torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2842 of 2870

CL-16

CLUTCH SYSTEM

Clutch Disc and Cover

2. Clutch Disc and Cover

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

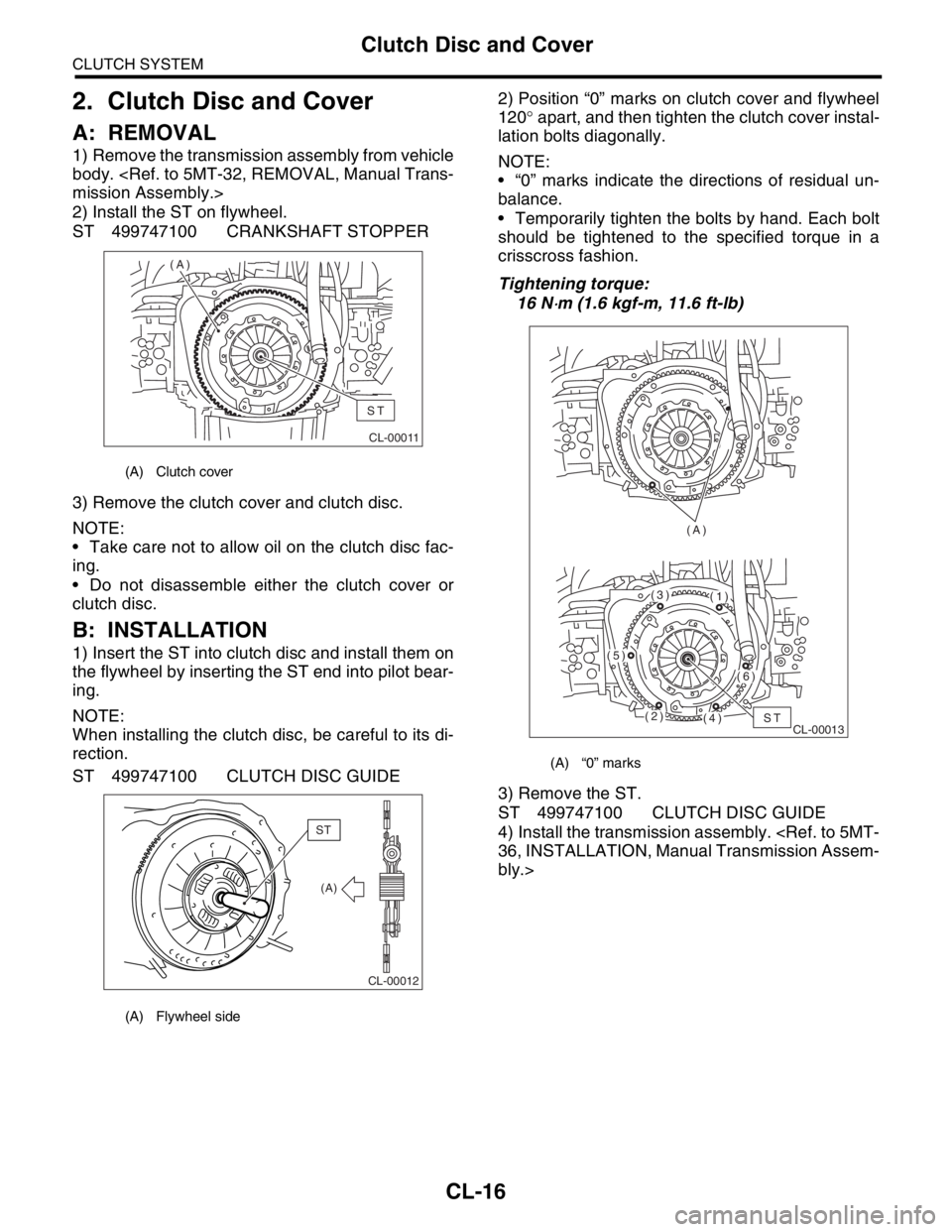

2) Install the ST on flywheel.

ST 499747100 CRANKSHAFT STOPPER

3) Remove the clutch cover and clutch disc.

NOTE:

Take care not to allow oil on the clutch disc fac-

ing.

Do not disassemble either the clutch cover or

clutch disc.

B: INSTALLATION

1) Insert the ST into clutch disc and install them on

the flywheel by inserting the ST end into pilot bear-

ing.

NOTE:

When installing the clutch disc, be careful to its di-

rection.

ST 499747100 CLUTCH DISC GUIDE2) Position “0” marks on clutch cover and flywheel

120° apart, and then tighten the clutch cover instal-

lation bolts diagonally.

NOTE:

“0” marks indicate the directions of residual un-

balance.

Temporarily tighten the bolts by hand. Each bolt

should be tightened to the specified torque in a

crisscross fashion.

Tightening torque:

16 N

⋅m (1.6 kgf-m, 11.6 ft-lb)

3) Remove the ST.

ST 499747100 CLUTCH DISC GUIDE

4) Install the transmission assembly.

bly.>

(A) Clutch cover

(A) Flywheel side

CL-00011

(A)

ST

CL-00012

(A)

ST

(A) “0” marks

CL-00013 (A)ST(2)

(5)

(3)(1)

(6)

(4)

Page 2845 of 2870

CL-19

CLUTCH SYSTEM

Flywheel

3. Flywheel

A: REMOVAL

1) Remove the transmission assembly.

sembly.>

2) Remove the clutch cover and clutch disc.

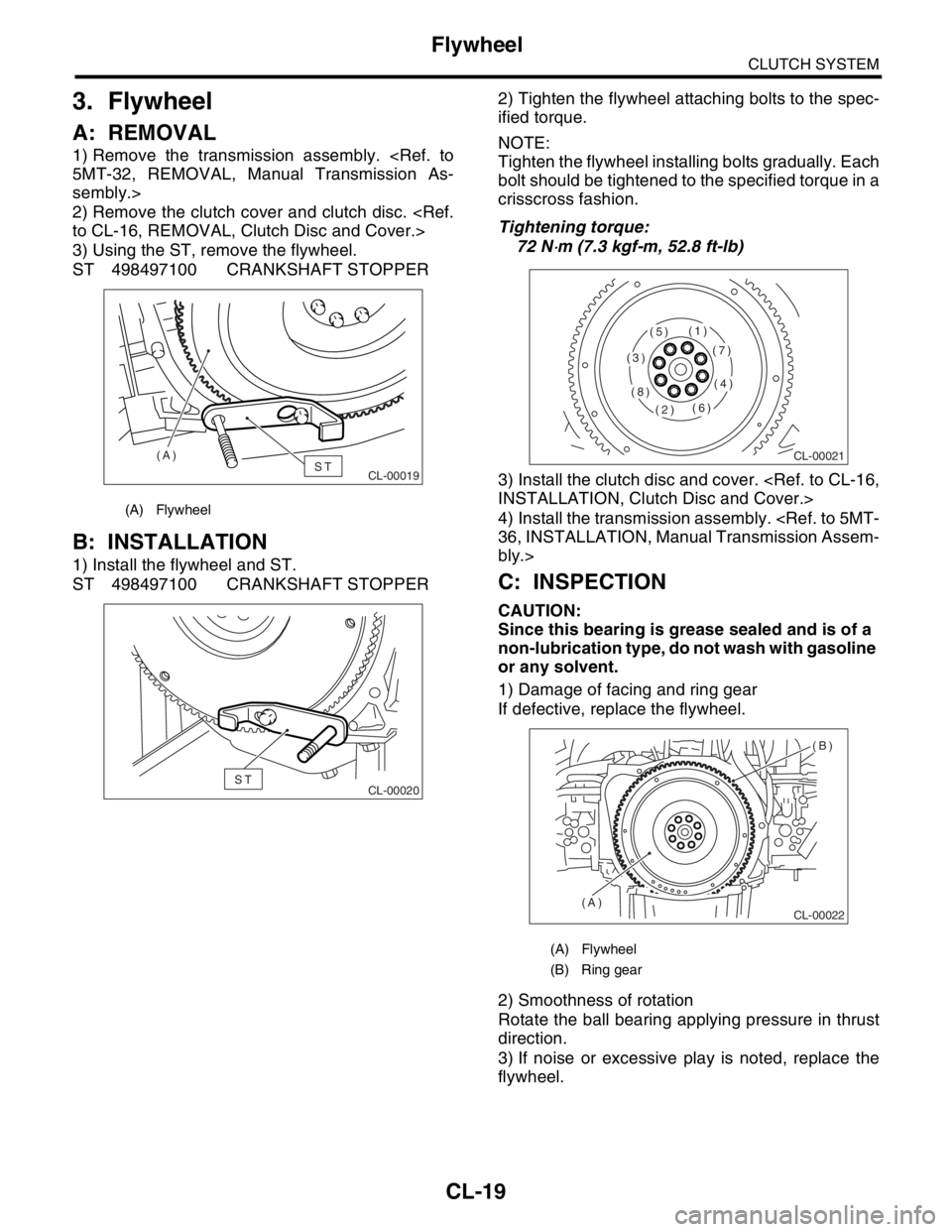

3) Using the ST, remove the flywheel.

ST 498497100 CRANKSHAFT STOPPER

B: INSTALLATION

1) Install the flywheel and ST.

ST 498497100 CRANKSHAFT STOPPER2) Tighten the flywheel attaching bolts to the spec-

ified torque.

NOTE:

Tighten the flywheel installing bolts gradually. Each

bolt should be tightened to the specified torque in a

crisscross fashion.

Tightening torque:

72 N

⋅m (7.3 kgf-m, 52.8 ft-lb)

3) Install the clutch disc and cover.

4) Install the transmission assembly.

bly.>

C: INSPECTION

CAUTION:

Since this bearing is grease sealed and is of a

non-lubrication type, do not wash with gasoline

or any solvent.

1) Damage of facing and ring gear

If defective, replace the flywheel.

2) Smoothness of rotation

Rotate the ball bearing applying pressure in thrust

direction.

3) If noise or excessive play is noted, replace the

flywheel.

(A) Flywheel

CL-00019ST (A)

CL-00020ST

(A) Flywheel

(B) Ring gear

CL-00021

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

CL-00022

(B)

(A)

Page 2848 of 2870

CL-22

CLUTCH SYSTEM

Release Bearing and Lever

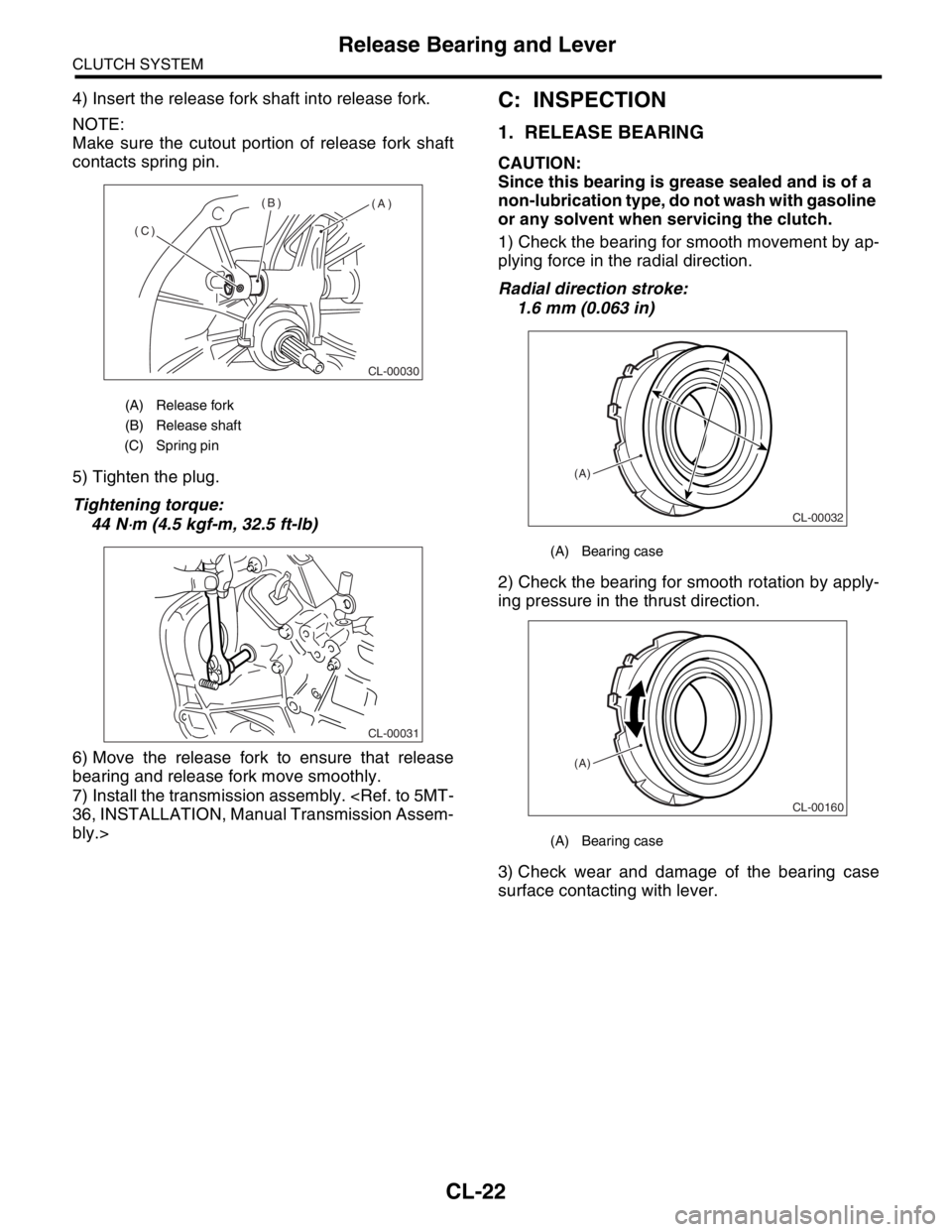

4) Insert the release fork shaft into release fork.

NOTE:

Make sure the cutout portion of release fork shaft

contacts spring pin.

5) Tighten the plug.

Tightening torque:

44 N

⋅m (4.5 kgf-m, 32.5 ft-lb)

6) Move the release fork to ensure that release

bearing and release fork move smoothly.

7) Install the transmission assembly.

bly.>

C: INSPECTION

1. RELEASE BEARING

CAUTION:

Since this bearing is grease sealed and is of a

non-lubrication type, do not wash with gasoline

or any solvent when servicing the clutch.

1) Check the bearing for smooth movement by ap-

plying force in the radial direction.

Radial direction stroke:

1.6 mm (0.063 in)

2) Check the bearing for smooth rotation by apply-

ing pressure in the thrust direction.

3) Check wear and damage of the bearing case

surface contacting with lever.

(A) Release fork

(B) Release shaft

(C) Spring pin

CL-00030

(A) (B)

(C)

CL-00031

(A) Bearing case

(A) Bearing case

CL-00032

(A)

CL-00160

(A)

Page 2851 of 2870

CL-25

CLUTCH SYSTEM

Operating Cylinder

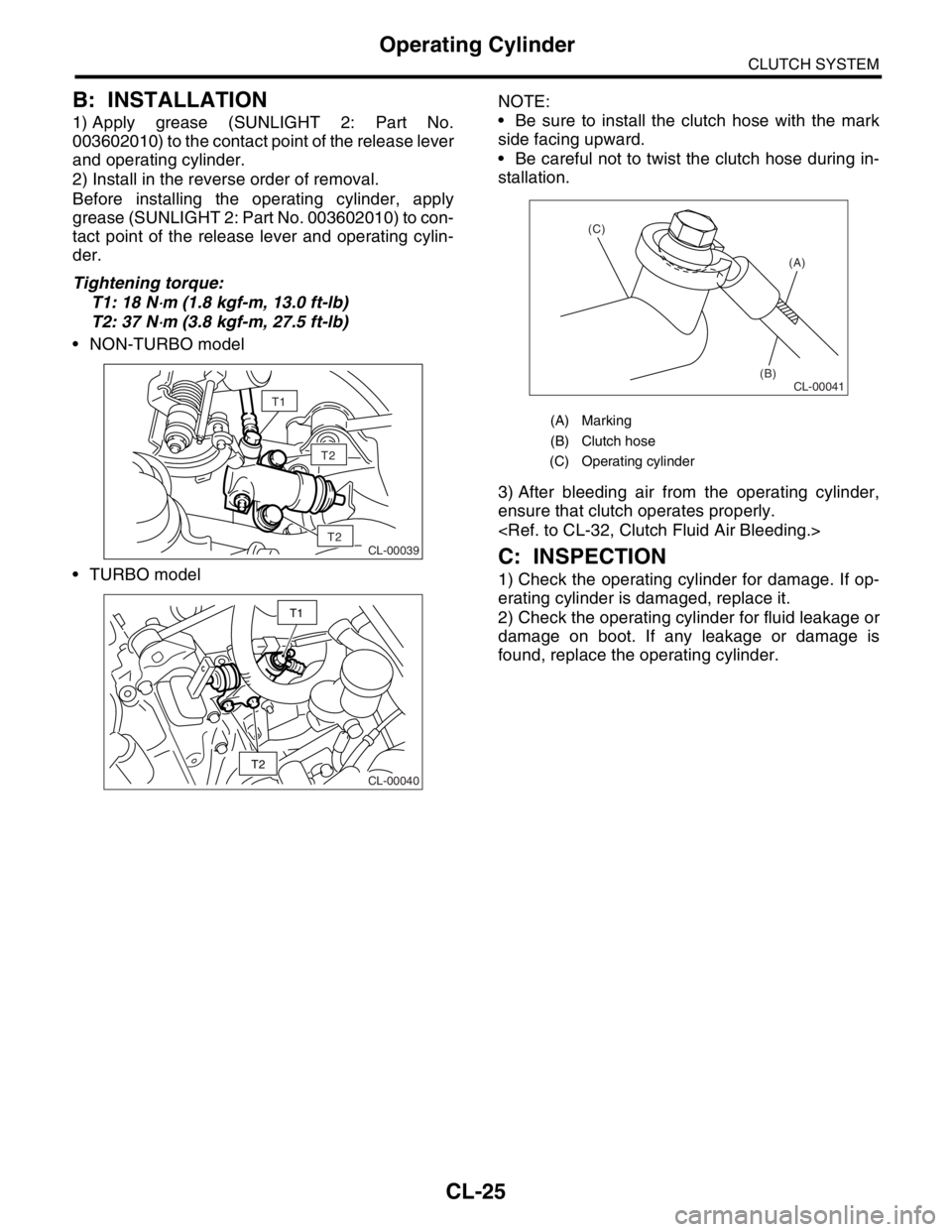

B: INSTALLATION

1) Apply grease (SUNLIGHT 2: Part No.

003602010) to the contact point of the release lever

and operating cylinder.

2) Install in the reverse order of removal.

Before installing the operating cylinder, apply

grease (SUNLIGHT 2: Part No. 003602010) to con-

tact point of the release lever and operating cylin-

der.

Tightening torque:

T1: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

T2: 37 N

⋅m (3.8 kgf-m, 27.5 ft-lb)

NON-TURBO model

TURBO modelNOTE:

Be sure to install the clutch hose with the mark

side facing upward.

Be careful not to twist the clutch hose during in-

stallation.

3) After bleeding air from the operating cylinder,

ensure that clutch operates properly.

C: INSPECTION

1) Check the operating cylinder for damage. If op-

erating cylinder is damaged, replace it.

2) Check the operating cylinder for fluid leakage or

damage on boot. If any leakage or damage is

found, replace the operating cylinder.

T2

CL-00039T2

T1

CL-00040

T2

T1

(A) Marking

(B) Clutch hose

(C) Operating cylinder

CL-00041

(A)

(B) (C)

Page 2852 of 2870

CL-26

CLUTCH SYSTEM

Master Cylinder

6. Master Cylinder

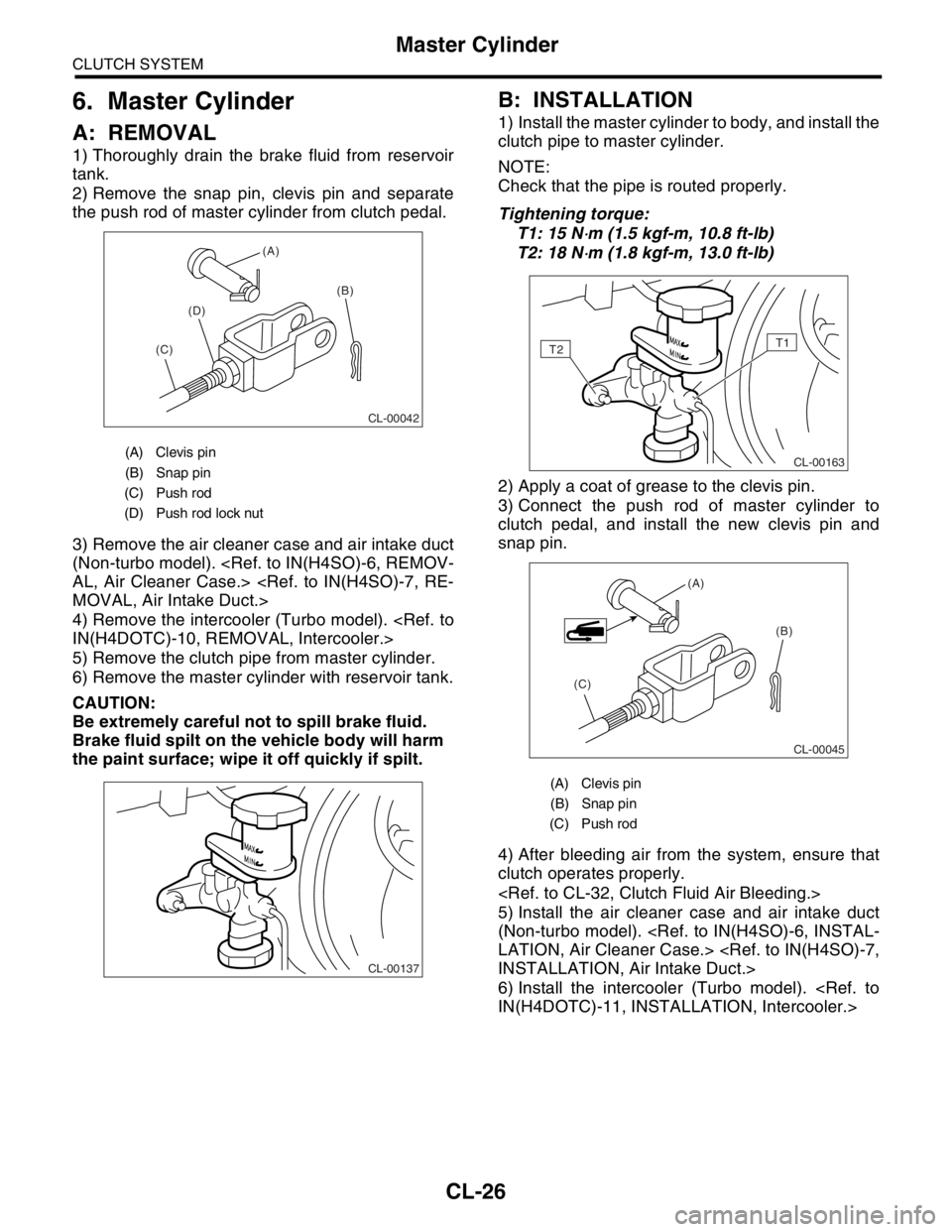

A: REMOVAL

1) Thoroughly drain the brake fluid from reservoir

tank.

2) Remove the snap pin, clevis pin and separate

the push rod of master cylinder from clutch pedal.

3) Remove the air cleaner case and air intake duct

(Non-turbo model).

4) Remove the intercooler (Turbo model).

5) Remove the clutch pipe from master cylinder.

6) Remove the master cylinder with reservoir tank.

CAUTION:

Be extremely careful not to spill brake fluid.

Brake fluid spilt on the vehicle body will harm

the paint surface; wipe it off quickly if spilt.

B: INSTALLATION

1) Install the master cylinder to body, and install the

clutch pipe to master cylinder.

NOTE:

Check that the pipe is routed properly.

Tightening torque:

T1: 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

T2: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

2) Apply a coat of grease to the clevis pin.

3) Connect the push rod of master cylinder to

clutch pedal, and install the new clevis pin and

snap pin.

4) After bleeding air from the system, ensure that

clutch operates properly.

5) Install the air cleaner case and air intake duct

(Non-turbo model).

6) Install the intercooler (Turbo model).

(A) Clevis pin

(B) Snap pin

(C) Push rod

(D) Push rod lock nut

CL-00042

(A)

(B)

(C)(D)

CL-00137

(A) Clevis pin

(B) Snap pin

(C) Push rod

CL-00163

T2T1

CL-00045

(A)

(B)

(C)

Page 2854 of 2870

CL-28

CLUTCH SYSTEM

Master Cylinder

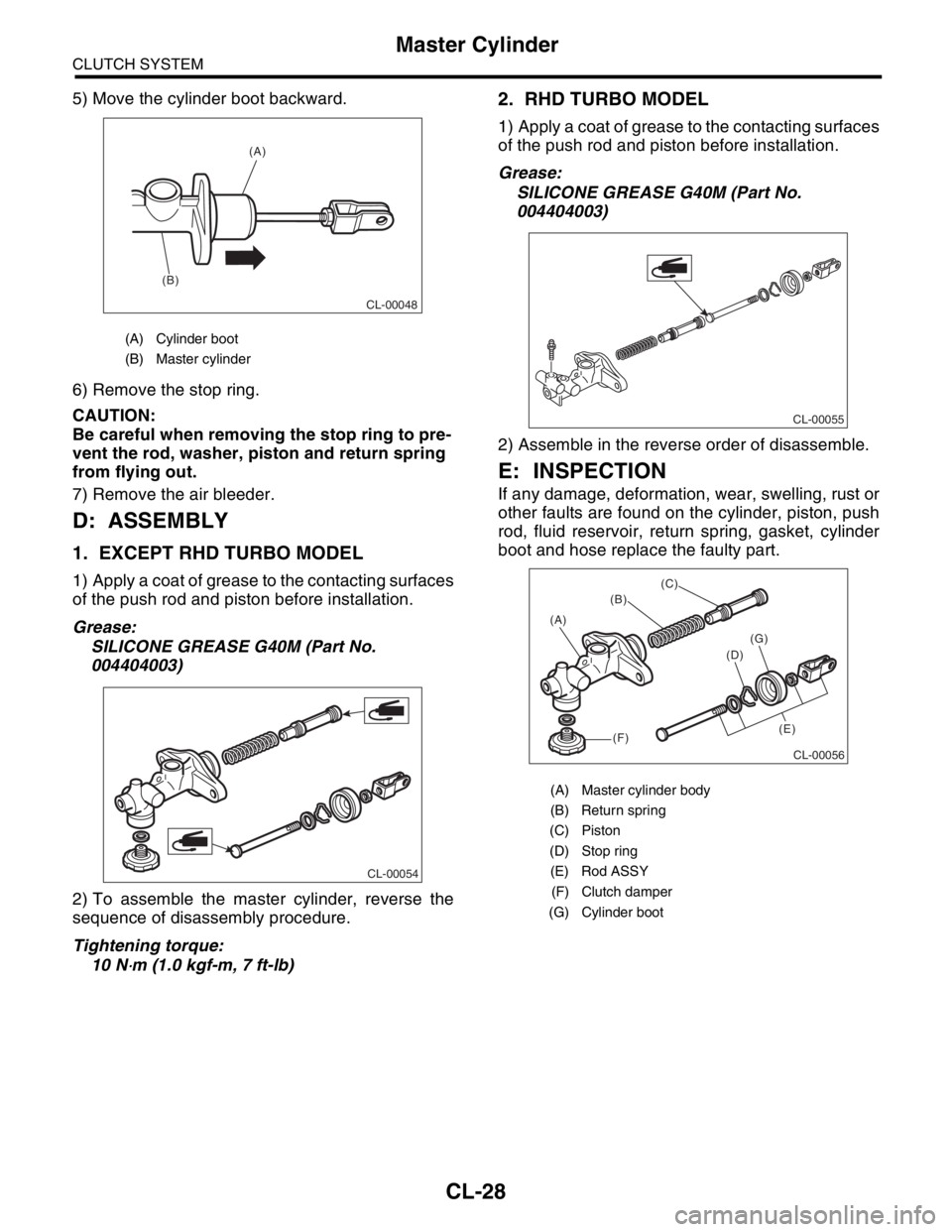

5) Move the cylinder boot backward.

6) Remove the stop ring.

CAUTION:

Be careful when removing the stop ring to pre-

vent the rod, washer, piston and return spring

from flying out.

7) Remove the air bleeder.

D: ASSEMBLY

1. EXCEPT RHD TURBO MODEL

1) Apply a coat of grease to the contacting surfaces

of the push rod and piston before installation.

Grease:

SILICONE GREASE G40M (Part No.

004404003)

2) To assemble the master cylinder, reverse the

sequence of disassembly procedure.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7 ft-lb)

2. RHD TURBO MODEL

1) Apply a coat of grease to the contacting surfaces

of the push rod and piston before installation.

Grease:

SILICONE GREASE G40M (Part No.

004404003)

2) Assemble in the reverse order of disassemble.

E: INSPECTION

If any damage, deformation, wear, swelling, rust or

other faults are found on the cylinder, piston, push

rod, fluid reservoir, return spring, gasket, cylinder

boot and hose replace the faulty part.

(A) Cylinder boot

(B) Master cylinder

CL-00048

(A)

(B)

CL-00054

(A) Master cylinder body

(B) Return spring

(C) Piston

(D) Stop ring

(E) Rod ASSY

(F) Clutch damper

(G) Cylinder boot

CL-00055

CL-00056

(B)

(C)

(D)

(E) (A)

(F)

(G)

Page 2856 of 2870

CL-30

CLUTCH SYSTEM

Clutch Pipe and Hose

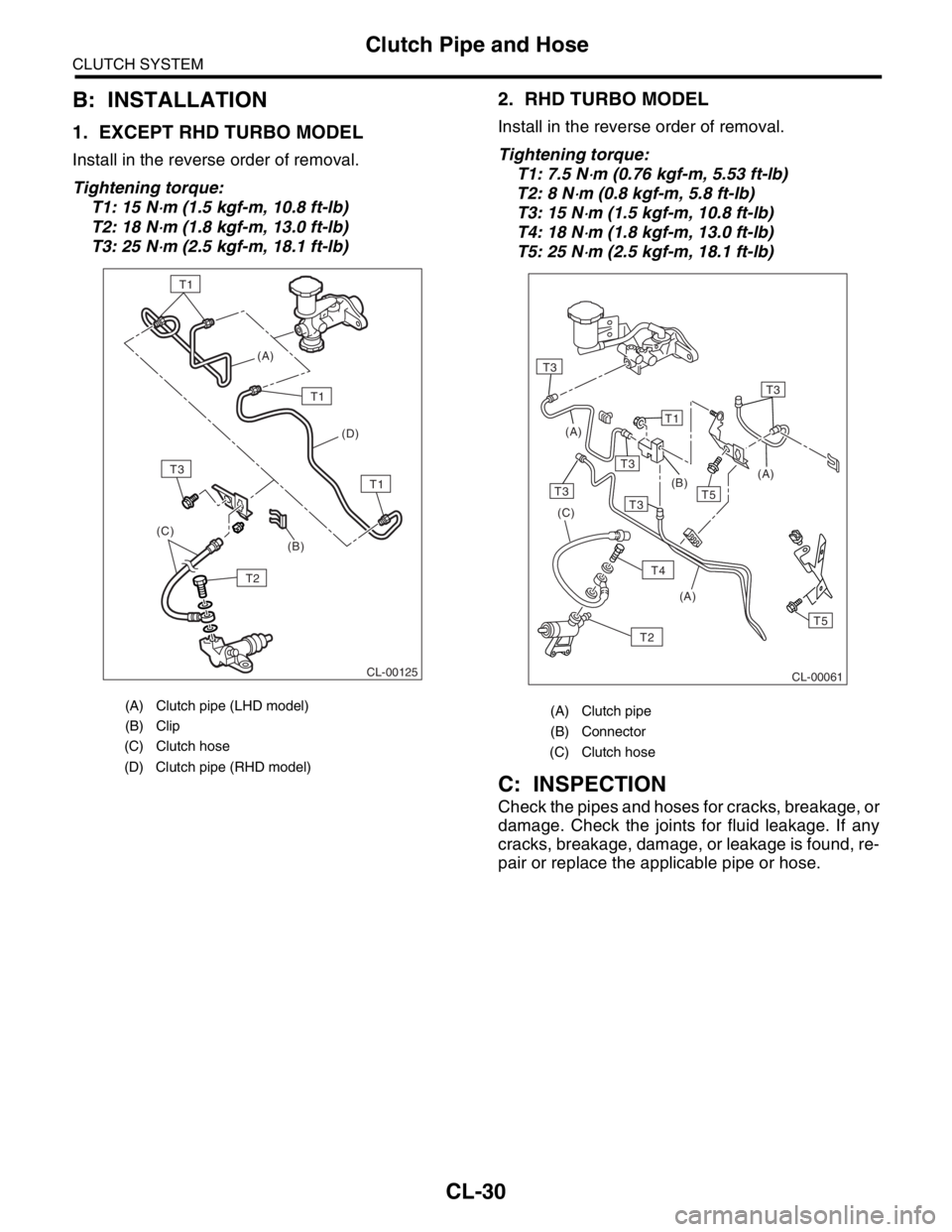

B: INSTALLATION

1. EXCEPT RHD TURBO MODEL

Install in the reverse order of removal.

Tightening torque:

T1: 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

T2: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

T3: 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

2. RHD TURBO MODEL

Install in the reverse order of removal.

Tightening torque:

T1: 7.5 N

⋅m (0.76 kgf-m, 5.53 ft-lb)

T2: 8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

T3: 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

T4: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

T5: 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

C: INSPECTION

Check the pipes and hoses for cracks, breakage, or

damage. Check the joints for fluid leakage. If any

cracks, breakage, damage, or leakage is found, re-

pair or replace the applicable pipe or hose.

(A) Clutch pipe (LHD model)

(B) Clip

(C) Clutch hose

(D) Clutch pipe (RHD model)

(D)

(B) (C)(A)

T1

T1

T2

T1

T3

CL-00125

(A) Clutch pipe

(B) Connector

(C) Clutch hose

(A)

(A) (A)

T3

T3T3

T3

T1

T3

T5

T5

(C)

T2

T4

(B)

CL-00061

Page 2858 of 2870

CL-32

CLUTCH SYSTEM

Clutch Fluid Air Bleeding

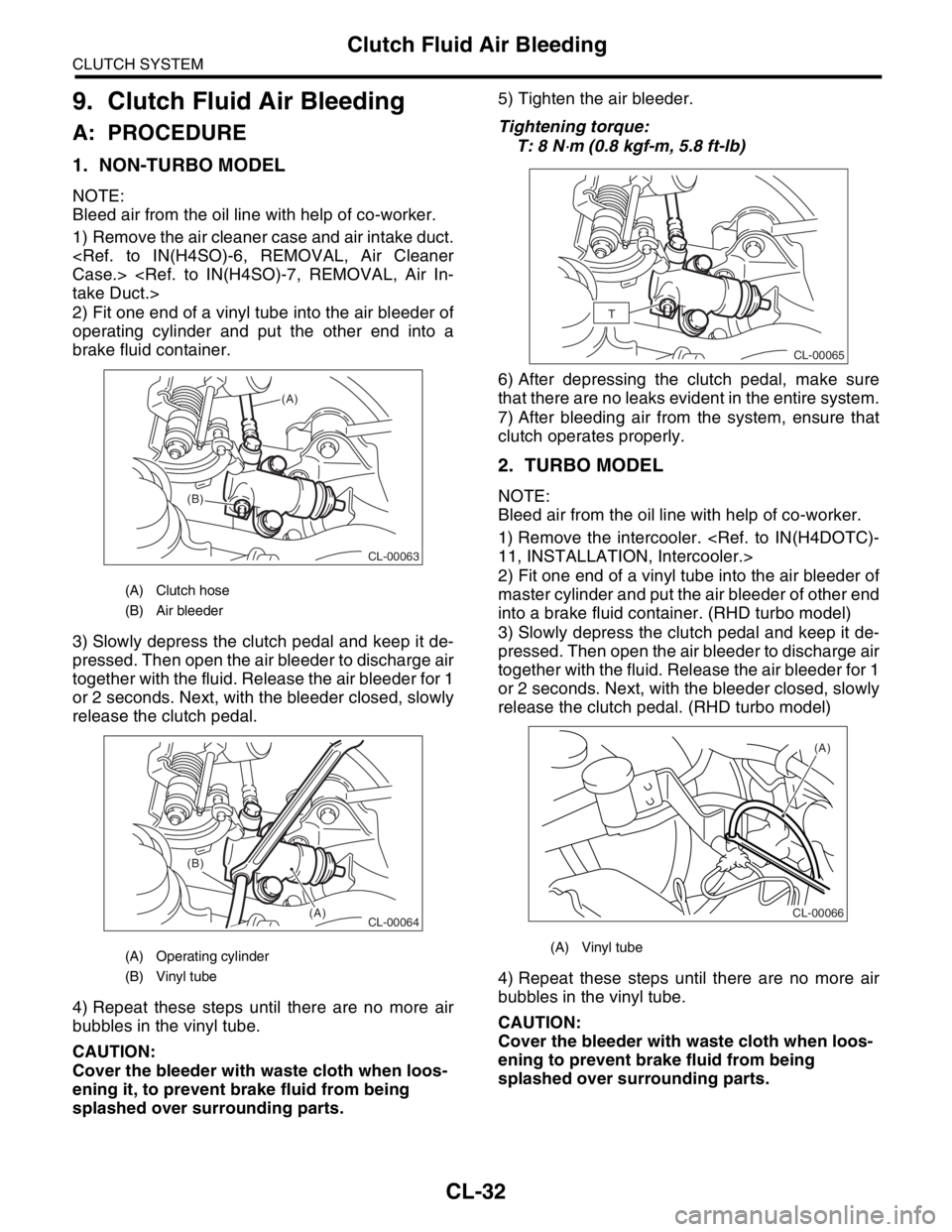

9. Clutch Fluid Air Bleeding

A: PROCEDURE

1. NON-TURBO MODEL

NOTE:

Bleed air from the oil line with help of co-worker.

1) Remove the air cleaner case and air intake duct.

2) Fit one end of a vinyl tube into the air bleeder of

operating cylinder and put the other end into a

brake fluid container.

3) Slowly depress the clutch pedal and keep it de-

pressed. Then open the air bleeder to discharge air

together with the fluid. Release the air bleeder for 1

or 2 seconds. Next, with the bleeder closed, slowly

release the clutch pedal.

4) Repeat these steps until there are no more air

bubbles in the vinyl tube.

CAUTION:

Cover the bleeder with waste cloth when loos-

ening it, to prevent brake fluid from being

splashed over surrounding parts.5) Tighten the air bleeder.

Tightening torque:

T: 8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

6) After depressing the clutch pedal, make sure

that there are no leaks evident in the entire system.

7) After bleeding air from the system, ensure that

clutch operates properly.

2. TURBO MODEL

NOTE:

Bleed air from the oil line with help of co-worker.

1) Remove the intercooler.

2) Fit one end of a vinyl tube into the air bleeder of

master cylinder and put the air bleeder of other end

into a brake fluid container. (RHD turbo model)

3) Slowly depress the clutch pedal and keep it de-

pressed. Then open the air bleeder to discharge air

together with the fluid. Release the air bleeder for 1

or 2 seconds. Next, with the bleeder closed, slowly

release the clutch pedal. (RHD turbo model)

4) Repeat these steps until there are no more air

bubbles in the vinyl tube.

CAUTION:

Cover the bleeder with waste cloth when loos-

ening to prevent brake fluid from being

splashed over surrounding parts.

(A) Clutch hose

(B) Air bleeder

(A) Operating cylinder

(B) Vinyl tube

CL-00063

(B)(A)

CL-00064

(B)

(A)

(A) Vinyl tube

CL-00065

T

(A)

CL-00066

Page 2859 of 2870

CL-33

CLUTCH SYSTEM

Clutch Fluid Air Bleeding

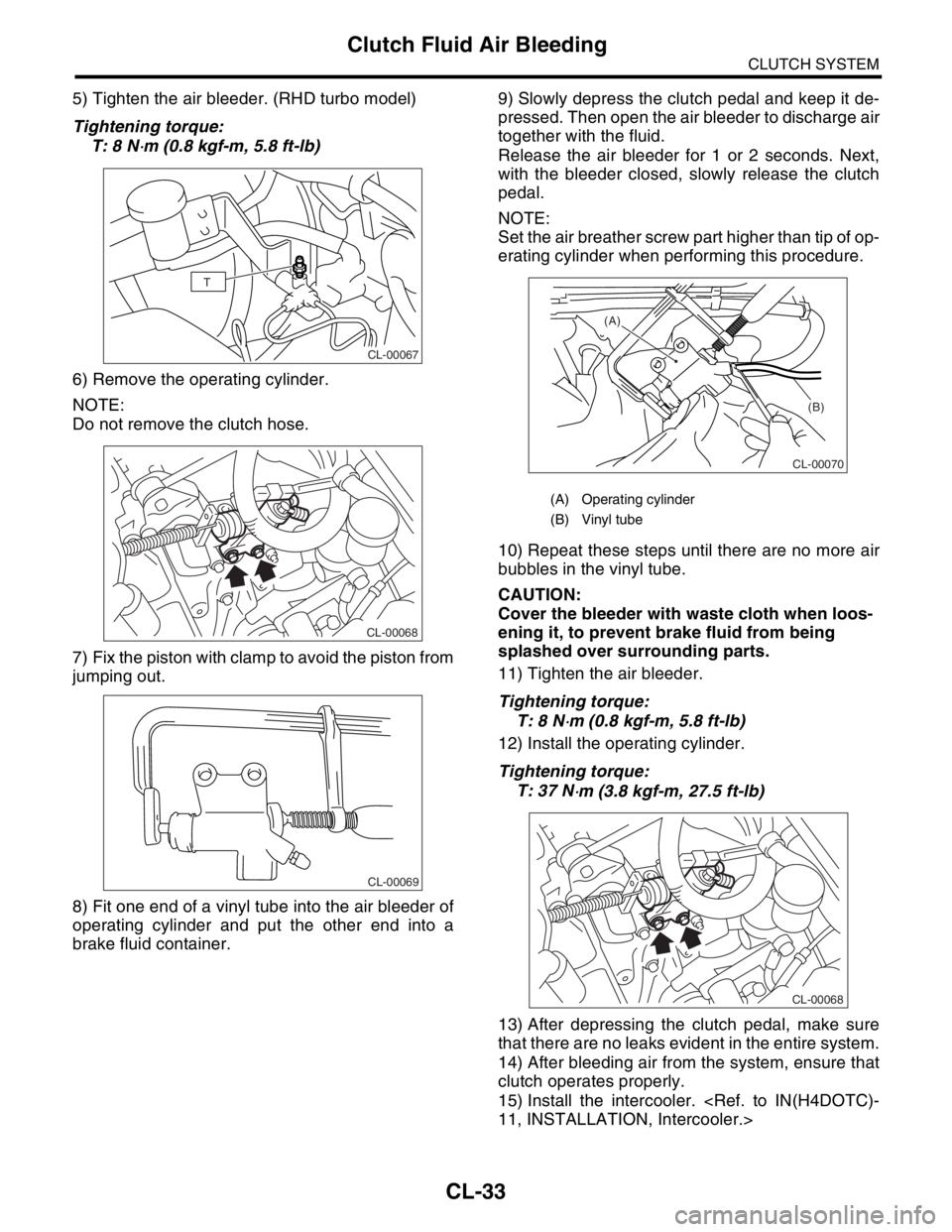

5) Tighten the air bleeder. (RHD turbo model)

Tightening torque:

T: 8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

6) Remove the operating cylinder.

NOTE:

Do not remove the clutch hose.

7) Fix the piston with clamp to avoid the piston from

jumping out.

8) Fit one end of a vinyl tube into the air bleeder of

operating cylinder and put the other end into a

brake fluid container.9) Slowly depress the clutch pedal and keep it de-

pressed. Then open the air bleeder to discharge air

together with the fluid.

Release the air bleeder for 1 or 2 seconds. Next,

with the bleeder closed, slowly release the clutch

pedal.

NOTE:

Set the air breather screw part higher than tip of op-

erating cylinder when performing this procedure.

10) Repeat these steps until there are no more air

bubbles in the vinyl tube.

CAUTION:

Cover the bleeder with waste cloth when loos-

ening it, to prevent brake fluid from being

splashed over surrounding parts.

11) Tighten the air bleeder.

Tightening torque:

T: 8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

12) Install the operating cylinder.

Tightening torque:

T: 37 N

⋅m (3.8 kgf-m, 27.5 ft-lb)

13) After depressing the clutch pedal, make sure

that there are no leaks evident in the entire system.

14) After bleeding air from the system, ensure that

clutch operates properly.

15) Install the intercooler.

CL-00067

T

CL-00068

CL-00069

(A) Operating cylinder

(B) Vinyl tube

CL-00070

(B) (A)

CL-00068

Page 2861 of 2870

CL-35

CLUTCH SYSTEM

Clutch Pedal

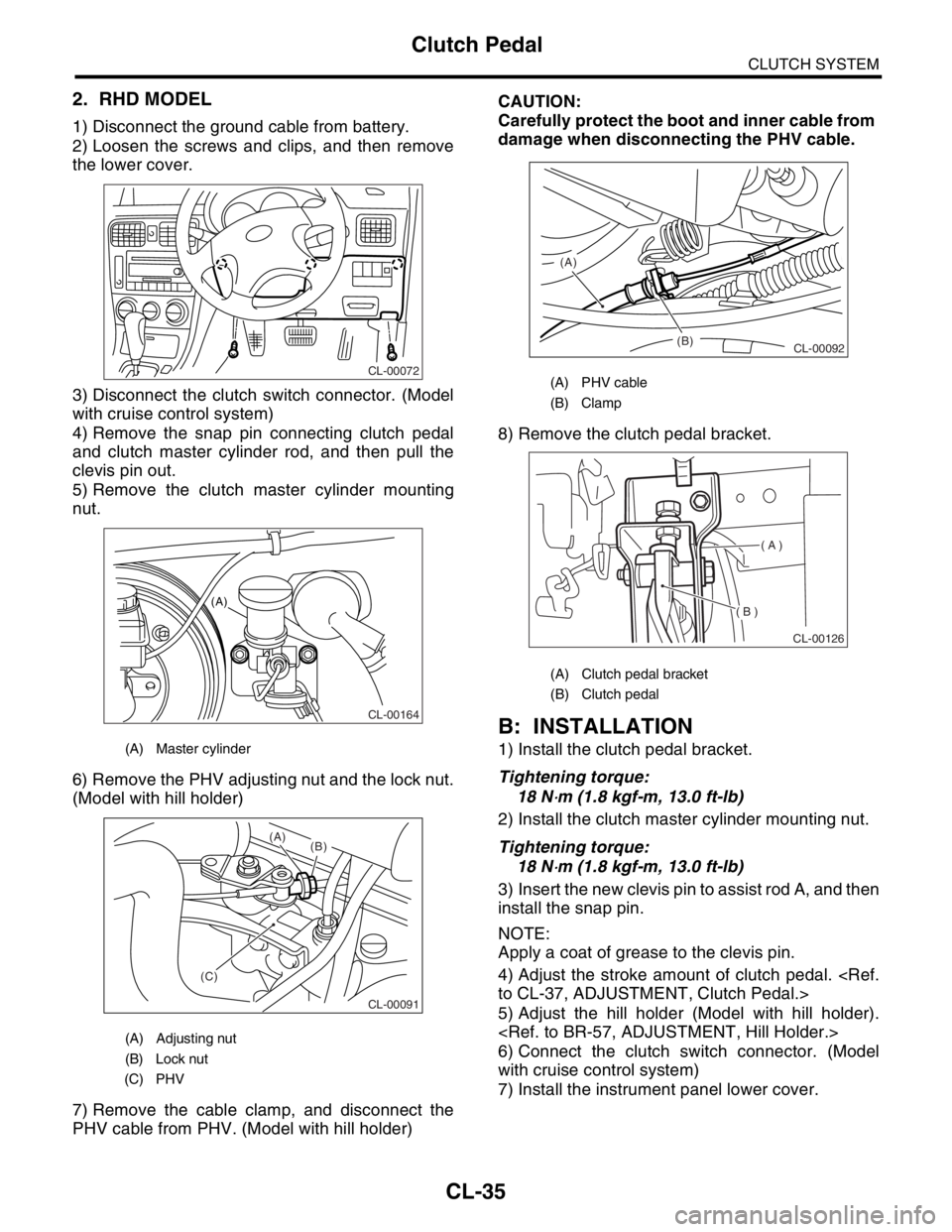

2. RHD MODEL

1) Disconnect the ground cable from battery.

2) Loosen the screws and clips, and then remove

the lower cover.

3) Disconnect the clutch switch connector. (Model

with cruise control system)

4) Remove the snap pin connecting clutch pedal

and clutch master cylinder rod, and then pull the

clevis pin out.

5) Remove the clutch master cylinder mounting

nut.

6) Remove the PHV adjusting nut and the lock nut.

(Model with hill holder)

7) Remove the cable clamp, and disconnect the

PHV cable from PHV. (Model with hill holder)CAUTION:

Carefully protect the boot and inner cable from

damage when disconnecting the PHV cable.

8) Remove the clutch pedal bracket.

B: INSTALLATION

1) Install the clutch pedal bracket.

Tightening torque:

18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

2) Install the clutch master cylinder mounting nut.

Tightening torque:

18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

3) Insert the new clevis pin to assist rod A, and then

install the snap pin.

NOTE:

Apply a coat of grease to the clevis pin.

4) Adjust the stroke amount of clutch pedal.

5) Adjust the hill holder (Model with hill holder).

6) Connect the clutch switch connector. (Model

with cruise control system)

7) Install the instrument panel lower cover.

(A) Master cylinder

(A) Adjusting nut

(B) Lock nut

(C) PHV

CL-00072

CL-00164

(A)

CL-00091

(C)(B) (A)

(A) PHV cable

(B) Clamp

(A) Clutch pedal bracket

(B) Clutch pedal

(B) (A)

CL-00092

( A )

( B )

CL-00126