oxygen SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2135 of 2870

EN(H4DOTC 2.5)-111

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

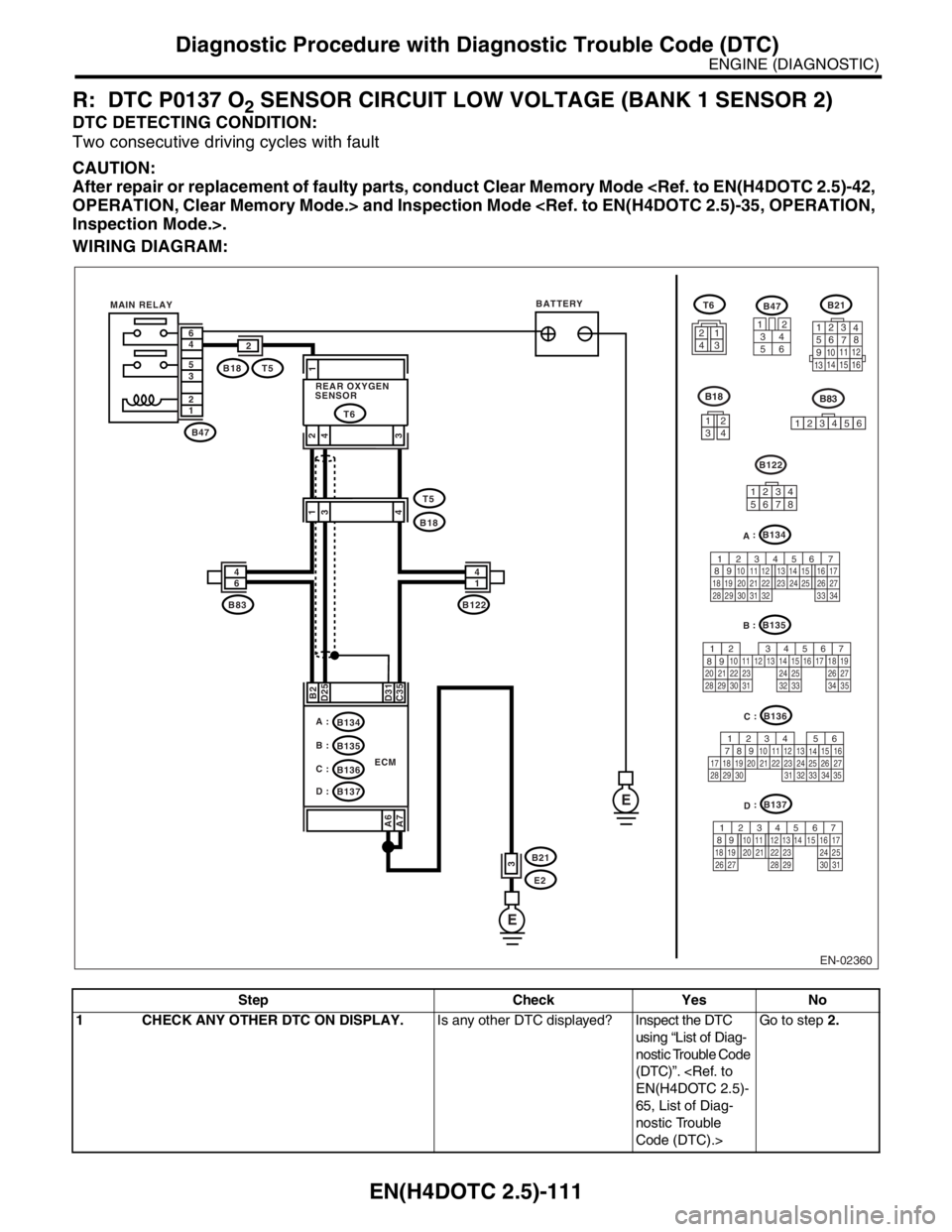

R: DTC P0137 O2 SENSOR CIRCUIT LOW VOLTAGE (BANK 1 SENSOR 2)

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the DTC

using “List of Diag-

nostic Trouble Code

(DTC)”.

65, List of Diag-

nostic Trouble

Code (DTC).>Go to step 2.

EN-02360

B122 B47 1 2 3 5 4 6

E

E

B21

E23

4

1

B122

34 12

56123

4

56

78

9

1011 12

1314 15 16

: B134

: B135B21

B47 T6

: B136 T6

A6

A7B2

D25

D31

C35

C : B :

D :

4

6

B83A

B

C

B136

B137 B135 B134 A :

: B137

D

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

ECM MAIN RELAYBATTERY

REAR OXYGEN

SENSOR

12345678

B18 T52

B18

T5

B18

1234

B83

1

23456

1234

3 1

4

1

2

4

3

Page 2136 of 2870

EN(H4DOTC 2.5)-112

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

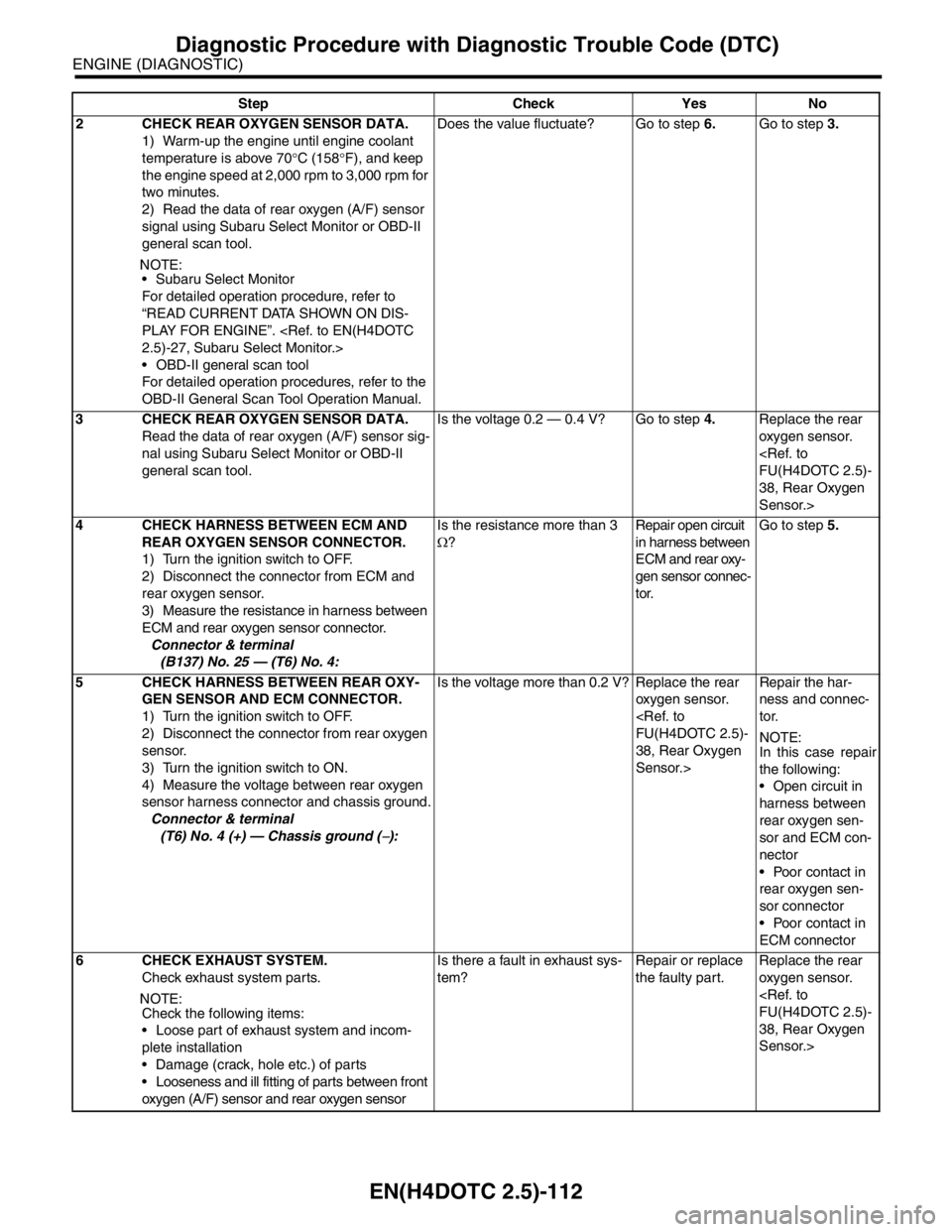

2 CHECK REAR OXYGEN SENSOR DATA.

1) Warm-up the engine until engine coolant

temperature is above 70°C (158°F), and keep

the engine speed at 2,000 rpm to 3,000 rpm for

two minutes.

2) Read the data of rear oxygen (A/F) sensor

signal using Subaru Select Monitor or OBD-II

general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Does the value fluctuate? Go to step 6.Go to step 3.

3 CHECK REAR OXYGEN SENSOR DATA.

Read the data of rear oxygen (A/F) sensor sig-

nal using Subaru Select Monitor or OBD-II

general scan tool.Is the voltage 0.2 — 0.4 V? Go to step 4.Replace the rear

oxygen sensor.

38, Rear Oxygen

Sensor.>

4 CHECK HARNESS BETWEEN ECM AND

REAR OXYGEN SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

rear oxygen sensor.

3) Measure the resistance in harness between

ECM and rear oxygen sensor connector.

Connector & terminal

(B137) No. 25 — (T6) No. 4:Is the resistance more than 3

Ω?Repair open circuit

in harness between

ECM and rear oxy-

gen sensor connec-

tor.Go to step 5.

5 CHECK HARNESS BETWEEN REAR OXY-

GEN SENSOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from rear oxygen

sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between rear oxygen

sensor harness connector and chassis ground.

Connector & terminal

(T6) No. 4 (+) — Chassis ground (

−):Is the voltage more than 0.2 V? Replace the rear

oxygen sensor.

38, Rear Oxygen

Sensor.>Repair the har-

ness and connec-

tor.

NOTE:

In this case repair

the following:

Open circuit in

harness between

rear oxygen sen-

sor and ECM con-

nector

Poor contact in

rear oxygen sen-

sor connector

Poor contact in

ECM connector

6 CHECK EXHAUST SYSTEM.

Check exhaust system parts.

N

OTE:

Check the following items:

Loose part of exhaust system and incom-

plete installation

Damage (crack, hole etc.) of parts

Looseness and ill fitting of parts between front

oxygen (A/F) sensor and rear oxygen sensorIs there a fault in exhaust sys-

tem?Repair or replace

the faulty par t.Replace the rear

oxygen sensor.

38, Rear Oxygen

Sensor.> Step Check Yes No

Page 2137 of 2870

EN(H4DOTC 2.5)-113

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

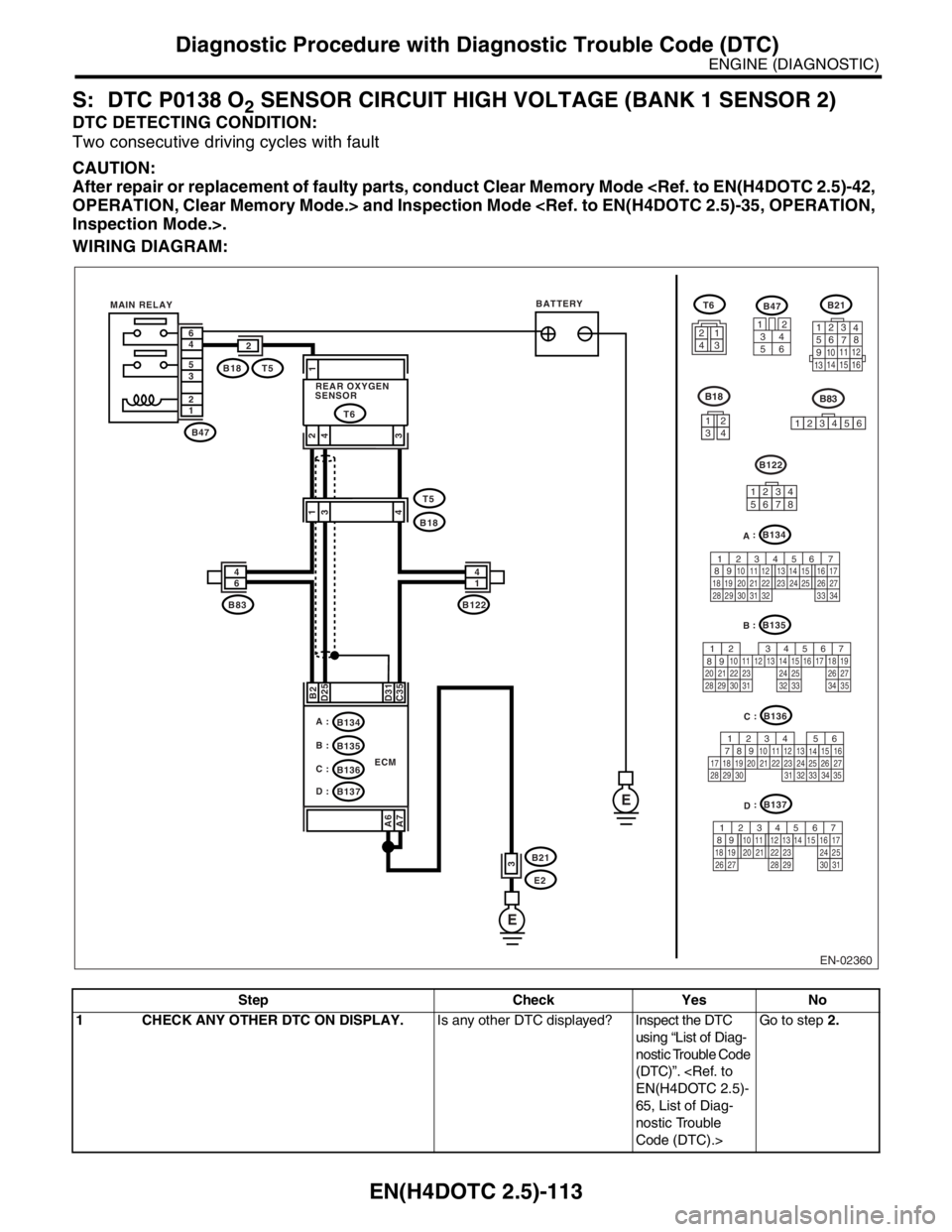

S: DTC P0138 O2 SENSOR CIRCUIT HIGH VOLTAGE (BANK 1 SENSOR 2)

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the DTC

using “List of Diag-

nostic Trouble Code

(DTC)”.

65, List of Diag-

nostic Trouble

Code (DTC).>Go to step 2.

EN-02360

B122 B47 1 2 3 5 4 6

E

E

B21

E23

4

1

B122

34 12

56123

4

56

78

9

1011 12

1314 15 16

: B134

: B135B21

B47 T6

: B136 T6

A6

A7B2

D25

D31

C35

C : B :

D :

4

6

B83A

B

C

B136

B137 B135 B134 A :

: B137

D

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

ECM MAIN RELAYBATTERY

REAR OXYGEN

SENSOR

12345678

B18 T52

B18

T5

B18

1234

B83

1

23456

1234

3 1

4

1

2

4

3

Page 2138 of 2870

EN(H4DOTC 2.5)-114

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

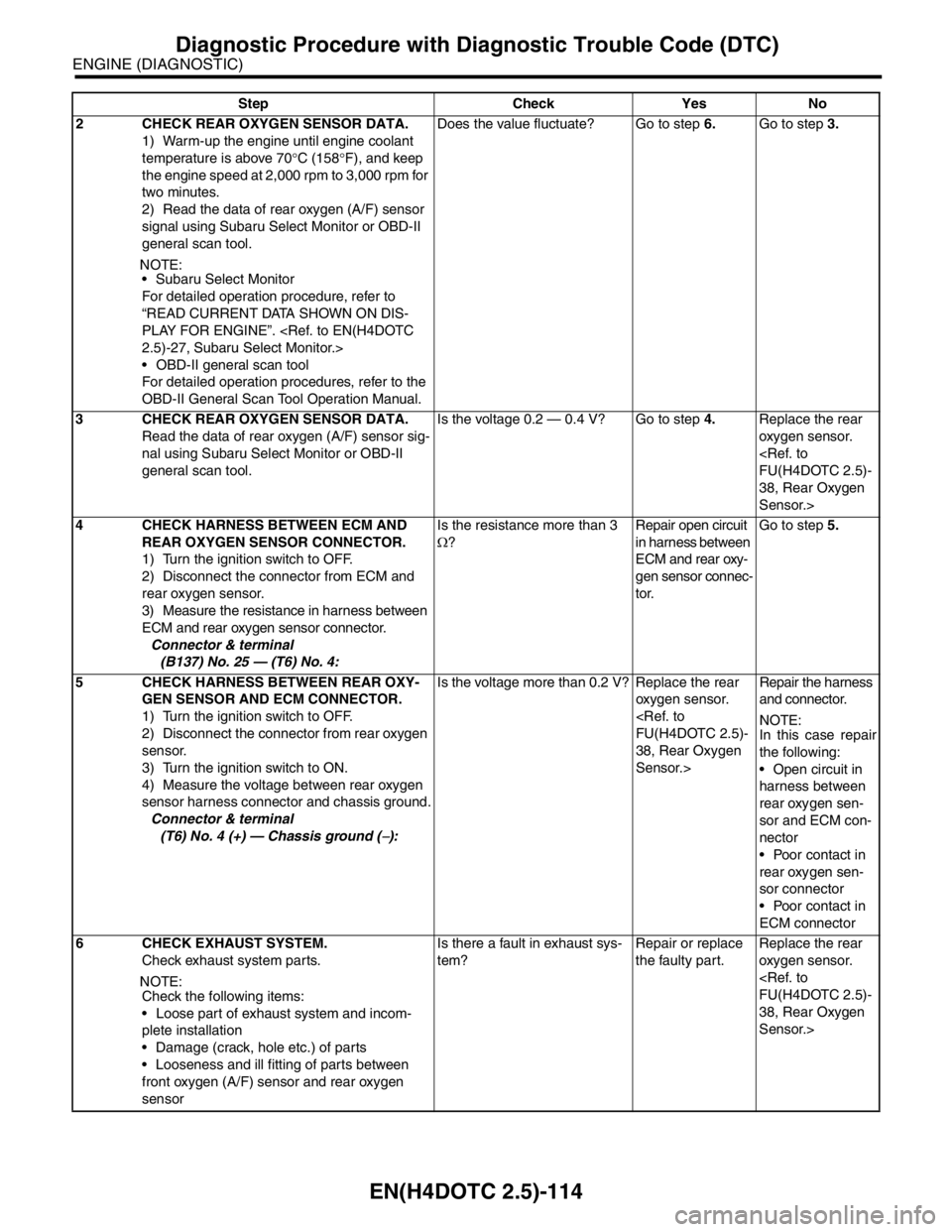

2 CHECK REAR OXYGEN SENSOR DATA.

1) Warm-up the engine until engine coolant

temperature is above 70°C (158°F), and keep

the engine speed at 2,000 rpm to 3,000 rpm for

two minutes.

2) Read the data of rear oxygen (A/F) sensor

signal using Subaru Select Monitor or OBD-II

general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Does the value fluctuate? Go to step 6.Go to step 3.

3 CHECK REAR OXYGEN SENSOR DATA.

Read the data of rear oxygen (A/F) sensor sig-

nal using Subaru Select Monitor or OBD-II

general scan tool.Is the voltage 0.2 — 0.4 V? Go to step 4.Replace the rear

oxygen sensor.

38, Rear Oxygen

Sensor.>

4 CHECK HARNESS BETWEEN ECM AND

REAR OXYGEN SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

rear oxygen sensor.

3) Measure the resistance in harness between

ECM and rear oxygen sensor connector.

Connector & terminal

(B137) No. 25 — (T6) No. 4:Is the resistance more than 3

Ω?Repair open circuit

in harness between

ECM and rear oxy-

gen sensor connec-

tor.Go to step 5.

5 CHECK HARNESS BETWEEN REAR OXY-

GEN SENSOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from rear oxygen

sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between rear oxygen

sensor harness connector and chassis ground.

Connector & terminal

(T6) No. 4 (+) — Chassis ground (

−):Is the voltage more than 0.2 V? Replace the rear

oxygen sensor.

38, Rear Oxygen

Sensor.>Repair the harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

rear oxygen sen-

sor and ECM con-

nector

Poor contact in

rear oxygen sen-

sor connector

Poor contact in

ECM connector

6 CHECK EXHAUST SYSTEM.

Check exhaust system parts.

N

OTE:

Check the following items:

Loose part of exhaust system and incom-

plete installation

Damage (crack, hole etc.) of parts

Looseness and ill fitting of parts between

front oxygen (A/F) sensor and rear oxygen

sensorIs there a fault in exhaust sys-

tem?Repair or replace

the faulty par t.Replace the rear

oxygen sensor.

38, Rear Oxygen

Sensor.> Step Check Yes No

Page 2237 of 2870

EN(H4DOTC 2.5)-213

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

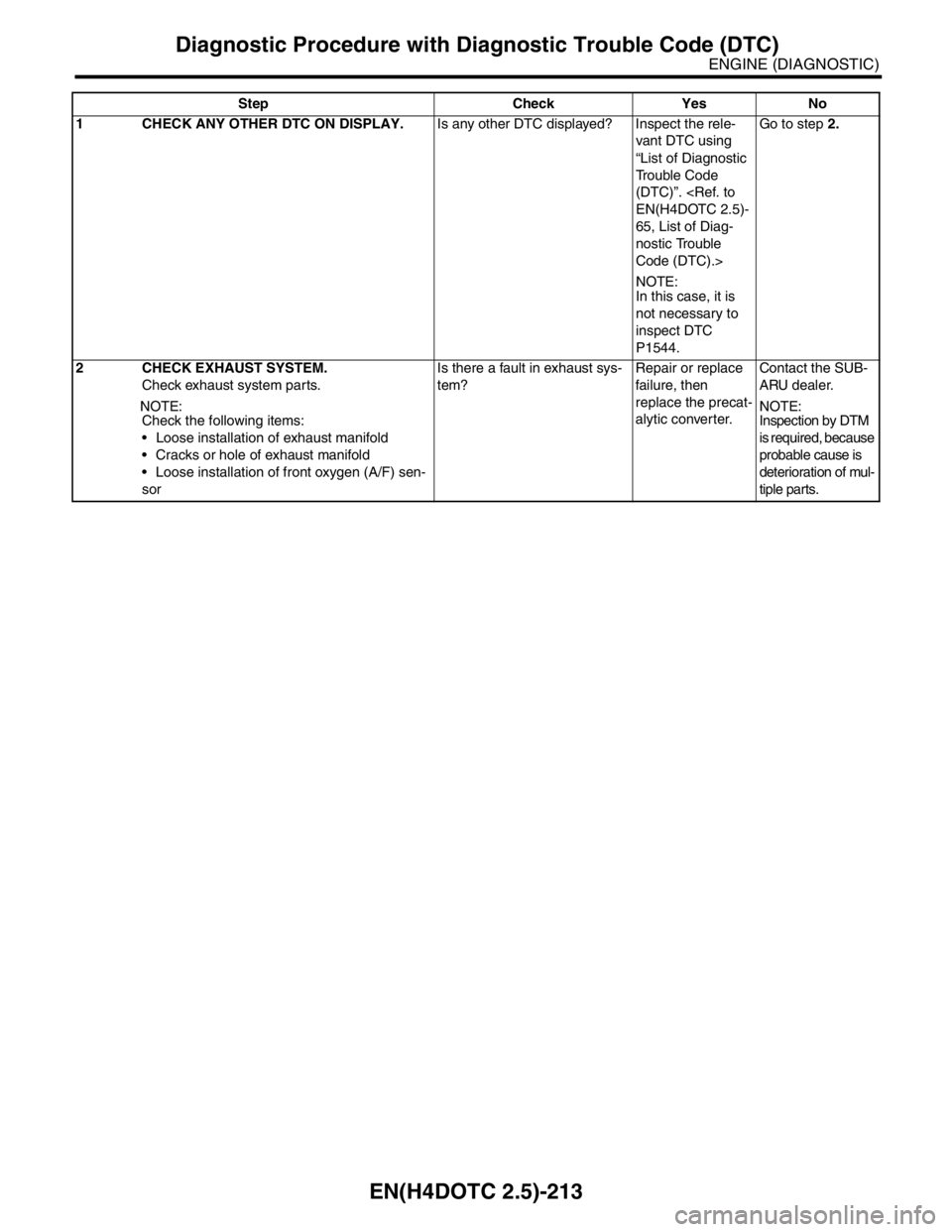

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

65, List of Diag-

nostic Trouble

Code (DTC).>

N

OTE:

In this case, it is

not necessary to

inspect DTC

P1544.Go to step 2.

2 CHECK EXHAUST SYSTEM.

Check exhaust system parts.

NOTE:

Check the following items:

Loose installation of exhaust manifold

Cracks or hole of exhaust manifold

Loose installation of front oxygen (A/F) sen-

sorIs there a fault in exhaust sys-

tem?Repair or replace

failure, then

replace the precat-

alytic converter.Contact the SUB-

ARU dealer.

NOTE:

Inspection by DTM

is required, because

probable cause is

deterioration of mul-

tiple parts.

Page 2282 of 2870

EN(H4DOTC 2.5)-258

ENGINE (DIAGNOSTIC)

General Diagnostic Table

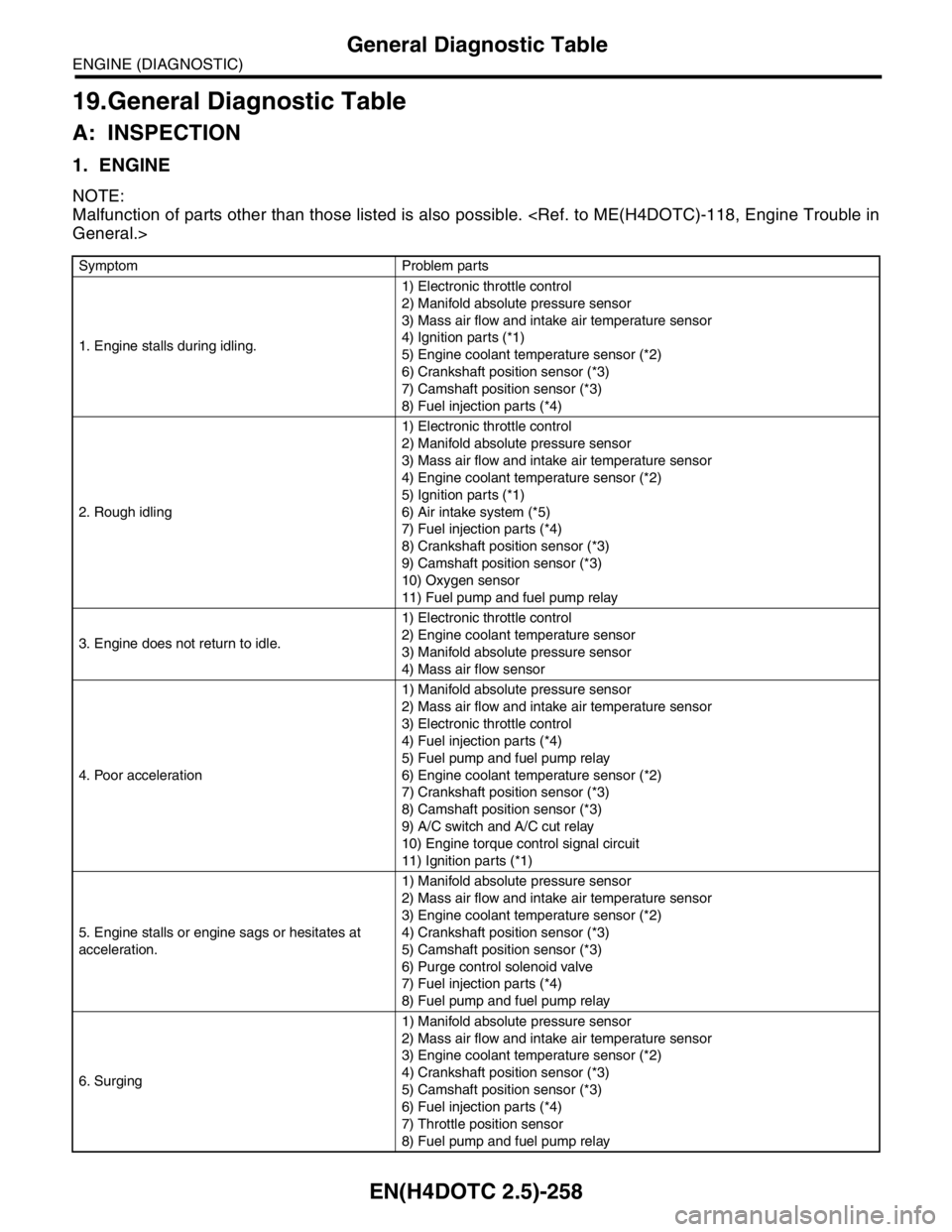

19.General Diagnostic Table

A: INSPECTION

1. ENGINE

NOTE:

Malfunction of parts other than those listed is also possible.

Symptom Problem parts

1. Engine stalls during idling.1) Electronic throttle control

2) Manifold absolute pressure sensor

3) Mass air flow and intake air temperature sensor

4) Ignition parts (*1)

5) Engine coolant temperature sensor (*2)

6) Crankshaft position sensor (*3)

7) Camshaft position sensor (*3)

8) Fuel injection parts (*4)

2. Rough idling1) Electronic throttle control

2) Manifold absolute pressure sensor

3) Mass air flow and intake air temperature sensor

4) Engine coolant temperature sensor (*2)

5) Ignition parts (*1)

6) Air intake system (*5)

7) Fuel injection parts (*4)

8) Crankshaft position sensor (*3)

9) Camshaft position sensor (*3)

10) Oxygen sensor

11) Fuel pump and fuel pump relay

3. Engine does not return to idle.1) Electronic throttle control

2) Engine coolant temperature sensor

3) Manifold absolute pressure sensor

4) Mass air flow sensor

4. Poor acceleration1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Electronic throttle control

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay

6) Engine coolant temperature sensor (*2)

7) Crankshaft position sensor (*3)

8) Camshaft position sensor (*3)

9) A/C switch and A/C cut relay

10) Engine torque control signal circuit

11) Ignition parts (*1)

5. Engine stalls or engine sags or hesitates at

acceleration.1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Purge control solenoid valve

7) Fuel injection parts (*4)

8) Fuel pump and fuel pump relay

6. Surging1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Fuel injection parts (*4)

7) Throttle position sensor

8) Fuel pump and fuel pump relay