service SUBARU FORESTER 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: FORESTER, Model: SUBARU FORESTER 1999Pages: 345, PDF Size: 5.6 MB

Page 194 of 345

Process

No.Process name Job contents

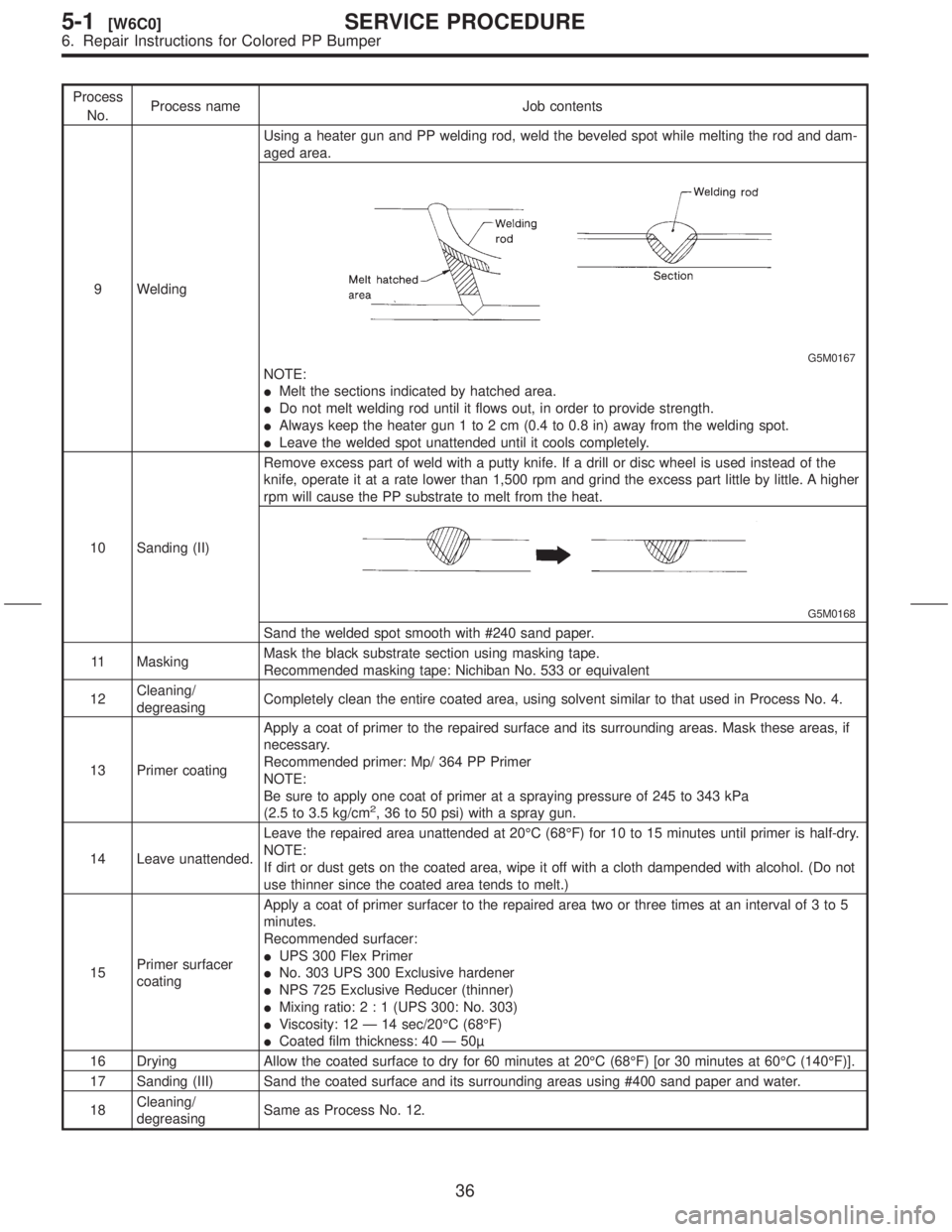

9 WeldingUsing a heater gun and PP welding rod, weld the beveled spot while melting the rod and dam-

aged area.

G5M0167

NOTE:

IMelt the sections indicated by hatched area.

IDo not melt welding rod until it flows out, in order to provide strength.

IAlways keep the heater gun 1 to 2 cm (0.4 to 0.8 in) away from the welding spot.

ILeave the welded spot unattended until it cools completely.

10 Sanding (II)Remove excess part of weld with a putty knife. If a drill or disc wheel is used instead of the

knife, operate it at a rate lower than 1,500 rpm and grind the excess part little by little. A higher

rpm will cause the PP substrate to melt from the heat.

G5M0168

Sand the welded spot smooth with #240 sand paper.

11 MaskingMask the black substrate section using masking tape.

Recommended masking tape: Nichiban No. 533 or equivalent

12Cleaning/

degreasingCompletely clean the entire coated area, using solvent similar to that used in Process No. 4.

13 Primer coatingApply a coat of primer to the repaired surface and its surrounding areas. Mask these areas, if

necessary.

Recommended primer: Mp/ 364 PP Primer

NOTE:

Be sure to apply one coat of primer at a spraying pressure of 245 to 343 kPa

(2.5 to 3.5 kg/cm

2, 36 to 50 psi) with a spray gun.

14 Leave unattended.Leave the repaired area unattended at 20ÉC (68ÉF) for 10 to 15 minutes until primer is half-dry.

NOTE:

If dirt or dust gets on the coated area, wipe it off with a cloth dampended with alcohol. (Do not

use thinner since the coated area tends to melt.)

15Primer surfacer

coatingApply a coat of primer surfacer to the repaired area two or three times at an interval of 3 to 5

minutes.

Recommended surfacer:

IUPS 300 Flex Primer

INo. 303 UPS 300 Exclusive hardener

INPS 725 Exclusive Reducer (thinner)

IMixing ratio:2:1(UPS 300: No. 303)

IViscosity: 12 Ð 14 sec/20ÉC (68ÉF)

ICoated film thickness: 40 Ð 50

16 Drying Allow the coated surface to dry for 60 minutes at 20ÉC (68ÉF) [or 30 minutes at 60ÉC (140ÉF)].

17 Sanding (III) Sand the coated surface and its surrounding areas using #400 sand paper and water.

18Cleaning/

degreasingSame as Process No. 12.

36

5-1[W6C0]SERVICE PROCEDURE

6. Repair Instructions for Colored PP Bumper

Page 195 of 345

Process

No.Process name Job contents

19 Top coat (I)Solid color Metallic color

Use a ªblockº coating method.

IRecommended paint:

Suncryl (SC)

No. 307 Flex Hardener

SC Reducer (thinner)

IMixing ratio:3:1

Suncryl (SC) vs. No. 307 Flex Hardener

IViscosity: 11 Ð 13 sec/20ÉC (68ÉF)

ICoated film thickness: 40 Ð 50

ISpraying thickness: 245 Ð 343 kPa

(2.5 Ð 3.5 kg/cm

2, 36 Ð 50 psi)Use a ªblockº coating method.

IRecommended paint:

Suncryl (SC)

No. 307 Flex Hardener

SC Reducer (thinner)

IMixing ratio:3:1

Suncryl (SC) vs. No. 307 Flex Hardener

IViscosity: 11 Ð 13 sec/20ÉC (68ÉF)

ICoated film thickness: 20 Ð 30

ISpraying thickness: 245 Ð 343 kPa

(2.5 Ð 3.5 kg/cm2, 36 Ð 50 psi)

20 Leave unattended. Not required.Leave unattended at 20ÉC (68ÉF) for at least

10 minutes until the topcoated area is half-dry.

NOTE:

Be careful to keep dust or dirt from getting on

the affected area.

21 Top coat (II) Not required.Apply a clear coat three times at an interval of

3 to 5 minutes.

IRecommended paint:

SC710 Overlay Clear

No. 307 Flex Hardener

SC Reducer (thinner)

IMixing ratio:3:1

Suncryl (SC) vs. No. 307 Flex Hardener

IViscosity: 10 Ð 13 sec/20ÉC (68ÉF)

ICoated film thickness: 20 Ð 30

ISpraying pressure: 245 Ð 343 kPa

(2.5 Ð 3.5 kg/cm

2, 36 Ð 50 psi)

22 DryingAllow the coated surface to dry at 20ÉC (68ÉF) for two hours or 60ÉC (140ÉF) for 30 minutes.

NOTE:

Do not allow the temperature to exceed 80ÉC (176ÉF) since this will deform the PP substrate.

23 Inspection Carefully check the condition of the repaired area.

24 Masking removal Remove masking tape applied in Process No. 11 and 13.

25 Parts installation Install parts on bumper in reverse order of removal.

26Bumper installa-

tionInstall bumper.

37

[W6C0]5-1SERVICE PROCEDURE

6. Repair Instructions for Colored PP Bumper

Page 204 of 345

15. Sunroof

A: REMOVAL AND INSTALLATION

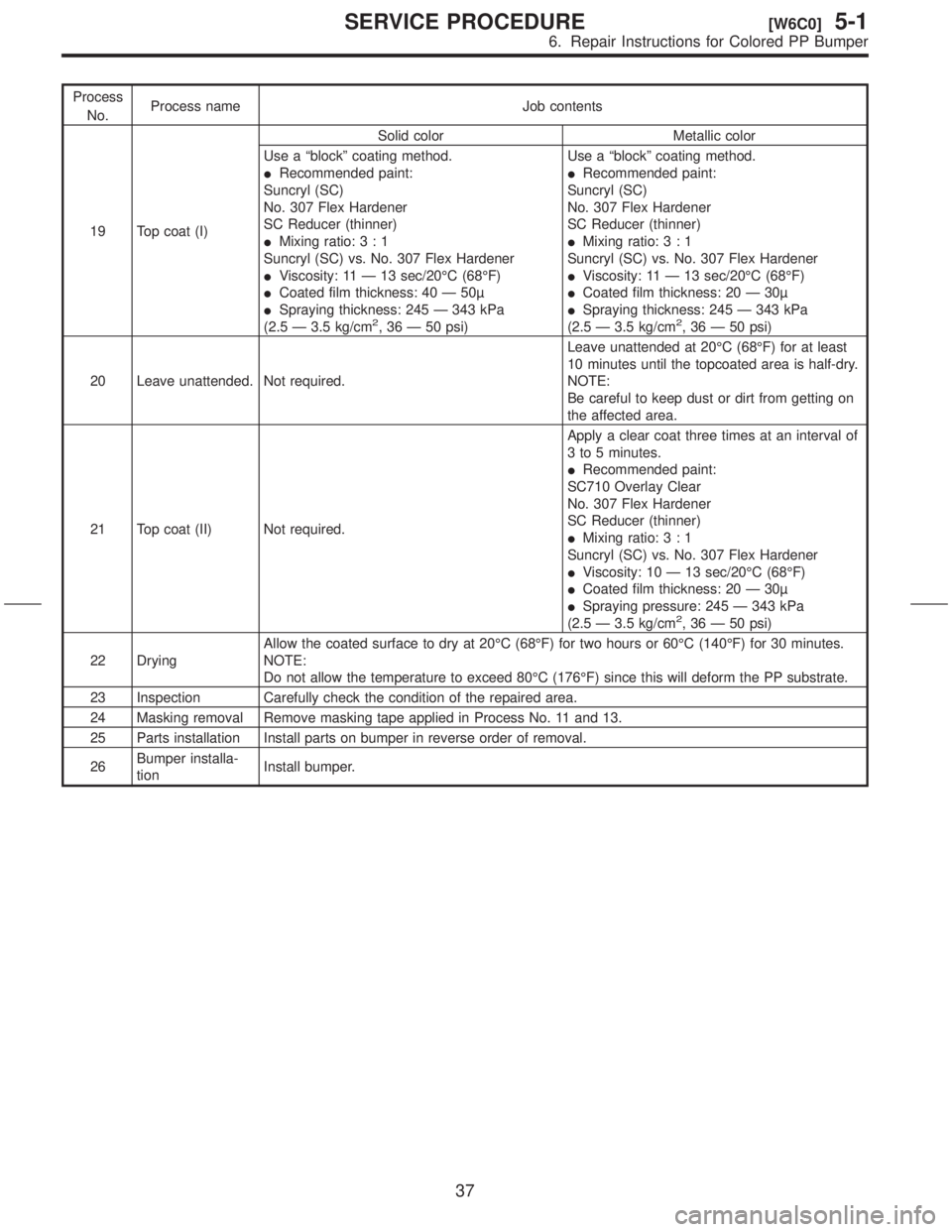

1. GLASS LID

1) Completely close glass lid and open sunshade.

2) Detach the four covers (A) and then remove

eight nuts.

S5M0292A

3) Carefully remove glass lid.

4) Install in the reverse order of removal.

2. SUNROOF FRAME

1) Remove roof trim.

2) Remove glass lid.

3) Disconnect the four drain tubes (A) from sun-

roof frame.

4) Disconnect sunroof harness connector.

5) Remove installation bolts and nuts and then

detach sunroof frame.

S5M0293A

6) Install in the reverse order of removal.

CAUTION:

Be careful not to snag the harness.

NOTE:

IMake sure to connect harness connector.IWhen installing drain tube, insert it securely into

drain pipe.

Length A:

15 mm (0.59 in) or more

G5M0205

B: ADJUSTMENT

1. ALIGNMENT OF HEIGHT BETWEEN

SUNROOF GLASS LID AND ROOF PANEL

Loosen sunroof glass lid installation nuts and then

adjust height by adding (max: two pieces) and

extracting (max: one piece) shim(s) (A) (standard:

one piece) between sunroof glass lid (B) and roof

panel (C).

Difference in height between sunroof glass lid

and roof panel:

0

±1.0 mm (0±0.039 in)

S5M0294B

42

5-1[W15A1]SERVICE PROCEDURE

15. Sunroof

Page 205 of 345

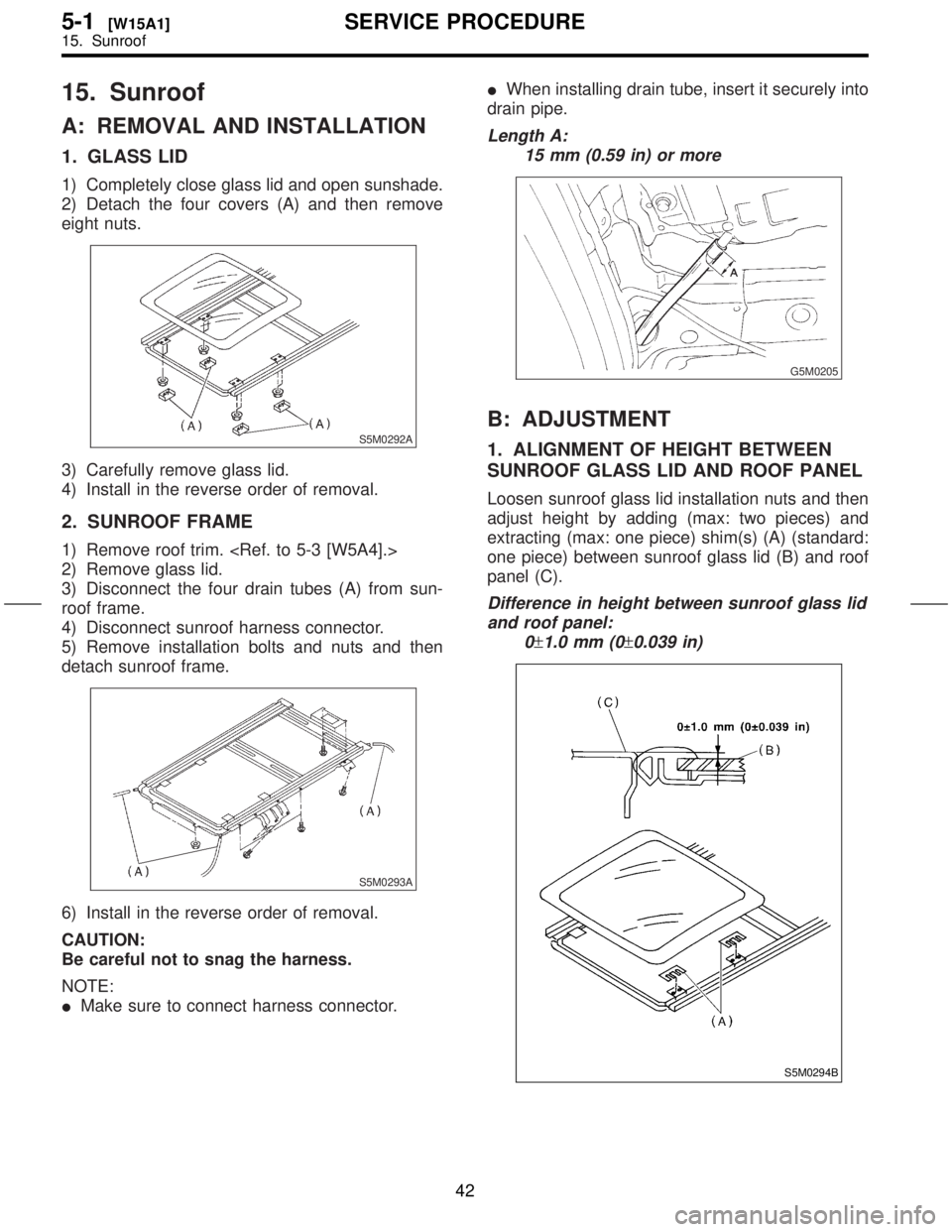

2. CHECKING FOR MOVEMENT OF

SUNROOF PANEL ITSELF

1) Place a cloth on sunshade, and attach a spring

scale to sunshade edge using the cloth.

S5M0295

2) Pull spring scale to measure force required to

move sunshade.

Force required to move sunshade:

Less than 24.5

±4.9 N (2.5±0.5 kg, 5.5±1.1

lb)

NOTE:

Considerable effort is required to start sunshade

moving, so take scale reading while sunroof panel

is moving smoothly.

3) If force required exceeds specifications, check

the sunroof glass lid, sunshade and deflector, and

guide rail assembly for improper installation.

16. Crossbar

A: REMOVAL

1) Loosen and remove TORX bolt T30 from the

top of each crossbar end support, and then remove

inner clamp.

S5M0330A

(1) TORX bolt T30

(2) End support

(3) Inner clamp

(4) Roof rail

2) Remove crossbar.

NOTE:

When removing the front crossbar from the roof

rail, first move the front crossbar to the center of

the roof rail.

B: INSTALLATION

1. FRONT CROSSBAR

NOTE:

Front crossbar has ªMAXIMUM LOAD ROOF

RACK-150LBS. EVENLY DISTRIBUTED ROOF

SURFACE-100LBS. EVENLY DISTRIBUTEDº

label on LH side.

1) Loosen and remove TORX bolt T30 from the

top of each crossbar end support, and then remove

the inner clamp.

43

[W16B1]5-1SERVICE PROCEDURE

16. Crossbar

Page 210 of 345

![SUBARU FORESTER 1999 Service Owners Guide 1. Door Alignment

S5M0380A

2

5-2[S100]SPECIFICATIONS AND SERVICE DATA

1. Door Alignment SUBARU FORESTER 1999 Service Owners Guide 1. Door Alignment

S5M0380A

2

5-2[S100]SPECIFICATIONS AND SERVICE DATA

1. Door Alignment](/img/17/57427/w960_57427-209.png)

1. Door Alignment

S5M0380A

2

5-2[S100]SPECIFICATIONS AND SERVICE DATA

1. Door Alignment

Page 222 of 345

![SUBARU FORESTER 1999 Service Owners Guide 2. Door

A: REMOVAL AND INSTALLATION

1. DOOR ASSEMBLY

1) Remove front pillar lower trim <Ref. to 5-3

[W5A1].> and disconnect connectors from body

harness.

B5M0726

2) Place a cloth or a wood block under SUBARU FORESTER 1999 Service Owners Guide 2. Door

A: REMOVAL AND INSTALLATION

1. DOOR ASSEMBLY

1) Remove front pillar lower trim <Ref. to 5-3

[W5A1].> and disconnect connectors from body

harness.

B5M0726

2) Place a cloth or a wood block under](/img/17/57427/w960_57427-221.png)

2. Door

A: REMOVAL AND INSTALLATION

1. DOOR ASSEMBLY

1) Remove front pillar lower trim

harness.

B5M0726

2) Place a cloth or a wood block under door to

prevent damage, and support it with a jack.

3) Remove checker bolt.

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 23.9±7.2 ft-lb)

S5M0183

4) Remove bolts (M8) securing upper and lower

hinges to door, and remove door from hinges.

Tightening torque:

25

±3 N´m (2.5±0.3 kg-m, 18.1±2.2 ft-lb)

5) Remove hinges by loosening hinges mounting

bolt (M8) off of body.

Tightening torque:

29

±5 N´m (3.0±0.5 kg-m, 21.7±3.6 ft-lb)

CAUTION:

Work carefully to avoid damaging door.

G5M0385

6) Install in the reverse order of removal.

NOTE:

Apply grease to moving parts of door hinges.

14

5-2[W2A1]SERVICE PROCEDURE

2. Door

Page 223 of 345

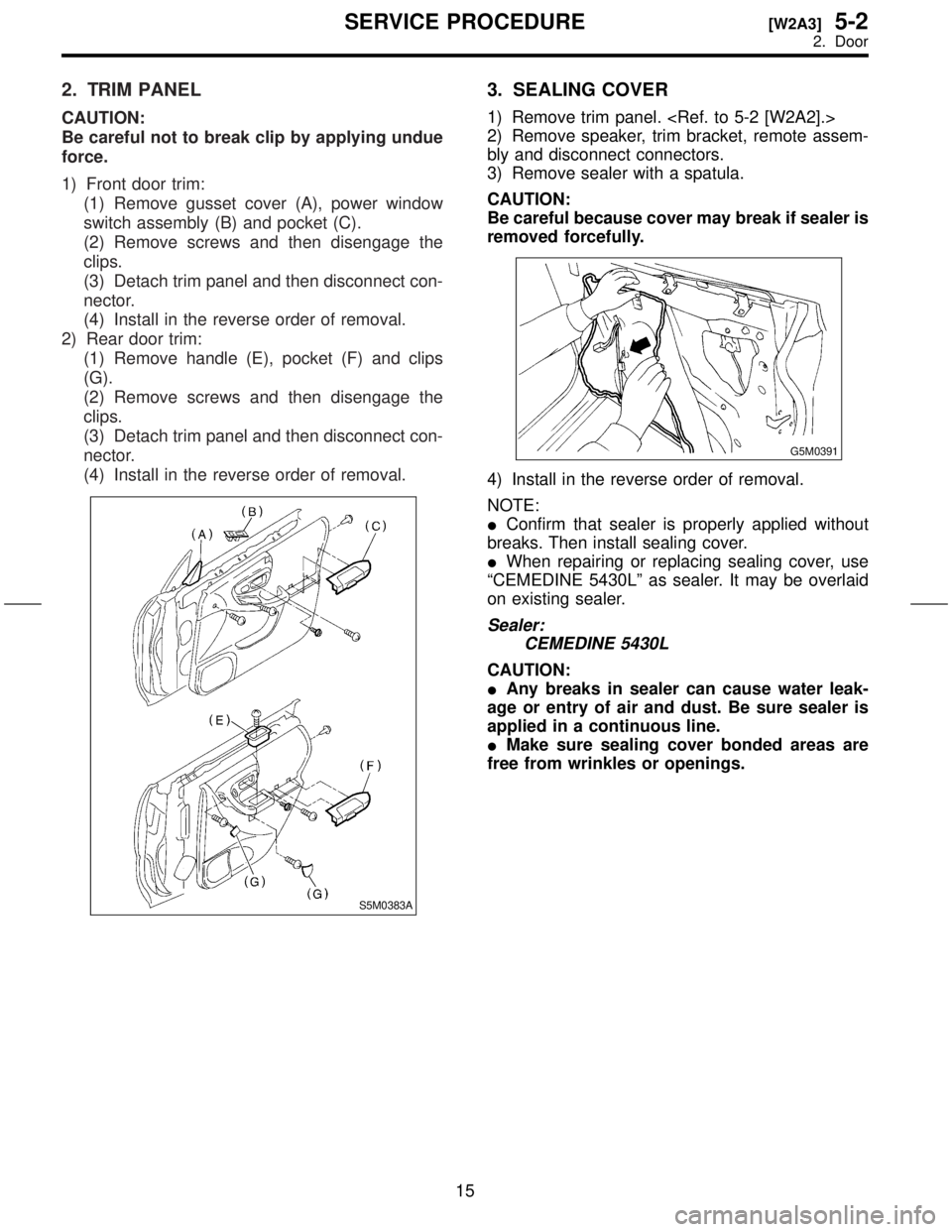

2. TRIM PANEL

CAUTION:

Be careful not to break clip by applying undue

force.

1) Front door trim:

(1) Remove gusset cover (A), power window

switch assembly (B) and pocket (C).

(2) Remove screws and then disengage the

clips.

(3) Detach trim panel and then disconnect con-

nector.

(4) Install in the reverse order of removal.

2) Rear door trim:

(1) Remove handle (E), pocket (F) and clips

(G).

(2) Remove screws and then disengage the

clips.

(3) Detach trim panel and then disconnect con-

nector.

(4) Install in the reverse order of removal.

S5M0383A

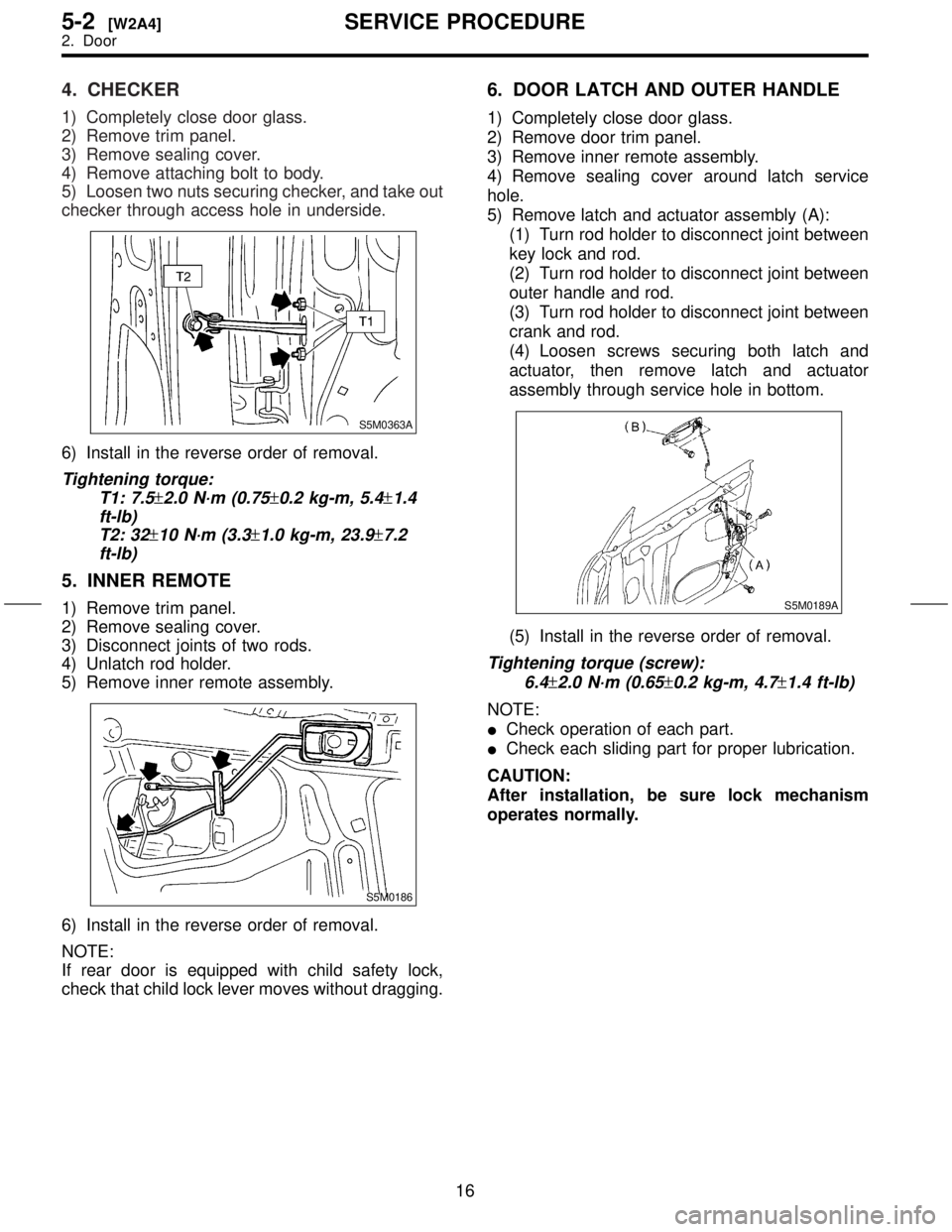

3. SEALING COVER

1) Remove trim panel.

2) Remove speaker, trim bracket, remote assem-

bly and disconnect connectors.

3) Remove sealer with a spatula.

CAUTION:

Be careful because cover may break if sealer is

removed forcefully.

G5M0391

4) Install in the reverse order of removal.

NOTE:

IConfirm that sealer is properly applied without

breaks. Then install sealing cover.

IWhen repairing or replacing sealing cover, use

ªCEMEDINE 5430Lº as sealer. It may be overlaid

on existing sealer.

Sealer:

CEMEDINE 5430L

CAUTION:

IAny breaks in sealer can cause water leak-

age or entry of air and dust. Be sure sealer is

applied in a continuous line.

IMake sure sealing cover bonded areas are

free from wrinkles or openings.

15

[W2A3]5-2SERVICE PROCEDURE

2. Door

Page 224 of 345

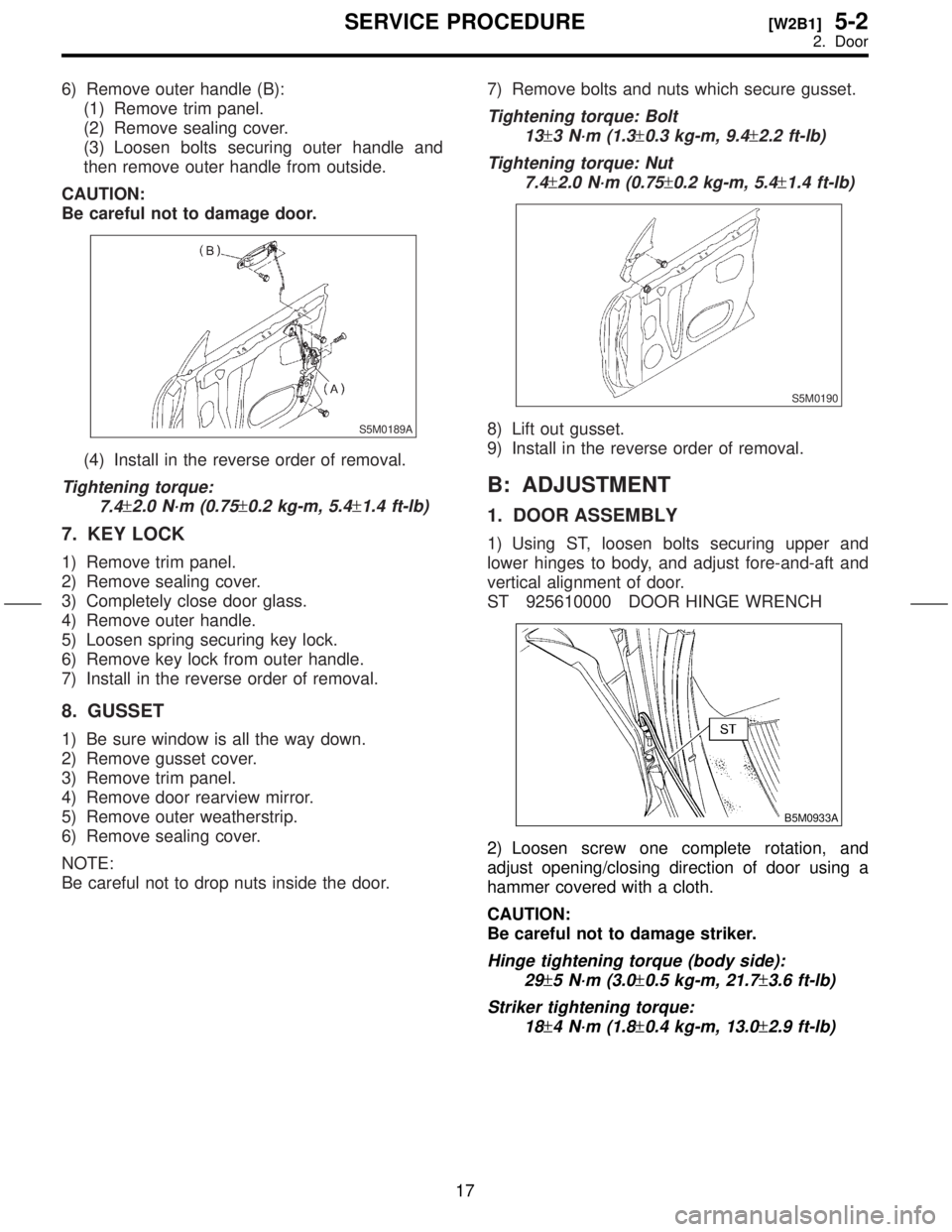

4. CHECKER

1) Completely close door glass.

2) Remove trim panel.

3) Remove sealing cover.

4) Remove attaching bolt to body.

5) Loosen two nuts securing checker, and take out

checker through access hole in underside.

S5M0363A

6) Install in the reverse order of removal.

Tightening torque:

T1: 7.5

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4

ft-lb)

T2: 32

±10 N´m (3.3±1.0 kg-m, 23.9±7.2

ft-lb)

5. INNER REMOTE

1) Remove trim panel.

2) Remove sealing cover.

3) Disconnect joints of two rods.

4) Unlatch rod holder.

5) Remove inner remote assembly.

S5M0186

6) Install in the reverse order of removal.

NOTE:

If rear door is equipped with child safety lock,

check that child lock lever moves without dragging.

6. DOOR LATCH AND OUTER HANDLE

1) Completely close door glass.

2) Remove door trim panel.

3) Remove inner remote assembly.

4) Remove sealing cover around latch service

hole.

5) Remove latch and actuator assembly (A):

(1) Turn rod holder to disconnect joint between

key lock and rod.

(2) Turn rod holder to disconnect joint between

outer handle and rod.

(3) Turn rod holder to disconnect joint between

crank and rod.

(4) Loosen screws securing both latch and

actuator, then remove latch and actuator

assembly through service hole in bottom.

S5M0189A

(5) Install in the reverse order of removal.

Tightening torque (screw):

6.4

±2.0 N´m (0.65±0.2 kg-m, 4.7±1.4 ft-lb)

NOTE:

ICheck operation of each part.

ICheck each sliding part for proper lubrication.

CAUTION:

After installation, be sure lock mechanism

operates normally.

16

5-2[W2A4]SERVICE PROCEDURE

2. Door

Page 225 of 345

6) Remove outer handle (B):

(1) Remove trim panel.

(2) Remove sealing cover.

(3) Loosen bolts securing outer handle and

then remove outer handle from outside.

CAUTION:

Be careful not to damage door.

S5M0189A

(4) Install in the reverse order of removal.

Tightening torque:

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

7. KEY LOCK

1) Remove trim panel.

2) Remove sealing cover.

3) Completely close door glass.

4) Remove outer handle.

5) Loosen spring securing key lock.

6) Remove key lock from outer handle.

7) Install in the reverse order of removal.

8. GUSSET

1) Be sure window is all the way down.

2) Remove gusset cover.

3) Remove trim panel.

4) Remove door rearview mirror.

5) Remove outer weatherstrip.

6) Remove sealing cover.

NOTE:

Be careful not to drop nuts inside the door.7) Remove bolts and nuts which secure gusset.

Tightening torque: Bolt

13

±3 N´m (1.3±0.3 kg-m, 9.4±2.2 ft-lb)

Tightening torque: Nut

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

S5M0190

8) Lift out gusset.

9) Install in the reverse order of removal.

B: ADJUSTMENT

1. DOOR ASSEMBLY

1) Using ST, loosen bolts securing upper and

lower hinges to body, and adjust fore-and-aft and

vertical alignment of door.

ST 925610000 DOOR HINGE WRENCH

B5M0933A

2) Loosen screw one complete rotation, and

adjust opening/closing direction of door using a

hammer covered with a cloth.

CAUTION:

Be careful not to damage striker.

Hinge tightening torque (body side):

29

±5 N´m (3.0±0.5 kg-m, 21.7±3.6 ft-lb)

Striker tightening torque:

18

±4 N´m (1.8±0.4 kg-m, 13.0±2.9 ft-lb)

17

[W2B1]5-2SERVICE PROCEDURE

2. Door

Page 226 of 345

![SUBARU FORESTER 1999 Service Owners Guide 2. INNER REMOTE

1) Lock the door.

2) Loosen bolt (A).

3) Lower bell crank (B) and then tighten bolt (A).

S5M0191A

3. PROCEDURE CHART FOR ADJUSTING DOOR GLASS

H5M0912B

18

5-2[W2B2]SERVICE PROCEDURE

2. SUBARU FORESTER 1999 Service Owners Guide 2. INNER REMOTE

1) Lock the door.

2) Loosen bolt (A).

3) Lower bell crank (B) and then tighten bolt (A).

S5M0191A

3. PROCEDURE CHART FOR ADJUSTING DOOR GLASS

H5M0912B

18

5-2[W2B2]SERVICE PROCEDURE

2.](/img/17/57427/w960_57427-225.png)

2. INNER REMOTE

1) Lock the door.

2) Loosen bolt (A).

3) Lower bell crank (B) and then tighten bolt (A).

S5M0191A

3. PROCEDURE CHART FOR ADJUSTING DOOR GLASS

H5M0912B

18

5-2[W2B2]SERVICE PROCEDURE

2. Door