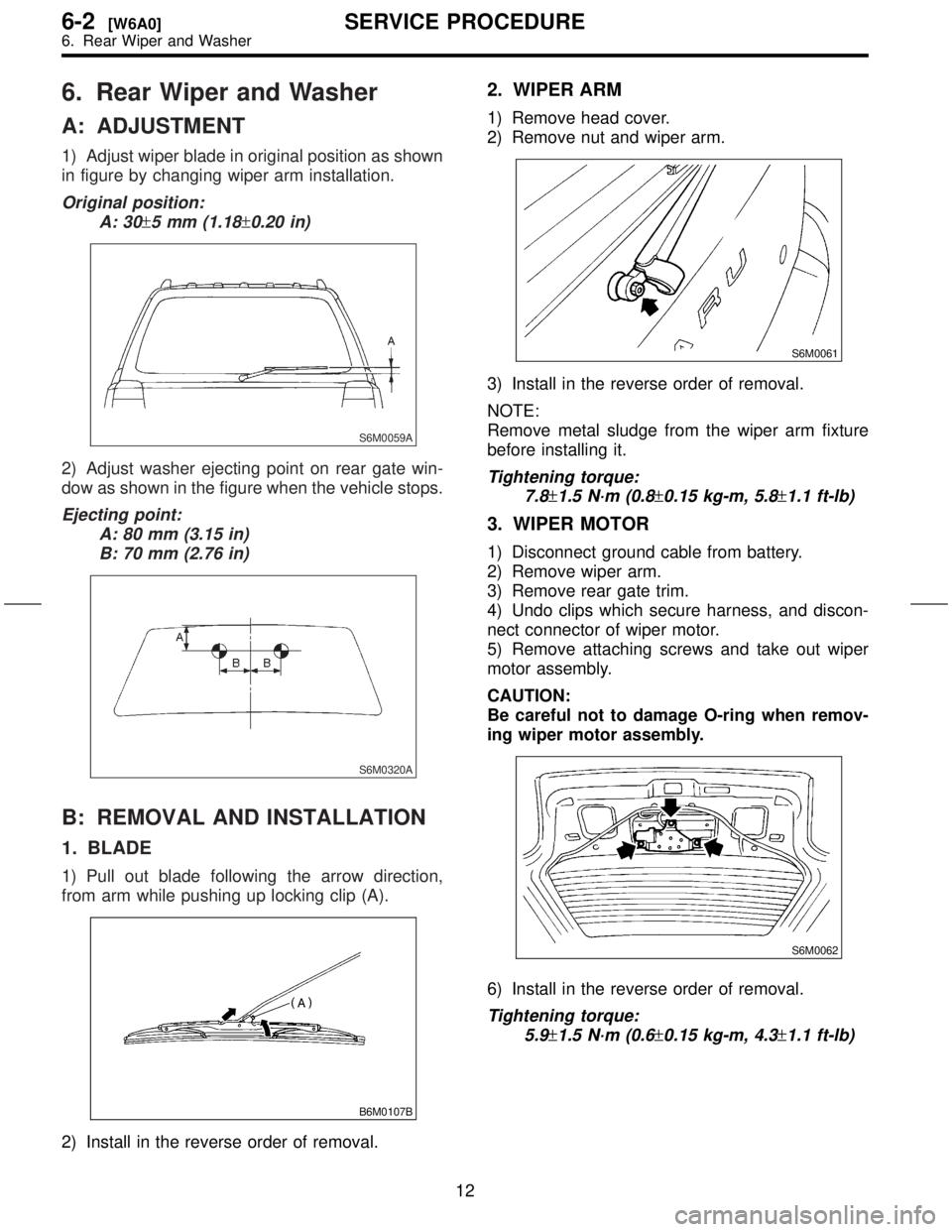

6. Rear Wiper and Washer

A: ADJUSTMENT

1) Adjust wiper blade in original position as shown

in figure by changing wiper arm installation.

Original position:

A: 30

±5 mm (1.18±0.20 in)

S6M0059A

2) Adjust washer ejecting point on rear gate win-

dow as shown in the figure when the vehicle stops.

Ejecting point:

A: 80 mm (3.15 in)

B: 70 mm (2.76 in)

S6M0320A

B: REMOVAL AND INSTALLATION

1. BLADE

1) Pull out blade following the arrow direction,

from arm while pushing up locking clip (A).

B6M0107B

2) Install in the reverse order of removal.

2. WIPER ARM

1) Remove head cover.

2) Remove nut and wiper arm.

S6M0061

3) Install in the reverse order of removal.

NOTE:

Remove metal sludge from the wiper arm fixture

before installing it.

Tightening torque:

7.8

±1.5 N´m (0.8±0.15 kg-m, 5.8±1.1 ft-lb)

3. WIPER MOTOR

1) Disconnect ground cable from battery.

2) Remove wiper arm.

3) Remove rear gate trim.

4) Undo clips which secure harness, and discon-

nect connector of wiper motor.

5) Remove attaching screws and take out wiper

motor assembly.

CAUTION:

Be careful not to damage O-ring when remov-

ing wiper motor assembly.

S6M0062

6) Install in the reverse order of removal.

Tightening torque:

5.9

±1.5 N´m (0.6±0.15 kg-m, 4.3±1.1 ft-lb)

12

6-2[W6A0]SERVICE PROCEDURE

6. Rear Wiper and Washer

Page 340 of 345

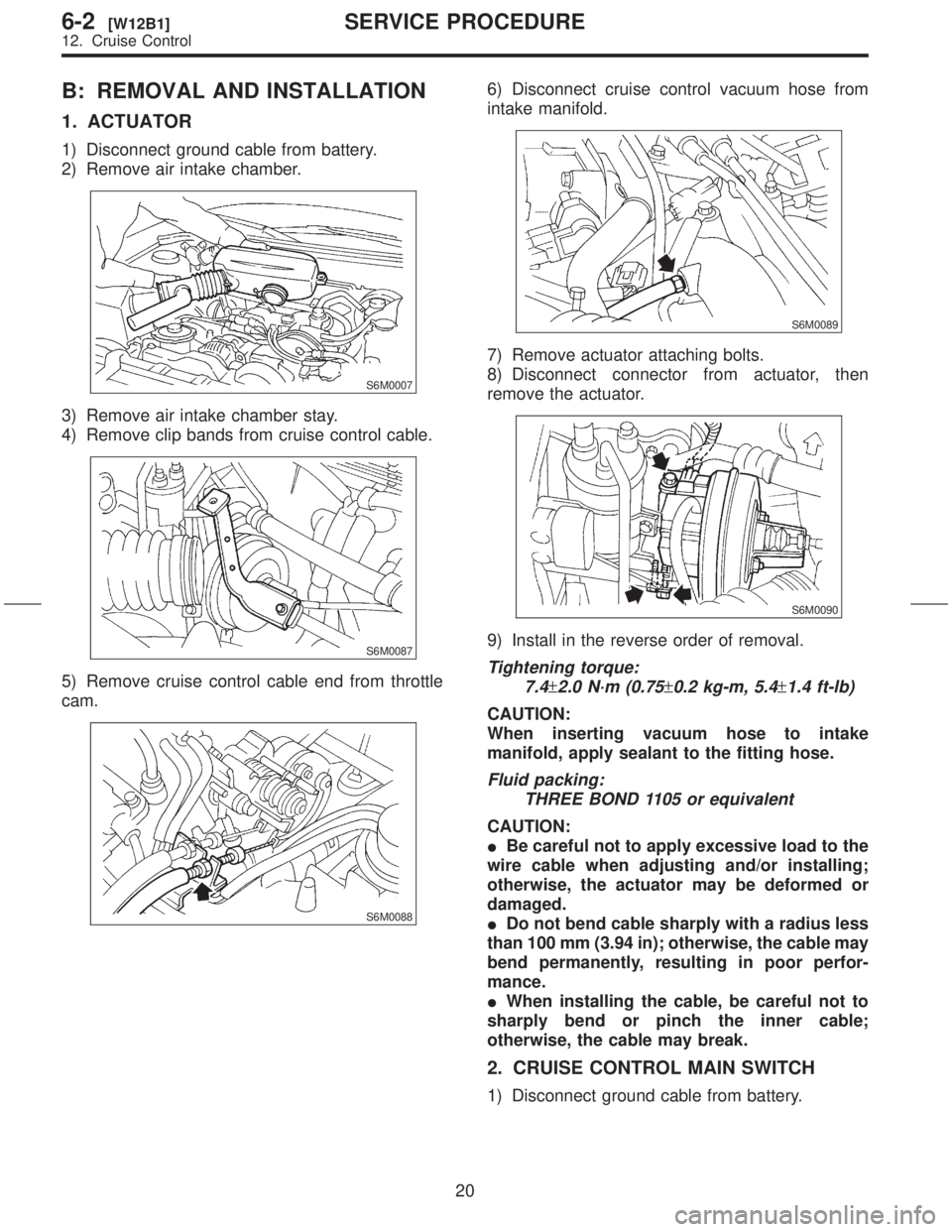

B: REMOVAL AND INSTALLATION

1. ACTUATOR

1) Disconnect ground cable from battery.

2) Remove air intake chamber.

S6M0007

3) Remove air intake chamber stay.

4) Remove clip bands from cruise control cable.

S6M0087

5) Remove cruise control cable end from throttle

cam.

S6M0088

6) Disconnect cruise control vacuum hose from

intake manifold.

S6M0089

7) Remove actuator attaching bolts.

8) Disconnect connector from actuator, then

remove the actuator.

S6M0090

9) Install in the reverse order of removal.

Tightening torque:

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

CAUTION:

When inserting vacuum hose to intake

manifold, apply sealant to the fitting hose.

Fluid packing:

THREE BOND 1105 or equivalent

CAUTION:

IBe careful not to apply excessive load to the

wire cable when adjusting and/or installing;

otherwise, the actuator may be deformed or

damaged.

IDo not bend cable sharply with a radius less

than 100 mm (3.94 in); otherwise, the cable may

bend permanently, resulting in poor perfor-

mance.

IWhen installing the cable, be careful not to

sharply bend or pinch the inner cable;

otherwise, the cable may break.

2. CRUISE CONTROL MAIN SWITCH

1) Disconnect ground cable from battery.

20

6-2[W12B1]SERVICE PROCEDURE

12. Cruise Control