C: DEEP DAMAGE SUCH AS A BREAK OR HOLE THAT REQUIRES FILLING

Much of the peripheral grained surface must be sacrificed for repair, and the degree of restoration may not

be worth the expense. (The surface, however, will become almost flush with adjacent areas.)

Recommended repair kit: PP Part Repair Kit (NRM)

Process

No.Process name Job contents

1 Bumper removal Remove bumper as required.

2 Part removal Remove parts built into bumper as required.

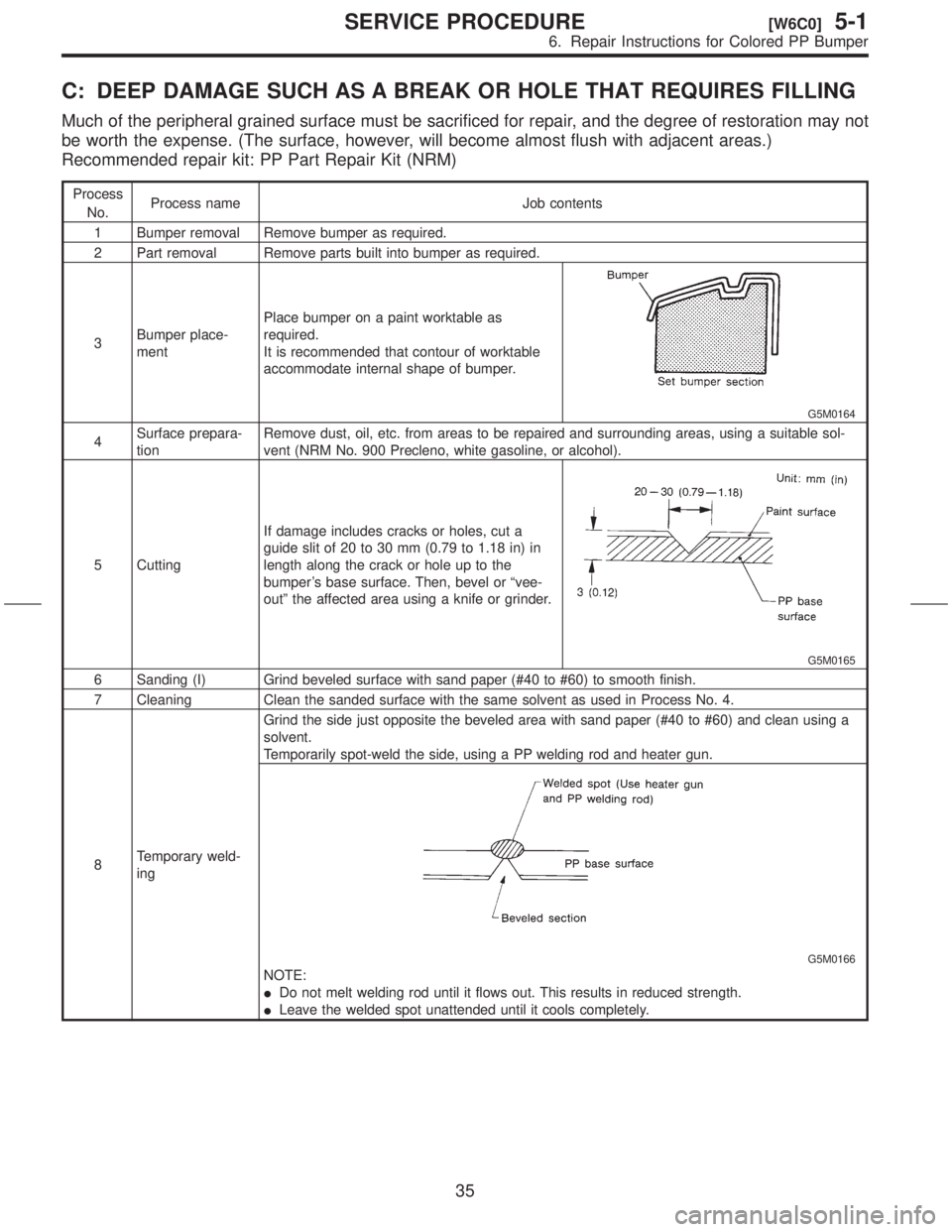

3Bumper place-

mentPlace bumper on a paint worktable as

required.

It is recommended that contour of worktable

accommodate internal shape of bumper.

G5M0164

4Surface prepara-

tionRemove dust, oil, etc. from areas to be repaired and surrounding areas, using a suitable sol-

vent (NRM No. 900 Precleno, white gasoline, or alcohol).

5 CuttingIf damage includes cracks or holes, cut a

guide slit of 20 to 30 mm (0.79 to 1.18 in) in

length along the crack or hole up to the

bumper's base surface. Then, bevel or ªvee-

outº the affected area using a knife or grinder.

G5M0165

6 Sanding (I) Grind beveled surface with sand paper (#40 to #60) to smooth finish.

7 Cleaning Clean the sanded surface with the same solvent as used in Process No. 4.

8Temporary weld-

ingGrind the side just opposite the beveled area with sand paper (#40 to #60) and clean using a

solvent.

Temporarily spot-weld the side, using a PP welding rod and heater gun.

G5M0166

NOTE:

IDo not melt welding rod until it flows out. This results in reduced strength.

ILeave the welded spot unattended until it cools completely.

35

[W6C0]5-1SERVICE PROCEDURE

6. Repair Instructions for Colored PP Bumper