combination meter SUBARU FORESTER 2004 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 170 of 2870

AB-38

AIRBAG SYSTEM (DIAGNOSTIC)

Airbag Warning Light Failure

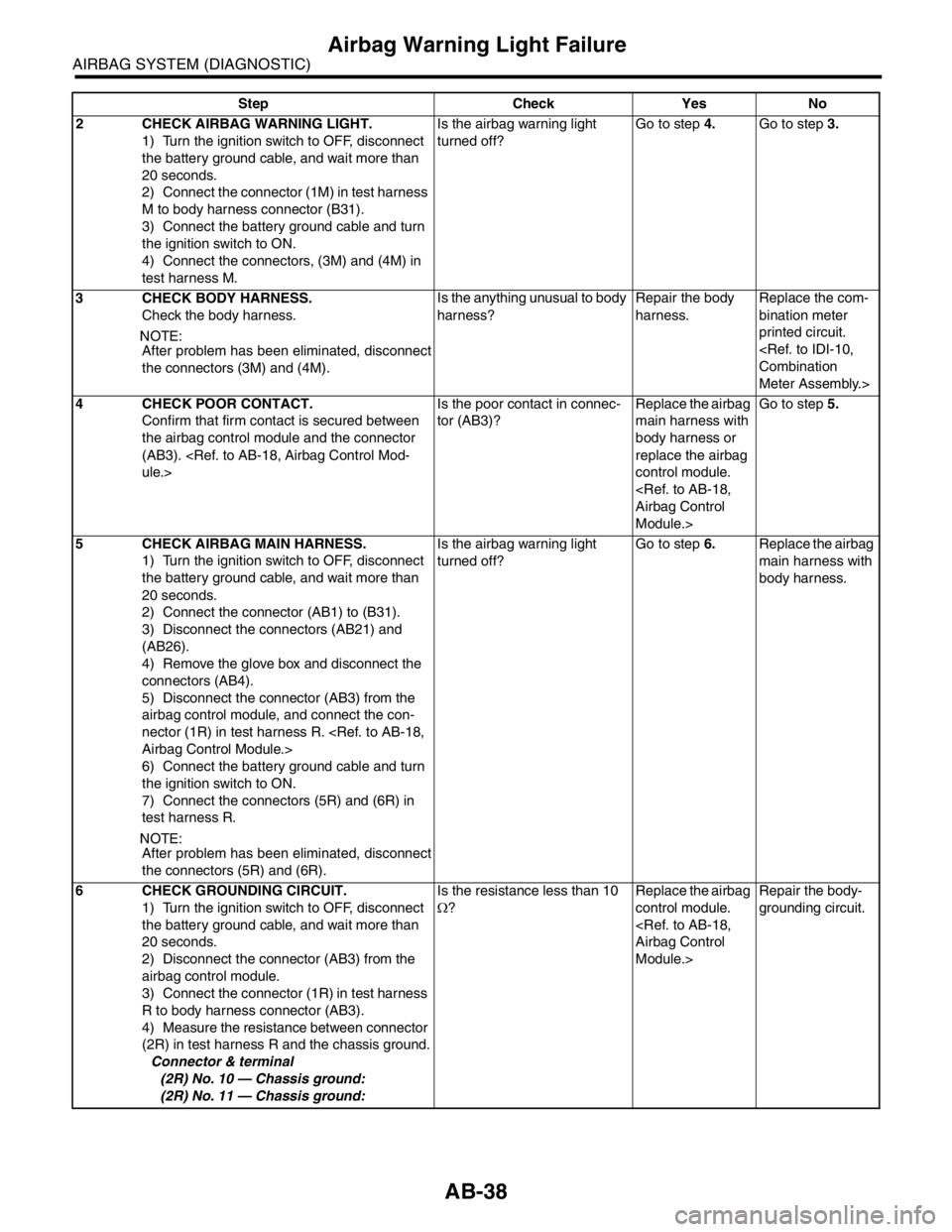

2 CHECK AIRBAG WARNING LIGHT.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Connect the connector (1M) in test harness

M to body harness connector (B31).

3) Connect the battery ground cable and turn

the ignition switch to ON.

4) Connect the connectors, (3M) and (4M) in

test harness M.Is the airbag warning light

turned off?Go to step 4.Go to step 3.

3 CHECK BODY HARNESS.

Check the body harness.

N

OTE:

After problem has been eliminated, disconnect

the connectors (3M) and (4M).Is the anything unusual to body

harness?Repair the body

harness.Replace the com-

bination meter

printed circuit.

Meter Assembly.>

4 CHECK POOR CONTACT.

Confirm that firm contact is secured between

the airbag control module and the connector

(AB3).

tor (AB3)? Replace the airbag

main harness with

body harness or

replace the airbag

control module.

Module.>Go to step 5.

5 CHECK AIRBAG MAIN HARNESS.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Connect the connector (AB1) to (B31).

3) Disconnect the connectors (AB21) and

(AB26).

4) Remove the glove box and disconnect the

connectors (AB4).

5) Disconnect the connector (AB3) from the

airbag control module, and connect the con-

nector (1R) in test harness R.

6) Connect the battery ground cable and turn

the ignition switch to ON.

7) Connect the connectors (5R) and (6R) in

test harness R.

N

OTE:

After problem has been eliminated, disconnect

the connectors (5R) and (6R).Is the airbag warning light

turned off? Go to step 6.Replace the airbag

main harness with

body harness.

6 CHECK GROUNDING CIRCUIT.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Disconnect the connector (AB3) from the

airbag control module.

3) Connect the connector (1R) in test harness

R to body harness connector (AB3).

4) Measure the resistance between connector

(2R) in test harness R and the chassis ground.

Connector & terminal

(2R) No. 10 — Chassis ground:

(2R) No. 11 — Chassis ground: Is the resistance less than 10

Ω?Replace the airbag

control module.

Module.>Repair the body-

grounding circuit. Step Check Yes No

Page 171 of 2870

AB-39

AIRBAG SYSTEM (DIAGNOSTIC)

Airbag Warning Light Failure

B: AIRBAG WARNING LIGHT REMAINS OFF.

DIAGNOSIS:

Fuse No. 14 (in fuse box) is blown.

Body harness circuit is open.

Airbag warning light is faulty.

Airbag main harness is faulty.

Airbag control module is faulty.

CAUTION:

Before diagnosing the airbag system, be sure to turn the ignition switch to OFF, disconnect the

ground cable from battery, and wait more than 20 seconds before starting to work.

After replacing the airbag module, seat belt pretensioner, roll connector, control module or sensor,

reconnect each part and confirm that the airbag warning light operates properly.

When inspecting the airbag main harness, disconnect the airbag module connector of the driver

and passenger seats for safety reasons.

1. LHD MODEL

WIRING DIAGRAM:

AB-00739

12

34561

2345678910123456789101112131415161718192021222324252627282930

B31 i11AB3

i10

B:

C: i10

i11

AIRBAG

WARNING

LIGHTCOMBINATION

METERB9

B8

B10

NO.14

i3B38 28

i2B37 19

5

AIRBAG CONTROL MODULEAB3

B31

AB1

3

3

AIRBAG

CIRCUIT

E

BATTERY

1234567891011121314151617

1819202122232425262728

IGNITION

SWITCH

B: C:

Page 172 of 2870

AB-40

AIRBAG SYSTEM (DIAGNOSTIC)

Airbag Warning Light Failure

Step Check Yes No

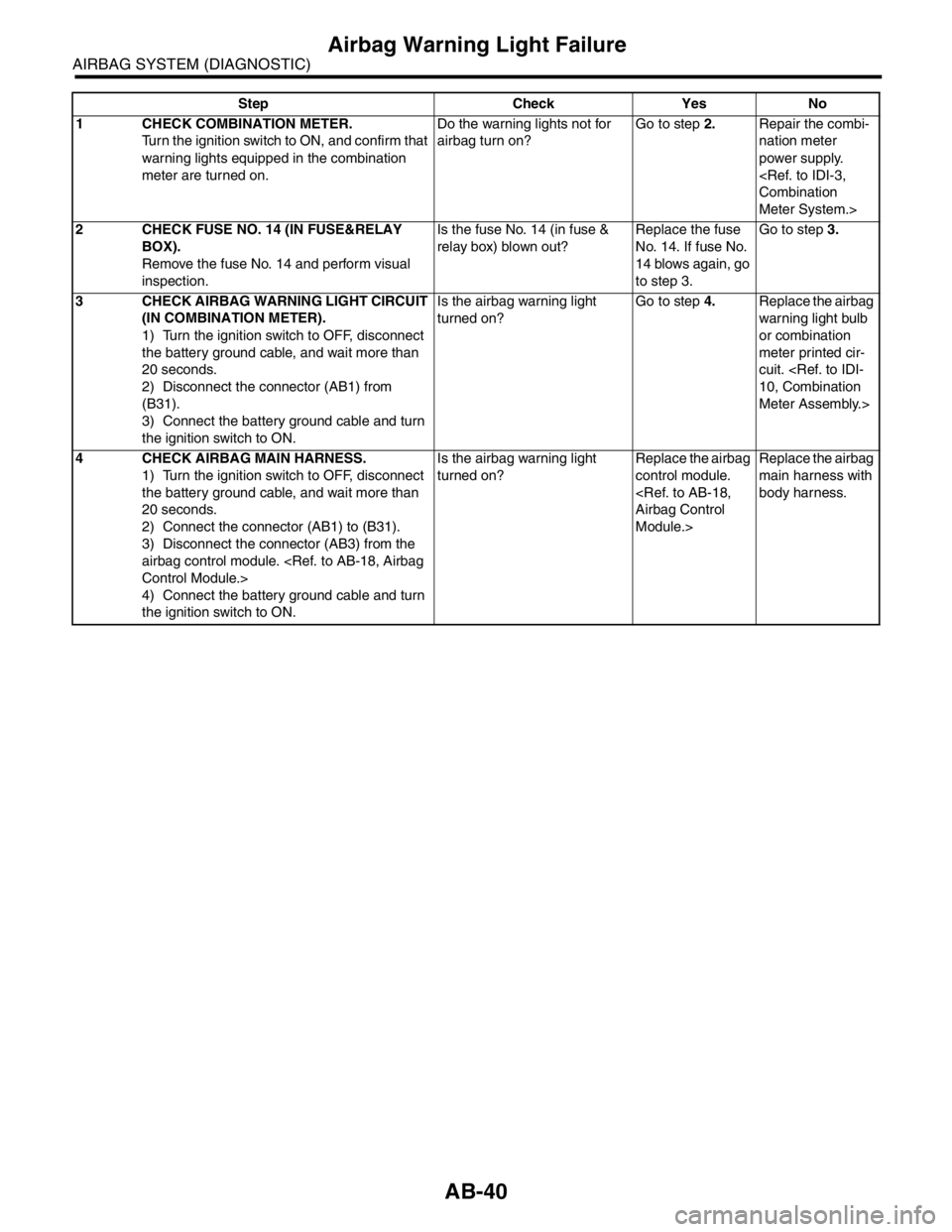

1 CHECK COMBINATION METER.

Turn the ignition switch to ON, and confirm that

warning lights equipped in the combination

meter are turned on.Do the warning lights not for

airbag turn on?Go to step 2.Repair the combi-

nation meter

power supply.

Meter System.>

2 CHECK FUSE NO. 14 (IN FUSE&RELAY

BOX).

Remove the fuse No. 14 and perform visual

inspection.Is the fuse No. 14 (in fuse &

relay box) blown out? Replace the fuse

No. 14. If fuse No.

14 blows again, go

to step 3. Go to step 3.

3 CHECK AIRBAG WARNING LIGHT CIRCUIT

(IN COMBINATION METER).

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Disconnect the connector (AB1) from

(B31).

3) Connect the battery ground cable and turn

the ignition switch to ON.Is the airbag warning light

turned on?Go to step 4.Replace the airbag

warning light bulb

or combination

meter printed cir-

cuit.

Meter Assembly.>

4 CHECK AIRBAG MAIN HARNESS.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Connect the connector (AB1) to (B31).

3) Disconnect the connector (AB3) from the

airbag control module.

4) Connect the battery ground cable and turn

the ignition switch to ON.Is the airbag warning light

turned on?Replace the airbag

control module.

Module.>Replace the airbag

main harness with

body harness.

Page 173 of 2870

AB-41

AIRBAG SYSTEM (DIAGNOSTIC)

Airbag Warning Light Failure

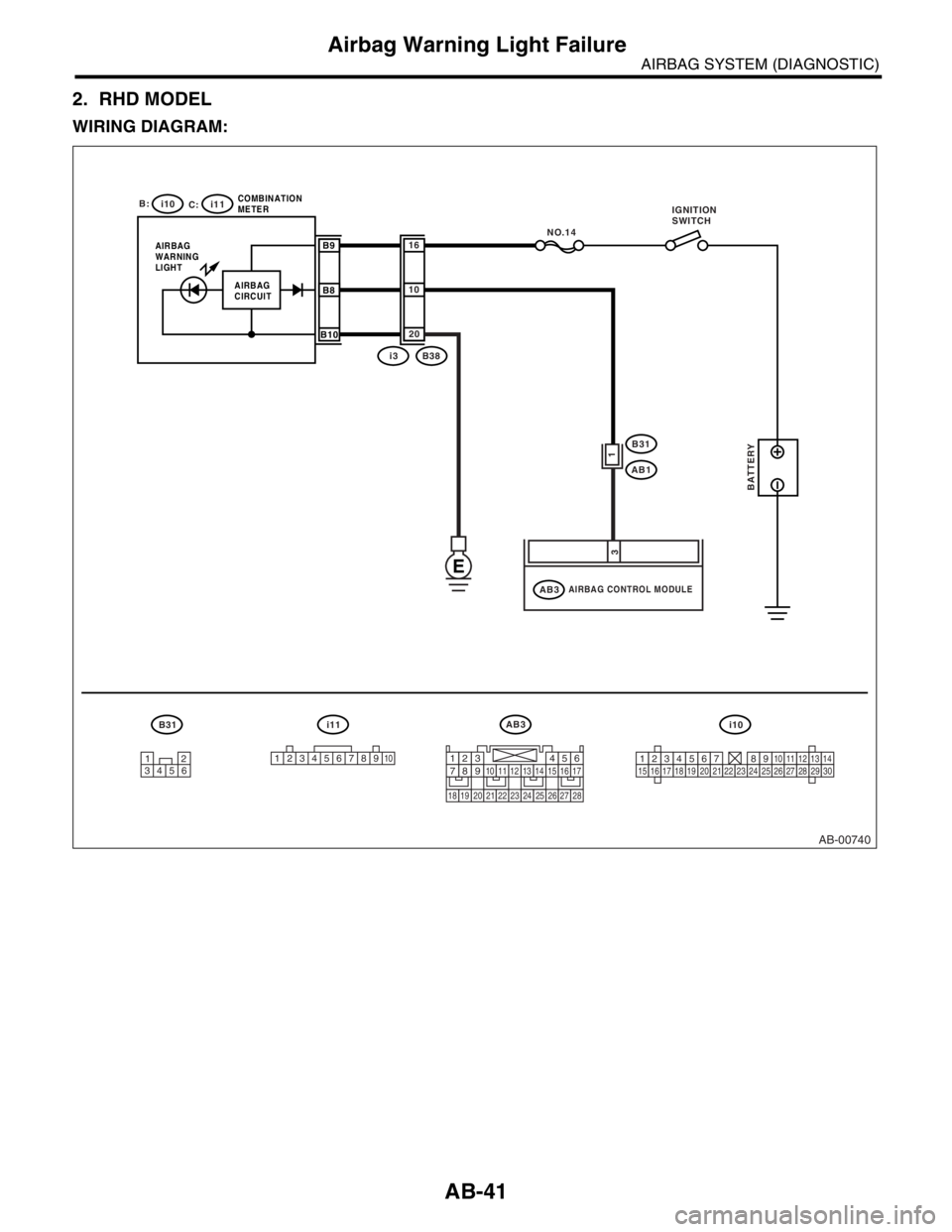

2. RHD MODEL

WIRING DIAGRAM:

AB-00740

12

34561

2345678910123456789101112131415161718192021222324252627282930

B31 i11AB3

i10

B:

C: i10

i11

AIRBAG

WARNING

LIGHTCOMBINATION

METERB9

B8

B10

NO.14

i3B38 20

10

16

AIRBAG CONTROL MODULEAB3

B31

AB1

1

3

AIRBAG

CIRCUIT

E

BATTERY

1234567891011121314151617

1819202122232425262728

IGNITION

SWITCH

Page 174 of 2870

AB-42

AIRBAG SYSTEM (DIAGNOSTIC)

Airbag Warning Light Failure

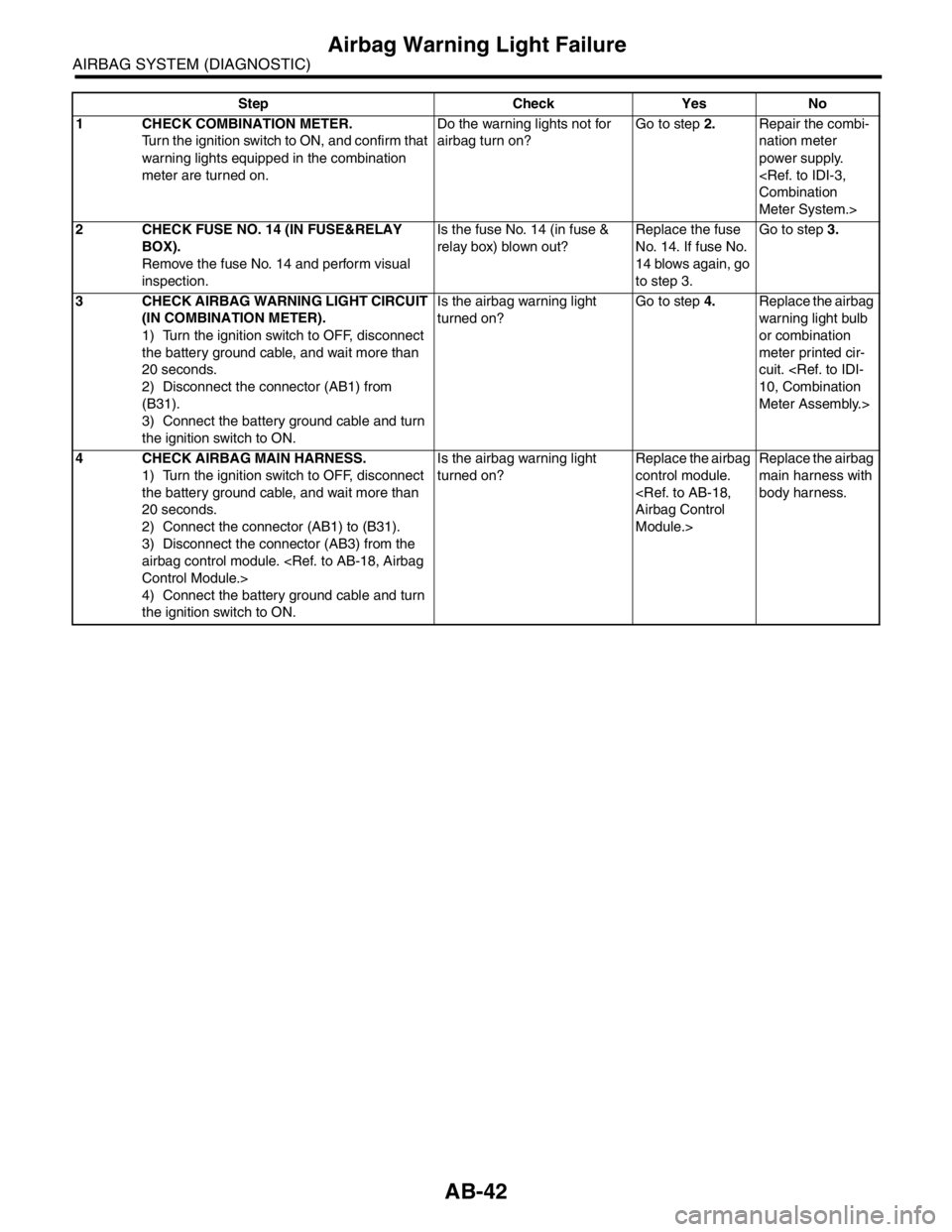

Step Check Yes No

1 CHECK COMBINATION METER.

Turn the ignition switch to ON, and confirm that

warning lights equipped in the combination

meter are turned on.Do the warning lights not for

airbag turn on?Go to step 2.Repair the combi-

nation meter

power supply.

Meter System.>

2 CHECK FUSE NO. 14 (IN FUSE&RELAY

BOX).

Remove the fuse No. 14 and perform visual

inspection.Is the fuse No. 14 (in fuse &

relay box) blown out?Replace the fuse

No. 14. If fuse No.

14 blows again, go

to step 3. Go to step 3.

3 CHECK AIRBAG WARNING LIGHT CIRCUIT

(IN COMBINATION METER).

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Disconnect the connector (AB1) from

(B31).

3) Connect the battery ground cable and turn

the ignition switch to ON.Is the airbag warning light

turned on?Go to step 4.Replace the airbag

warning light bulb

or combination

meter printed cir-

cuit.

Meter Assembly.>

4 CHECK AIRBAG MAIN HARNESS.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Connect the connector (AB1) to (B31).

3) Disconnect the connector (AB3) from the

airbag control module.

4) Connect the battery ground cable and turn

the ignition switch to ON.Is the airbag warning light

turned on?Replace the airbag

control module.

Module.>Replace the airbag

main harness with

body harness.

Page 242 of 2870

SB-8

SEAT BELT SYSTEM

Seat Belt Warning System

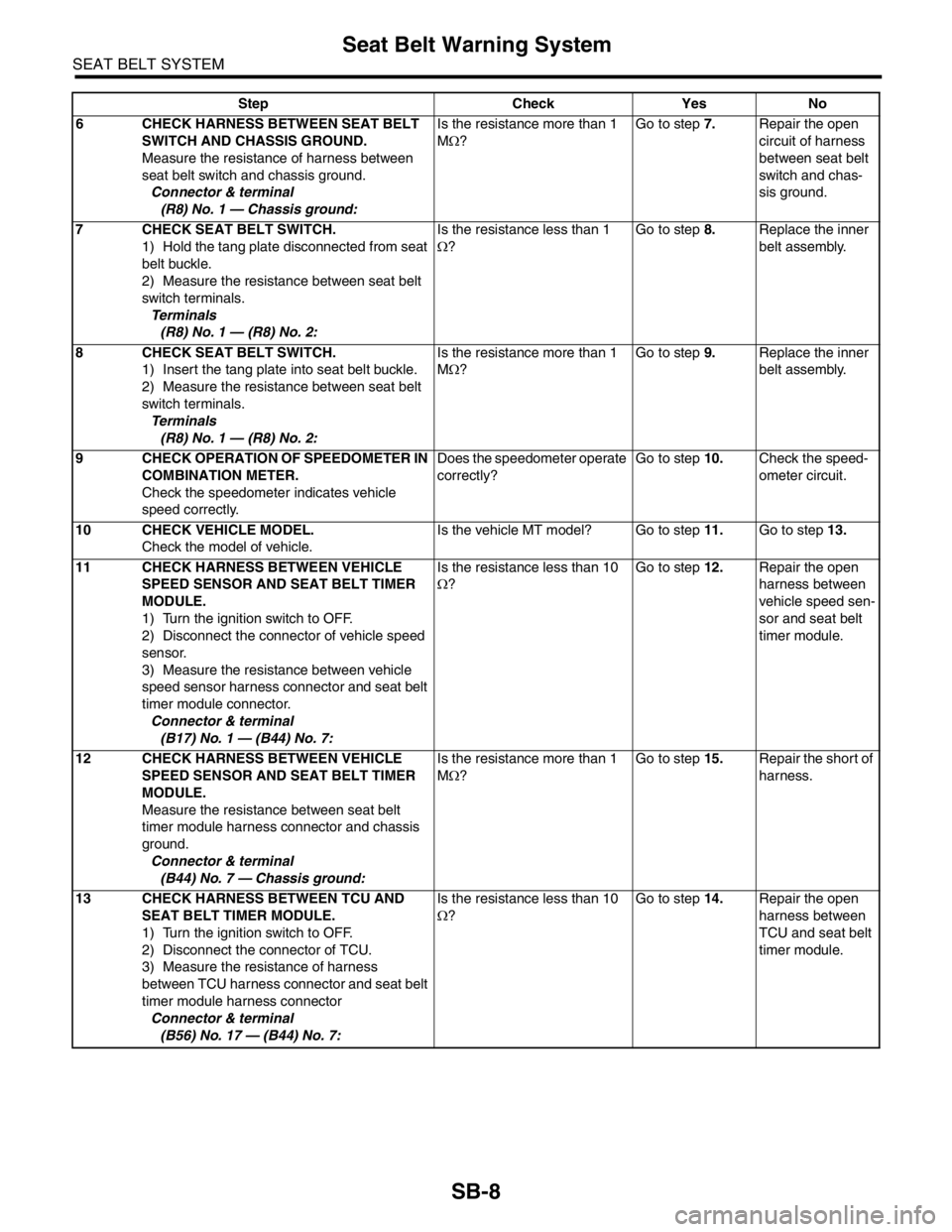

6 CHECK HARNESS BETWEEN SEAT BELT

SWITCH AND CHASSIS GROUND.

Measure the resistance of harness between

seat belt switch and chassis ground.

Connector & terminal

(R8) No. 1 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 7.Repair the open

circuit of harness

between seat belt

switch and chas-

sis ground.

7 CHECK SEAT BELT SWITCH.

1) Hold the tang plate disconnected from seat

belt buckle.

2) Measure the resistance between seat belt

switch terminals.

Te r m i n a l s

(R8) No. 1 — (R8) No. 2:Is the resistance less than 1

Ω?Go to step 8.Replace the inner

belt assembly.

8 CHECK SEAT BELT SWITCH.

1) Insert the tang plate into seat belt buckle.

2) Measure the resistance between seat belt

switch terminals.

Te r m i n a l s

(R8) No. 1 — (R8) No. 2:Is the resistance more than 1

MΩ?Go to step 9.Replace the inner

belt assembly.

9 CHECK OPERATION OF SPEEDOMETER IN

COMBINATION METER.

Check the speedometer indicates vehicle

speed correctly.Does the speedometer operate

correctly?Go to step 10.Check the speed-

ometer circuit.

10 CHECK VEHICLE MODEL.

Check the model of vehicle.Is the vehicle MT model? Go to step 11.Go to step 13.

11 CHECK HARNESS BETWEEN VEHICLE

SPEED SENSOR AND SEAT BELT TIMER

MODULE.

1) Turn the ignition switch to OFF.

2) Disconnect the connector of vehicle speed

sensor.

3) Measure the resistance between vehicle

speed sensor harness connector and seat belt

timer module connector.

Connector & terminal

(B17) No. 1 — (B44) No. 7:Is the resistance less than 10

Ω?Go to step 12.Repair the open

harness between

vehicle speed sen-

sor and seat belt

timer module.

12 CHECK HARNESS BETWEEN VEHICLE

SPEED SENSOR AND SEAT BELT TIMER

MODULE.

Measure the resistance between seat belt

timer module harness connector and chassis

ground.

Connector & terminal

(B44) No. 7 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 15.Repair the short of

harness.

13 CHECK HARNESS BETWEEN TCU AND

SEAT BELT TIMER MODULE.

1) Turn the ignition switch to OFF.

2) Disconnect the connector of TCU.

3) Measure the resistance of harness

between TCU harness connector and seat belt

timer module harness connector

Connector & terminal

(B56) No. 17 — (B44) No. 7:Is the resistance less than 10

Ω?Go to step 14.Repair the open

harness between

TCU and seat belt

timer module. Step Check Yes No

Page 385 of 2870

INSTRUMENTATION/DRIVER INFO

IDI

Page

1. General Description ....................................................................................2

2. Combination Meter System .........................................................................3

3. Combination Meter Assembly ...................................................................10

4. Speedometer.............................................................................................13

5. Tachometer ...............................................................................................14

6. Fuel Gauge ...............................................................................................15

7. Water Temperature Gauge .......................................................................16

8. Ambient Sensor.........................................................................................17

Page 386 of 2870

IDI-2

INSTRUMENTATION/DRIVER INFO

General Description

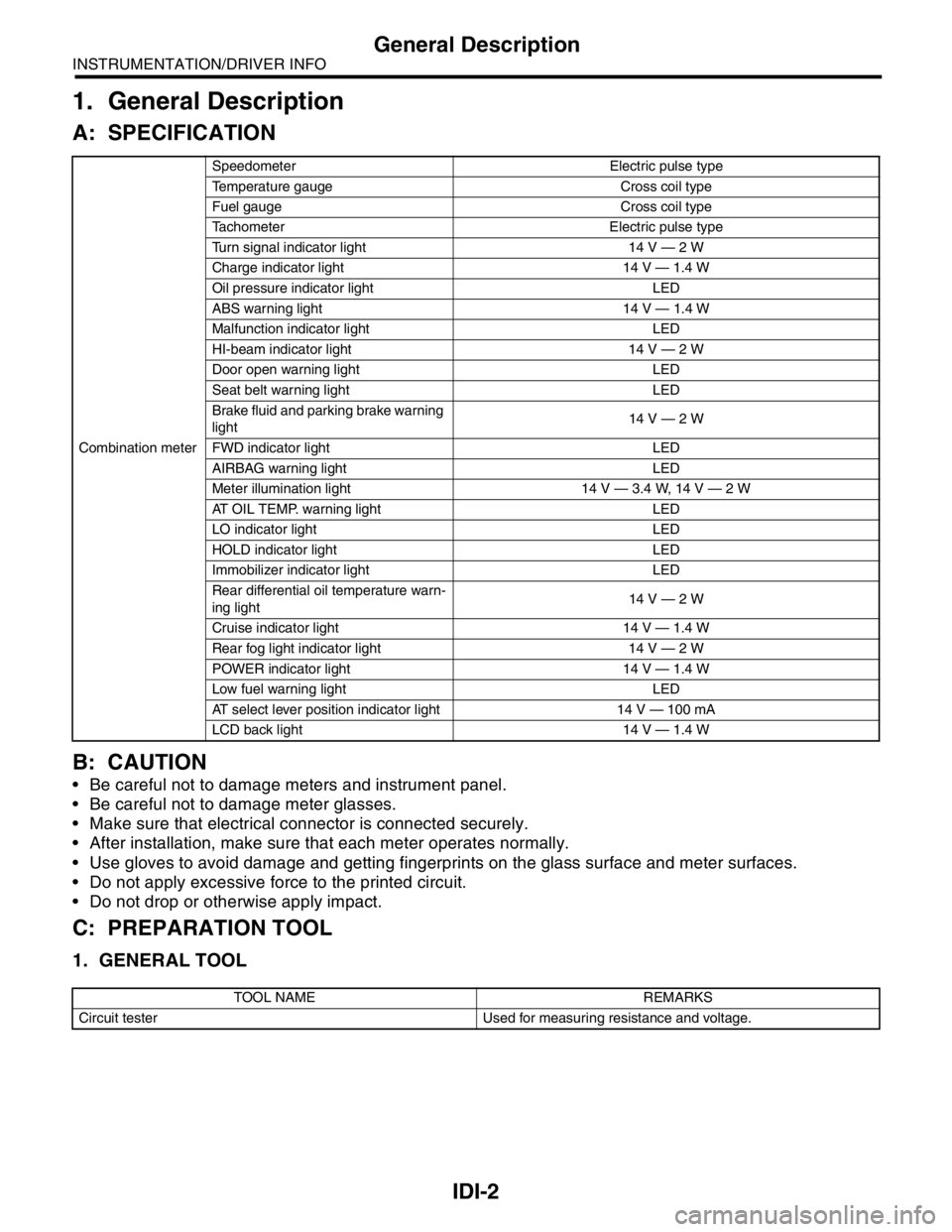

1. General Description

A: SPECIFICATION

B: CAUTION

Be careful not to damage meters and instrument panel.

Be careful not to damage meter glasses.

Make sure that electrical connector is connected securely.

After installation, make sure that each meter operates normally.

Use gloves to avoid damage and getting fingerprints on the glass surface and meter surfaces.

Do not apply excessive force to the printed circuit.

Do not drop or otherwise apply impact.

C: PREPARATION TOOL

1. GENERAL TOOL

Combination meterSpeedometer Electric pulse type

Temperature gauge Cross coil type

Fuel gauge Cross coil type

Tachometer Electric pulse type

Turn signal indicator light 14 V — 2 W

Charge indicator light 14 V — 1.4 W

Oil pressure indicator light LED

ABS warning light 14 V — 1.4 W

Malfunction indicator light LED

HI-beam indicator light 14 V — 2 W

Door open warning light LED

Seat belt warning light LED

Brake fluid and parking brake warning

light14 V — 2 W

FWD indicator light LED

AIRBAG warning light LED

Meter illumination light 14 V — 3.4 W, 14 V — 2 W

AT OIL TEMP. warning light LED

LO indicator light LED

HOLD indicator light LED

Immobilizer indicator light LED

Rear differential oil temperature warn-

ing light14 V — 2 W

Cruise indicator light 14 V — 1.4 W

Rear fog light indicator light 14 V — 2 W

POWER indicator light 14 V — 1.4 W

Low fuel warning light LED

AT select lever position indicator light 14 V — 100 mA

LCD back light 14 V — 1.4 W

TOOL NAME REMARKS

Circuit tester Used for measuring resistance and voltage.

Page 387 of 2870

IDI-3

INSTRUMENTATION/DRIVER INFO

Combination Meter System

2. Combination Meter System

A: WIRING DIAGRAM

1. COMBINATION METER

2. OUTSIDE TEMPERATURE INDICATOR

Page 388 of 2870

IDI-4

INSTRUMENTATION/DRIVER INFO

Combination Meter System

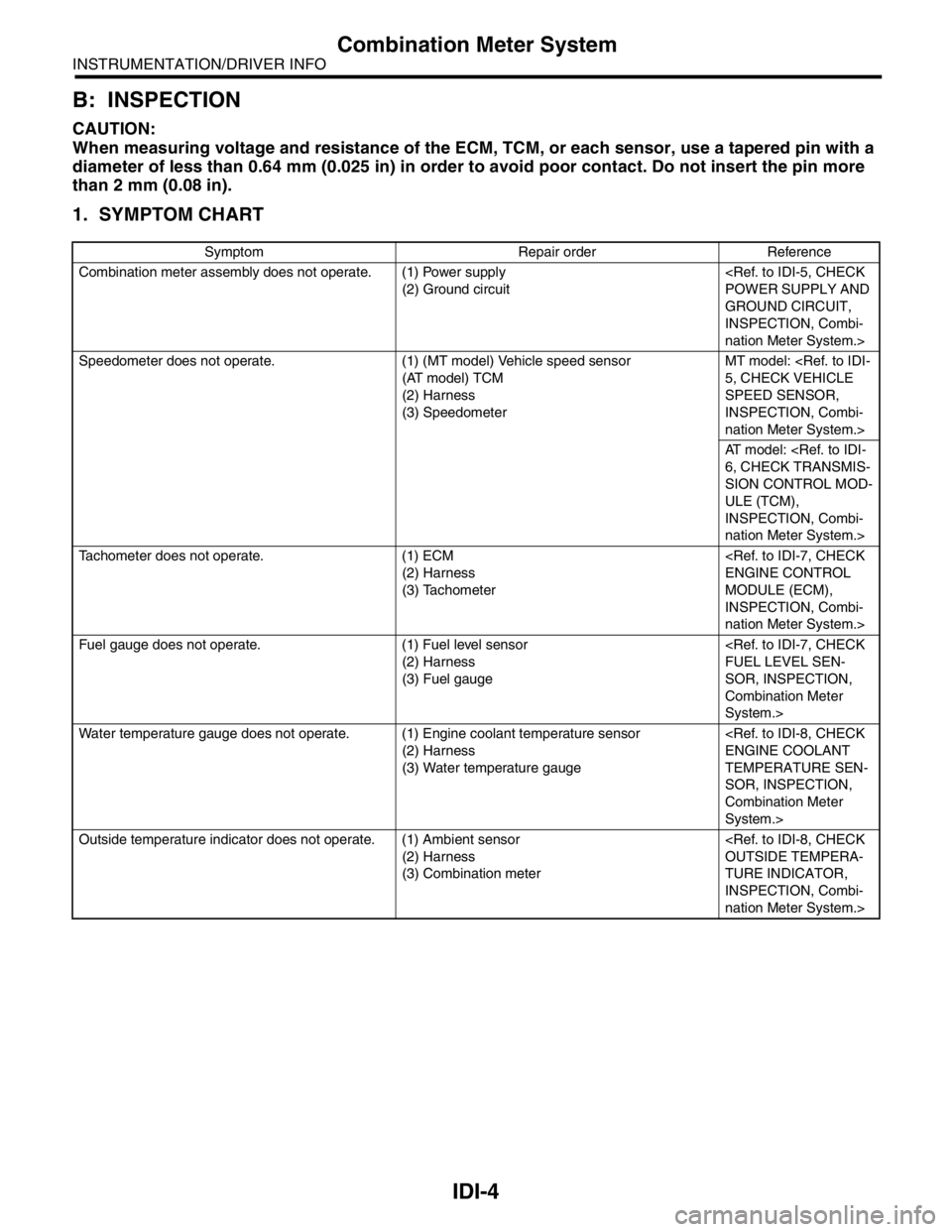

B: INSPECTION

CAUTION:

When measuring voltage and resistance of the ECM, TCM, or each sensor, use a tapered pin with a

diameter of less than 0.64 mm (0.025 in) in order to avoid poor contact. Do not insert the pin more

than 2 mm (0.08 in).

1. SYMPTOM CHART

Symptom Repair order Reference

Combination meter assembly does not operate. (1) Power supply

(2) Ground circuit

GROUND CIRCUIT,

INSPECTION, Combi-

nation Meter System.>

Speedometer does not operate. (1) (MT model) Vehicle speed sensor

(AT model) TCM

(2) Harness

(3) SpeedometerMT model:

SPEED SENSOR,

INSPECTION, Combi-

nation Meter System.>

AT model:

SION CONTROL MOD-

ULE (TCM),

INSPECTION, Combi-

nation Meter System.>

Tachometer does not operate. (1) ECM

(2) Harness

(3) Tachometer

MODULE (ECM),

INSPECTION, Combi-

nation Meter System.>

Fuel gauge does not operate. (1) Fuel level sensor

(2) Harness

(3) Fuel gauge

SOR, INSPECTION,

Combination Meter

System.>

Water temperature gauge does not operate. (1) Engine coolant temperature sensor

(2) Harness

(3) Water temperature gauge

TEMPERATURE SEN-

SOR, INSPECTION,

Combination Meter

System.>

Outside temperature indicator does not operate. (1) Ambient sensor

(2) Harness

(3) Combination meter

TURE INDICATOR,

INSPECTION, Combi-

nation Meter System.>