ECU SUBARU FORESTER 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: FORESTER, Model: SUBARU FORESTER 1999Pages: 345, PDF Size: 5.6 MB

Page 156 of 345

![SUBARU FORESTER 1999 Service Owners Guide 10. DIAGNOSTIC ITEM 9

5F101 : CHECK SECURITY CONTROL

MODULE.

Check and ensure that security control module is

installed on the bracket. <Ref. to 6-2 [W14A1].>

:Is the security control module

securely SUBARU FORESTER 1999 Service Owners Guide 10. DIAGNOSTIC ITEM 9

5F101 : CHECK SECURITY CONTROL

MODULE.

Check and ensure that security control module is

installed on the bracket. <Ref. to 6-2 [W14A1].>

:Is the security control module

securely](/img/17/57427/w960_57427-155.png)

10. DIAGNOSTIC ITEM 9

5F101 : CHECK SECURITY CONTROL

MODULE.

Check and ensure that security control module is

installed on the bracket.

:Is the security control module

securely installed?

: Go to step5F102.

: Securely install security control module.

5F102 : ADJUST SENSITIVITY.

1) Remove security control module.

2) Adjust the sensitivity adjust screw in security

control module.

NOTE:

After adjusting, be sure to plug the adjust screw

hole.

B6M1389A

3) Install security control module.

4) Perform impact sensitivity test.

:Is sensitivity adjustment possible?

: Impact sensitivity is normal.

: Replace security control module.

11. DIAGNOSTIC ITEM 10

5F111 : CHECK PASSIVE ARM CIRCUIT.

1) Connect connector (B183) and (B184) at driver

side front lower pillar.

2) Disconnect connector from security control

module.

3) Measure resistance between security control

module (B93) and chassis ground.

Connector & terminal

(B93) No. 3 (+) Ð Chassis ground (þ):

B6M1013A

:Is the resistance less than 10W?

: Replace security control module.

: Repair wiring harness between security

control module and chassis ground.

94

6-2[T5F10]DIAGNOSTICS

5. Security System

Page 185 of 345

1. Hood

A: REMOVAL AND INSTALLATION

NOTE:

The hood lock has a dual locking design which

consists of a main lock and a safety lock mecha-

nism. When the release knob located at the front

pillar on the driver's side is pulled back, the main

lock is released through the cable attached to the

knob.

The safety lock can be released by pushing the

lever protruding above the front grill while opening

the hood.

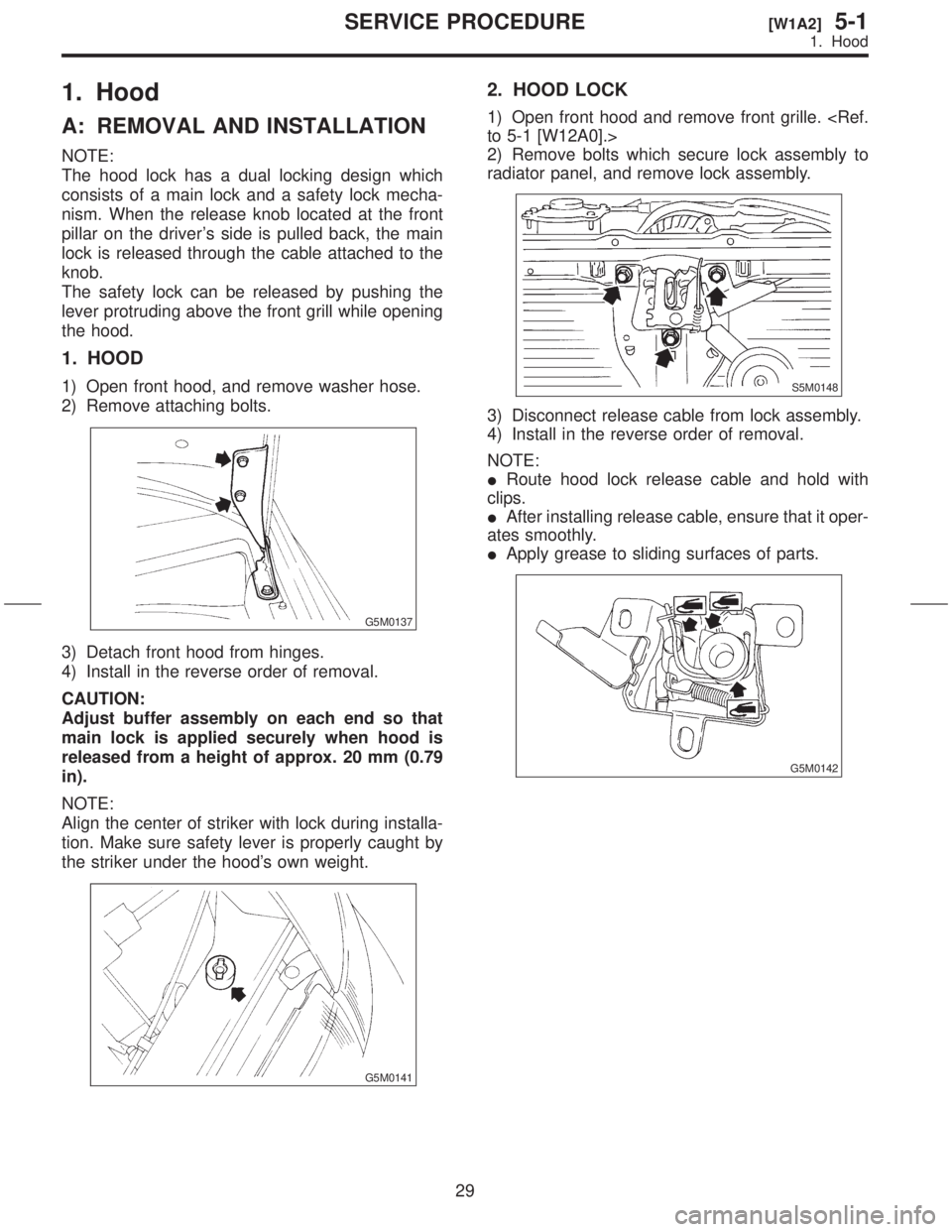

1. HOOD

1) Open front hood, and remove washer hose.

2) Remove attaching bolts.

G5M0137

3) Detach front hood from hinges.

4) Install in the reverse order of removal.

CAUTION:

Adjust buffer assembly on each end so that

main lock is applied securely when hood is

released from a height of approx. 20 mm (0.79

in).

NOTE:

Align the center of striker with lock during installa-

tion. Make sure safety lever is properly caught by

the striker under the hood's own weight.

G5M0141

2. HOOD LOCK

1) Open front hood and remove front grille.

2) Remove bolts which secure lock assembly to

radiator panel, and remove lock assembly.

S5M0148

3) Disconnect release cable from lock assembly.

4) Install in the reverse order of removal.

NOTE:

IRoute hood lock release cable and hold with

clips.

IAfter installing release cable, ensure that it oper-

ates smoothly.

IApply grease to sliding surfaces of parts.

G5M0142

29

[W1A2]5-1SERVICE PROCEDURE

1. Hood

Page 204 of 345

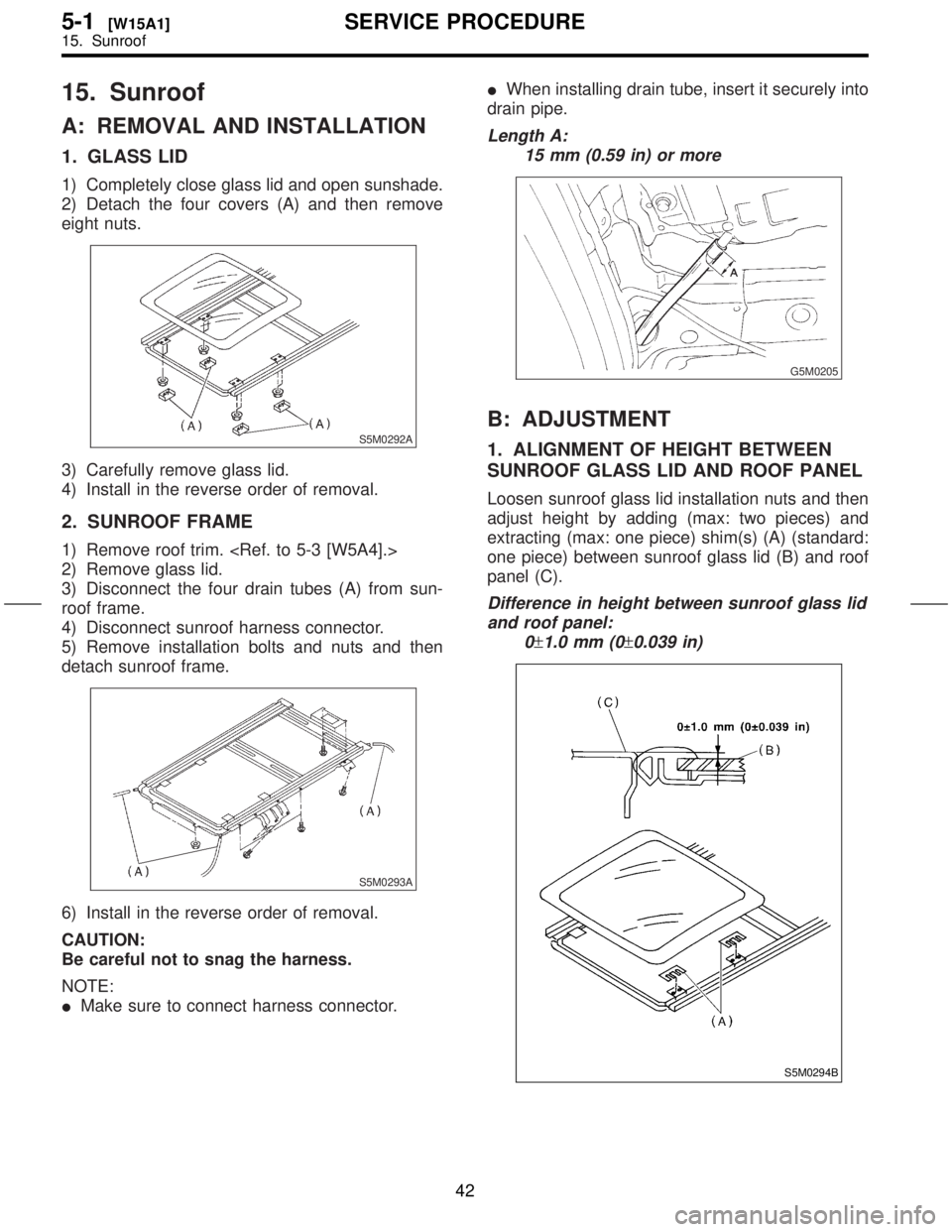

15. Sunroof

A: REMOVAL AND INSTALLATION

1. GLASS LID

1) Completely close glass lid and open sunshade.

2) Detach the four covers (A) and then remove

eight nuts.

S5M0292A

3) Carefully remove glass lid.

4) Install in the reverse order of removal.

2. SUNROOF FRAME

1) Remove roof trim.

2) Remove glass lid.

3) Disconnect the four drain tubes (A) from sun-

roof frame.

4) Disconnect sunroof harness connector.

5) Remove installation bolts and nuts and then

detach sunroof frame.

S5M0293A

6) Install in the reverse order of removal.

CAUTION:

Be careful not to snag the harness.

NOTE:

IMake sure to connect harness connector.IWhen installing drain tube, insert it securely into

drain pipe.

Length A:

15 mm (0.59 in) or more

G5M0205

B: ADJUSTMENT

1. ALIGNMENT OF HEIGHT BETWEEN

SUNROOF GLASS LID AND ROOF PANEL

Loosen sunroof glass lid installation nuts and then

adjust height by adding (max: two pieces) and

extracting (max: one piece) shim(s) (A) (standard:

one piece) between sunroof glass lid (B) and roof

panel (C).

Difference in height between sunroof glass lid

and roof panel:

0

±1.0 mm (0±0.039 in)

S5M0294B

42

5-1[W15A1]SERVICE PROCEDURE

15. Sunroof

Page 222 of 345

![SUBARU FORESTER 1999 Service Owners Guide 2. Door

A: REMOVAL AND INSTALLATION

1. DOOR ASSEMBLY

1) Remove front pillar lower trim <Ref. to 5-3

[W5A1].> and disconnect connectors from body

harness.

B5M0726

2) Place a cloth or a wood block under SUBARU FORESTER 1999 Service Owners Guide 2. Door

A: REMOVAL AND INSTALLATION

1. DOOR ASSEMBLY

1) Remove front pillar lower trim <Ref. to 5-3

[W5A1].> and disconnect connectors from body

harness.

B5M0726

2) Place a cloth or a wood block under](/img/17/57427/w960_57427-221.png)

2. Door

A: REMOVAL AND INSTALLATION

1. DOOR ASSEMBLY

1) Remove front pillar lower trim

harness.

B5M0726

2) Place a cloth or a wood block under door to

prevent damage, and support it with a jack.

3) Remove checker bolt.

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 23.9±7.2 ft-lb)

S5M0183

4) Remove bolts (M8) securing upper and lower

hinges to door, and remove door from hinges.

Tightening torque:

25

±3 N´m (2.5±0.3 kg-m, 18.1±2.2 ft-lb)

5) Remove hinges by loosening hinges mounting

bolt (M8) off of body.

Tightening torque:

29

±5 N´m (3.0±0.5 kg-m, 21.7±3.6 ft-lb)

CAUTION:

Work carefully to avoid damaging door.

G5M0385

6) Install in the reverse order of removal.

NOTE:

Apply grease to moving parts of door hinges.

14

5-2[W2A1]SERVICE PROCEDURE

2. Door

Page 224 of 345

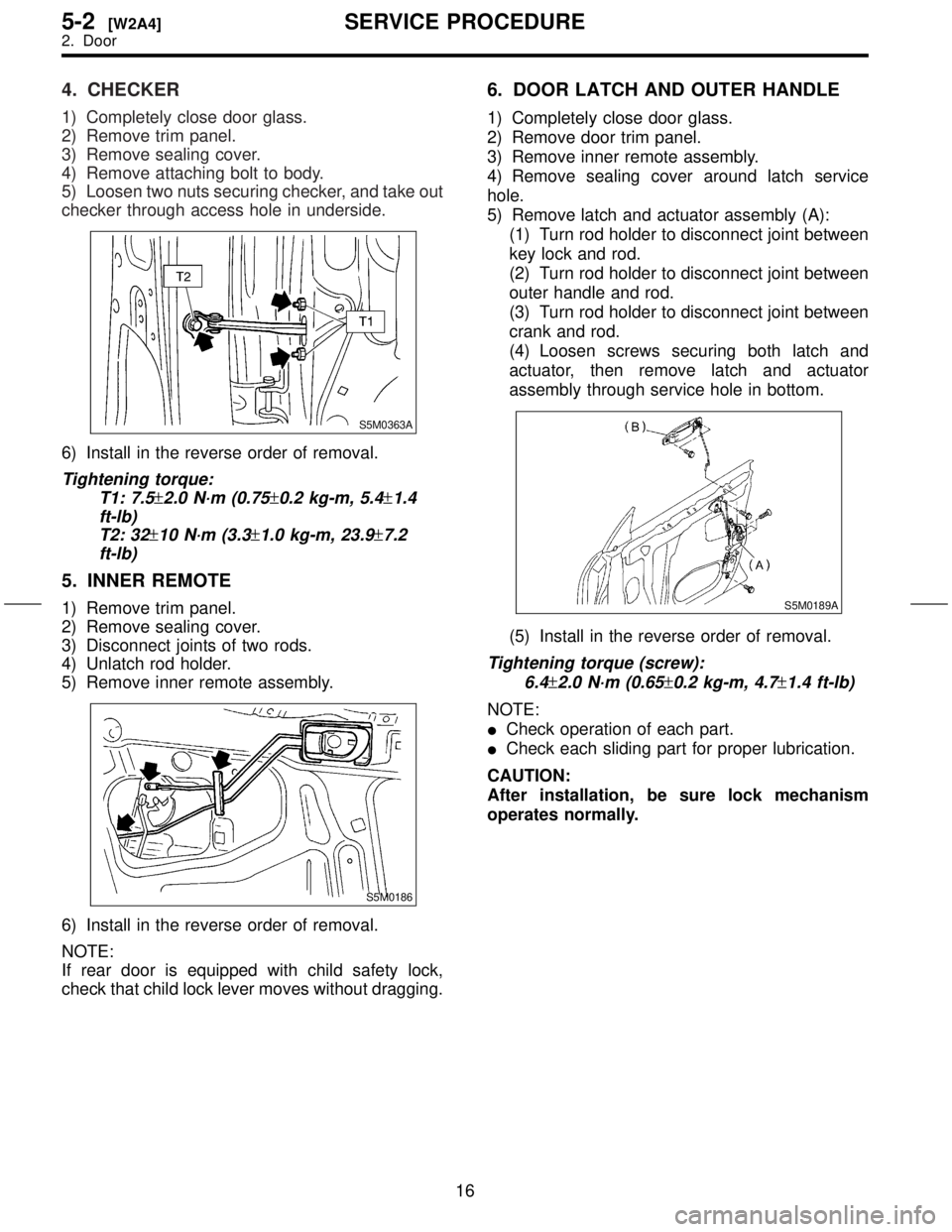

4. CHECKER

1) Completely close door glass.

2) Remove trim panel.

3) Remove sealing cover.

4) Remove attaching bolt to body.

5) Loosen two nuts securing checker, and take out

checker through access hole in underside.

S5M0363A

6) Install in the reverse order of removal.

Tightening torque:

T1: 7.5

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4

ft-lb)

T2: 32

±10 N´m (3.3±1.0 kg-m, 23.9±7.2

ft-lb)

5. INNER REMOTE

1) Remove trim panel.

2) Remove sealing cover.

3) Disconnect joints of two rods.

4) Unlatch rod holder.

5) Remove inner remote assembly.

S5M0186

6) Install in the reverse order of removal.

NOTE:

If rear door is equipped with child safety lock,

check that child lock lever moves without dragging.

6. DOOR LATCH AND OUTER HANDLE

1) Completely close door glass.

2) Remove door trim panel.

3) Remove inner remote assembly.

4) Remove sealing cover around latch service

hole.

5) Remove latch and actuator assembly (A):

(1) Turn rod holder to disconnect joint between

key lock and rod.

(2) Turn rod holder to disconnect joint between

outer handle and rod.

(3) Turn rod holder to disconnect joint between

crank and rod.

(4) Loosen screws securing both latch and

actuator, then remove latch and actuator

assembly through service hole in bottom.

S5M0189A

(5) Install in the reverse order of removal.

Tightening torque (screw):

6.4

±2.0 N´m (0.65±0.2 kg-m, 4.7±1.4 ft-lb)

NOTE:

ICheck operation of each part.

ICheck each sliding part for proper lubrication.

CAUTION:

After installation, be sure lock mechanism

operates normally.

16

5-2[W2A4]SERVICE PROCEDURE

2. Door

Page 225 of 345

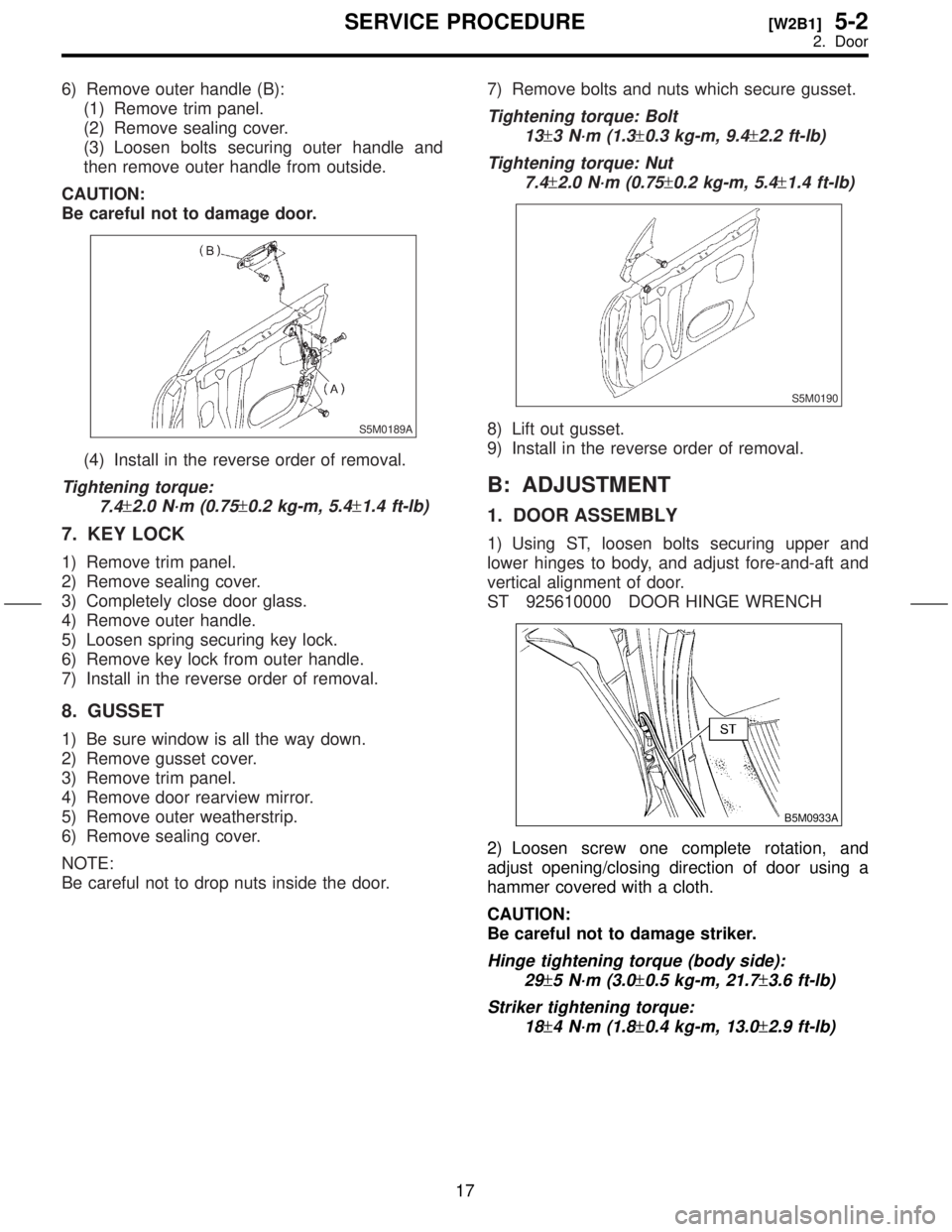

6) Remove outer handle (B):

(1) Remove trim panel.

(2) Remove sealing cover.

(3) Loosen bolts securing outer handle and

then remove outer handle from outside.

CAUTION:

Be careful not to damage door.

S5M0189A

(4) Install in the reverse order of removal.

Tightening torque:

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

7. KEY LOCK

1) Remove trim panel.

2) Remove sealing cover.

3) Completely close door glass.

4) Remove outer handle.

5) Loosen spring securing key lock.

6) Remove key lock from outer handle.

7) Install in the reverse order of removal.

8. GUSSET

1) Be sure window is all the way down.

2) Remove gusset cover.

3) Remove trim panel.

4) Remove door rearview mirror.

5) Remove outer weatherstrip.

6) Remove sealing cover.

NOTE:

Be careful not to drop nuts inside the door.7) Remove bolts and nuts which secure gusset.

Tightening torque: Bolt

13

±3 N´m (1.3±0.3 kg-m, 9.4±2.2 ft-lb)

Tightening torque: Nut

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

S5M0190

8) Lift out gusset.

9) Install in the reverse order of removal.

B: ADJUSTMENT

1. DOOR ASSEMBLY

1) Using ST, loosen bolts securing upper and

lower hinges to body, and adjust fore-and-aft and

vertical alignment of door.

ST 925610000 DOOR HINGE WRENCH

B5M0933A

2) Loosen screw one complete rotation, and

adjust opening/closing direction of door using a

hammer covered with a cloth.

CAUTION:

Be careful not to damage striker.

Hinge tightening torque (body side):

29

±5 N´m (3.0±0.5 kg-m, 21.7±3.6 ft-lb)

Striker tightening torque:

18

±4 N´m (1.8±0.4 kg-m, 13.0±2.9 ft-lb)

17

[W2B1]5-2SERVICE PROCEDURE

2. Door

Page 228 of 345

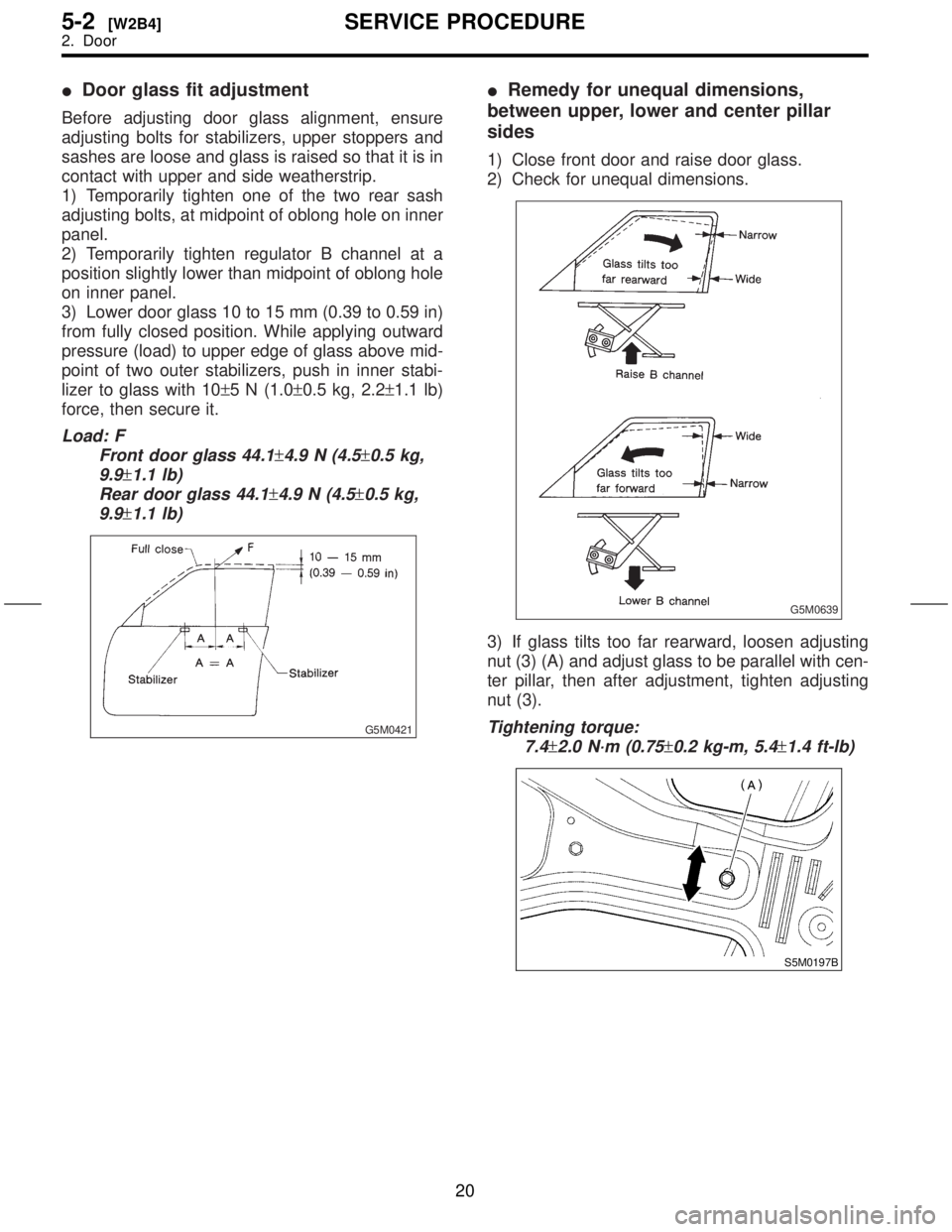

IDoor glass fit adjustment

Before adjusting door glass alignment, ensure

adjusting bolts for stabilizers, upper stoppers and

sashes are loose and glass is raised so that it is in

contact with upper and side weatherstrip.

1) Temporarily tighten one of the two rear sash

adjusting bolts, at midpoint of oblong hole on inner

panel.

2) Temporarily tighten regulator B channel at a

position slightly lower than midpoint of oblong hole

on inner panel.

3) Lower door glass 10 to 15 mm (0.39 to 0.59 in)

from fully closed position. While applying outward

pressure (load) to upper edge of glass above mid-

point of two outer stabilizers, push in inner stabi-

lizer to glass with 10±5 N (1.0±0.5 kg, 2.2±1.1 lb)

force, then secure it.

Load: F

Front door glass 44.1

±4.9 N (4.5±0.5 kg,

9.9

±1.1 lb)

Rear door glass 44.1

±4.9 N (4.5±0.5 kg,

9.9

±1.1 lb)

G5M0421

IRemedy for unequal dimensions,

between upper, lower and center pillar

sides

1) Close front door and raise door glass.

2) Check for unequal dimensions.

G5M0639

3) If glass tilts too far rearward, loosen adjusting

nut (3) (A) and adjust glass to be parallel with cen-

ter pillar, then after adjustment, tighten adjusting

nut (3).

Tightening torque:

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

S5M0197B

20

5-2[W2B4]SERVICE PROCEDURE

2. Door

Page 230 of 345

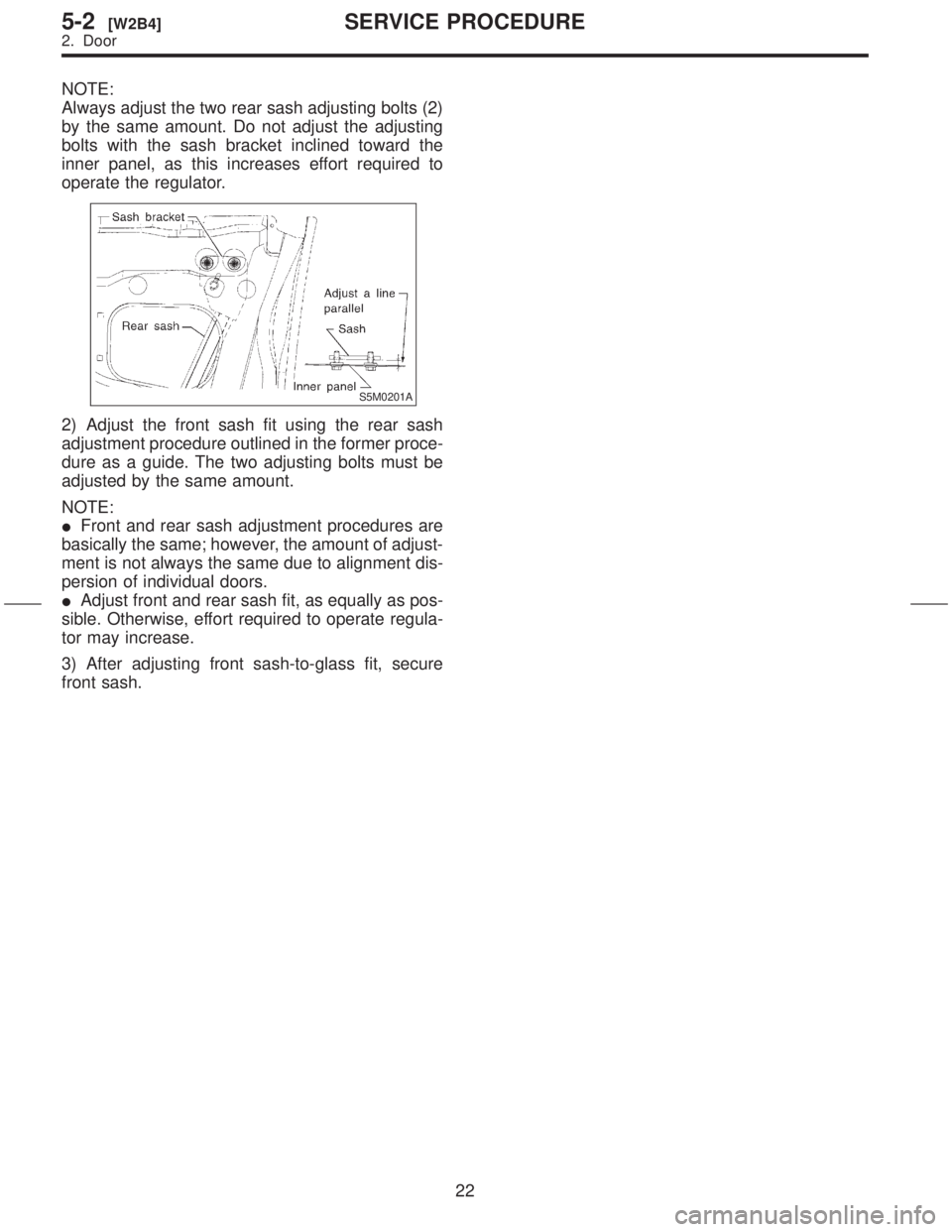

NOTE:

Always adjust the two rear sash adjusting bolts (2)

by the same amount. Do not adjust the adjusting

bolts with the sash bracket inclined toward the

inner panel, as this increases effort required to

operate the regulator.

S5M0201A

2) Adjust the front sash fit using the rear sash

adjustment procedure outlined in the former proce-

dure as a guide. The two adjusting bolts must be

adjusted by the same amount.

NOTE:

IFront and rear sash adjustment procedures are

basically the same; however, the amount of adjust-

ment is not always the same due to alignment dis-

persion of individual doors.

IAdjust front and rear sash fit, as equally as pos-

sible. Otherwise, effort required to operate regula-

tor may increase.

3) After adjusting front sash-to-glass fit, secure

front sash.

22

5-2[W2B4]SERVICE PROCEDURE

2. Door

Page 238 of 345

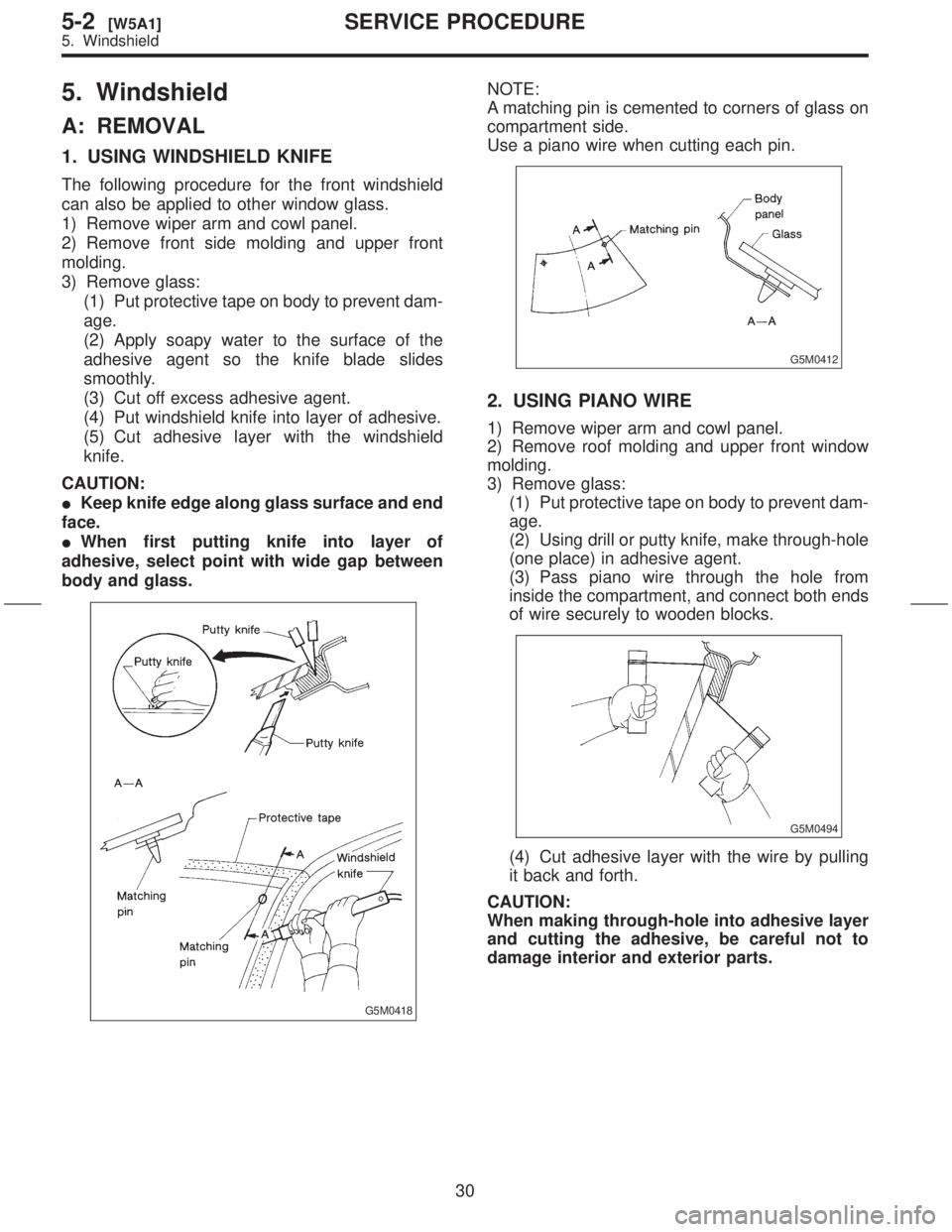

5. Windshield

A: REMOVAL

1. USING WINDSHIELD KNIFE

The following procedure for the front windshield

can also be applied to other window glass.

1) Remove wiper arm and cowl panel.

2) Remove front side molding and upper front

molding.

3) Remove glass:

(1) Put protective tape on body to prevent dam-

age.

(2) Apply soapy water to the surface of the

adhesive agent so the knife blade slides

smoothly.

(3) Cut off excess adhesive agent.

(4) Put windshield knife into layer of adhesive.

(5) Cut adhesive layer with the windshield

knife.

CAUTION:

IKeep knife edge along glass surface and end

face.

IWhen first putting knife into layer of

adhesive, select point with wide gap between

body and glass.

G5M0418

NOTE:

A matching pin is cemented to corners of glass on

compartment side.

Use a piano wire when cutting each pin.

G5M0412

2. USING PIANO WIRE

1) Remove wiper arm and cowl panel.

2) Remove roof molding and upper front window

molding.

3) Remove glass:

(1) Put protective tape on body to prevent dam-

age.

(2) Using drill or putty knife, make through-hole

(one place) in adhesive agent.

(3) Pass piano wire through the hole from

inside the compartment, and connect both ends

of wire securely to wooden blocks.

G5M0494

(4) Cut adhesive layer with the wire by pulling

it back and forth.

CAUTION:

When making through-hole into adhesive layer

and cutting the adhesive, be careful not to

damage interior and exterior parts.

30

5-2[W5A1]SERVICE PROCEDURE

5. Windshield

Page 256 of 345

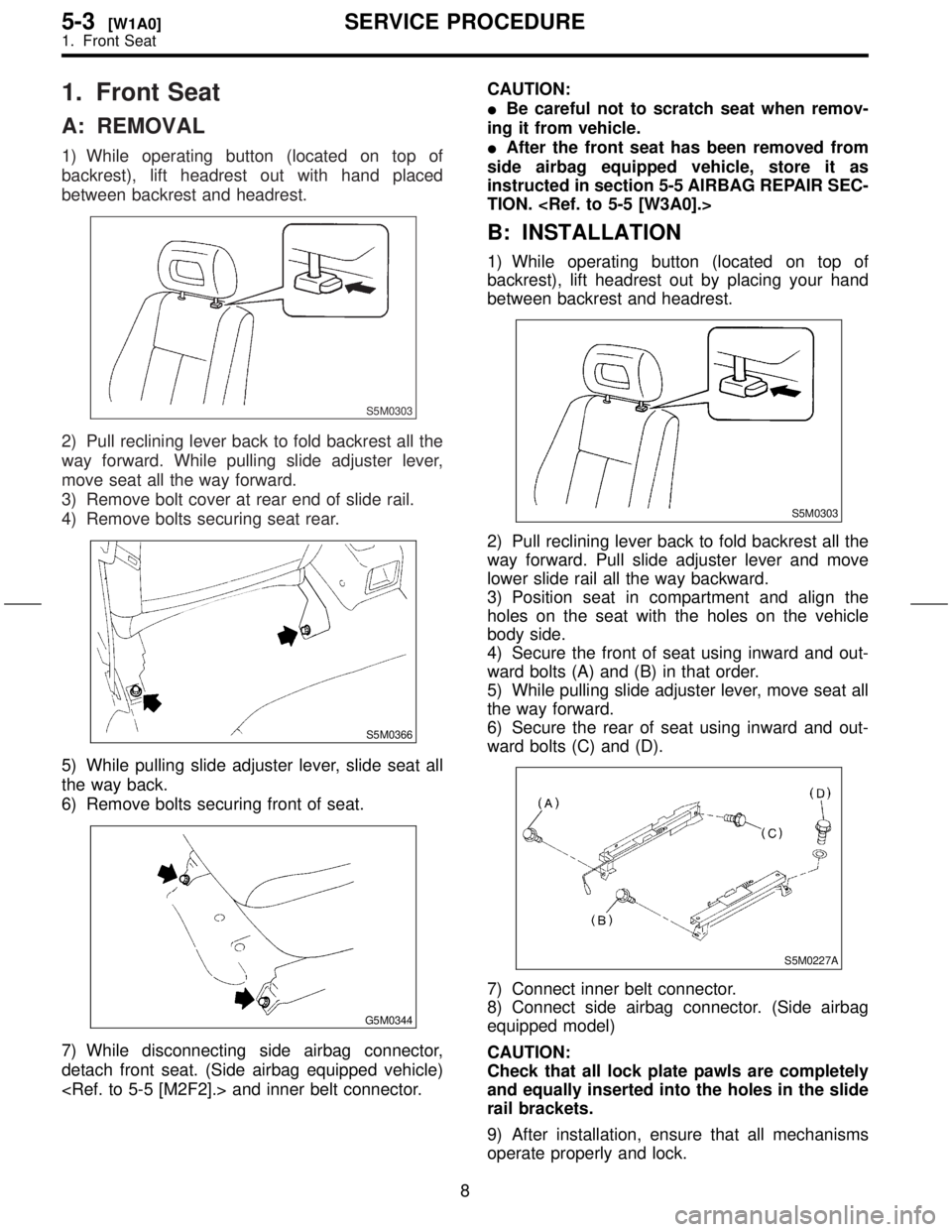

1. Front Seat

A: REMOVAL

1) While operating button (located on top of

backrest), lift headrest out with hand placed

between backrest and headrest.

S5M0303

2) Pull reclining lever back to fold backrest all the

way forward. While pulling slide adjuster lever,

move seat all the way forward.

3) Remove bolt cover at rear end of slide rail.

4) Remove bolts securing seat rear.

S5M0366

5) While pulling slide adjuster lever, slide seat all

the way back.

6) Remove bolts securing front of seat.

G5M0344

7) While disconnecting side airbag connector,

detach front seat. (Side airbag equipped vehicle)

IBe careful not to scratch seat when remov-

ing it from vehicle.

IAfter the front seat has been removed from

side airbag equipped vehicle, store it as

instructed in section 5-5 AIRBAG REPAIR SEC-

TION.

B: INSTALLATION

1) While operating button (located on top of

backrest), lift headrest out by placing your hand

between backrest and headrest.

S5M0303

2) Pull reclining lever back to fold backrest all the

way forward. Pull slide adjuster lever and move

lower slide rail all the way backward.

3) Position seat in compartment and align the

holes on the seat with the holes on the vehicle

body side.

4) Secure the front of seat using inward and out-

ward bolts (A) and (B) in that order.

5) While pulling slide adjuster lever, move seat all

the way forward.

6) Secure the rear of seat using inward and out-

ward bolts (C) and (D).

S5M0227A

7) Connect inner belt connector.

8) Connect side airbag connector. (Side airbag

equipped model)

CAUTION:

Check that all lock plate pawls are completely

and equally inserted into the holes in the slide

rail brackets.

9) After installation, ensure that all mechanisms

operate properly and lock.

8

5-3[W1A0]SERVICE PROCEDURE

1. Front Seat