oxygen SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1931 of 2870

FUEL INJECTION (FUEL SYSTEM)

FU(H4DOTC 2.5)

Page

1. General Description ....................................................................................2

2. Throttle Body .............................................................................................13

3. Intake Manifold ..........................................................................................14

4. Engine Coolant Temperature Sensor........................................................26

5. Crankshaft Position Sensor.......................................................................27

6. Camshaft Position Sensor.........................................................................28

7. Knock Sensor ............................................................................................29

8. Mass Air Flow and Intake Air Temperature Sensor ..................................30

9. Manifold Absolute Pressure Sensor ..........................................................31

10. Fuel Injector ..............................................................................................32

11. Tumble Generator Valve Assembly ..........................................................33

12. Tumble Generator Valve Actuator.............................................................34

13. Wastegate Control Solenoid Valve ...........................................................35

14. Front Oxygen (A/F) Sensor .......................................................................36

15. Rear Oxygen Sensor.................................................................................38

16. Exhaust Temperature Sensor ...................................................................40

17. Engine Control Module (ECM) ..................................................................41

18. Main Relay ................................................................................................42

19. Fuel Pump Relay.......................................................................................43

20. Fuel Pump Control Unit .............................................................................44

21. Fuel ...........................................................................................................45

22. Fuel Tank ..................................................................................................46

23. Fuel Filler Pipe ..........................................................................................48

24. Fuel Pump .................................................................................................52

25. Fuel Level Sensor .....................................................................................54

26. Fuel Sub Level Sensor ..............................................................................55

27. Fuel Filter ..................................................................................................57

28. Fuel Cut Valve...........................................................................................58

29. Fuel Damper Valve ...................................................................................59

30. Fuel Delivery, Return and Evaporation Lines............................................60

31. Fuel System Trouble in General ...............................................................63

Page 1966 of 2870

FU(H4DOTC 2.5)-36

FUEL INJECTION (FUEL SYSTEM)

Front Oxygen (A/F) Sensor

14.Front Oxygen (A/F) Sensor

A: REMOVAL

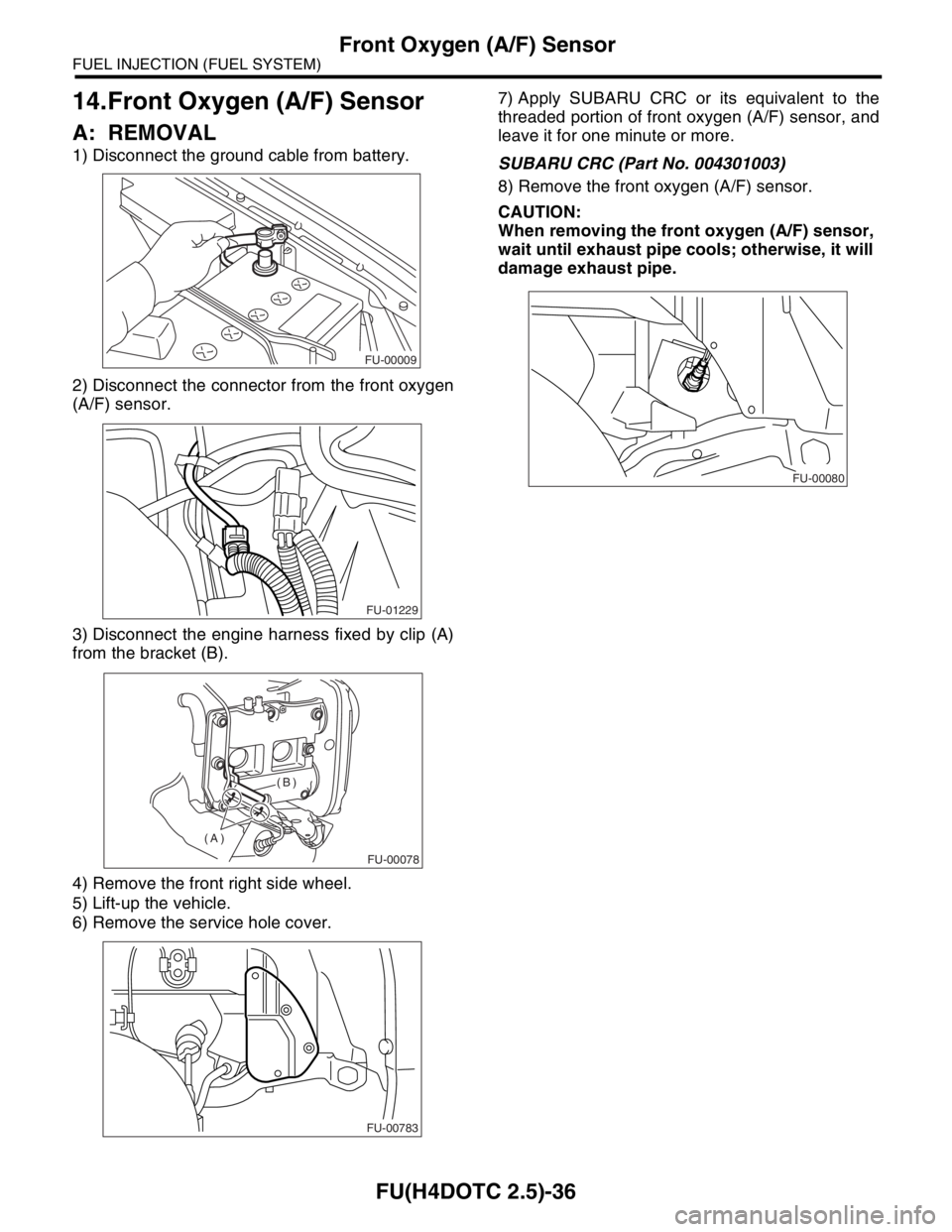

1) Disconnect the ground cable from battery.

2) Disconnect the connector from the front oxygen

(A/F) sensor.

3) Disconnect the engine harness fixed by clip (A)

from the bracket (B).

4) Remove the front right side wheel.

5) Lift-up the vehicle.

6) Remove the service hole cover.7) Apply SUBARU CRC or its equivalent to the

threaded portion of front oxygen (A/F) sensor, and

leave it for one minute or more.

SUBARU CRC (Part No. 004301003)

8) Remove the front oxygen (A/F) sensor.

CAUTION:

When removing the front oxygen (A/F) sensor,

wait until exhaust pipe cools; otherwise, it will

damage exhaust pipe.

FU-00009

FU-01229

FU-00078

(A)(B)

FU-00783

FU-00080

Page 1967 of 2870

FU(H4DOTC 2.5)-37

FUEL INJECTION (FUEL SYSTEM)

Front Oxygen (A/F) Sensor

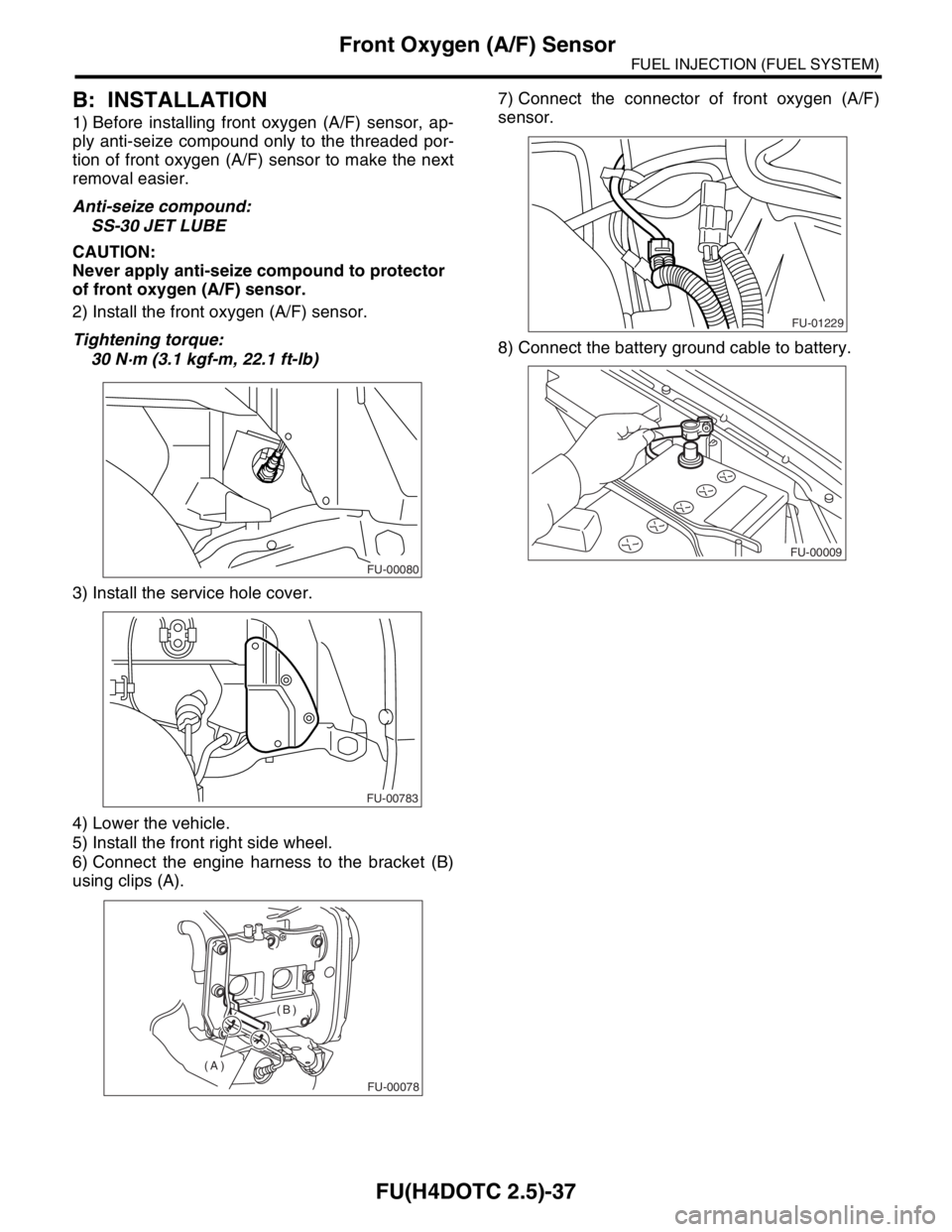

B: INSTALLATION

1) Before installing front oxygen (A/F) sensor, ap-

ply anti-seize compound only to the threaded por-

tion of front oxygen (A/F) sensor to make the next

removal easier.

Anti-seize compound:

SS-30 JET LUBE

CAUTION:

Never apply anti-seize compound to protector

of front oxygen (A/F) sensor.

2) Install the front oxygen (A/F) sensor.

Tightening torque:

30 N·m (3.1 kgf-m, 22.1 ft-lb)

3) Install the service hole cover.

4) Lower the vehicle.

5) Install the front right side wheel.

6) Connect the engine harness to the bracket (B)

using clips (A).7) Connect the connector of front oxygen (A/F)

sensor.

8) Connect the battery ground cable to battery.

FU-00080

FU-00783

FU-00078

(A)(B)

FU-01229

FU-00009

Page 1968 of 2870

FU(H4DOTC 2.5)-38

FUEL INJECTION (FUEL SYSTEM)

Rear Oxygen Sensor

15.Rear Oxygen Sensor

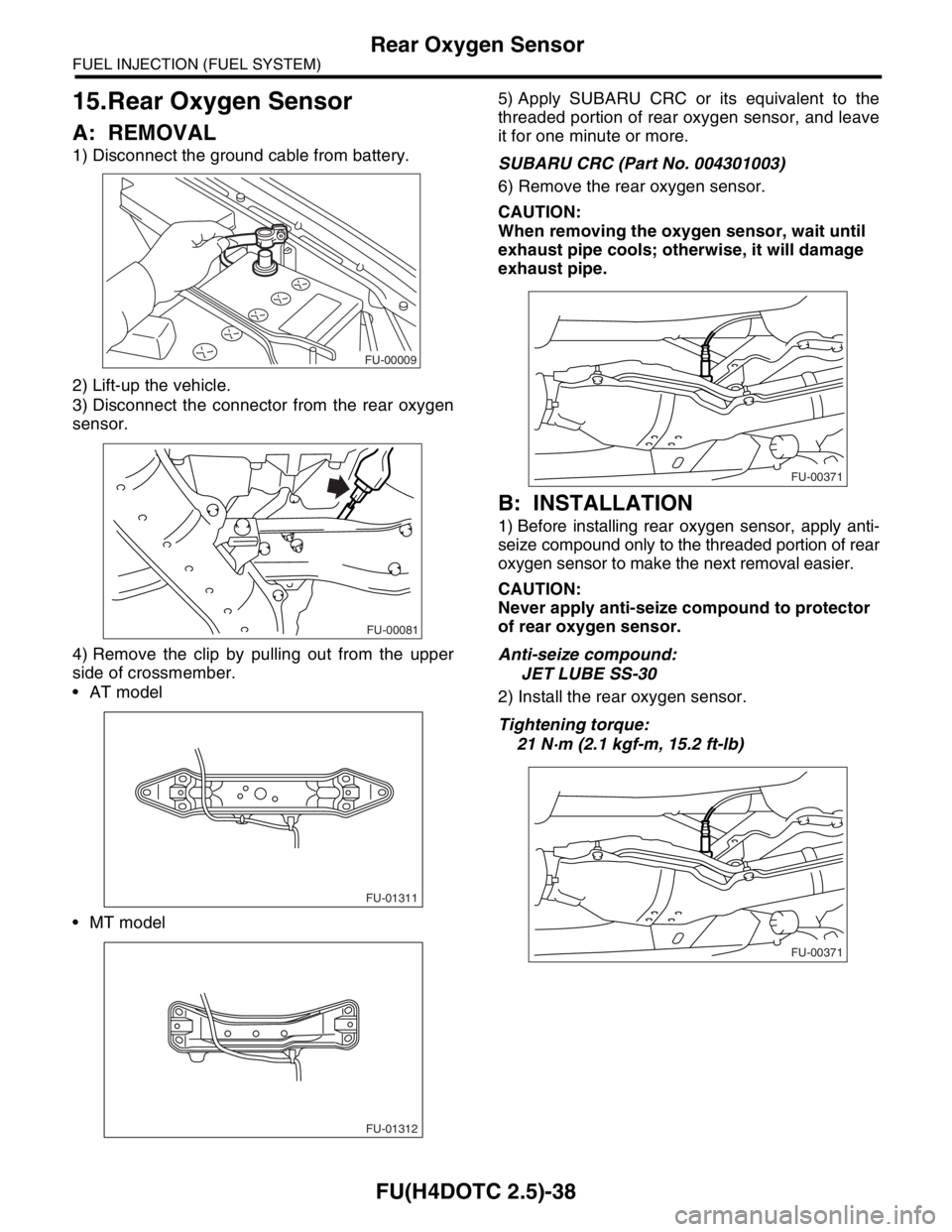

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Lift-up the vehicle.

3) Disconnect the connector from the rear oxygen

sensor.

4) Remove the clip by pulling out from the upper

side of crossmember.

AT model

MT model5) Apply SUBARU CRC or its equivalent to the

threaded portion of rear oxygen sensor, and leave

it for one minute or more.

SUBARU CRC (Part No. 004301003)

6) Remove the rear oxygen sensor.

CAUTION:

When removing the oxygen sensor, wait until

exhaust pipe cools; otherwise, it will damage

exhaust pipe.

B: INSTALLATION

1) Before installing rear oxygen sensor, apply anti-

seize compound only to the threaded portion of rear

oxygen sensor to make the next removal easier.

CAUTION:

Never apply anti-seize compound to protector

of rear oxygen sensor.

Anti-seize compound:

JET LUBE SS-30

2) Install the rear oxygen sensor.

Tightening torque:

21 N·m (2.1 kgf-m, 15.2 ft-lb)

FU-00009

FU-00081

FU-01311

FU-01312

FU-00371

FU-00371

Page 1969 of 2870

FU(H4DOTC 2.5)-39

FUEL INJECTION (FUEL SYSTEM)

Rear Oxygen Sensor

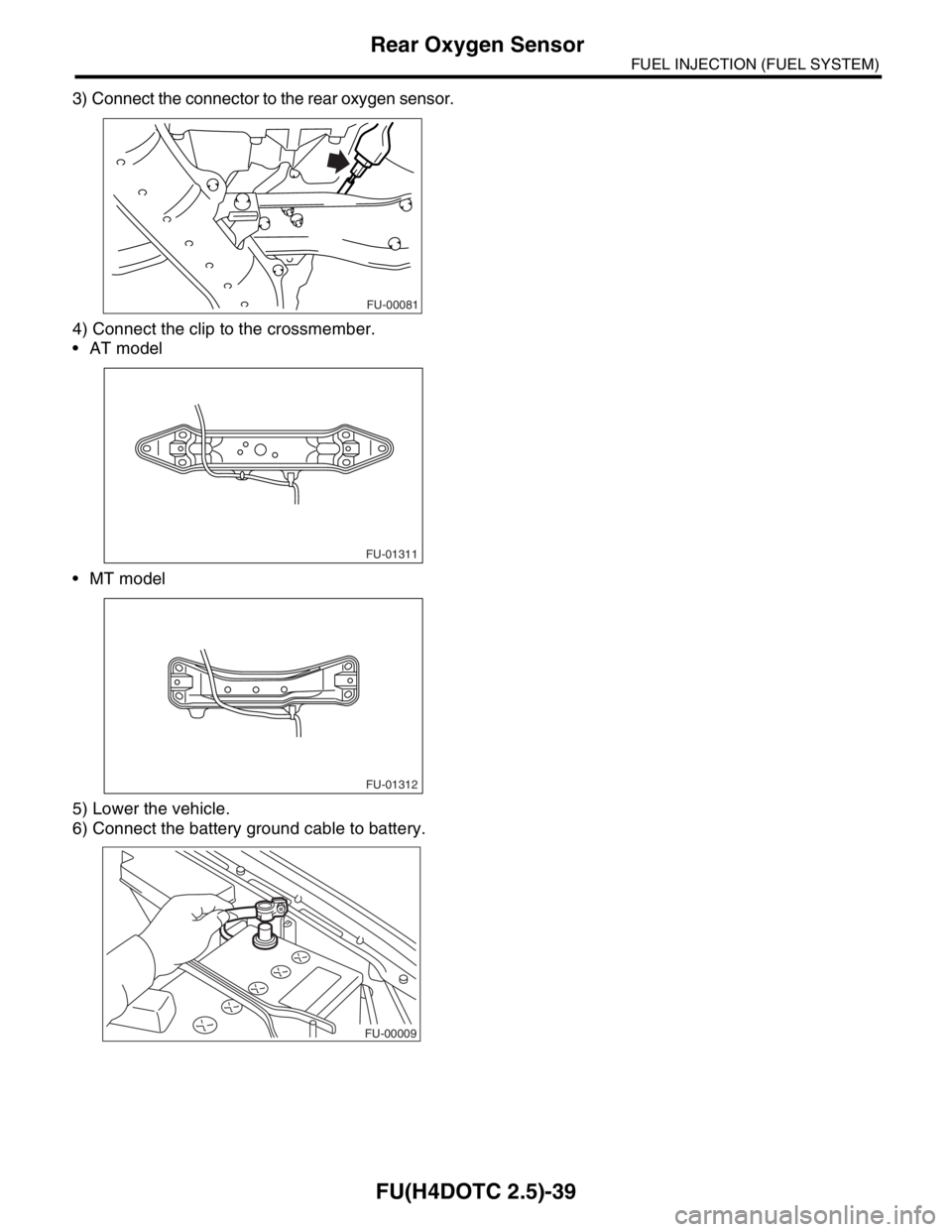

3) Connect the connector to the rear oxygen sensor.

4) Connect the clip to the crossmember.

AT model

MT model

5) Lower the vehicle.

6) Connect the battery ground cable to battery.

FU-00081

FU-01311

FU-01312

FU-00009

Page 2035 of 2870

EN(H4DOTC 2.5)-11

ENGINE (DIAGNOSTIC)

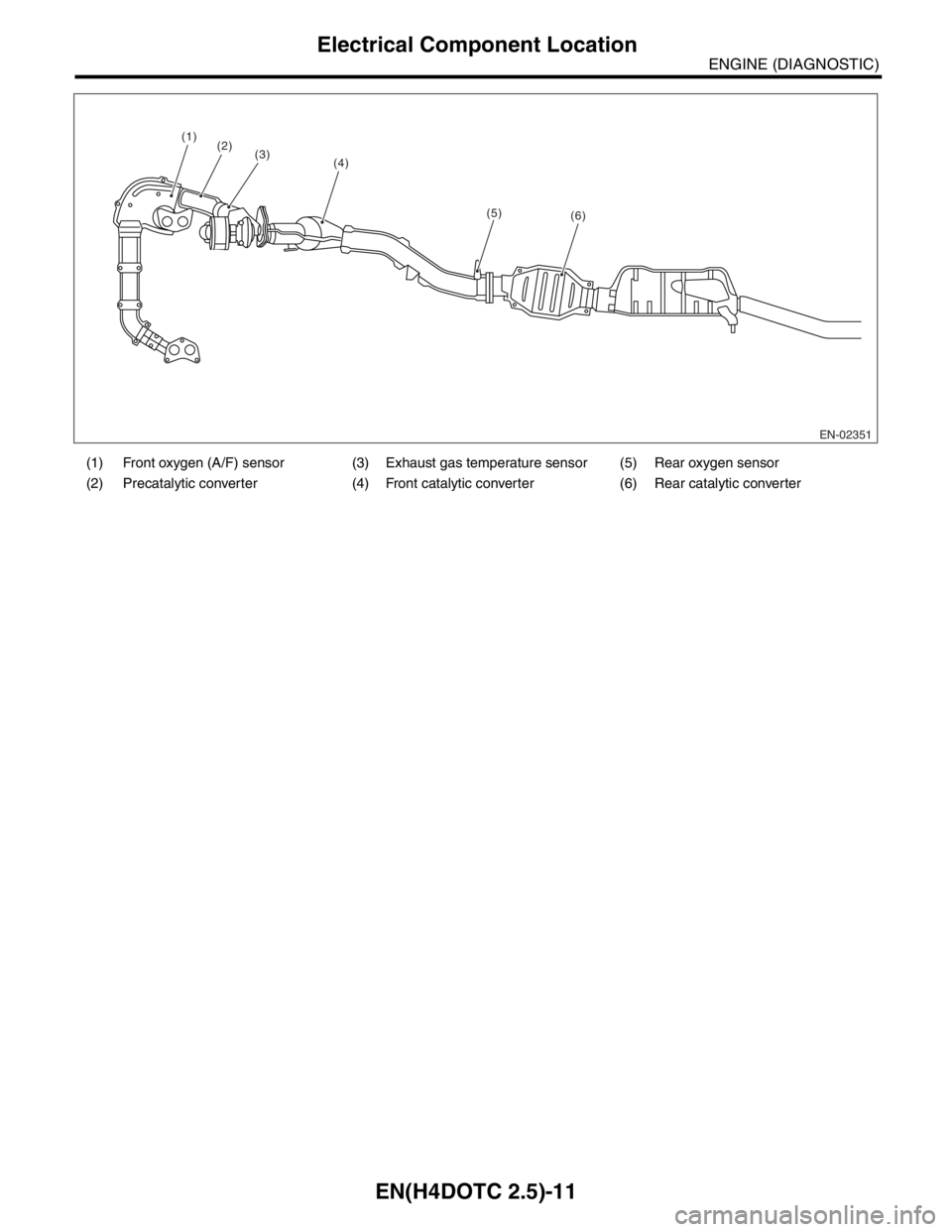

Electrical Component Location

(1) Front oxygen (A/F) sensor (3) Exhaust gas temperature sensor (5) Rear oxygen sensor

(2) Precatalytic converter (4) Front catalytic converter (6) Rear catalytic converter

EN-02351 (1)

(5)

(6)

(4)

(2)(3)

Page 2041 of 2870

EN(H4DOTC 2.5)-17

ENGINE (DIAGNOSTIC)

Engine Control Module (ECM) I/O Signal

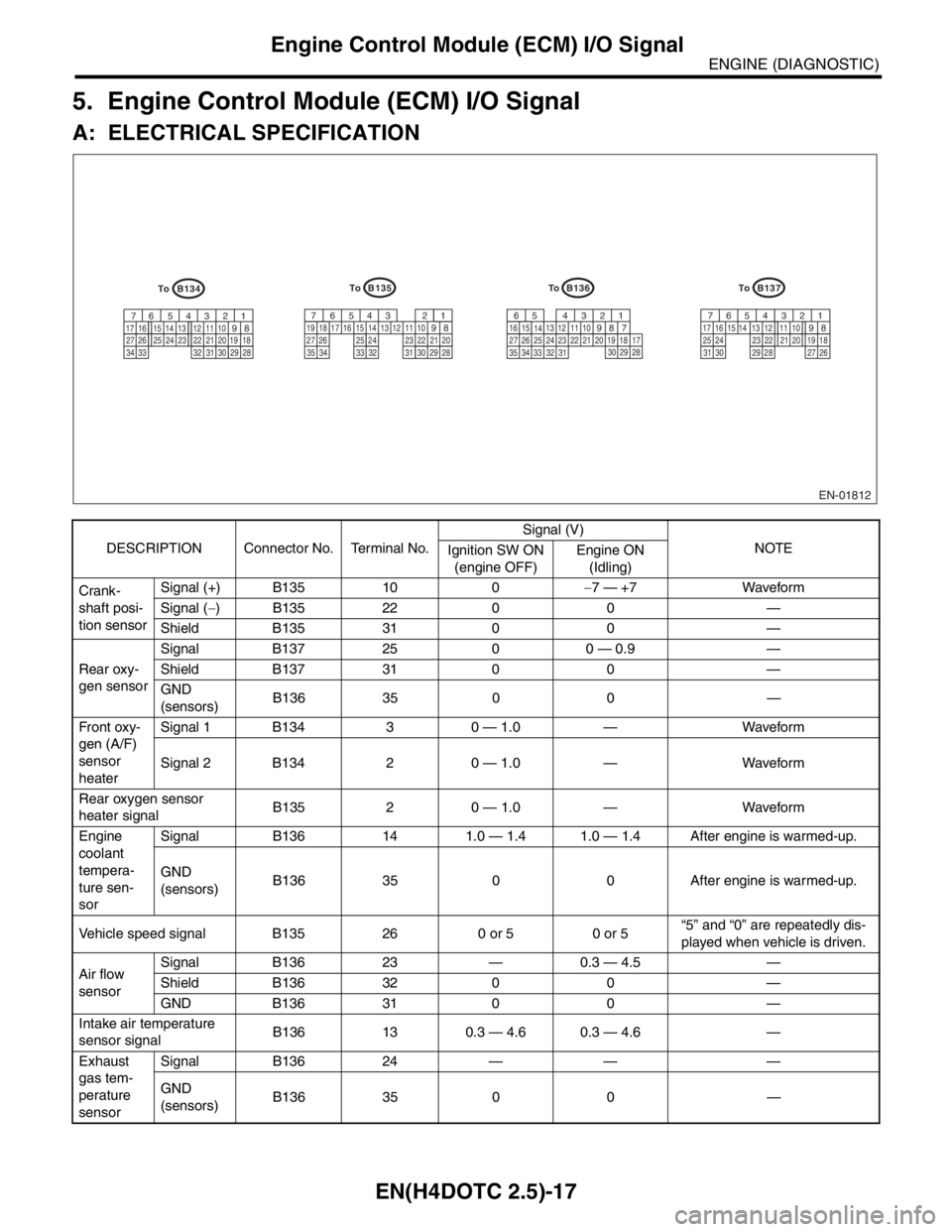

5. Engine Control Module (ECM) I/O Signal

A: ELECTRICAL SPECIFICATION

DESCRIPTION Connector No. Terminal No.Signal (V)

NOTE

Ignition SW ON

(engine OFF)Engine ON

(Idling)

Crank-

shaft posi-

tion sensorSignal (+) B135 10 0−7 — +7 Waveform

Signal (−) B135 22 0 0 —

Shield B135 31 0 0 —

Rear oxy-

gen sensorSignal B137 25 0 0 — 0.9 —

Shield B137 31 0 0 —

GND

(sensors)B136 35 0 0 —

Fr o nt ox y-

gen (A/F)

sensor

heaterSignal 1 B134 3 0 — 1.0 — Waveform

Signal 2 B134 2 0 — 1.0 — Waveform

Rear oxygen sensor

heater signalB135 2 0 — 1.0 — Waveform

Engine

coolant

tempera-

ture sen-

sorSignal B136 14 1.0 — 1.4 1.0 — 1.4 After engine is warmed-up.

GND

(sensors)B136 35 0 0 After engine is warmed-up.

Vehicle speed signal B135 26 0 or 5 0 or 5“5” and “0” are repeatedly dis-

played when vehicle is driven.

Air flow

sensorSignal B136 23 — 0.3 — 4.5 —

Shield B136 32 0 0 —

GND B136 31 0 0 —

Intake air temperature

sensor signalB136 13 0.3 — 4.6 0.3 — 4.6 —

Exhaust

gas tem-

perature

sensorSignal B136 24 — — —

GND

(sensors)B136 35 0 0 —

EN-01812

B134

5 6 7

8 21

9 43

10

24 2223 2511 12 13 14 15

26 27

28 16 17

18 19 20 21

33 34 29

32 3031

B136

5 6

7 8 21

9 43

10

24 2223 2511 12 13

14 15

26 27

28 16

17 18 19 20 21

33 3429

3230

31 35

B135

5 6 7

8 21

9 43

10

24 2223 2511 12 13 14 15

26 27

28 16 17 18 19

20 21

29 30 31 32 33 34 35

B137

5 6 7

8 21

9 43

10

22 2311 12 13 14 15

24 25

26 16 17

18 19 20 21

27 28 29 30 31

To

To To

To

Page 2043 of 2870

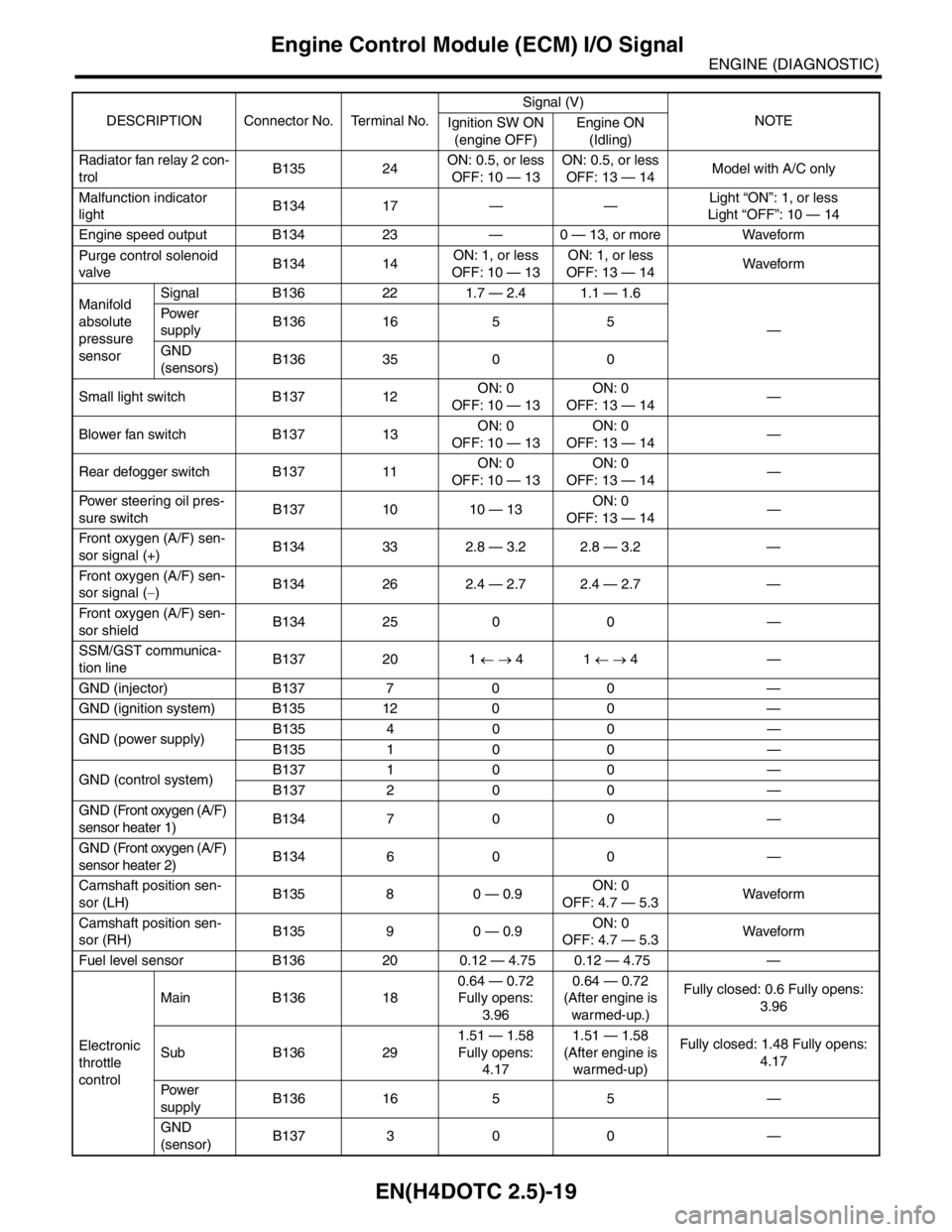

EN(H4DOTC 2.5)-19

ENGINE (DIAGNOSTIC)

Engine Control Module (ECM) I/O Signal

Radiator fan relay 2 con-

trolB135 24ON: 0.5, or less

OFF: 10 — 13ON: 0.5, or less

OFF: 13 — 14Model with A/C only

Malfunction indicator

lightB134 17 — —Light “ON”: 1, or less

Light “OFF”: 10 — 14

Engine speed output B134 23 — 0 — 13, or more Waveform

Purge control solenoid

valveB134 14ON: 1, or less

OFF: 10 — 13ON: 1, or less

OFF: 13 — 14Wavefor m

Manifold

absolute

pressure

sensorSignal B136 22 1.7 — 2.4 1.1 — 1.6

— Pow er

supplyB136 16 5 5

GND

(sensors)B136 35 0 0

Small light switch B137 12ON: 0

OFF: 10 — 13ON: 0

OFF: 13 — 14—

Blower fan switch B137 13ON: 0

OFF: 10 — 13ON: 0

OFF: 13 — 14—

Rear defogger switch B137 11ON: 0

OFF: 10 — 13ON: 0

OFF: 13 — 14—

Power steering oil pres-

sure switchB137 10 10 — 13ON: 0

OFF: 13 — 14—

Front oxygen (A/F) sen-

sor signal (+)B134 33 2.8 — 3.2 2.8 — 3.2 —

Front oxygen (A/F) sen-

sor signal (−)B134 26 2.4 — 2.7 2.4 — 2.7 —

Front oxygen (A/F) sen-

sor shieldB134 25 0 0 —

SSM/GST communica-

tion lineB137 20 1 ← → 41 ← → 4—

GND (injector) B137 7 0 0 —

GND (ignition system) B135 12 0 0 —

GND (power supply)B135 4 0 0 —

B135 1 0 0 —

GND (control system)B137 1 0 0 —

B137 2 0 0 —

GND (Front oxygen (A/F)

sensor heater 1)B134 7 0 0 —

GND (Front oxygen (A/F)

sensor heater 2)B134 6 0 0 —

Camshaft position sen-

sor (LH)B135 8 0 — 0.9ON: 0

OFF: 4.7 — 5.3Wavefor m

Camshaft position sen-

sor (RH)B135 9 0 — 0.9ON: 0

OFF: 4.7 — 5.3Wavefor m

Fuel level sensor B136 20 0.12 — 4.75 0.12 — 4.75 —

Electronic

throttle

controlMain B136 180.64 — 0.72

Fully opens:

3.960.64 — 0.72

(After engine is

warmed-up.)Fully closed: 0.6 Fully opens:

3.96

Sub B136 291.51 — 1.58

Fully opens:

4.171.51 — 1.58

(After engine is

warmed-up)Fully closed: 1.48 Fully opens:

4.17

Pow er

supplyB136 16 5 5 —

GND

(sensor)B137 3 0 0 — DESCRIPTION Connector No. Terminal No.Signal (V)

NOTE

Ignition SW ON

(engine OFF)Engine ON

(Idling)

Page 2049 of 2870

EN(H4DOTC 2.5)-25

ENGINE (DIAGNOSTIC)

OBD-II General Scan Tool

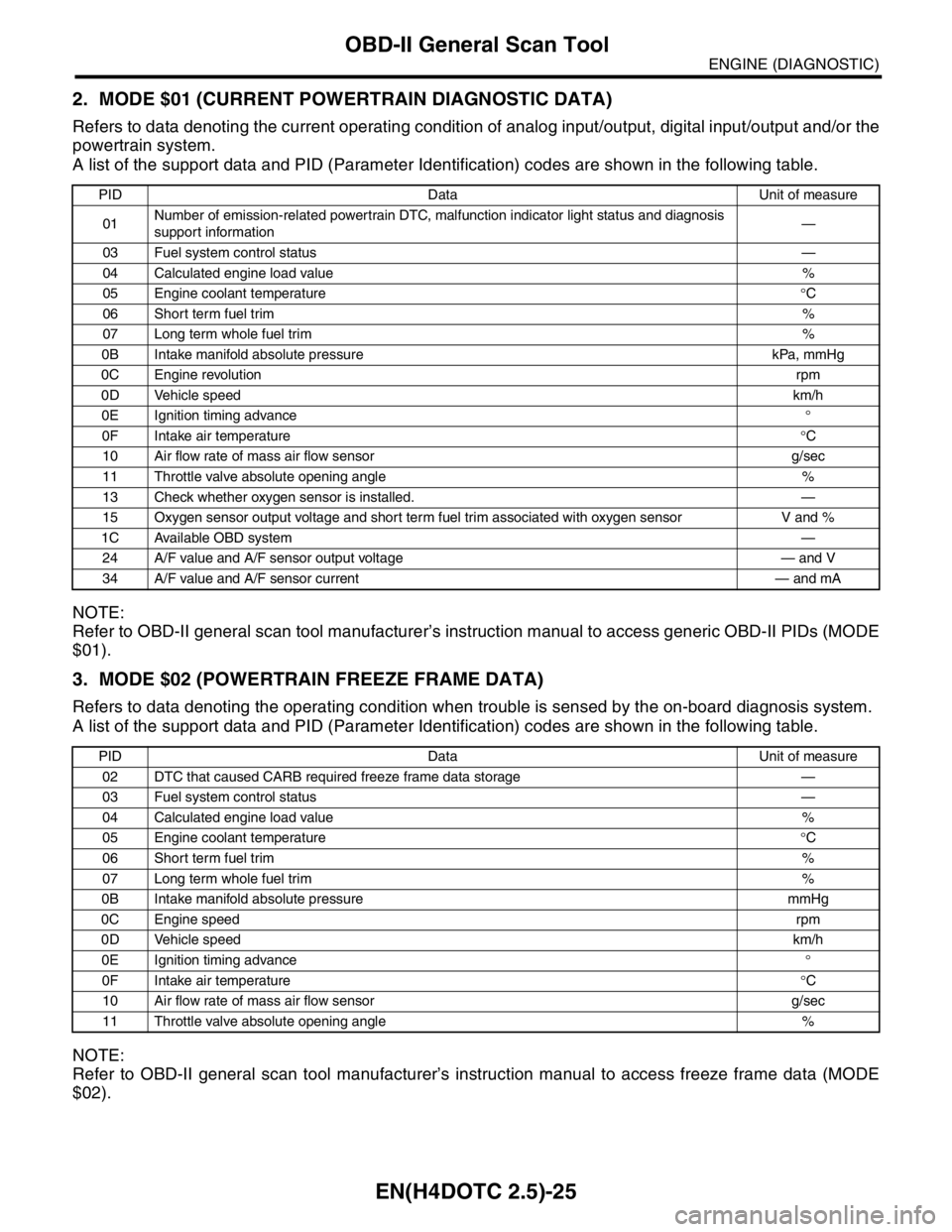

2. MODE $01 (CURRENT POWERTRAIN DIAGNOSTIC DATA)

Refers to data denoting the current operating condition of analog input/output, digital input/output and/or the

powertrain system.

A list of the support data and PID (Parameter Identification) codes are shown in the following table.

NOTE:

Refer to OBD-II general scan tool manufacturer’s instruction manual to access generic OBD-II PIDs (MODE

$01).

3. MODE $02 (POWERTRAIN FREEZE FRAME DATA)

Refers to data denoting the operating condition when trouble is sensed by the on-board diagnosis system.

A list of the support data and PID (Parameter Identification) codes are shown in the following table.

NOTE:

Refer to OBD-II general scan tool manufacturer’s instruction manual to access freeze frame data (MODE

$02).

PID Data Unit of measure

01Number of emission-related powertrain DTC, malfunction indicator light status and diagnosis

support information—

03 Fuel system control status—

04 Calculated engine load value%

05 Engine coolant temperature°C

06 Short term fuel trim%

07 Long term whole fuel trim%

0B Intake manifold absolute pressure kPa, mmHg

0C Engine revolutionrpm

0D Vehicle speedkm/h

0E Ignition timing advance°

0F Intake air temperature°C

10 Air flow rate of mass air flow sensor g/sec

11 Throttle valve absolute opening angle %

13 Check whether oxygen sensor is installed. —

15 Oxygen sensor output voltage and short term fuel trim associated with oxygen sensor V and %

1C Available OBD system—

24 A/F value and A/F sensor output voltage — and V

34 A/F value and A/F sensor current — and mA

PID Data Unit of measure

02 DTC that caused CARB required freeze frame data storage —

03 Fuel system control status—

04 Calculated engine load value%

05 Engine coolant temperature°C

06 Short term fuel trim%

07 Long term whole fuel trim%

0B Intake manifold absolute pressure mmHg

0C Engine speedrpm

0D Vehicle speedkm/h

0E Ignition timing advance°

0F Intake air temperature°C

10 Air flow rate of mass air flow sensor g/sec

11 Throttle valve absolute opening angle %

Page 2052 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4DOTC 2.5)-28

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

4. READ CURRENT DATA FOR ENGINE. (NORMAL MODE)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] ke SUBARU FORESTER 2004 Service Repair Manual EN(H4DOTC 2.5)-28

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

4. READ CURRENT DATA FOR ENGINE. (NORMAL MODE)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] ke](/img/17/57426/w960_57426-2051.png)

EN(H4DOTC 2.5)-28

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

4. READ CURRENT DATA FOR ENGINE. (NORMAL MODE)

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Engine} and press the [YES] key.

3) Press the [YES] key after the information of engine type was displayed.

4) On the «Engine Diagnosis» screen, select the {Current Data Display/Save}, and then press the [YES] key.

5) On the «Data Display Menu» screen, select the {Data Display} and press the [YES] key.

6) Using the scroll key, move the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

Remarks Display Unit of measure

Battery voltage Battery Voltage V

Vehicle speed signal Vehicle Speed km/h or MPH

Engine speed signal Engine Speed rpm

Engine coolant temperature signal Coolant Temp.°C or °F

Ignition timing signal Ignition Timing deg

Throttle position signal Throttle Opening Angle %

Injection pulse width Fuel Injection #1 Pulse ms

Fuel pump duty control signal Fuel Pump Duty %

A/F sensor current A/F Sensor #1 Current mA

A/F sensor resistance A/F Sensor #1 ResistanceΩ

Front oxygen (A/F) sensor lambda value A/F Sensor #1 —

Rear oxygen sensor output signalRear O

2 Sensor

V

Short term fuel trim A/F Correction #1 %

Knock sensor compensation Knocking Correction deg

Atmospheric pressure signal Atmosphere Pressure mmHg, kPa, inHg or psi

Intake manifold relative pressure signal Mani. Relative Pressure mmHg, kPa, inHg or psi

Intake manifold absolute pressure signal Mani. Absolute Pressure mmHg, kPa, inHg or psi

A/F correction (short term fuel trim) by rear oxygen sensor A/F Correction #3 %

Long term whole fuel trim A/F Learning #1 %

Canister purge control solenoid valve duty ratio CPC Valve Duty Ratio %

Primary supercharged pressure control signal Primary Control %

Tumble generated valve position sensor signal (RH side) TGV Position Sensor R V

Tumble generated valve position sensor signal (LH side) TGV Position Sensor L V

Acceleration opening angle Accel Opening Angle %

VVT advance angle amount (R) VVT Adv. Amount R deg

VVT advance angle amount (L) VVT Adv. amount L deg

OCV duty R OCV Duty R %

OCV duty L OCV Duty L %

OCV current R OCV current R mA

OCV current L OCV Current L mA

Throttle motor duty Throttle Motor Duty %

Throttle power supply voltage Throttle Motor Voltage V

Sub throttle sensor voltage Sub-Throttle Sensor V

Main throttle sensor voltage Main-Throttle Sensor V

Sub acceleration sensor voltage Sub-Accelerator Sensor V

Main acceleration sensor voltage Main-Accelerator Sensor V

Memory vehicle speed Memorized Cruise Speed km/h

Alternate duty ratio ALT Duty %

Exhaust gas temperature signal Exhaust gas temperature°C

Estimated cumulative driving distance Odd Meter Km

Fuel level signal Fuel Level Voltage V

Intake air temperature signal Intake Air Temp.°C or °F

Mass air flow sensor signal Mass Air Flow g/s