combination meter SUBARU FORESTER 2004 Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 652 of 2870

IM-10

IMMOBILIZER (DIAGNOSTIC)

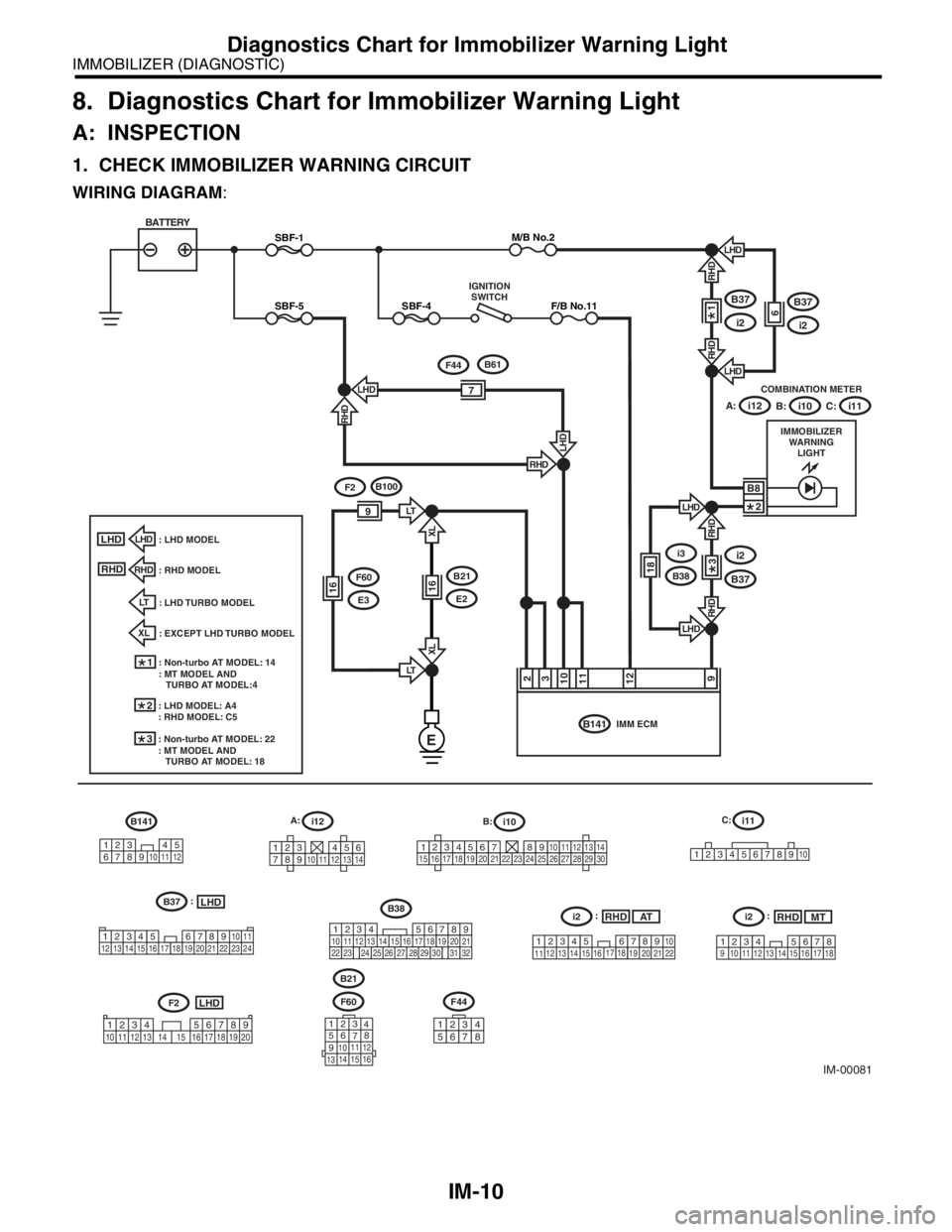

Diagnostics Chart for Immobilizer Warning Light

8. Diagnostics Chart for Immobilizer Warning Light

A: INSPECTION

1. CHECK IMMOBILIZER WARNING CIRCUIT

WIRING DIAGRAM:

IM-00081

F60

B21

RHD

SBF-1

SBF-5SBF-4

BATTERY

IMMOBILIZER

WARNING

LIGHT COMBINATION METER

B141IMM ECM

B37

i2

i2

B37

i12

B37

i2

LHD

RHDLHD

6

RHD

M/B No.2

F/B No.11

IGNITION

SWITCH

91211102

B8

3: RHD MODEL

1: Non-turbo AT MODEL: 14

: MT MODEL AND

TURBO AT MODEL:4

i12B141

34 12

89

10 11125

67

219

32

B38

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

123456789101112131415161718192021222324252627282930

LHDB37

34 12 89

10 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

i10

1

23456789

10

B:

E

A:i10 B:

i11C:

: LHD TURBO MODELLT

: EXCEPT LHD TURBO MODEL

XL

34 12 8910

1112 13 14 15 161718

19 20 21 22567

i2RHD

F2LHD

LHD

LHD

7

F44B61

RHD

RHD

LHD

: LHD MODEL

1

2

i11 C:

LHD

LHD

18

i3

B38

RHD

RHD

3

XL

LT

XL

LT9

1616

F2B100

B21

E2

F60

E3

LHD

RHD

2: LHD MODEL: A4

: RHD MODEL: C5

3: Non-turbo AT MODEL: 22

: MT MODEL AND

TURBO AT MODEL: 18

A:

:

AT:

23 1789 1011121314 15

16 1718456

i2RHDMT:

1234 5678910 11 12 13 14 15 16 17 18 19 20123

4

56

78

9

1011 12

1314 15 16

1234568791011121314

F44

12345678

Page 653 of 2870

IM-11

IMMOBILIZER (DIAGNOSTIC)

Diagnostics Chart for Immobilizer Warning Light

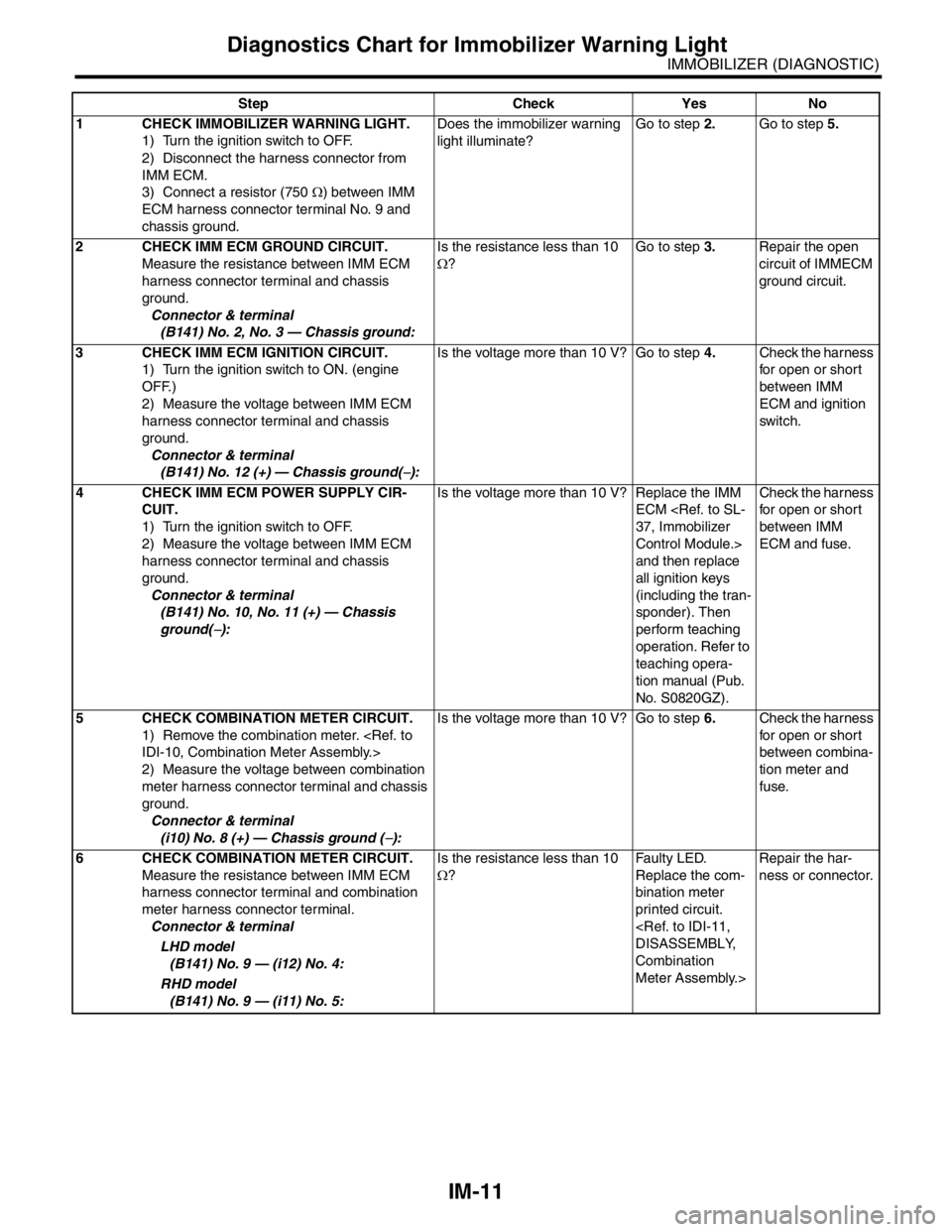

Step Check Yes No

1 CHECK IMMOBILIZER WARNING LIGHT.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector from

IMM ECM.

3) Connect a resistor (750 Ω) between IMM

ECM harness connector terminal No. 9 and

chassis ground.Does the immobilizer warning

light illuminate?Go to step 2.Go to step 5.

2 CHECK IMM ECM GROUND CIRCUIT.

Measure the resistance between IMM ECM

harness connector terminal and chassis

ground.

Connector & terminal

(B141) No. 2, No. 3 — Chassis ground:Is the resistance less than 10

Ω?Go to step 3.Repair the open

circuit of IMMECM

ground circuit.

3 CHECK IMM ECM IGNITION CIRCUIT.

1) Turn the ignition switch to ON. (engine

OFF.)

2) Measure the voltage between IMM ECM

harness connector terminal and chassis

ground.

Connector & terminal

(B141) No. 12 (+) — Chassis ground(

−):Is the voltage more than 10 V? Go to step 4.Check the harness

for open or short

between IMM

ECM and ignition

switch.

4 CHECK IMM ECM POWER SUPPLY CIR-

CUIT.

1) Turn the ignition switch to OFF.

2) Measure the voltage between IMM ECM

harness connector terminal and chassis

ground.

Connector & terminal

(B141) No. 10, No. 11 (+) — Chassis

ground(

−):Is the voltage more than 10 V? Replace the IMM

ECM

Control Module.>

and then replace

all ignition keys

(including the tran-

sponder). Then

perform teaching

operation. Refer to

teaching opera-

tion manual (Pub.

No. S0820GZ).Check the harness

for open or short

between IMM

ECM and fuse.

5 CHECK COMBINATION METER CIRCUIT.

1) Remove the combination meter.

2) Measure the voltage between combination

meter harness connector terminal and chassis

ground.

Connector & terminal

(i10) No. 8 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 6.Check the harness

for open or short

between combina-

tion meter and

fuse.

6 CHECK COMBINATION METER CIRCUIT.

Measure the resistance between IMM ECM

harness connector terminal and combination

meter harness connector terminal.

Connector & terminal

LHD model

(B141) No. 9 — (i12) No. 4:

RHD model

(B141) No. 9 — (i11) No. 5:Is the resistance less than 10

Ω?Faulty LED.

Replace the com-

bination meter

printed circuit.

Combination

Meter Assembly.>Repair the har-

ness or connector.

Page 767 of 2870

PM-30

PERIODIC MAINTENANCE SERVICE

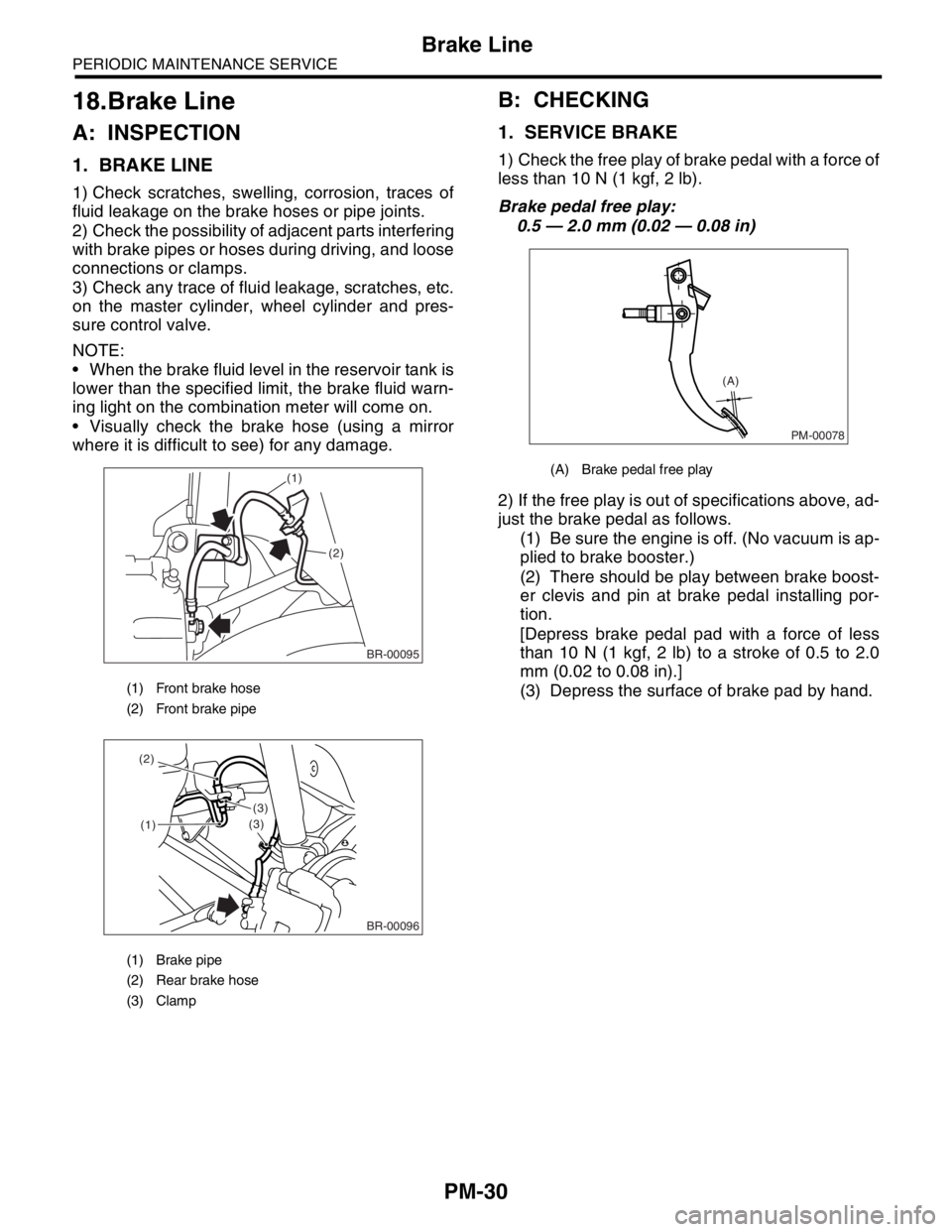

Brake Line

18.Brake Line

A: INSPECTION

1. BRAKE LINE

1) Check scratches, swelling, corrosion, traces of

fluid leakage on the brake hoses or pipe joints.

2) Check the possibility of adjacent parts interfering

with brake pipes or hoses during driving, and loose

connections or clamps.

3) Check any trace of fluid leakage, scratches, etc.

on the master cylinder, wheel cylinder and pres-

sure control valve.

NOTE:

When the brake fluid level in the reservoir tank is

lower than the specified limit, the brake fluid warn-

ing light on the combination meter will come on.

Visually check the brake hose (using a mirror

where it is difficult to see) for any damage.

B: CHECKING

1. SERVICE BRAKE

1) Check the free play of brake pedal with a force of

less than 10 N (1 kgf, 2 lb).

Brake pedal free play:

0.5 — 2.0 mm (0.02 — 0.08 in)

2) If the free play is out of specifications above, ad-

just the brake pedal as follows.

(1) Be sure the engine is off. (No vacuum is ap-

plied to brake booster.)

(2) There should be play between brake boost-

er clevis and pin at brake pedal installing por-

tion.

[Depress brake pedal pad with a force of less

than 10 N (1 kgf, 2 lb) to a stroke of 0.5 to 2.0

mm (0.02 to 0.08 in).]

(3) Depress the surface of brake pad by hand.

(1) Front brake hose

(2) Front brake pipe

(1) Brake pipe

(2) Rear brake hose

(3) Clamp

BR-00095

(1)

(2)

(1)

(3)

(3) (2)

BR-00096

(A) Brake pedal free play

PM-00078

(A)

Page 955 of 2870

ME(H4SO)-84

MECHANICAL

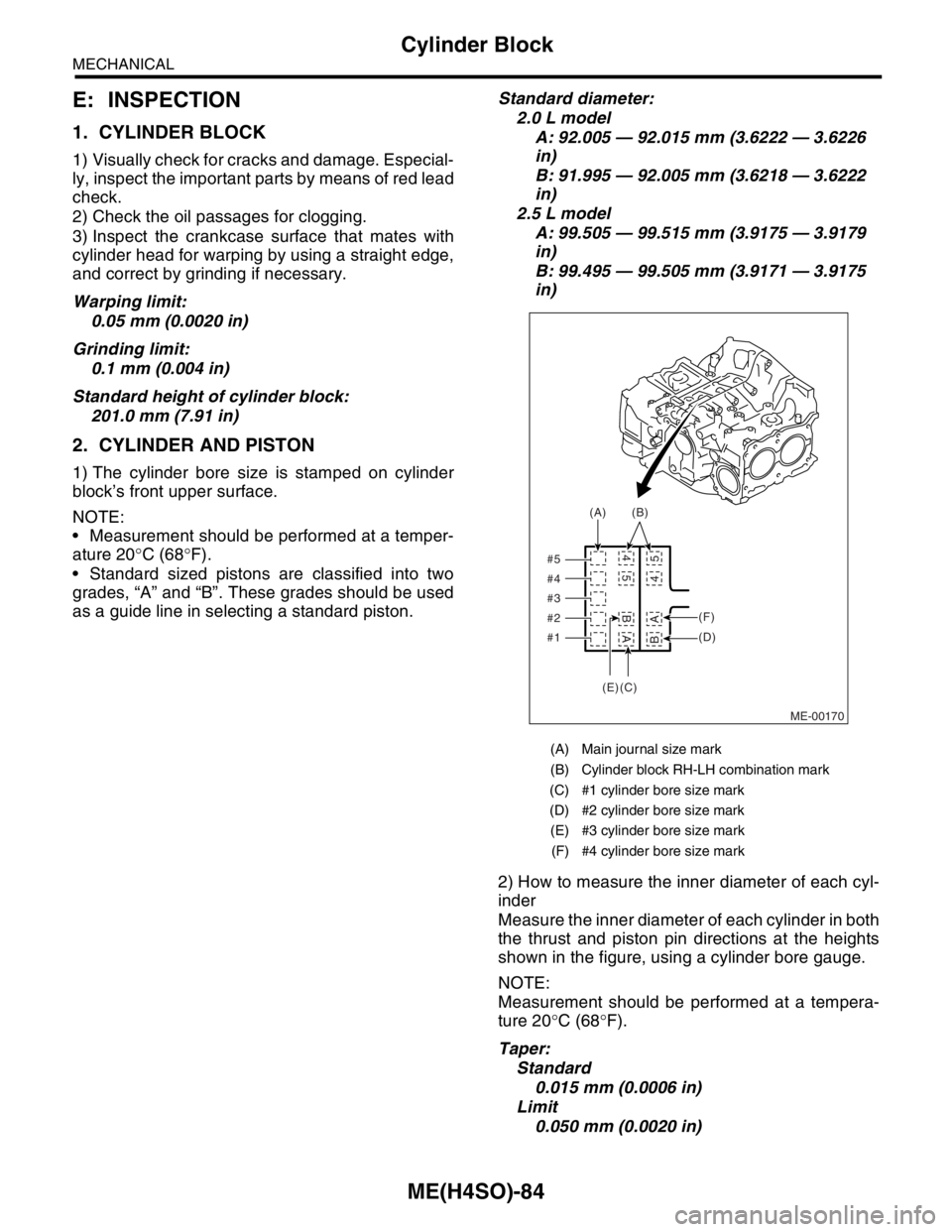

Cylinder Block

E: INSPECTION

1. CYLINDER BLOCK

1) Visually check for cracks and damage. Especial-

ly, inspect the important parts by means of red lead

check.

2) Check the oil passages for clogging.

3) Inspect the crankcase surface that mates with

cylinder head for warping by using a straight edge,

and correct by grinding if necessary.

Warping limit:

0.05 mm (0.0020 in)

Grinding limit:

0.1 mm (0.004 in)

Standard height of cylinder block:

201.0 mm (7.91 in)

2. CYLINDER AND PISTON

1) The cylinder bore size is stamped on cylinder

block’s front upper surface.

NOTE:

Measurement should be performed at a temper-

ature 20°C (68°F).

Standard sized pistons are classified into two

grades, “A” and “B”. These grades should be used

as a guide line in selecting a standard piston.Standard diameter:

2.0 L model

A: 92.005 — 92.015 mm (3.6222 — 3.6226

in)

B: 91.995 — 92.005 mm (3.6218 — 3.6222

in)

2.5 L model

A: 99.505 — 99.515 mm (3.9175 — 3.9179

in)

B: 99.495 — 99.505 mm (3.9171 — 3.9175

in)

2) How to measure the inner diameter of each cyl-

inder

Measure the inner diameter of each cylinder in both

the thrust and piston pin directions at the heights

shown in the figure, using a cylinder bore gauge.

NOTE:

Measurement should be performed at a tempera-

ture 20°C (68°F).

Taper:

Standard

0.015 mm (0.0006 in)

Limit

0.050 mm (0.0020 in)

(A) Main journal size mark

(B) Cylinder block RH-LH combination mark

(C) #1 cylinder bore size mark

(D) #2 cylinder bore size mark

(E) #3 cylinder bore size mark

(F) #4 cylinder bore size mark

ME-00170 #5

#4

#3

#2

#1(A)(B)

(F)

(D)

A BA B

5 45 4

(C) (E)

Page 1036 of 2870

LU(H4SO)-8

LUBRICATION

Oil Pressure System

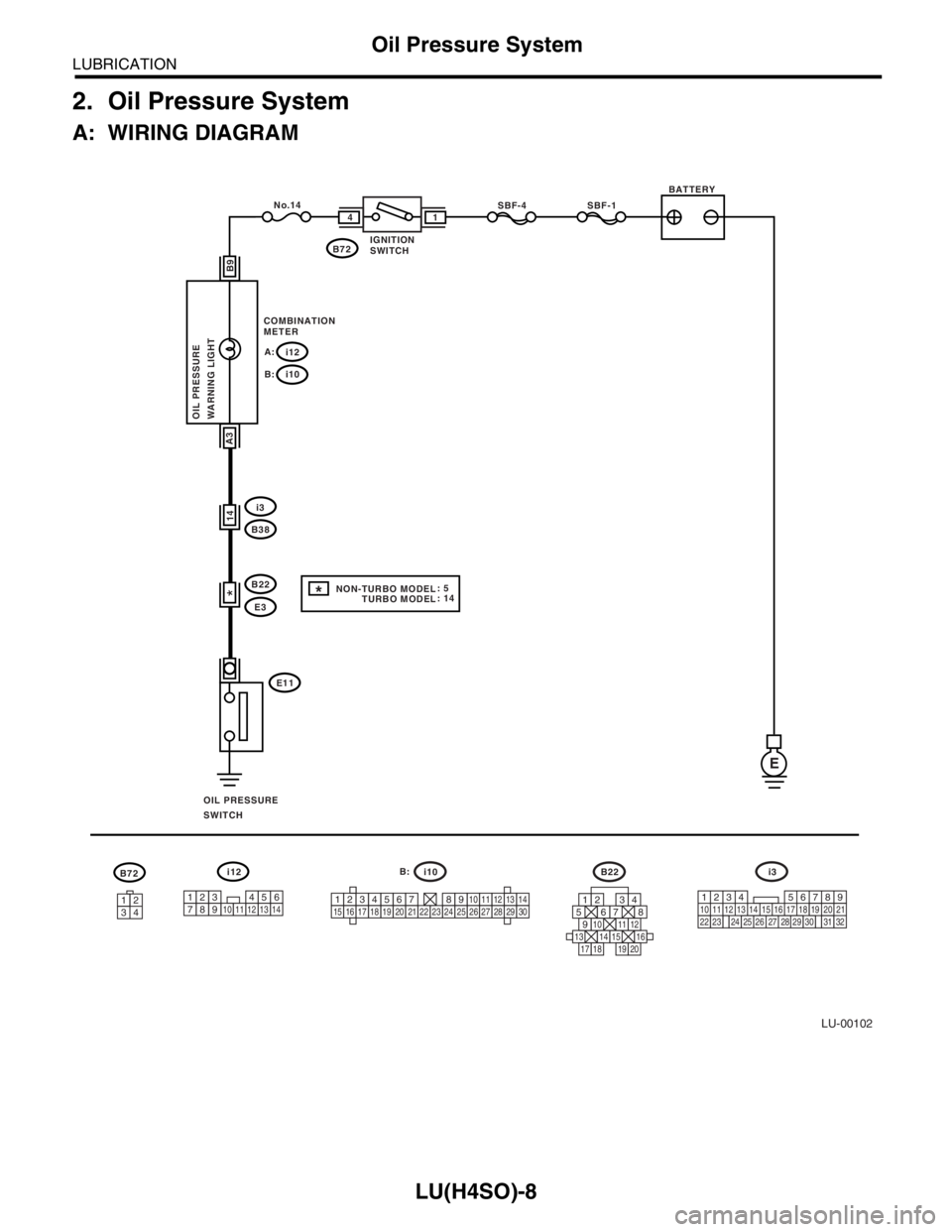

2. Oil Pressure System

A: WIRING DIAGRAM

LU-00102

E

i12

i10

i3

B38

B9

A3

B22

E3

14

E11

A:

B:

B:

i10

123456789101112131415161718192021222324252627282930219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

i3B22

125678

131415169101112

34

17181920

**: 5

: 14

No.14SBF-4SBF-1

B72

14

B72i12

12345678910111213143412

TURBO MODEL NON-TURBO MODELBATTERY

IGNITION

SWITCH

COMBINATION

METER

OIL PRESSURE

WARNING LIGHT

OIL PRESSURE

SWITCH

Page 1037 of 2870

LU(H4SO)-9

LUBRICATION

Oil Pressure System

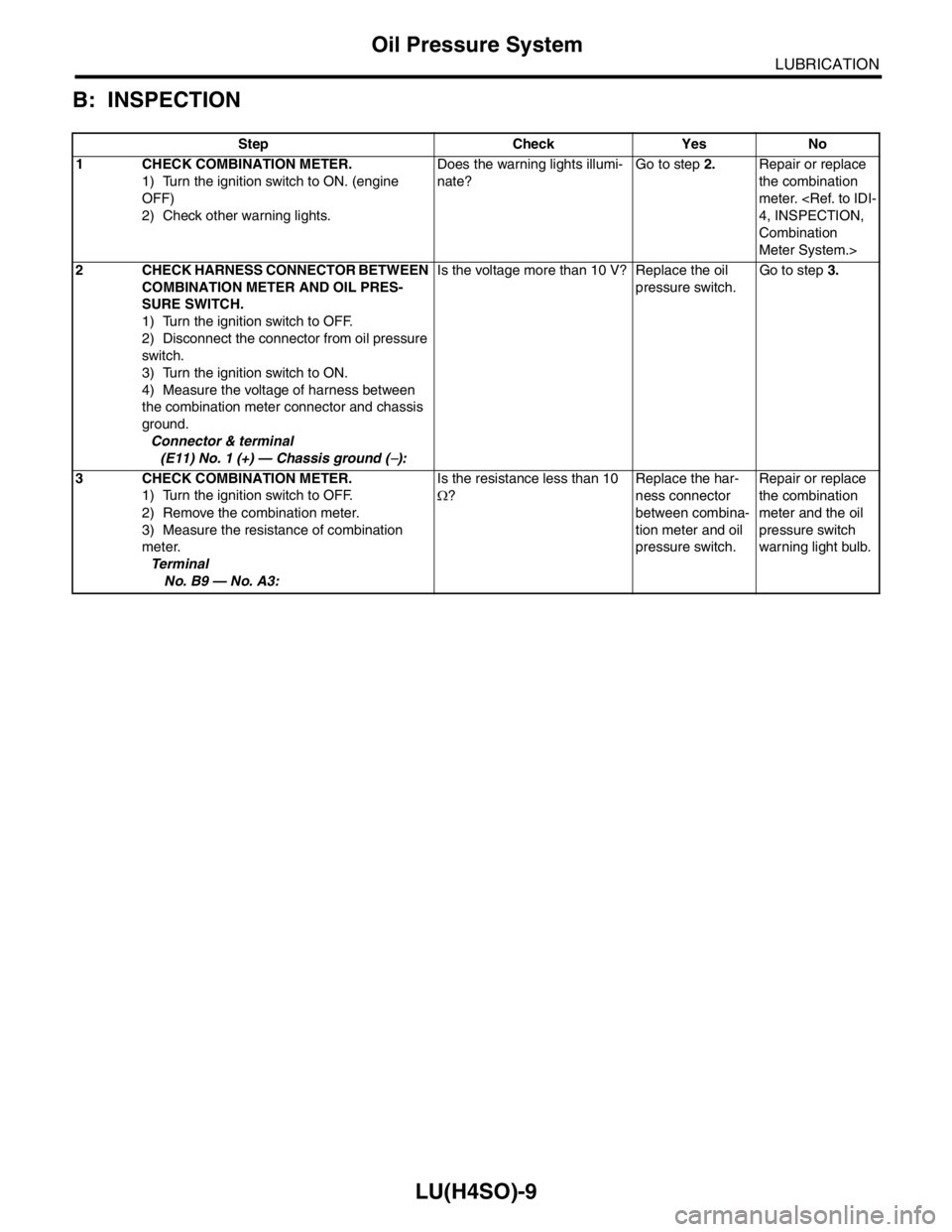

B: INSPECTION

Step Check Yes No

1 CHECK COMBINATION METER.

1) Turn the ignition switch to ON. (engine

OFF)

2) Check other warning lights.Does the warning lights illumi-

nate?Go to step 2.Repair or replace

the combination

meter.

Combination

Meter System.>

2 CHECK HARNESS CONNECTOR BETWEEN

COMBINATION METER AND OIL PRES-

SURE SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from oil pressure

switch.

3) Turn the ignition switch to ON.

4) Measure the voltage of harness between

the combination meter connector and chassis

ground.

Connector & terminal

(E11) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Replace the oil

pressure switch.Go to step 3.

3 CHECK COMBINATION METER.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Measure the resistance of combination

meter.

Te r m i n a l

No. B9 — No. A3:Is the resistance less than 10

Ω?Replace the har-

ness connector

between combina-

tion meter and oil

pressure switch.Repair or replace

the combination

meter and the oil

pressure switch

warning light bulb.

Page 1052 of 2870

LU(H4SO)-24

LUBRICATION

Engine Lubrication System Trouble in General

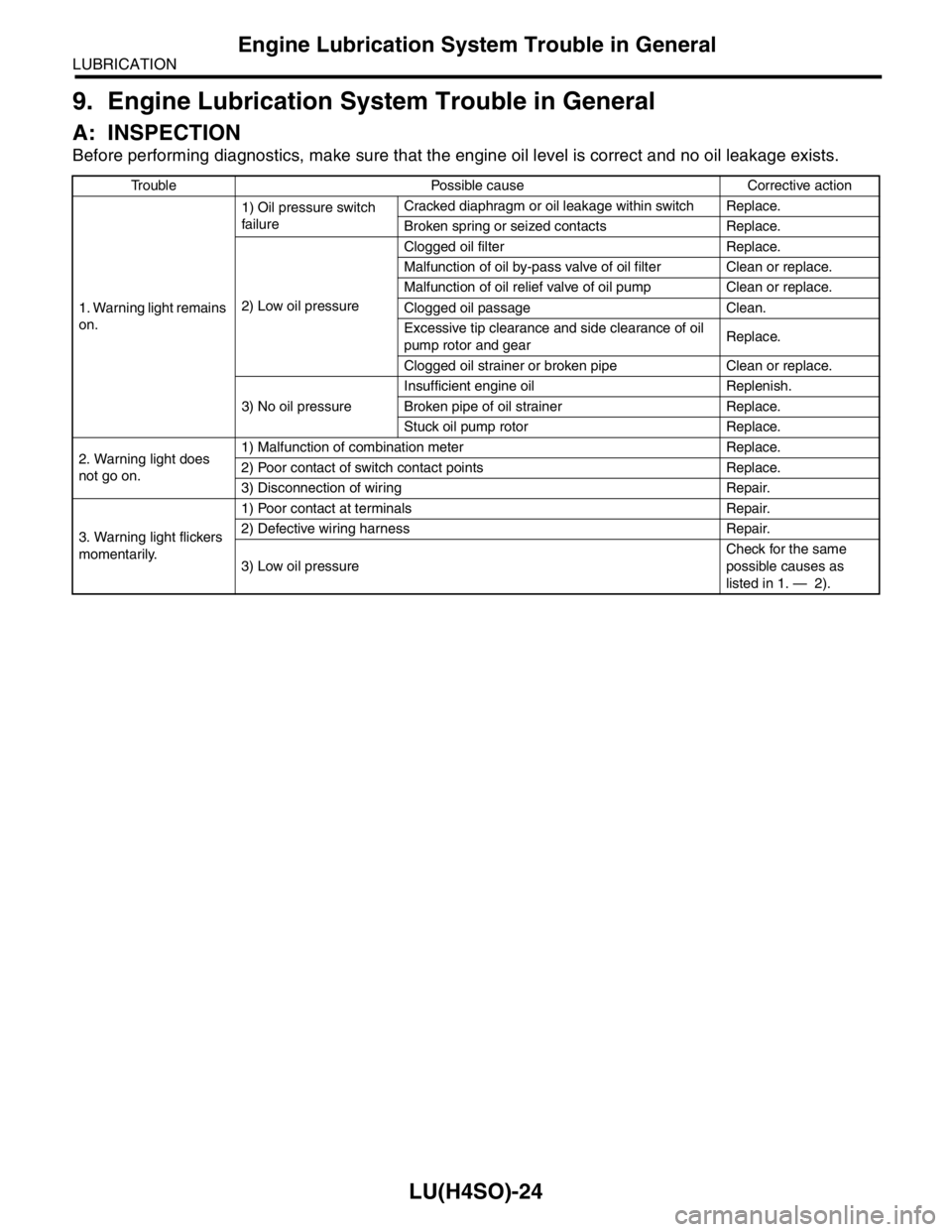

9. Engine Lubrication System Trouble in General

A: INSPECTION

Before performing diagnostics, make sure that the engine oil level is correct and no oil leakage exists.

Trouble Possible cause Corrective action

1. Warning light remains

on.1) Oil pressure switch

failureCracked diaphragm or oil leakage within switch Replace.

Broken spring or seized contacts Replace.

2) Low oil pressureClogged oil filter Replace.

Malfunction of oil by-pass valve of oil filter Clean or replace.

Malfunction of oil relief valve of oil pump Clean or replace.

Clogged oil passage Clean.

Excessive tip clearance and side clearance of oil

pump rotor and gearReplace.

Clogged oil strainer or broken pipe Clean or replace.

3) No oil pressureInsufficient engine oil Replenish.

Broken pipe of oil strainer Replace.

Stuck oil pump rotor Replace.

2. Warning light does

not go on.1) Malfunction of combination meter Replace.

2) Poor contact of switch contact points Replace.

3) Disconnection of wiring Repair.

3. Warning light flickers

momentarily.1) Poor contact at terminals Repair.

2) Defective wiring harness Repair.

3) Low oil pressureCheck for the same

possible causes as

listed in 1. — 2).

Page 1105 of 2870

EN(H4SO)-7

ENGINE (DIAGNOSTIC)

General Description

The antenna feeder must be placed as far

apart as possible from the ECM and MFI har-

ness.

Carefully adjust the antenna for correct

matching.

When mounting a large power type radio, pay

special attention to the three items above men-

tioned.

Incorrect installation of the radio may affect

the operation of the ECM.

13) Before disconnecting the fuel hose, disconnect

the fuel pump connector and crank the engine for

more than five seconds to release pressure in the

fuel system. If engine starts during this operation,

run it until it stops.

14) Problems in the electronic-controlled automatic

transmission may be caused by failure of the en-

gine, the electronic control system, the transmis-

sion proper, or by a combination of these. These

three causes must be distinguished clearly when

performing diagnostics.

15) Diagnostics should be conducted by rotating

with simple, easy operations and proceeding to

complicated, difficult operations. The most impor-

tant thing in diagnostics is to understand the cus-

tomer’s complaint, and distinguish between the

three causes.

16) In AT models, do not continue the stall for more

than five seconds. (from closed throttle, fully open

throttle to stall engine speed.)

17) On the model with ABS, when performing driv-

ing test in jacked-up or lifted-up position, some-

times the warning light may be lit, but this is not a

malfunction of the system. The reason for this is the

speed difference between the front and rear

wheels. After diagnosis of engine control system,

perform the ABS memory clearance procedure of

self-diagnosis function.

B: INSPECTION

Before performing diagnostics, check the following

items which might affect engine problems:

1. BATTERY

1) Measure battery voltage and specific gravity of

electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.260

2) Check the condition of the main and other fuses,

and harnesses and connectors. Also check for

proper grounding.

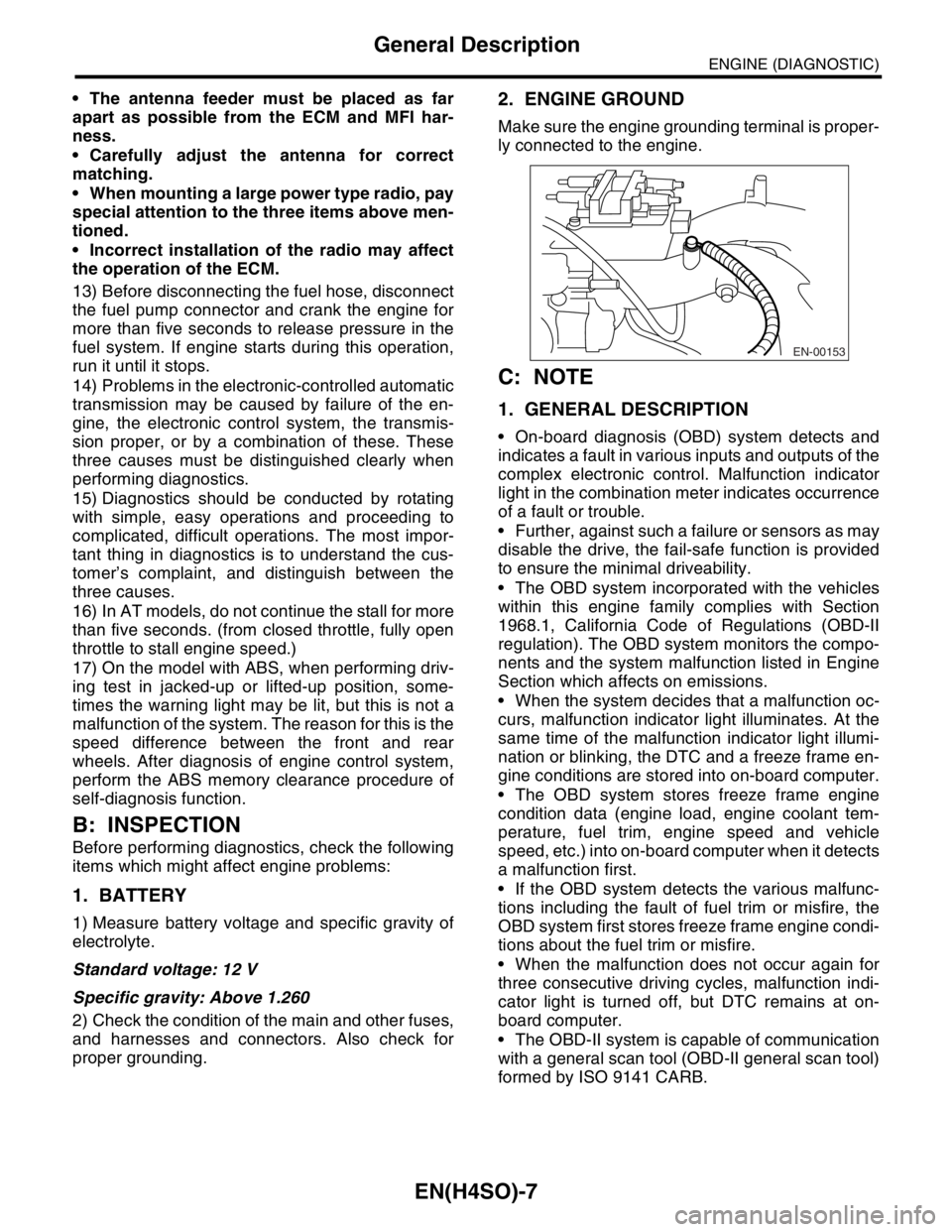

2. ENGINE GROUND

Make sure the engine grounding terminal is proper-

ly connected to the engine.

C: NOTE

1. GENERAL DESCRIPTION

On-board diagnosis (OBD) system detects and

indicates a fault in various inputs and outputs of the

complex electronic control. Malfunction indicator

light in the combination meter indicates occurrence

of a fault or trouble.

Further, against such a failure or sensors as may

disable the drive, the fail-safe function is provided

to ensure the minimal driveability.

The OBD system incorporated with the vehicles

within this engine family complies with Section

1968.1, California Code of Regulations (OBD-II

regulation). The OBD system monitors the compo-

nents and the system malfunction listed in Engine

Section which affects on emissions.

When the system decides that a malfunction oc-

curs, malfunction indicator light illuminates. At the

same time of the malfunction indicator light illumi-

nation or blinking, the DTC and a freeze frame en-

gine conditions are stored into on-board computer.

The OBD system stores freeze frame engine

condition data (engine load, engine coolant tem-

perature, fuel trim, engine speed and vehicle

speed, etc.) into on-board computer when it detects

a malfunction first.

If the OBD system detects the various malfunc-

tions including the fault of fuel trim or misfire, the

OBD system first stores freeze frame engine condi-

tions about the fuel trim or misfire.

When the malfunction does not occur again for

three consecutive driving cycles, malfunction indi-

cator light is turned off, but DTC remains at on-

board computer.

The OBD-II system is capable of communication

with a general scan tool (OBD-II general scan tool)

formed by ISO 9141 CARB.

EN-00153

Page 1145 of 2870

EN(H4SO)-47

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

16.Malfunction Indicator Light

A: PROCEDURE

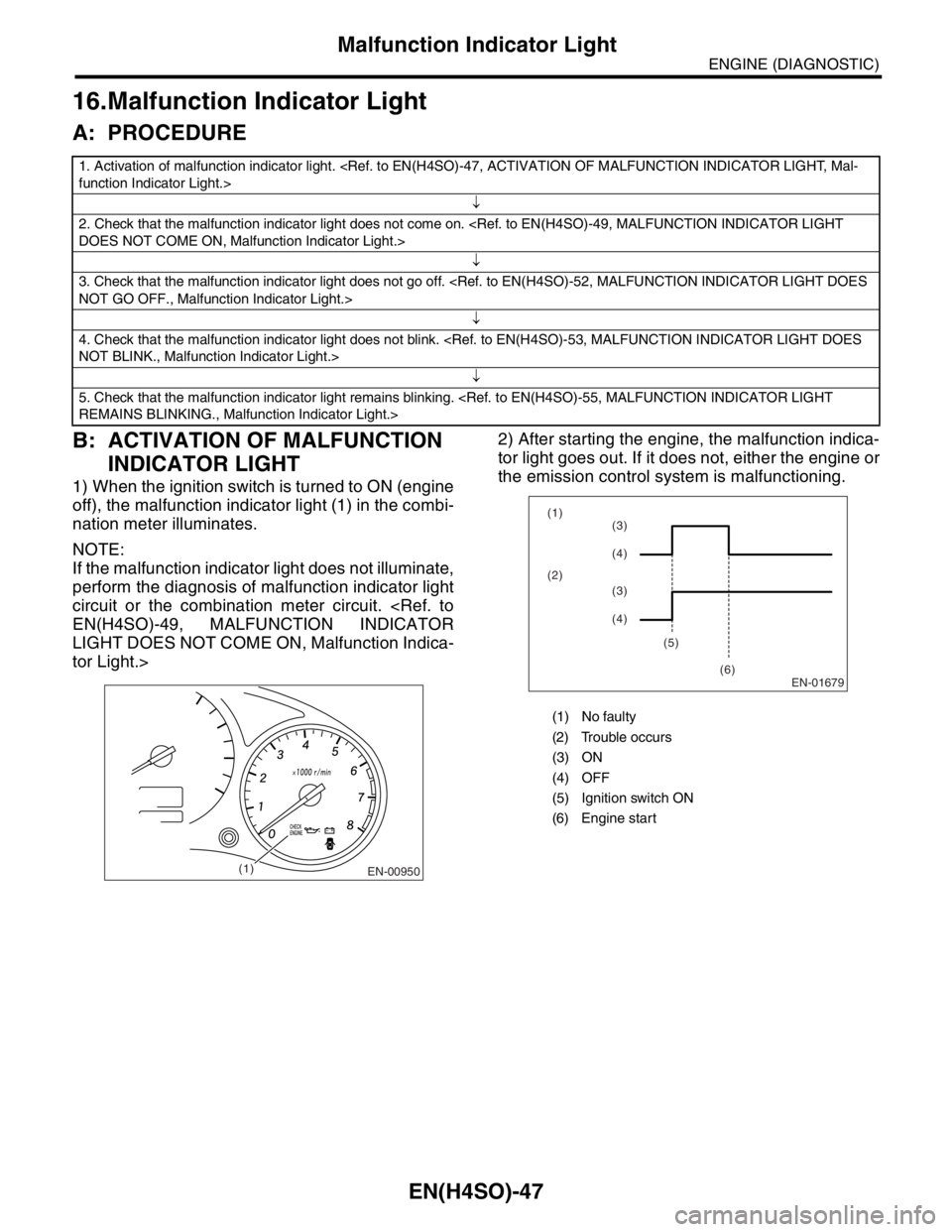

B: ACTIVATION OF MALFUNCTION

INDICATOR LIGHT

1) When the ignition switch is turned to ON (engine

off), the malfunction indicator light (1) in the combi-

nation meter illuminates.

NOTE:

If the malfunction indicator light does not illuminate,

perform the diagnosis of malfunction indicator light

circuit or the combination meter circuit.

LIGHT DOES NOT COME ON, Malfunction Indica-

tor Light.>2) After starting the engine, the malfunction indica-

tor light goes out. If it does not, either the engine or

the emission control system is malfunctioning.

1. Activation of malfunction indicator light.

↓

2. Check that the malfunction indicator light does not come on.

↓

3. Check that the malfunction indicator light does not go off.

↓

4. Check that the malfunction indicator light does not blink.

↓

5. Check that the malfunction indicator light remains blinking.

EN-00950(1)

(1) No faulty

(2) Trouble occurs

(3) ON

(4) OFF

(5) Ignition switch ON

(6) Engine start

EN-01679

(1)

(2)

(5)

(6)(3)

(4)

(3)

(4)

Page 1147 of 2870

EN(H4SO)-49

ENGINE (DIAGNOSTIC)

Malfunction Indicator Light

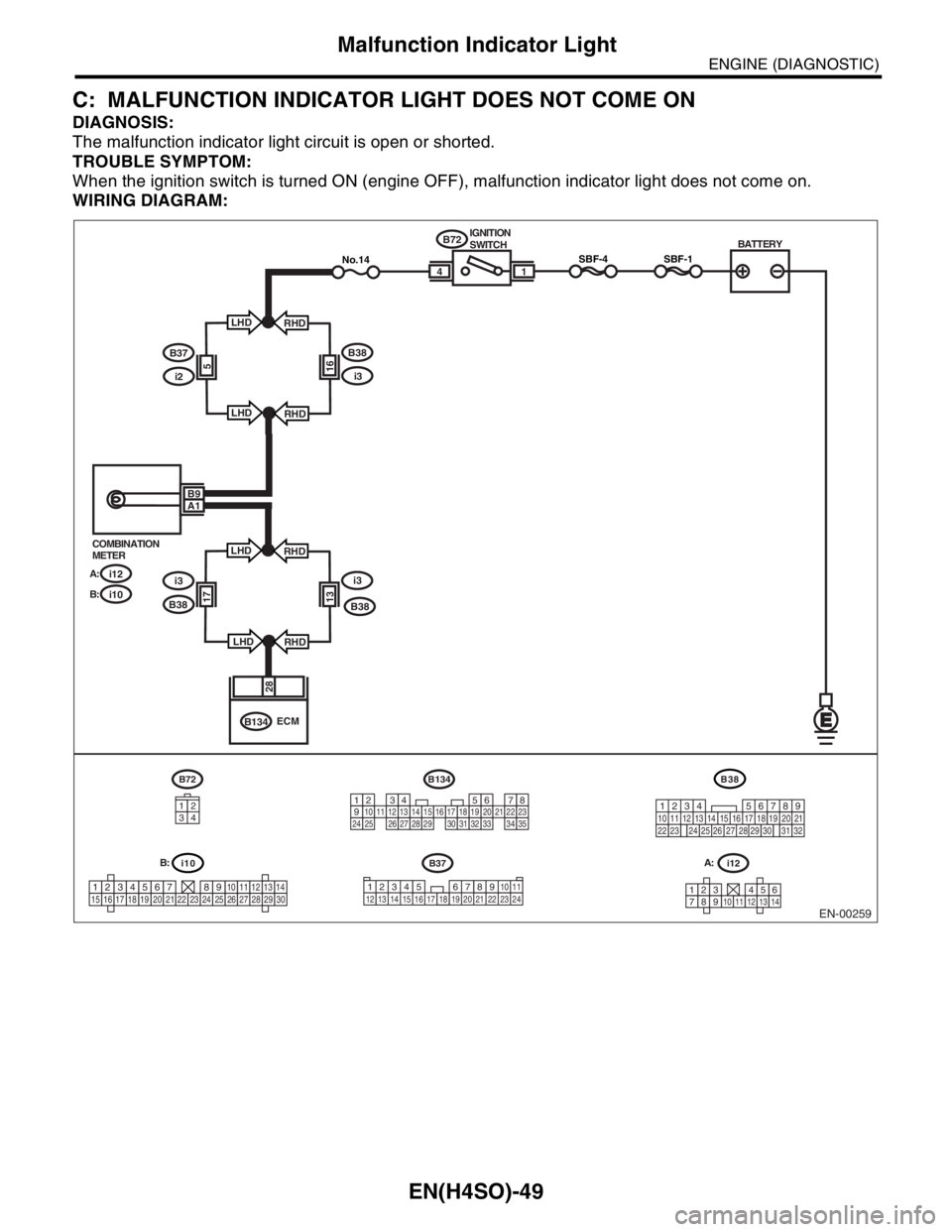

C: MALFUNCTION INDICATOR LIGHT DOES NOT COME ON

DIAGNOSIS:

The malfunction indicator light circuit is open or shorted.

TROUBLE SYMPTOM:

When the ignition switch is turned ON (engine OFF), malfunction indicator light does not come on.

WIRING DIAGRAM:

EN-00259

i10

123456789101112131415161718192021222324252627282930

BATTERY

1

B72

B134IGNITION

SWITCH

i12 COMBINATION

METER

A:

i10 B:

SBF-44

28

ECM

B9A1

i12

1234568791011121314

B134

1234567891011121314151617181920212223242526272829303132333435

B72

34

12

SBF-1No.14

B37

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

B38

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

B37

i2

B38

i3165

LHD

LHDRHD

RHD

i3i3

B381317

LHD

LHDRHD

RHD B38

A: B: