torque SUBARU FORESTER 1999 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: FORESTER, Model: SUBARU FORESTER 1999Pages: 345, PDF Size: 5.6 MB

Page 225 of 345

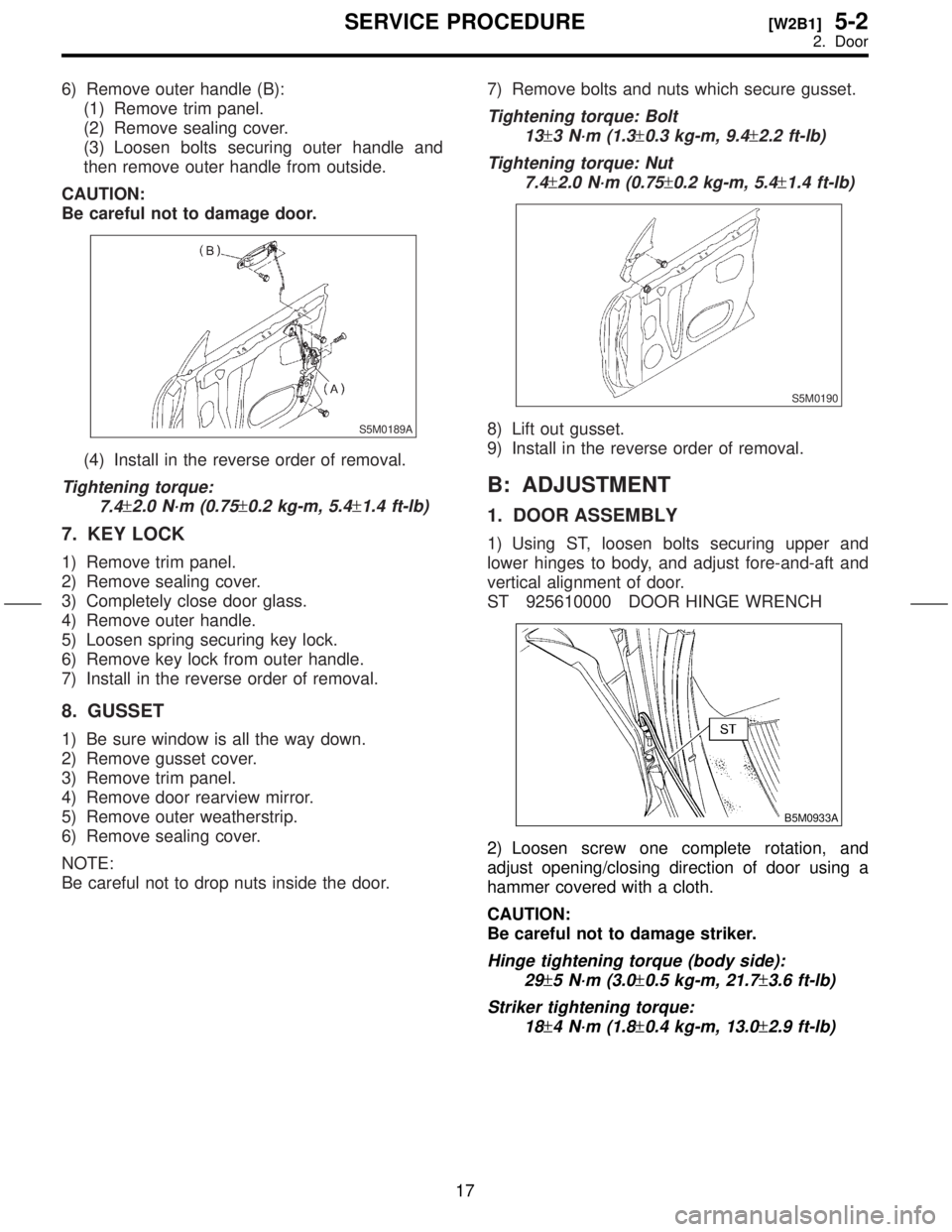

6) Remove outer handle (B):

(1) Remove trim panel.

(2) Remove sealing cover.

(3) Loosen bolts securing outer handle and

then remove outer handle from outside.

CAUTION:

Be careful not to damage door.

S5M0189A

(4) Install in the reverse order of removal.

Tightening torque:

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

7. KEY LOCK

1) Remove trim panel.

2) Remove sealing cover.

3) Completely close door glass.

4) Remove outer handle.

5) Loosen spring securing key lock.

6) Remove key lock from outer handle.

7) Install in the reverse order of removal.

8. GUSSET

1) Be sure window is all the way down.

2) Remove gusset cover.

3) Remove trim panel.

4) Remove door rearview mirror.

5) Remove outer weatherstrip.

6) Remove sealing cover.

NOTE:

Be careful not to drop nuts inside the door.7) Remove bolts and nuts which secure gusset.

Tightening torque: Bolt

13

±3 N´m (1.3±0.3 kg-m, 9.4±2.2 ft-lb)

Tightening torque: Nut

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

S5M0190

8) Lift out gusset.

9) Install in the reverse order of removal.

B: ADJUSTMENT

1. DOOR ASSEMBLY

1) Using ST, loosen bolts securing upper and

lower hinges to body, and adjust fore-and-aft and

vertical alignment of door.

ST 925610000 DOOR HINGE WRENCH

B5M0933A

2) Loosen screw one complete rotation, and

adjust opening/closing direction of door using a

hammer covered with a cloth.

CAUTION:

Be careful not to damage striker.

Hinge tightening torque (body side):

29

±5 N´m (3.0±0.5 kg-m, 21.7±3.6 ft-lb)

Striker tightening torque:

18

±4 N´m (1.8±0.4 kg-m, 13.0±2.9 ft-lb)

17

[W2B1]5-2SERVICE PROCEDURE

2. Door

Page 228 of 345

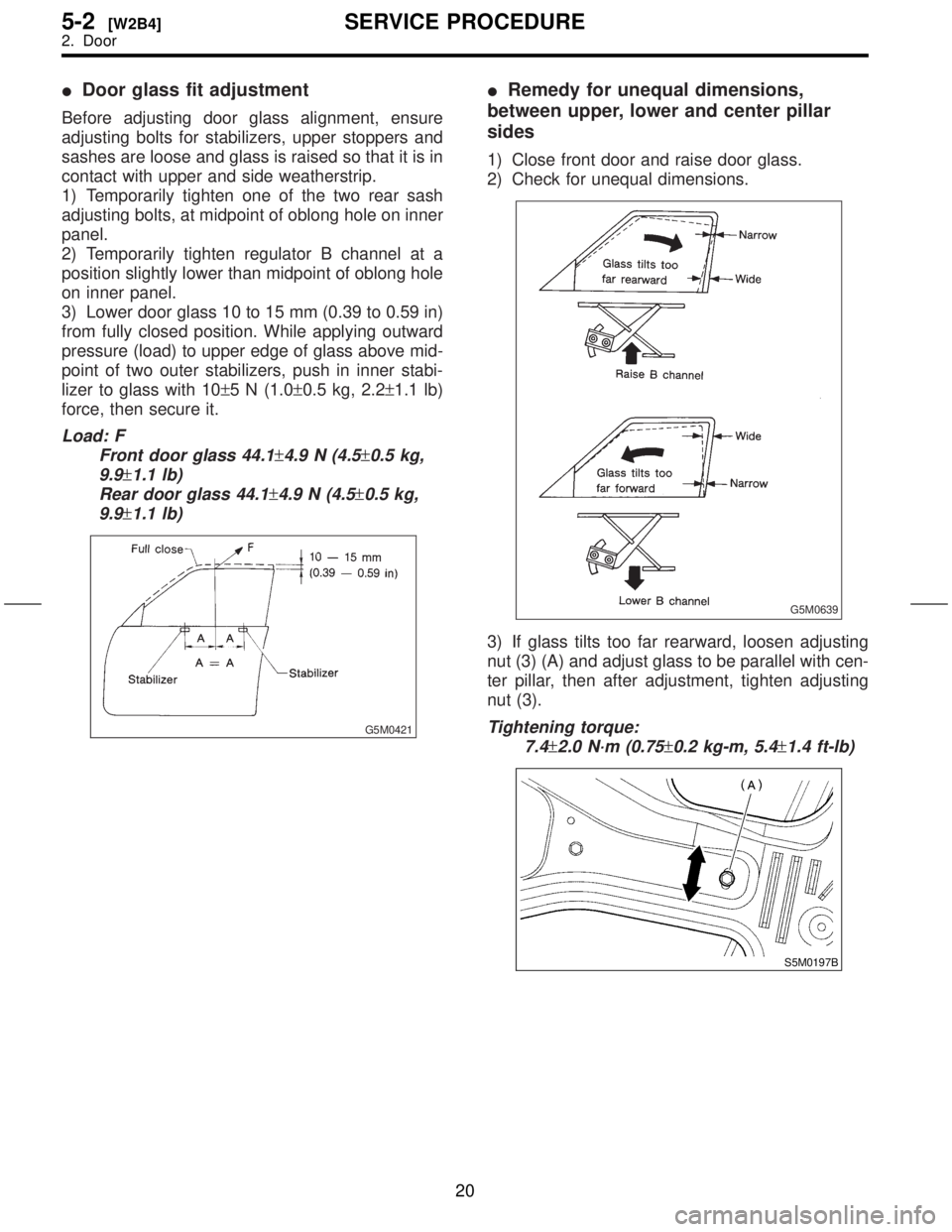

IDoor glass fit adjustment

Before adjusting door glass alignment, ensure

adjusting bolts for stabilizers, upper stoppers and

sashes are loose and glass is raised so that it is in

contact with upper and side weatherstrip.

1) Temporarily tighten one of the two rear sash

adjusting bolts, at midpoint of oblong hole on inner

panel.

2) Temporarily tighten regulator B channel at a

position slightly lower than midpoint of oblong hole

on inner panel.

3) Lower door glass 10 to 15 mm (0.39 to 0.59 in)

from fully closed position. While applying outward

pressure (load) to upper edge of glass above mid-

point of two outer stabilizers, push in inner stabi-

lizer to glass with 10±5 N (1.0±0.5 kg, 2.2±1.1 lb)

force, then secure it.

Load: F

Front door glass 44.1

±4.9 N (4.5±0.5 kg,

9.9

±1.1 lb)

Rear door glass 44.1

±4.9 N (4.5±0.5 kg,

9.9

±1.1 lb)

G5M0421

IRemedy for unequal dimensions,

between upper, lower and center pillar

sides

1) Close front door and raise door glass.

2) Check for unequal dimensions.

G5M0639

3) If glass tilts too far rearward, loosen adjusting

nut (3) (A) and adjust glass to be parallel with cen-

ter pillar, then after adjustment, tighten adjusting

nut (3).

Tightening torque:

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

S5M0197B

20

5-2[W2B4]SERVICE PROCEDURE

2. Door

Page 250 of 345

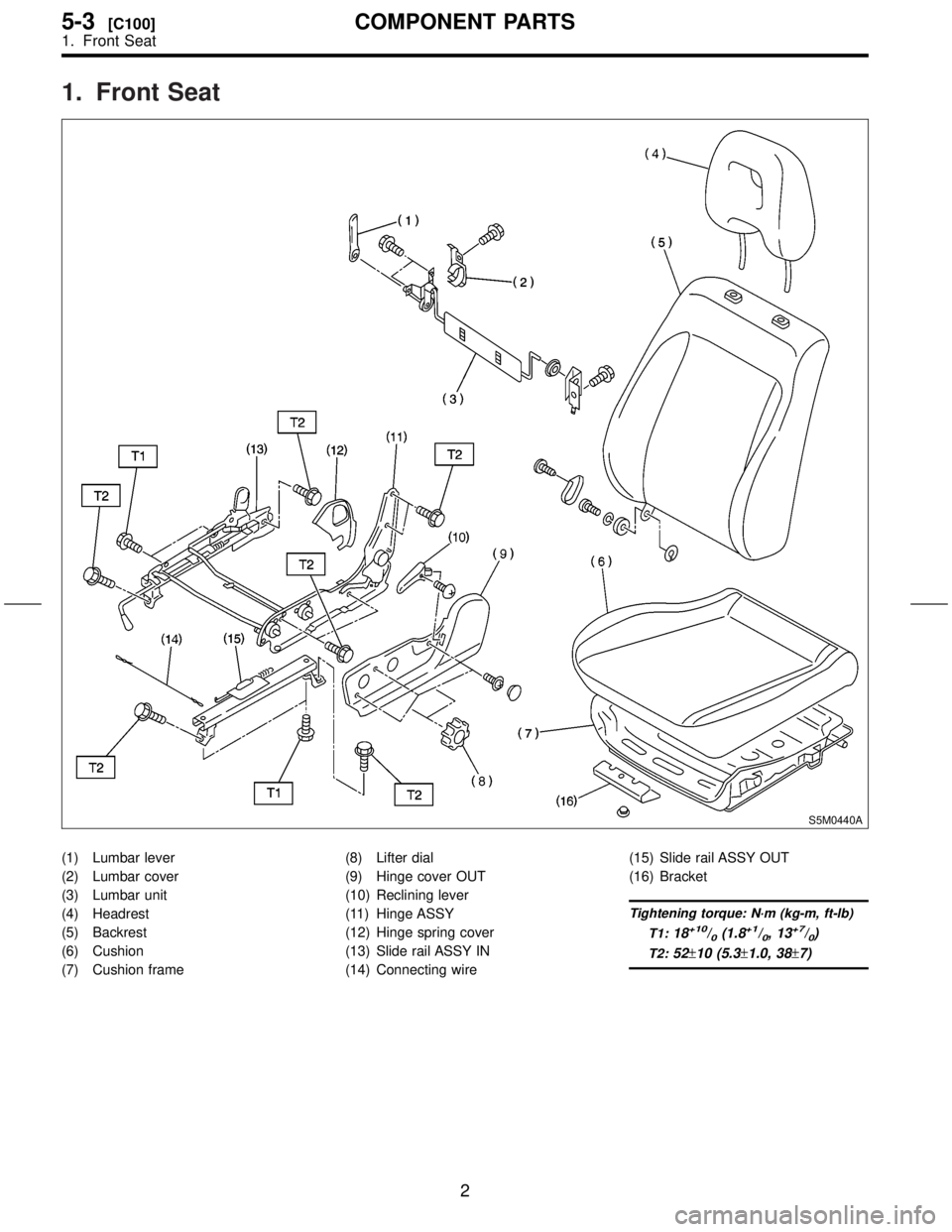

1. Front Seat

S5M0440A

(1) Lumbar lever

(2) Lumbar cover

(3) Lumbar unit

(4) Headrest

(5) Backrest

(6) Cushion

(7) Cushion frame(8) Lifter dial

(9) Hinge cover OUT

(10) Reclining lever

(11) Hinge ASSY

(12) Hinge spring cover

(13) Slide rail ASSY IN

(14) Connecting wire(15) Slide rail ASSY OUT

(16) Bracket

Tightening torque: N´m (kg-m, ft-lb)

T1:

18+10/0(1.8+1/0,13+7/0)

T2:52±10 (5.3±1.0, 38±7)

2

5-3[C100]COMPONENT PARTS

1. Front Seat

Page 267 of 345

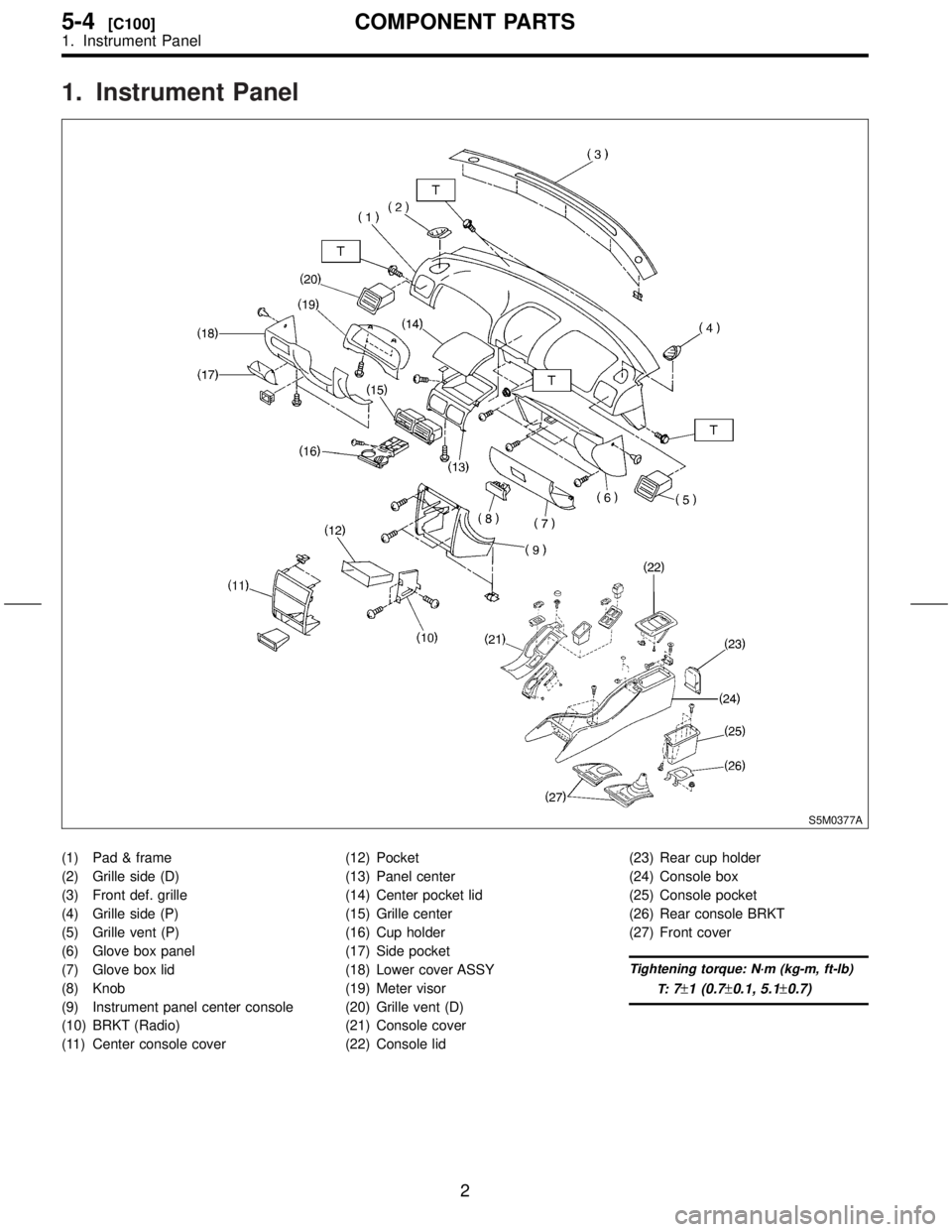

1. Instrument Panel

S5M0377A

(1) Pad & frame

(2) Grille side (D)

(3) Front def. grille

(4) Grille side (P)

(5) Grille vent (P)

(6) Glove box panel

(7) Glove box lid

(8) Knob

(9) Instrument panel center console

(10) BRKT (Radio)

(11) Center console cover(12) Pocket

(13) Panel center

(14) Center pocket lid

(15) Grille center

(16) Cup holder

(17) Side pocket

(18) Lower cover ASSY

(19) Meter visor

(20) Grille vent (D)

(21) Console cover

(22) Console lid(23) Rear cup holder

(24) Console box

(25) Console pocket

(26) Rear console BRKT

(27) Front cover

Tightening torque: N´m (kg-m, ft-lb)

T:

7±1 (0.7±0.1, 5.1±0.7)

2

5-4[C100]COMPONENT PARTS

1. Instrument Panel

Page 272 of 345

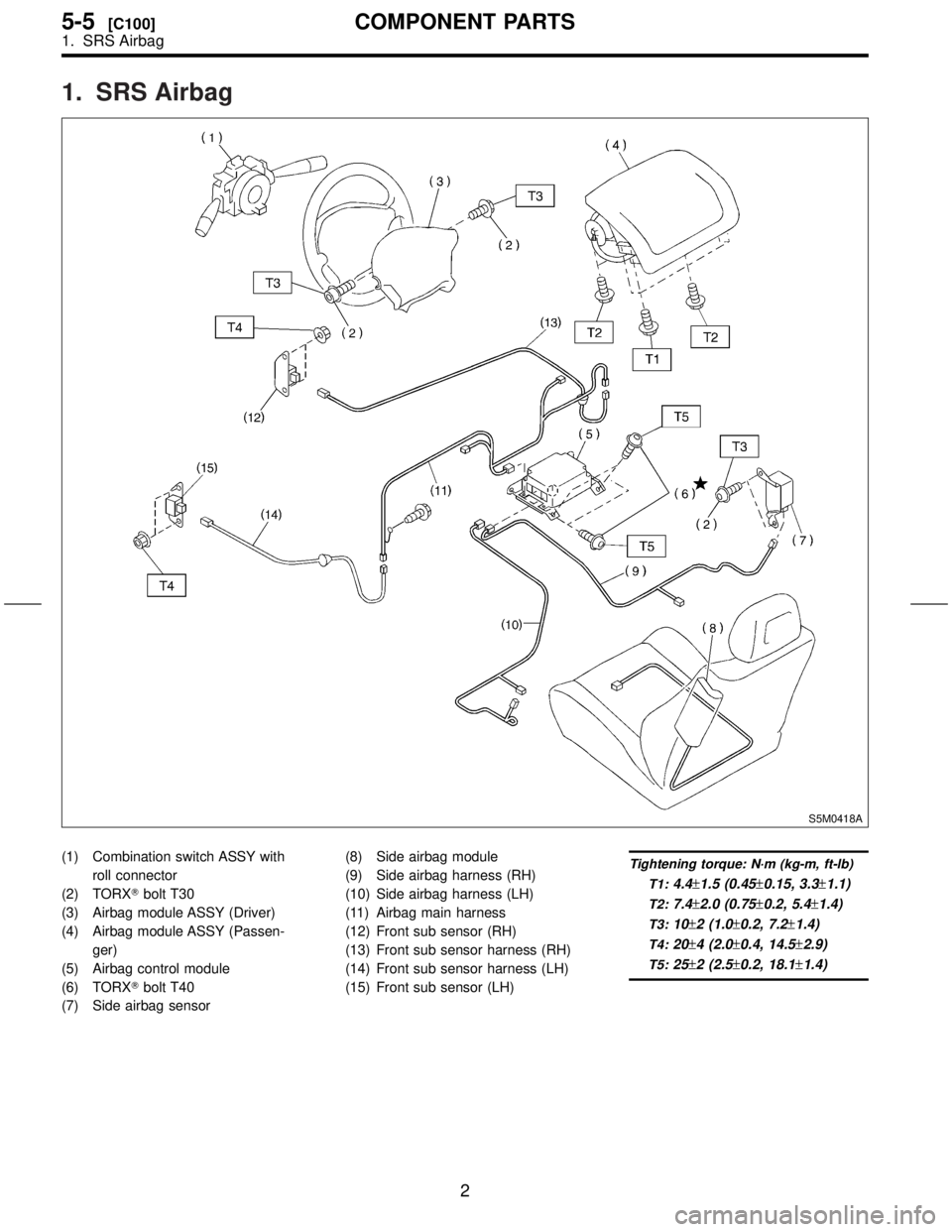

1. SRS Airbag

S5M0418A

(1) Combination switch ASSY with

roll connector

(2) TORXTbolt T30

(3) Airbag module ASSY (Driver)

(4) Airbag module ASSY (Passen-

ger)

(5) Airbag control module

(6) TORXTbolt T40

(7) Side airbag sensor(8) Side airbag module

(9) Side airbag harness (RH)

(10) Side airbag harness (LH)

(11) Airbag main harness

(12) Front sub sensor (RH)

(13) Front sub sensor harness (RH)

(14) Front sub sensor harness (LH)

(15) Front sub sensor (LH)Tightening torque: N´m (kg-m, ft-lb)

T1:

4.4±1.5 (0.45±0.15, 3.3±1.1)

T2:7.4±2.0 (0.75±0.2, 5.4±1.4)

T3:10±2 (1.0±0.2, 7.2±1.4)

T4:20±4 (2.0±0.4, 14.5±2.9)

T5:25±2 (2.5±0.2, 18.1±1.4)

2

5-5[C100]COMPONENT PARTS

1. SRS Airbag

Page 295 of 345

![SUBARU FORESTER 1999 Service User Guide 1. Starter

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove air cleaner case and air intake duct.

<Ref. to 2-7 [W1A0].>

H2M2931

3) Remove air intake chamber stay.

S2M0 SUBARU FORESTER 1999 Service User Guide 1. Starter

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove air cleaner case and air intake duct.

<Ref. to 2-7 [W1A0].>

H2M2931

3) Remove air intake chamber stay.

S2M0](/img/17/57427/w960_57427-294.png)

1. Starter

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove air cleaner case and air intake duct.

H2M2931

3) Remove air intake chamber stay.

S2M0900A

S2M0901A

4) Disconnect connector and terminal from starter.

S6M0002A

(A) Terminal

(B) Connector

5) Remove starter from transmission.

G2M0309

6) Install in the reverse order of removal.

Tightening torque:

50

±4 N´m (5.1±0.4 kg-m, 37±2.9 ft-lb)

G2M0309

B: TEST

1. SWITCH ASSEMBLY OPERATION

1) Connect terminal S of switch assembly to posi-

tive terminal of battery with a lead wire, and starter

body to ground terminal of battery. Pinion should

be forced endwise on shaft.

CAUTION:

With pinion forced endwise on shaft, starter

motor can sometimes rotate because current

flows, through pull-in coil, to motor. This is not

a problem.

6

6-1[W1A0]SERVICE PROCEDURE

1. Starter

Page 296 of 345

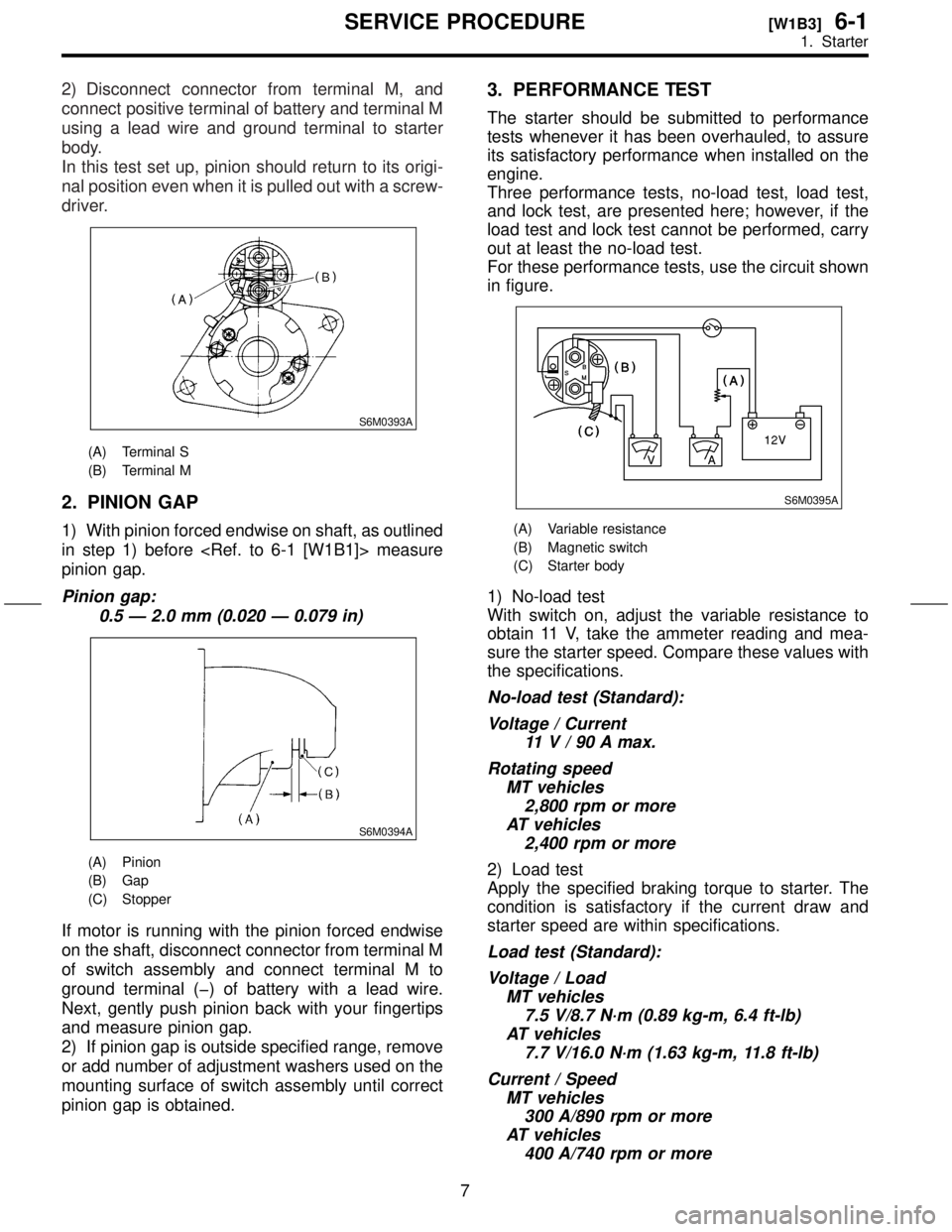

2) Disconnect connector from terminal M, and

connect positive terminal of battery and terminal M

using a lead wire and ground terminal to starter

body.

In this test set up, pinion should return to its origi-

nal position even when it is pulled out with a screw-

driver.

S6M0393A

(A) Terminal S

(B) Terminal M

2. PINION GAP

1) With pinion forced endwise on shaft, as outlined

in step 1) before

pinion gap.

Pinion gap:

0.5 Ð 2.0 mm (0.020 Ð 0.079 in)

S6M0394A

(A) Pinion

(B) Gap

(C) Stopper

If motor is running with the pinion forced endwise

on the shaft, disconnect connector from terminal M

of switch assembly and connect terminal M to

ground terminal (þ) of battery with a lead wire.

Next, gently push pinion back with your fingertips

and measure pinion gap.

2) If pinion gap is outside specified range, remove

or add number of adjustment washers used on the

mounting surface of switch assembly until correct

pinion gap is obtained.

3. PERFORMANCE TEST

The starter should be submitted to performance

tests whenever it has been overhauled, to assure

its satisfactory performance when installed on the

engine.

Three performance tests, no-load test, load test,

and lock test, are presented here; however, if the

load test and lock test cannot be performed, carry

out at least the no-load test.

For these performance tests, use the circuit shown

in figure.

S6M0395A

(A) Variable resistance

(B) Magnetic switch

(C) Starter body

1) No-load test

With switch on, adjust the variable resistance to

obtain 11 V, take the ammeter reading and mea-

sure the starter speed. Compare these values with

the specifications.

No-load test (Standard):

Voltage / Current

11V/90Amax.

Rotating speed

MT vehicles

2,800 rpm or more

AT vehicles

2,400 rpm or more

2) Load test

Apply the specified braking torque to starter. The

condition is satisfactory if the current draw and

starter speed are within specifications.

Load test (Standard):

Voltage / Load

MT vehicles

7.5 V/8.7 N´m (0.89 kg-m, 6.4 ft-lb)

AT vehicles

7.7 V/16.0 N´m (1.63 kg-m, 11.8 ft-lb)

Current / Speed

MT vehicles

300 A/890 rpm or more

AT vehicles

400 A/740 rpm or more

7

[W1B3]6-1SERVICE PROCEDURE

1. Starter

Page 297 of 345

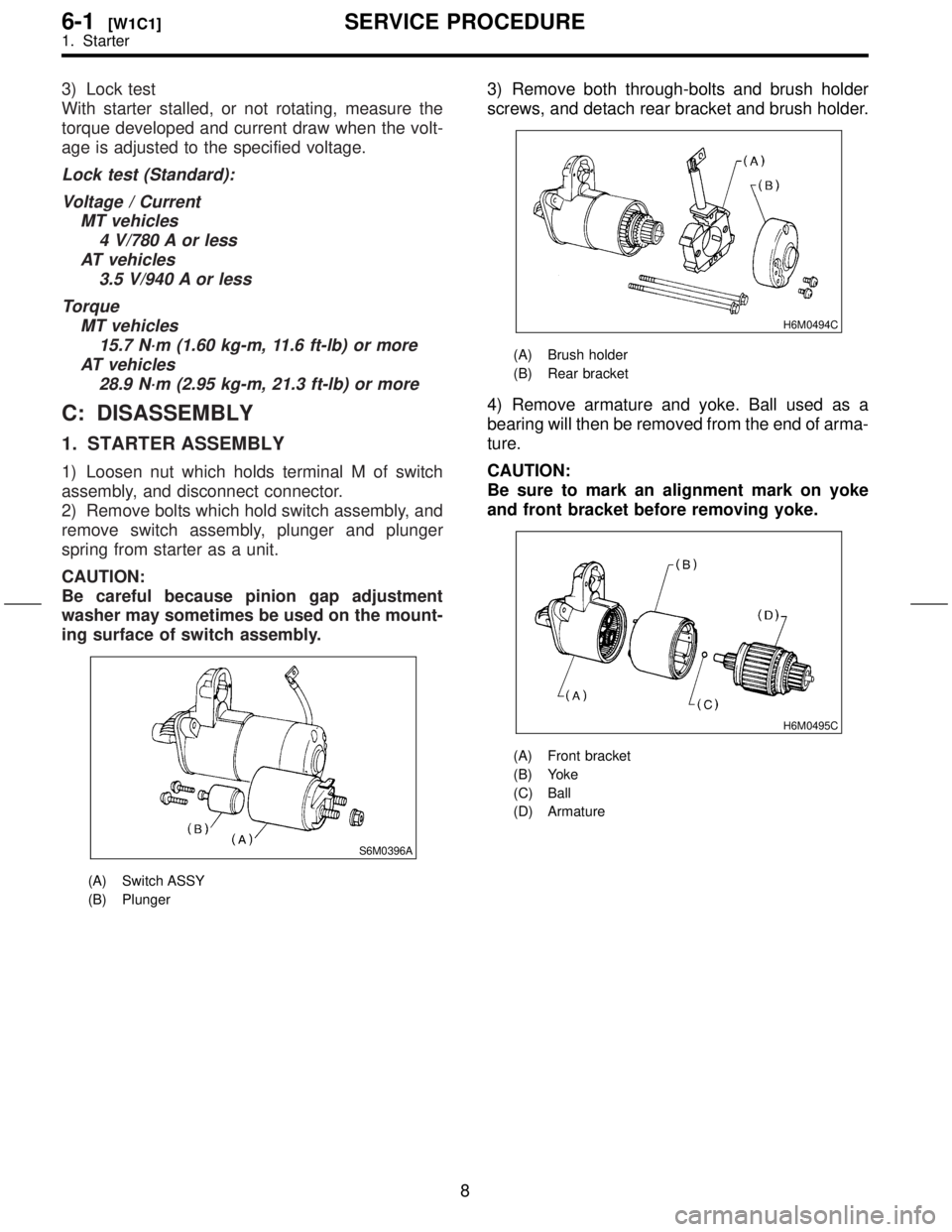

3) Lock test

With starter stalled, or not rotating, measure the

torque developed and current draw when the volt-

age is adjusted to the specified voltage.

Lock test (Standard):

Voltage / Current

MT vehicles

4 V/780 A or less

AT vehicles

3.5 V/940 A or less

Torque

MT vehicles

15.7 N´m (1.60 kg-m, 11.6 ft-lb) or more

AT vehicles

28.9 N´m (2.95 kg-m, 21.3 ft-lb) or more

C: DISASSEMBLY

1. STARTER ASSEMBLY

1) Loosen nut which holds terminal M of switch

assembly, and disconnect connector.

2) Remove bolts which hold switch assembly, and

remove switch assembly, plunger and plunger

spring from starter as a unit.

CAUTION:

Be careful because pinion gap adjustment

washer may sometimes be used on the mount-

ing surface of switch assembly.

S6M0396A

(A) Switch ASSY

(B) Plunger

3) Remove both through-bolts and brush holder

screws, and detach rear bracket and brush holder.

H6M0494C

(A) Brush holder

(B) Rear bracket

4) Remove armature and yoke. Ball used as a

bearing will then be removed from the end of arma-

ture.

CAUTION:

Be sure to mark an alignment mark on yoke

and front bracket before removing yoke.

H6M0495C

(A) Front bracket

(B) Yoke

(C) Ball

(D) Armature

8

6-1[W1C1]SERVICE PROCEDURE

1. Starter

Page 307 of 345

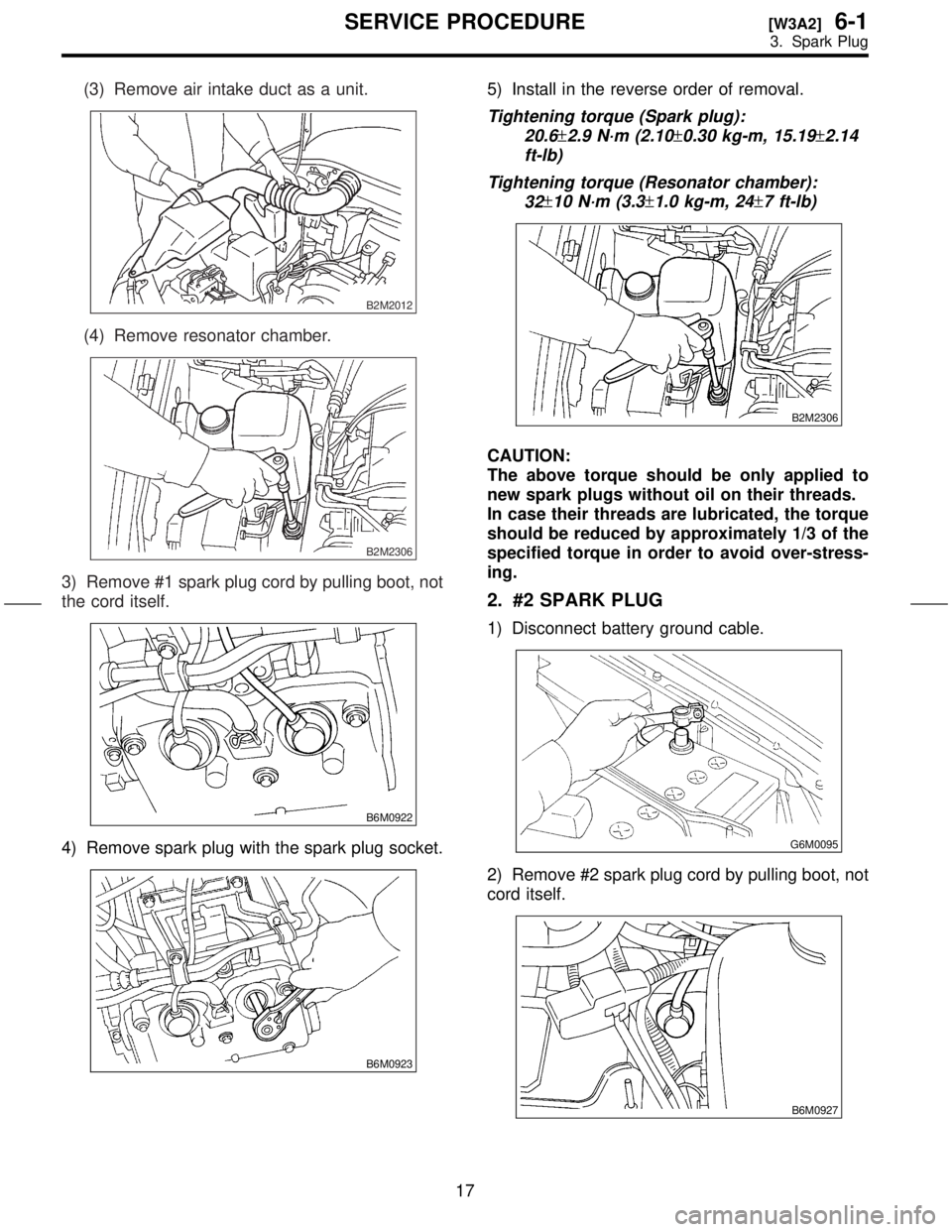

(3) Remove air intake duct as a unit.

B2M2012

(4) Remove resonator chamber.

B2M2306

3) Remove #1 spark plug cord by pulling boot, not

the cord itself.

B6M0922

4) Remove spark plug with the spark plug socket.

B6M0923

5) Install in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

Tightening torque (Resonator chamber):

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

B2M2306

CAUTION:

The above torque should be only applied to

new spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approximately 1/3 of the

specified torque in order to avoid over-stress-

ing.

2. #2 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Remove #2 spark plug cord by pulling boot, not

cord itself.

B6M0927

17

[W3A2]6-1SERVICE PROCEDURE

3. Spark Plug

Page 308 of 345

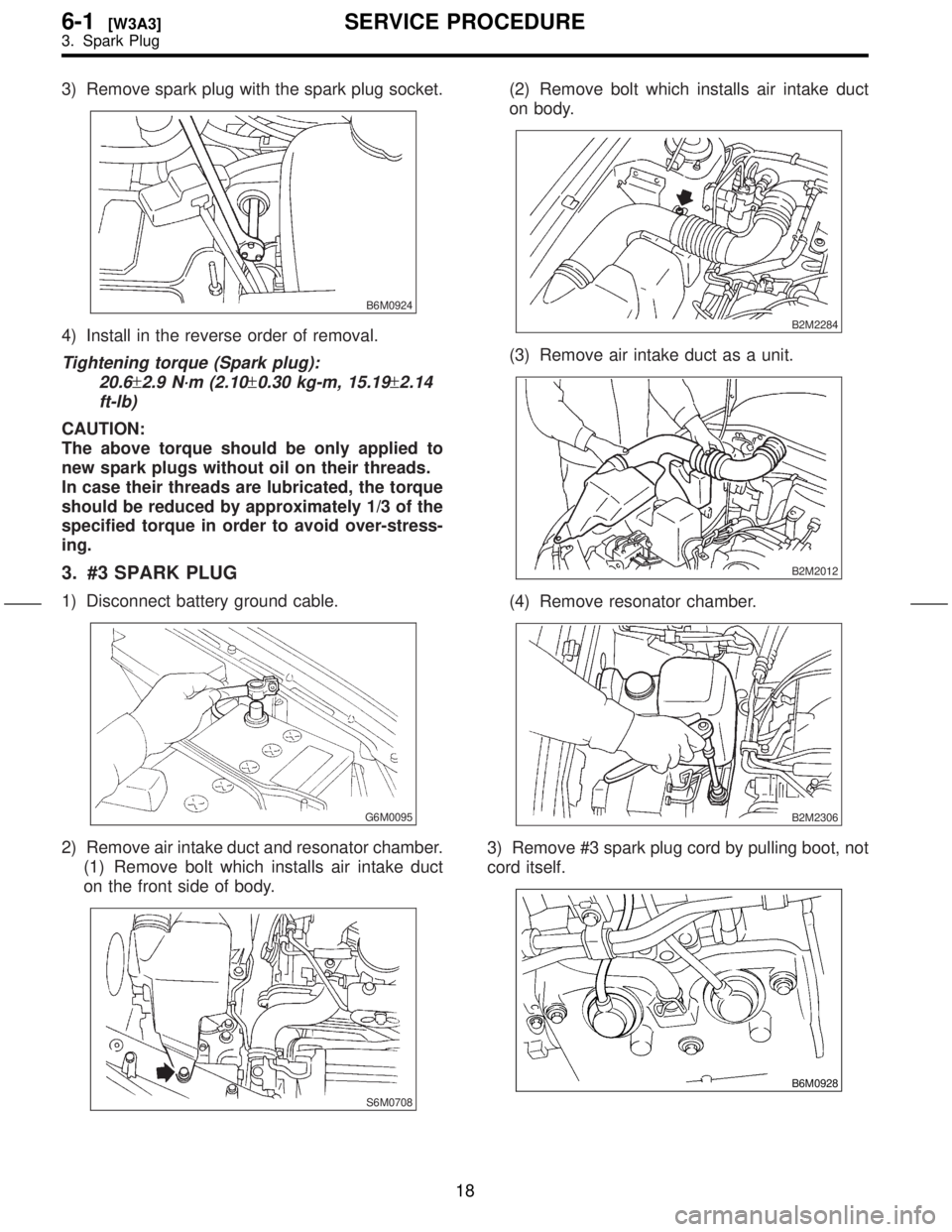

3) Remove spark plug with the spark plug socket.

B6M0924

4) Install in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

CAUTION:

The above torque should be only applied to

new spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approximately 1/3 of the

specified torque in order to avoid over-stress-

ing.

3. #3 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Remove air intake duct and resonator chamber.

(1) Remove bolt which installs air intake duct

on the front side of body.

S6M0708

(2) Remove bolt which installs air intake duct

on body.

B2M2284

(3) Remove air intake duct as a unit.

B2M2012

(4) Remove resonator chamber.

B2M2306

3) Remove #3 spark plug cord by pulling boot, not

cord itself.

B6M0928

18

6-1[W3A3]SERVICE PROCEDURE

3. Spark Plug