torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2760 of 2870

5MT-48

MANUAL TRANSMISSION AND DIFFERENTIAL

Oil Pump

10.Oil Pump

A: REMOVAL

For extension case removal procedure, refer to

“Transfer Case and Extension Case Assembly”.

B: INSTALLATION

For extension case installation procedure, refer to

“Transfer Case Pump and Extension Case Assem-

bly”.

C: DISASSEMBLY

1) Remove the transfer drive gear assembly.

2) Remove the oil strainer from extension case.

3) Remove the shift bracket.

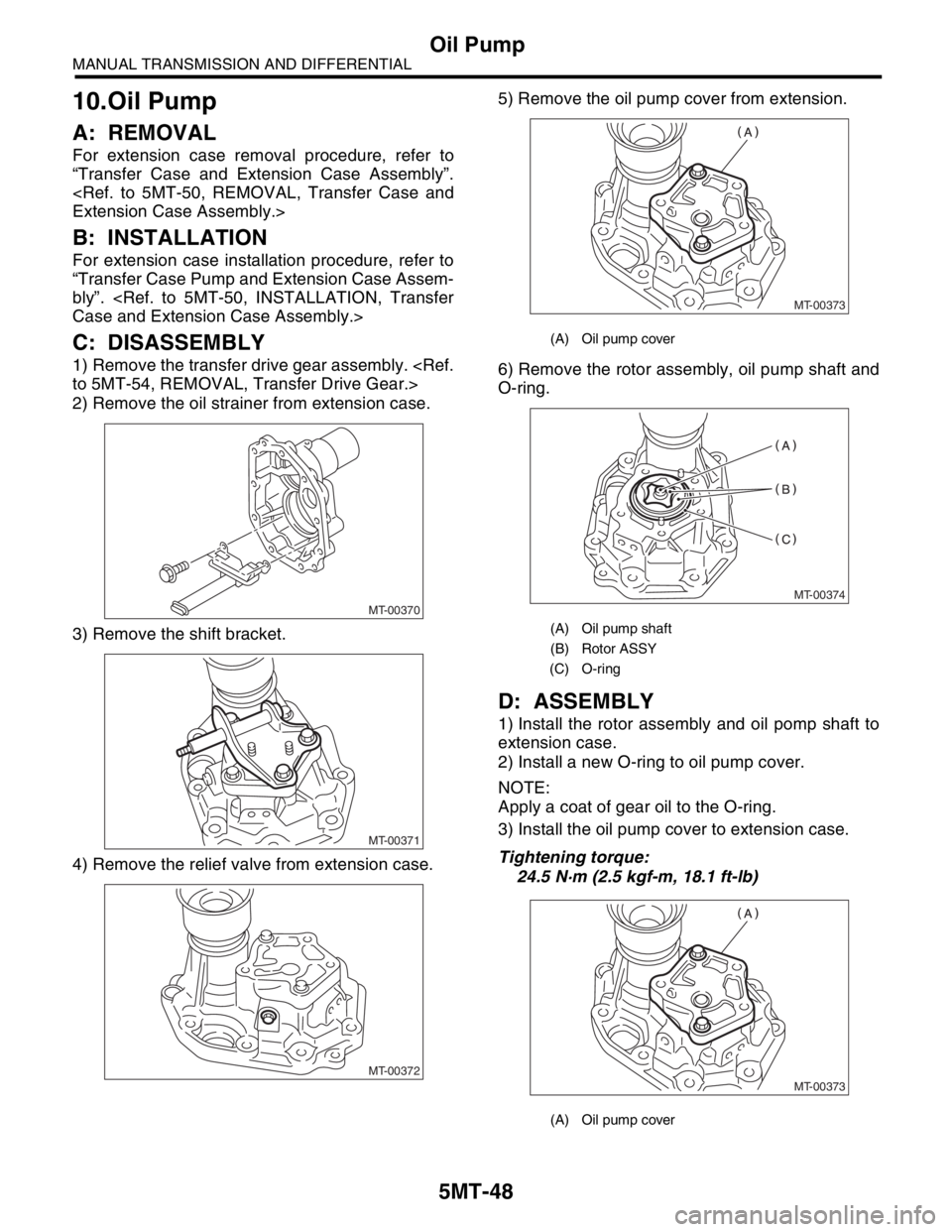

4) Remove the relief valve from extension case.5) Remove the oil pump cover from extension.

6) Remove the rotor assembly, oil pump shaft and

O-ring.

D: ASSEMBLY

1) Install the rotor assembly and oil pomp shaft to

extension case.

2) Install a new O-ring to oil pump cover.

NOTE:

Apply a coat of gear oil to the O-ring.

3) Install the oil pump cover to extension case.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

MT-00370

MT-00371

MT-00372

(A) Oil pump cover

(A) Oil pump shaft

(B) Rotor ASSY

(C) O-ring

(A) Oil pump cover

MT-00373

MT-00374

MT-00373

Page 2761 of 2870

5MT-49

MANUAL TRANSMISSION AND DIFFERENTIAL

Oil Pump

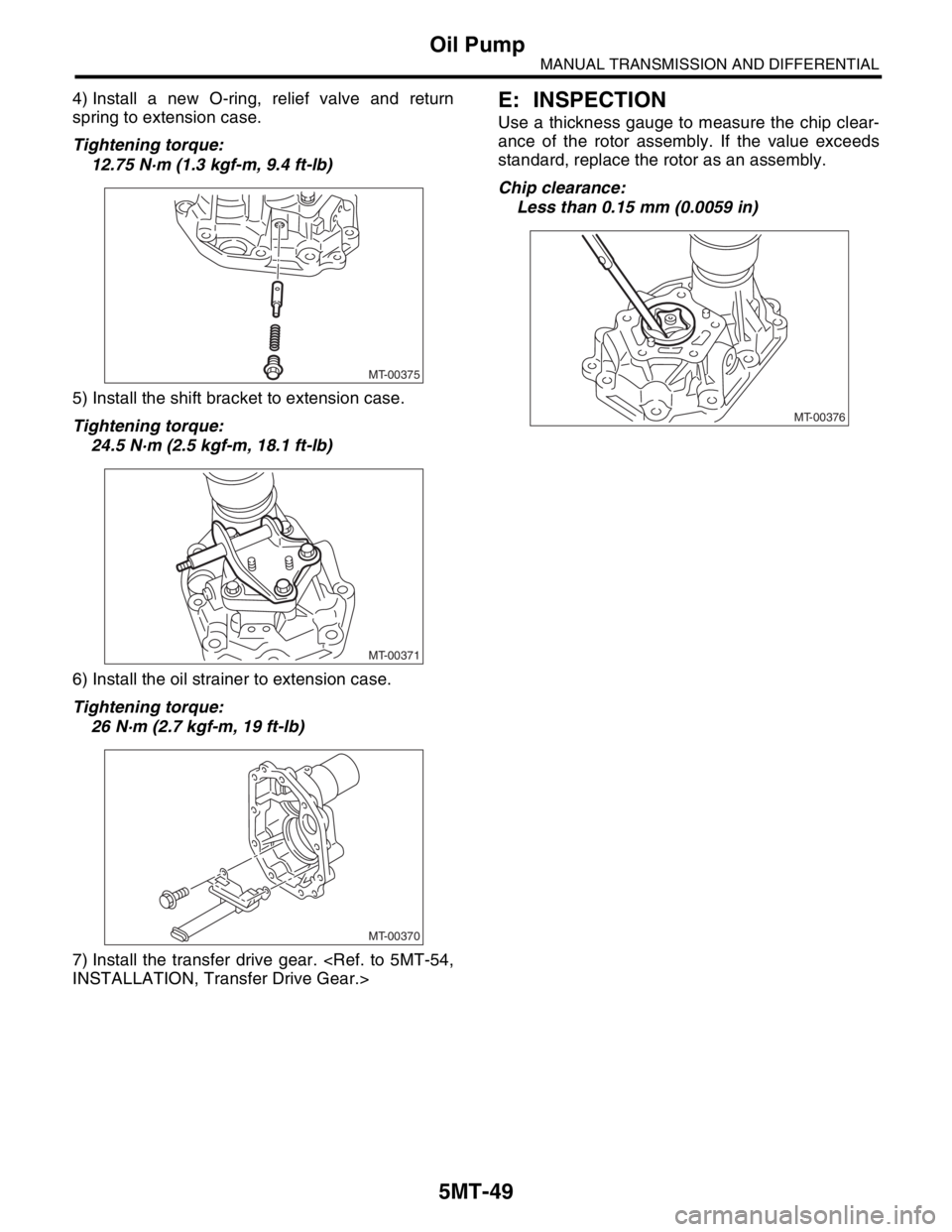

4) Install a new O-ring, relief valve and return

spring to extension case.

Tightening torque:

12.75 N·m (1.3 kgf-m, 9.4 ft-lb)

5) Install the shift bracket to extension case.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

6) Install the oil strainer to extension case.

Tightening torque:

26 N·m (2.7 kgf-m, 19 ft-lb)

7) Install the transfer drive gear.

Use a thickness gauge to measure the chip clear-

ance of the rotor assembly. If the value exceeds

standard, replace the rotor as an assembly.

Chip clearance:

Less than 0.15 mm (0.0059 in)

MT-00375

MT-00371

MT-00370

MT-00376

Page 2763 of 2870

5MT-51

MANUAL TRANSMISSION AND DIFFERENTIAL

Transfer Case and Extension Case Assembly

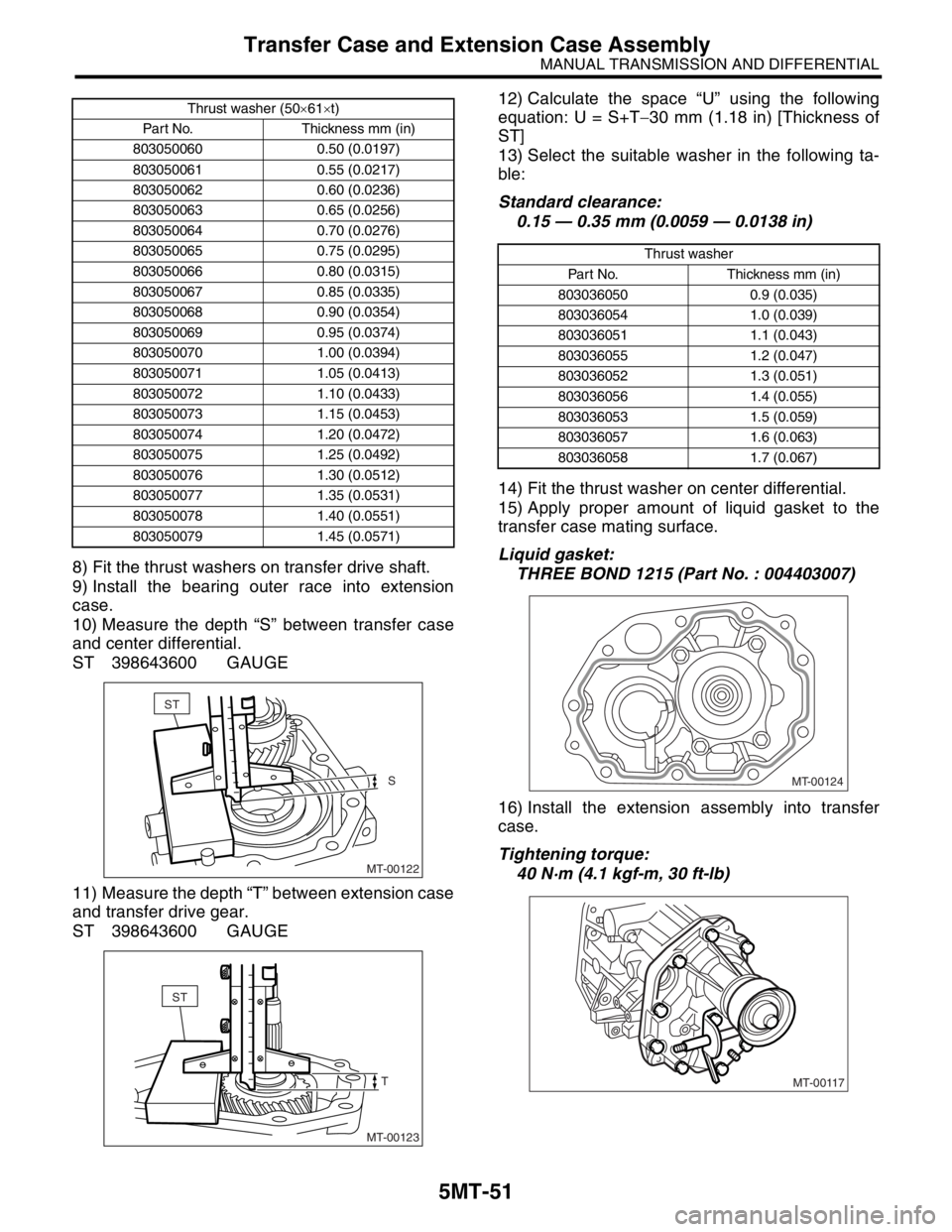

8) Fit the thrust washers on transfer drive shaft.

9) Install the bearing outer race into extension

case.

10) Measure the depth “S” between transfer case

and center differential.

ST 398643600 GAUGE

11) Measure the depth “T” between extension case

and transfer drive gear.

ST 398643600 GAUGE12) Calculate the space “U” using the following

equation: U = S+T−30 mm (1.18 in) [Thickness of

ST]

13) Select the suitable washer in the following ta-

ble:

Standard clearance:

0.15 — 0.35 mm (0.0059 — 0.0138 in)

14) Fit the thrust washer on center differential.

15) Apply proper amount of liquid gasket to the

transfer case mating surface.

Liquid gasket:

THREE BOND 1215 (Part No. : 004403007)

16) Install the extension assembly into transfer

case.

Tightening torque:

40 N·m (4.1 kgf-m, 30 ft-lb)

Thrust washer (50×61×t)

Part No. Thickness mm (in)

803050060 0.50 (0.0197)

803050061 0.55 (0.0217)

803050062 0.60 (0.0236)

803050063 0.65 (0.0256)

803050064 0.70 (0.0276)

803050065 0.75 (0.0295)

803050066 0.80 (0.0315)

803050067 0.85 (0.0335)

803050068 0.90 (0.0354)

803050069 0.95 (0.0374)

803050070 1.00 (0.0394)

803050071 1.05 (0.0413)

803050072 1.10 (0.0433)

803050073 1.15 (0.0453)

803050074 1.20 (0.0472)

803050075 1.25 (0.0492)

803050076 1.30 (0.0512)

803050077 1.35 (0.0531)

803050078 1.40 (0.0551)

803050079 1.45 (0.0571)

MT-00122

ST

S

MT-00123

T

ST

Thrust washer

Part No. Thickness mm (in)

803036050 0.9 (0.035)

803036054 1.0 (0.039)

803036051 1.1 (0.043)

803036055 1.2 (0.047)

803036052 1.3 (0.051)

803036056 1.4 (0.055)

803036053 1.5 (0.059)

803036057 1.6 (0.063)

803036058 1.7 (0.067)

MT-00124

MT-00117

Page 2764 of 2870

5MT-52

MANUAL TRANSMISSION AND DIFFERENTIAL

Transfer Case and Extension Case Assembly

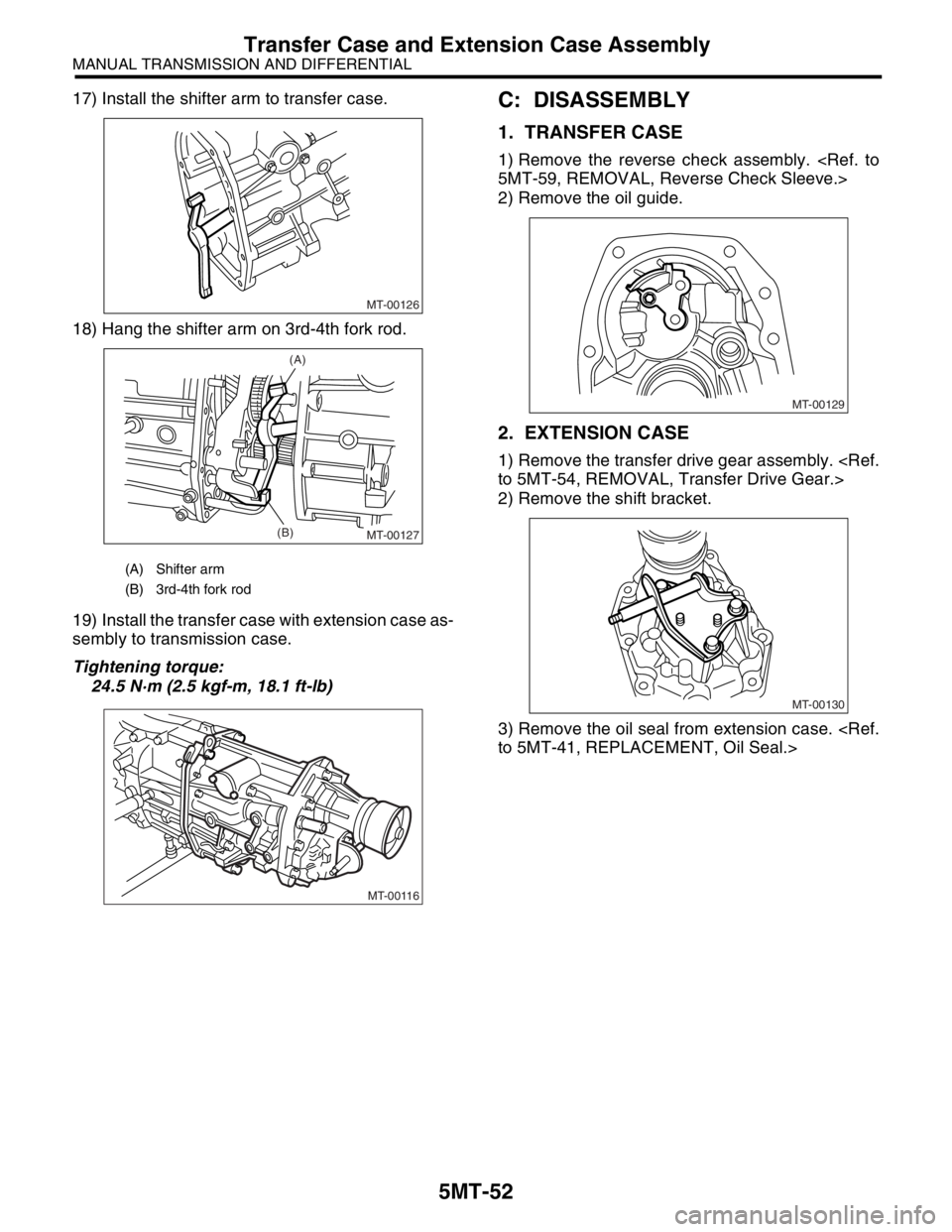

17) Install the shifter arm to transfer case.

18) Hang the shifter arm on 3rd-4th fork rod.

19) Install the transfer case with extension case as-

sembly to transmission case.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)C: DISASSEMBLY

1. TRANSFER CASE

1) Remove the reverse check assembly.

2) Remove the oil guide.

2. EXTENSION CASE

1) Remove the transfer drive gear assembly.

2) Remove the shift bracket.

3) Remove the oil seal from extension case.

(A) Shifter arm

(B) 3rd-4th fork rod

MT-00126

MT-00127

(A)

(B)

MT-00116

MT-00129

MT-00130

Page 2765 of 2870

5MT-53

MANUAL TRANSMISSION AND DIFFERENTIAL

Transfer Case and Extension Case Assembly

D: ASSEMBLY

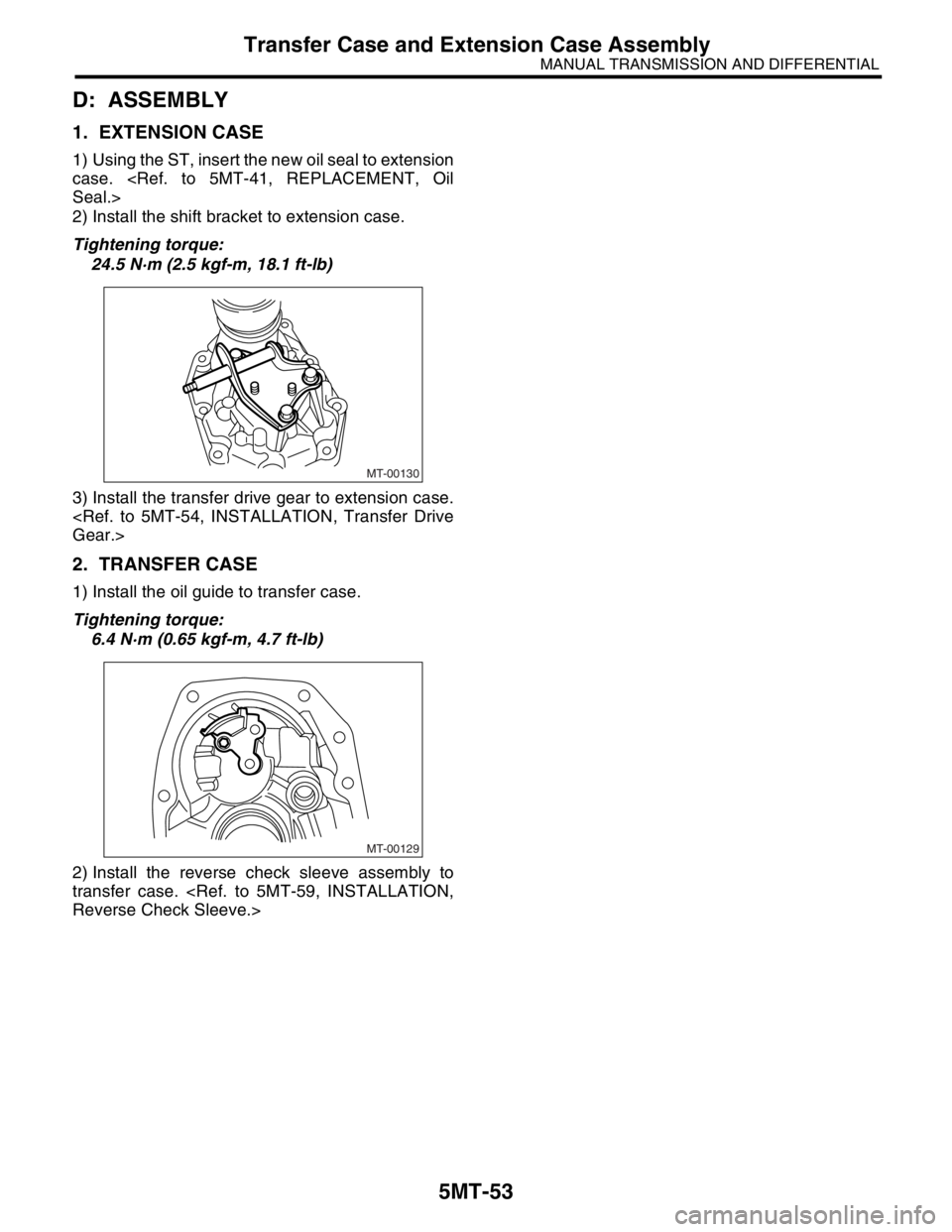

1. EXTENSION CASE

1) Using the ST, insert the new oil seal to extension

case.

2) Install the shift bracket to extension case.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

3) Install the transfer drive gear to extension case.

2. TRANSFER CASE

1) Install the oil guide to transfer case.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

2) Install the reverse check sleeve assembly to

transfer case.

MT-00130

MT-00129

Page 2766 of 2870

5MT-54

MANUAL TRANSMISSION AND DIFFERENTIAL

Transfer Drive Gear

12.Transfer Drive Gear

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the back-up light switch and neutral po-

sition switch.

3) Remove the transfer case with extension case

assembly.

4) Remove the extension case assembly.

5) Remove the transfer driven gear.

6) Remove the transfer drive gear.

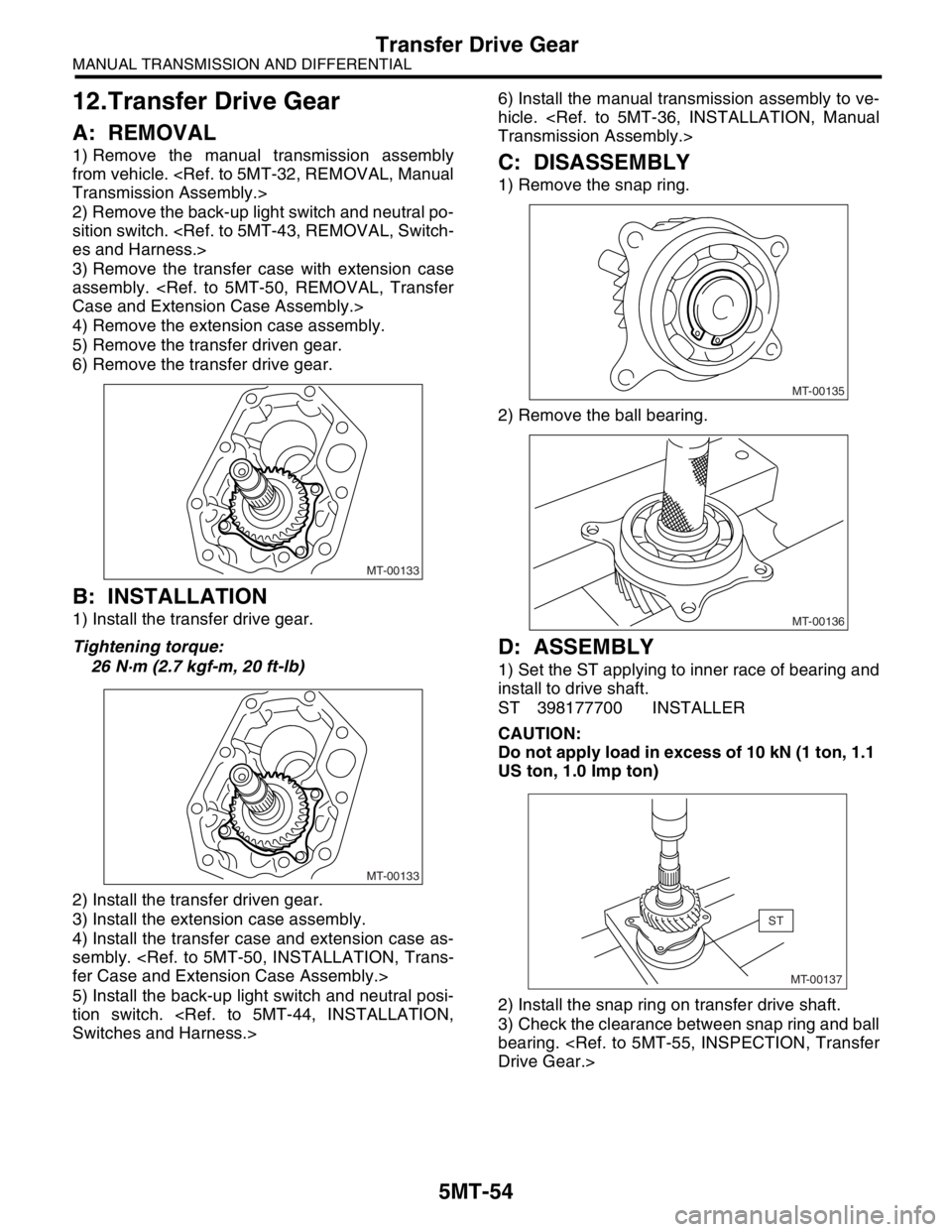

B: INSTALLATION

1) Install the transfer drive gear.

Tightening torque:

26 N·m (2.7 kgf-m, 20 ft-lb)

2) Install the transfer driven gear.

3) Install the extension case assembly.

4) Install the transfer case and extension case as-

sembly.

5) Install the back-up light switch and neutral posi-

tion switch.

hicle.

C: DISASSEMBLY

1) Remove the snap ring.

2) Remove the ball bearing.

D: ASSEMBLY

1) Set the ST applying to inner race of bearing and

install to drive shaft.

ST 398177700 INSTALLER

CAUTION:

Do not apply load in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton)

2) Install the snap ring on transfer drive shaft.

3) Check the clearance between snap ring and ball

bearing.

MT-00133

MT-00133

MT-00135

MT-00136

MT-00137

ST

Page 2772 of 2870

5MT-59

MANUAL TRANSMISSION AND DIFFERENTIAL

Reverse Check Sleeve

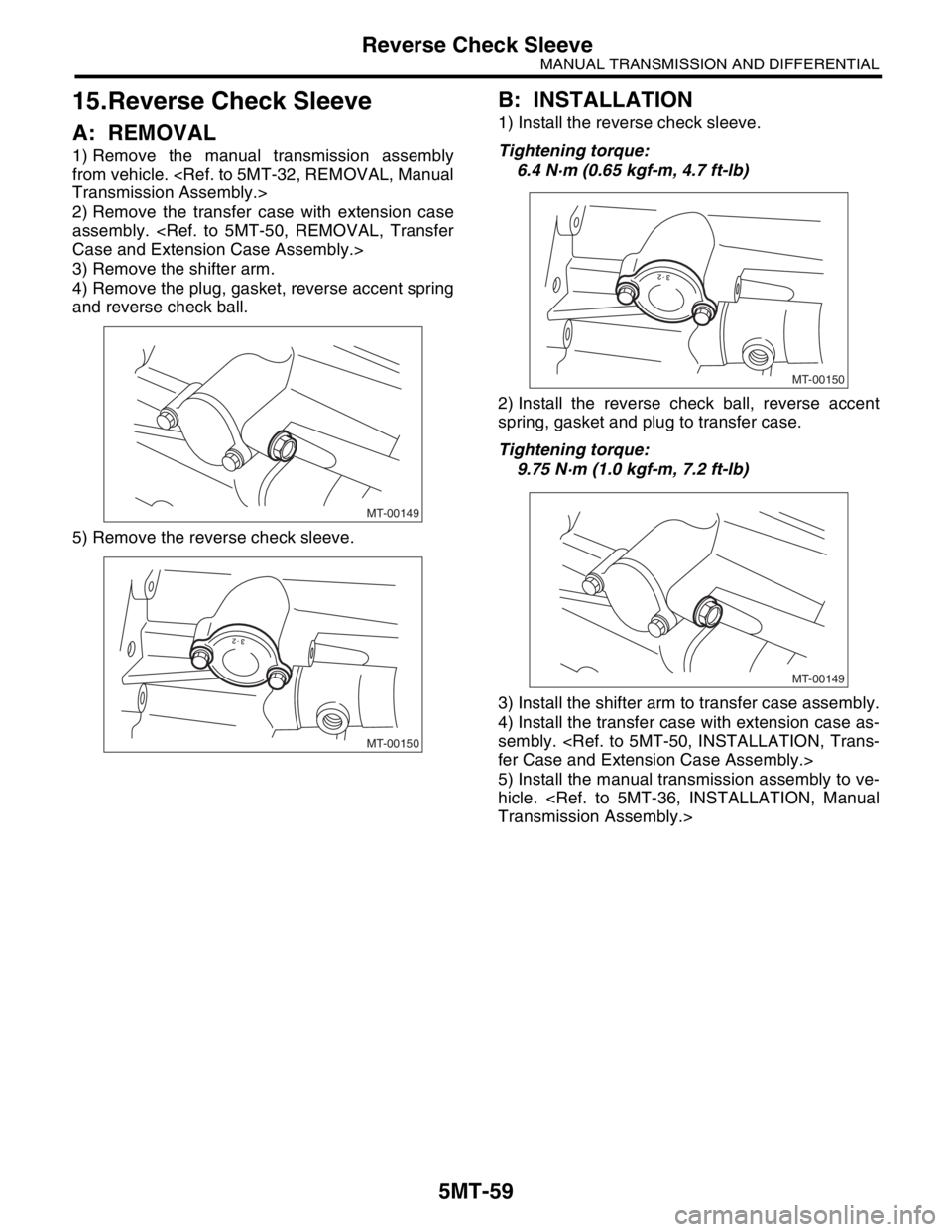

15.Reverse Check Sleeve

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the transfer case with extension case

assembly.

3) Remove the shifter arm.

4) Remove the plug, gasket, reverse accent spring

and reverse check ball.

5) Remove the reverse check sleeve.

B: INSTALLATION

1) Install the reverse check sleeve.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

2) Install the reverse check ball, reverse accent

spring, gasket and plug to transfer case.

Tightening torque:

9.75 N·m (1.0 kgf-m, 7.2 ft-lb)

3) Install the shifter arm to transfer case assembly.

4) Install the transfer case with extension case as-

sembly.

5) Install the manual transmission assembly to ve-

hicle.

MT-00149

MT-00150

MT-00150

MT-00149

Page 2777 of 2870

5MT-64

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Case

11) Remove the main shaft assembly and input

shaft assembly.

NOTE:

Be careful not to drop the input shaft and main shaft

as they are separable.

12) Remove the differential assembly.

NOTE:

Be careful not to confuse the right and left roller

bearing outer races.

Be careful not to damage the retainer oil seal.

B: INSTALLATION

1. SINGLE-RANGE

1) Wipe off grease, oil and dust on the mating sur-

faces of transmission cases with white gasoline.

2) Install the front differential assembly.

3) Install the main shaft assembly.

Install the needle bearing knock pin hole into trans-

mission case knock pin.

4) Install the drive pinion shaft assembly.

Install the roller bearing knock pin hole into trans-

mission case knock pin.

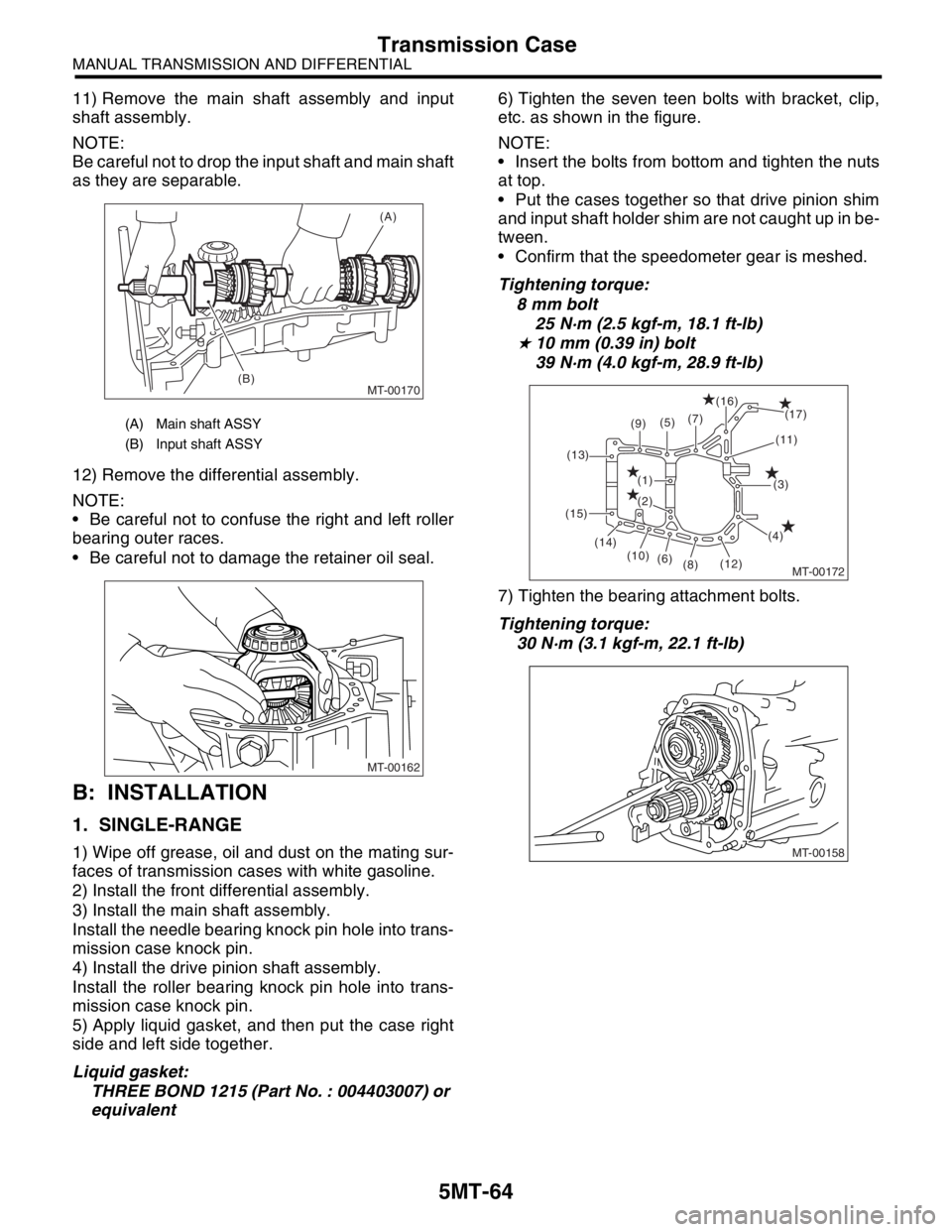

5) Apply liquid gasket, and then put the case right

side and left side together.

Liquid gasket:

THREE BOND 1215 (Part No. : 004403007) or

equivalent6) Tighten the seven teen bolts with bracket, clip,

etc. as shown in the figure.

NOTE:

Insert the bolts from bottom and tighten the nuts

at top.

Put the cases together so that drive pinion shim

and input shaft holder shim are not caught up in be-

tween.

Confirm that the speedometer gear is meshed.

Tightening torque:

8 mm bolt

25 N·m (2.5 kgf-m, 18.1 ft-lb)

★ 10 mm (0.39 in) bolt

39 N·m (4.0 kgf-m, 28.9 ft-lb)

7) Tighten the bearing attachment bolts.

Tightening torque:

30 N·m (3.1 kgf-m, 22.1 ft-lb)

(A) Main shaft ASSY

(B) Input shaft ASSY

MT-00170

(A)

(B)

MT-00162

(9)(7)

(5)

(1)

(2)(16)

(17)

(11)

(3)

(4)

(12)

(8) (6) (10) (14) (15)(13)

MT-00172

MT-00158

Page 2779 of 2870

5MT-66

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Case

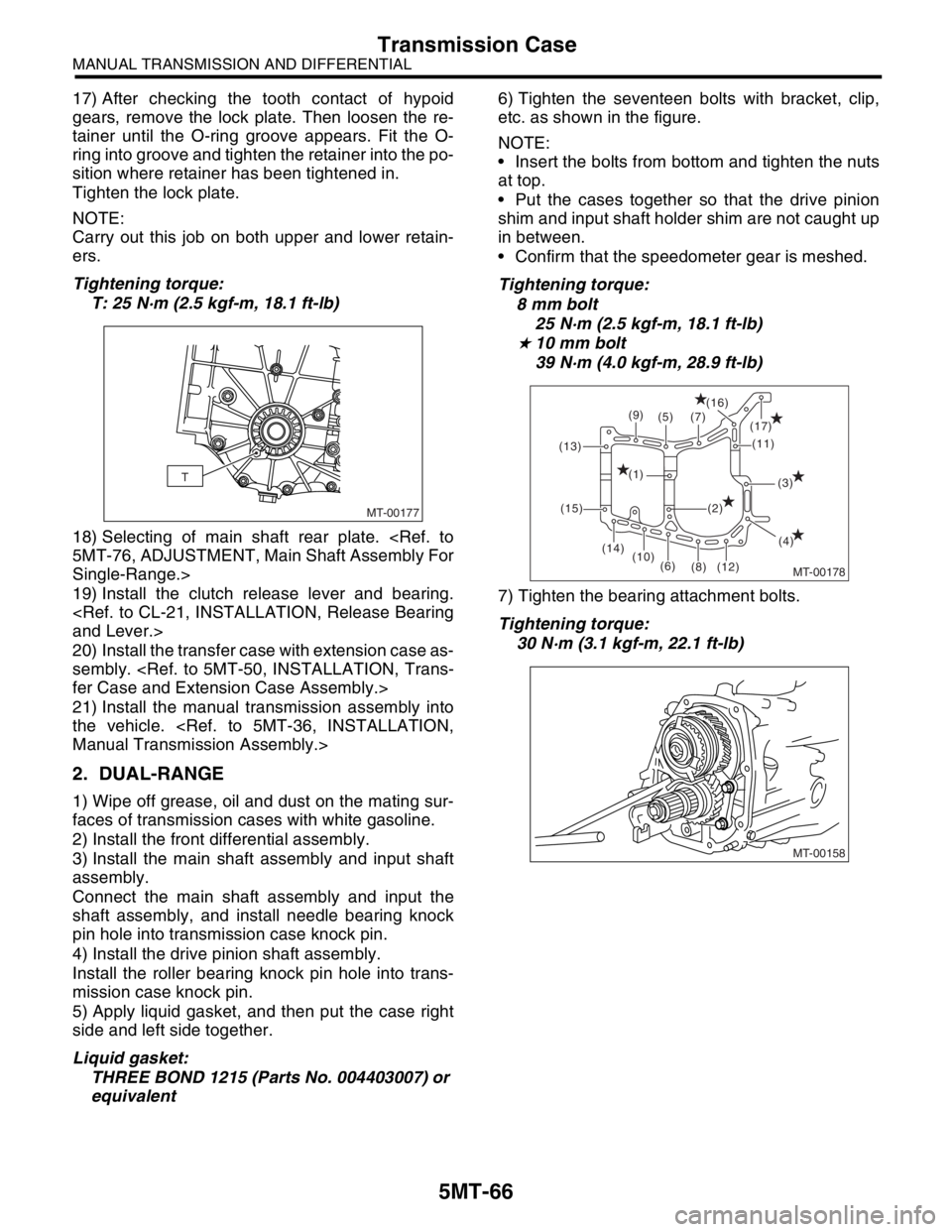

17) After checking the tooth contact of hypoid

gears, remove the lock plate. Then loosen the re-

tainer until the O-ring groove appears. Fit the O-

ring into groove and tighten the retainer into the po-

sition where retainer has been tightened in.

Tighten the lock plate.

NOTE:

Carry out this job on both upper and lower retain-

ers.

Tightening torque:

T: 25 N·m (2.5 kgf-m, 18.1 ft-lb)

18) Selecting of main shaft rear plate.

Single-Range.>

19) Install the clutch release lever and bearing.

20) Install the transfer case with extension case as-

sembly.

21) Install the manual transmission assembly into

the vehicle.

2. DUAL-RANGE

1) Wipe off grease, oil and dust on the mating sur-

faces of transmission cases with white gasoline.

2) Install the front differential assembly.

3) Install the main shaft assembly and input shaft

assembly.

Connect the main shaft assembly and input the

shaft assembly, and install needle bearing knock

pin hole into transmission case knock pin.

4) Install the drive pinion shaft assembly.

Install the roller bearing knock pin hole into trans-

mission case knock pin.

5) Apply liquid gasket, and then put the case right

side and left side together.

Liquid gasket:

THREE BOND 1215 (Parts No. 004403007) or

equivalent6) Tighten the seventeen bolts with bracket, clip,

etc. as shown in the figure.

NOTE:

Insert the bolts from bottom and tighten the nuts

at top.

Put the cases together so that the drive pinion

shim and input shaft holder shim are not caught up

in between.

Confirm that the speedometer gear is meshed.

Tightening torque:

8 mm bolt

25 N·m (2.5 kgf-m, 18.1 ft-lb)

★ 10 mm bolt

39 N·m (4.0 kgf-m, 28.9 ft-lb)

7) Tighten the bearing attachment bolts.

Tightening torque:

30 N·m (3.1 kgf-m, 22.1 ft-lb)

MT-00177

T

MT-00178

(9)

(7) (5)(16)

(17)

(11)

(3)

(4) (2) (1)

(12) (8) (6) (10) (14) (15) (13)

MT-00158

Page 2780 of 2870

5MT-67

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Case

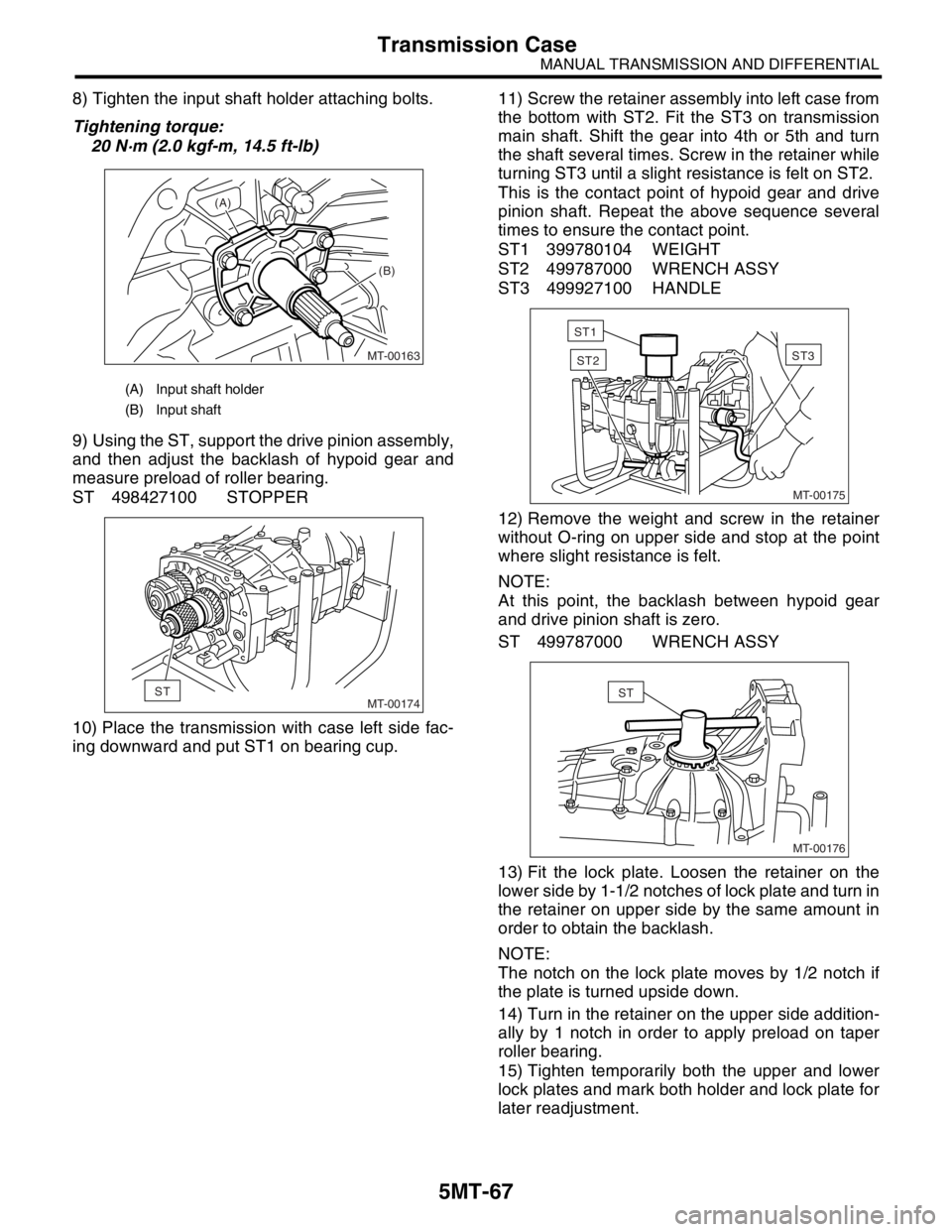

8) Tighten the input shaft holder attaching bolts.

Tightening torque:

20 N·m (2.0 kgf-m, 14.5 ft-lb)

9) Using the ST, support the drive pinion assembly,

and then adjust the backlash of hypoid gear and

measure preload of roller bearing.

ST 498427100 STOPPER

10) Place the transmission with case left side fac-

ing downward and put ST1 on bearing cup.11) Screw the retainer assembly into left case from

the bottom with ST2. Fit the ST3 on transmission

main shaft. Shift the gear into 4th or 5th and turn

the shaft several times. Screw in the retainer while

turning ST3 until a slight resistance is felt on ST2.

This is the contact point of hypoid gear and drive

pinion shaft. Repeat the above sequence several

times to ensure the contact point.

ST1 399780104 WEIGHT

ST2 499787000 WRENCH ASSY

ST3 499927100 HANDLE

12) Remove the weight and screw in the retainer

without O-ring on upper side and stop at the point

where slight resistance is felt.

NOTE:

At this point, the backlash between hypoid gear

and drive pinion shaft is zero.

ST 499787000 WRENCH ASSY

13) Fit the lock plate. Loosen the retainer on the

lower side by 1-1/2 notches of lock plate and turn in

the retainer on upper side by the same amount in

order to obtain the backlash.

NOTE:

The notch on the lock plate moves by 1/2 notch if

the plate is turned upside down.

14) Turn in the retainer on the upper side addition-

ally by 1 notch in order to apply preload on taper

roller bearing.

15) Tighten temporarily both the upper and lower

lock plates and mark both holder and lock plate for

later readjustment.

(A) Input shaft holder

(B) Input shaft

MT-00163

(A)

(B)

MT-00174ST

MT-00175

ST3ST2

ST1

MT-00176

ST