torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2864 of 2870

CL-38

CLUTCH SYSTEM

Clutch Pedal

2) If not as specified, loosen the clutch stopper nut

to adjust it.

Tightening torque (Clutch stopper nut):

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

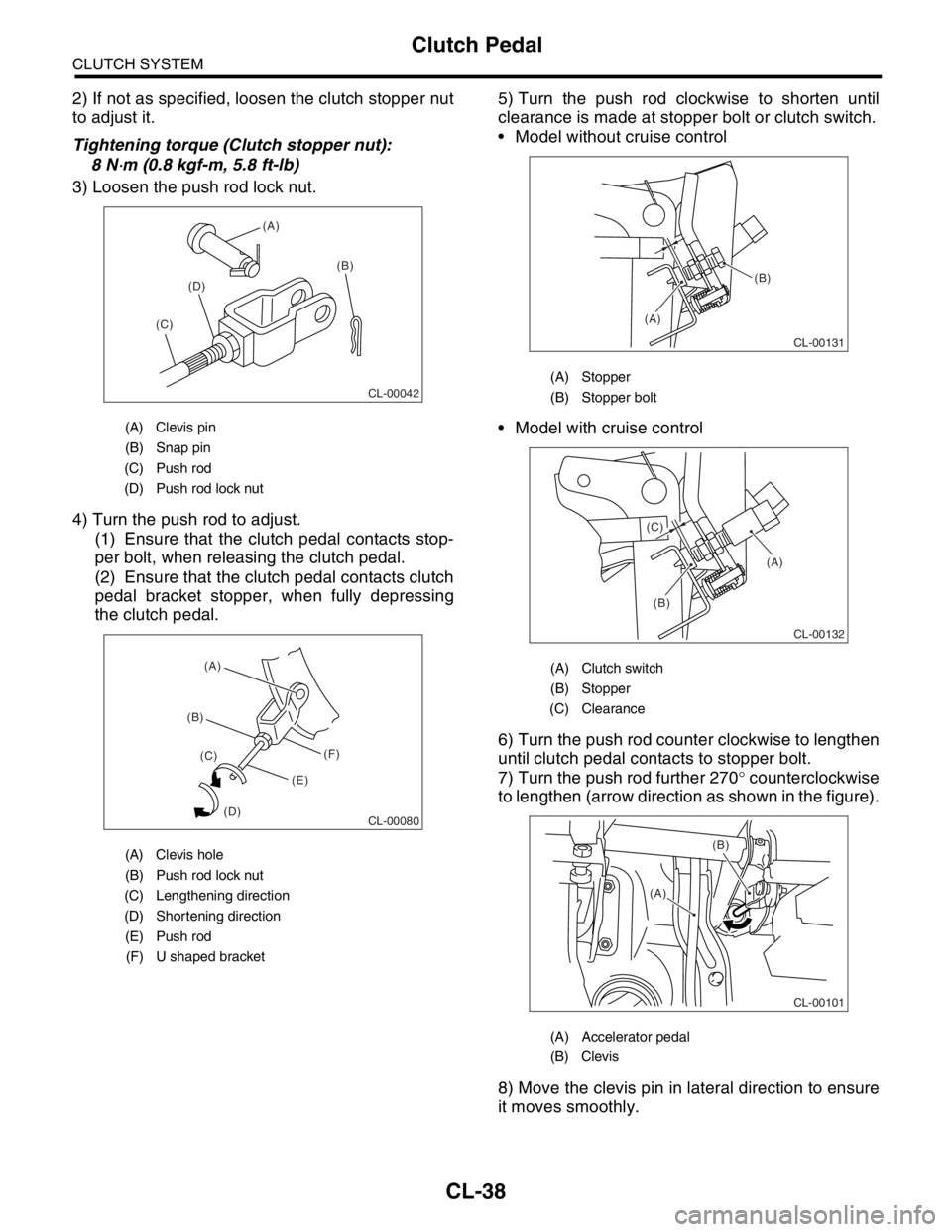

3) Loosen the push rod lock nut.

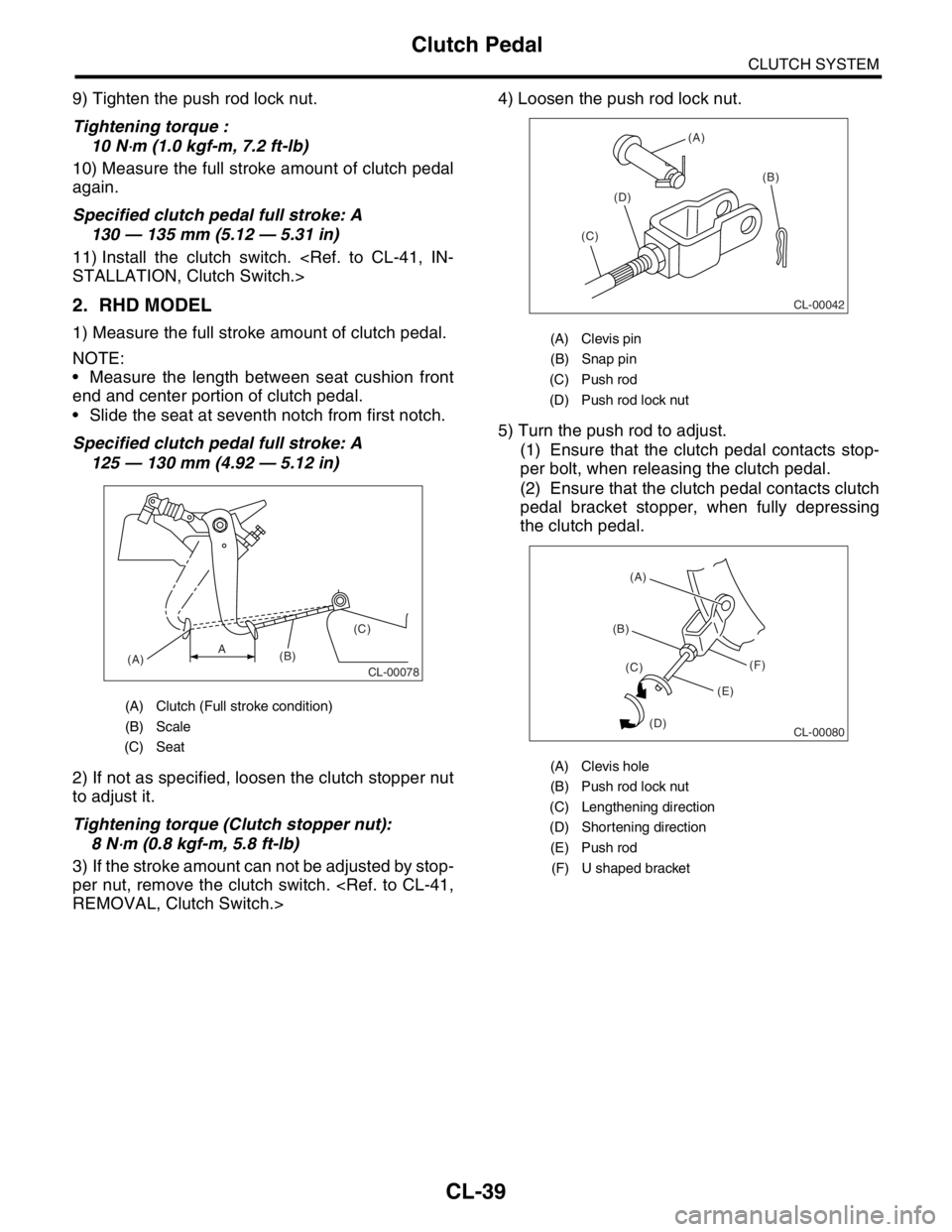

4) Turn the push rod to adjust.

(1) Ensure that the clutch pedal contacts stop-

per bolt, when releasing the clutch pedal.

(2) Ensure that the clutch pedal contacts clutch

pedal bracket stopper, when fully depressing

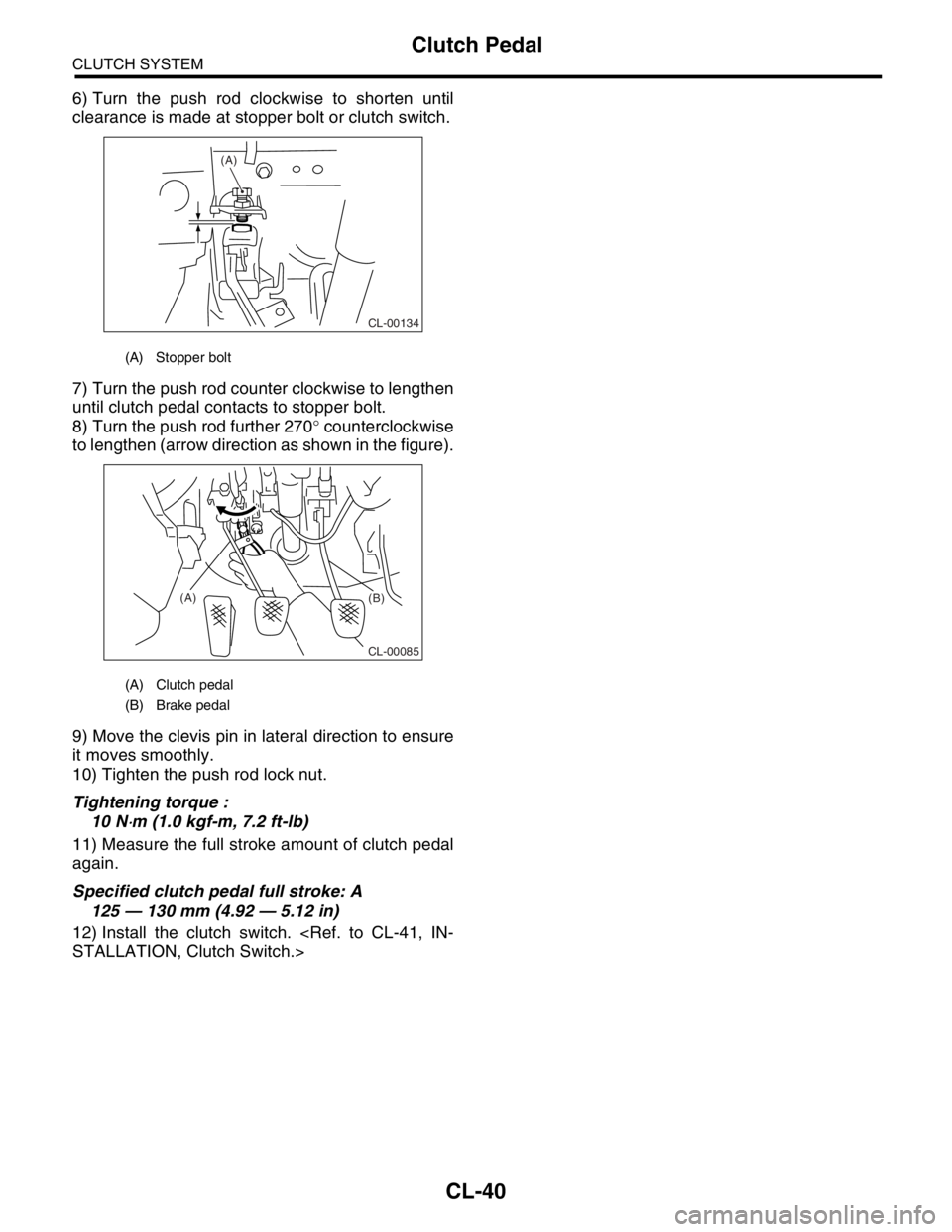

the clutch pedal.5) Turn the push rod clockwise to shorten until

clearance is made at stopper bolt or clutch switch.

Model without cruise control

Model with cruise control

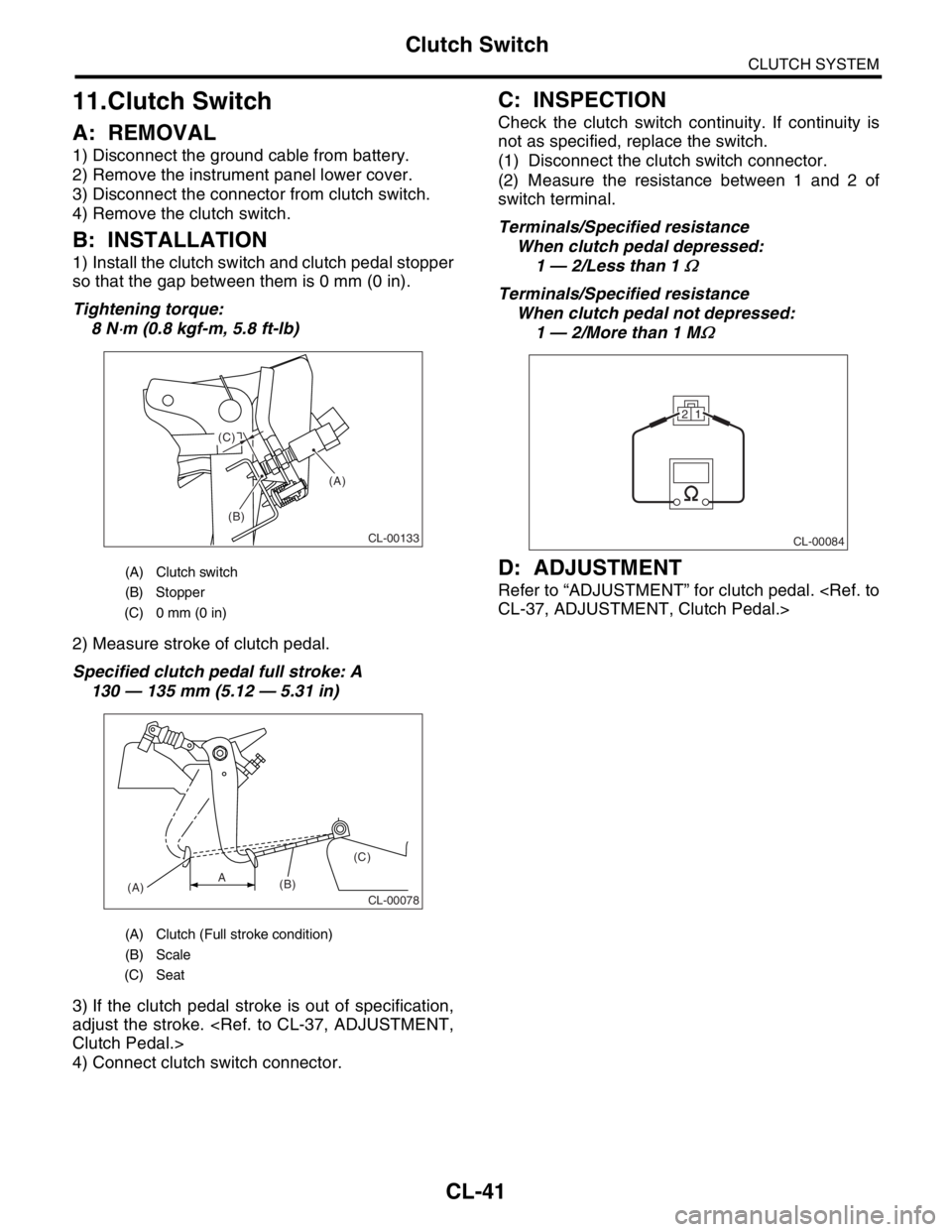

6) Turn the push rod counter clockwise to lengthen

until clutch pedal contacts to stopper bolt.

7) Turn the push rod further 270° counterclockwise

to lengthen (arrow direction as shown in the figure).

8) Move the clevis pin in lateral direction to ensure

it moves smoothly.

(A) Clevis pin

(B) Snap pin

(C) Push rod

(D) Push rod lock nut

(A) Clevis hole

(B) Push rod lock nut

(C) Lengthening direction

(D) Shortening direction

(E) Push rod

(F) U shaped bracket

CL-00042

(A)

(B)

(C)(D)

CL-00080

(B)(A)

(C)

(D)(E)(F)

(A) Stopper

(B) Stopper bolt

(A) Clutch switch

(B) Stopper

(C) Clearance

(A) Accelerator pedal

(B) Clevis

(A)

(B)

CL-00131

(A)

(B) (C)

CL-00132

CL-00101

(B)

(A)

Page 2865 of 2870

CL-39

CLUTCH SYSTEM

Clutch Pedal

9) Tighten the push rod lock nut.

Tightening torque :

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

10) Measure the full stroke amount of clutch pedal

again.

Specified clutch pedal full stroke: A

130 — 135 mm (5.12 — 5.31 in)

11) Install the clutch switch.

2. RHD MODEL

1) Measure the full stroke amount of clutch pedal.

NOTE:

Measure the length between seat cushion front

end and center portion of clutch pedal.

Slide the seat at seventh notch from first notch.

Specified clutch pedal full stroke: A

125 — 130 mm (4.92 — 5.12 in)

2) If not as specified, loosen the clutch stopper nut

to adjust it.

Tightening torque (Clutch stopper nut):

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

3) If the stroke amount can not be adjusted by stop-

per nut, remove the clutch switch.

5) Turn the push rod to adjust.

(1) Ensure that the clutch pedal contacts stop-

per bolt, when releasing the clutch pedal.

(2) Ensure that the clutch pedal contacts clutch

pedal bracket stopper, when fully depressing

the clutch pedal.

(A) Clutch (Full stroke condition)

(B) Scale

(C) Seat

CL-00078(A)(B)(C)A

(A) Clevis pin

(B) Snap pin

(C) Push rod

(D) Push rod lock nut

(A) Clevis hole

(B) Push rod lock nut

(C) Lengthening direction

(D) Shortening direction

(E) Push rod

(F) U shaped bracket

CL-00042

(A)

(B)

(C)(D)

CL-00080

(B)(A)

(C)

(D)(E)(F)

Page 2866 of 2870

CL-40

CLUTCH SYSTEM

Clutch Pedal

6) Turn the push rod clockwise to shorten until

clearance is made at stopper bolt or clutch switch.

7) Turn the push rod counter clockwise to lengthen

until clutch pedal contacts to stopper bolt.

8) Turn the push rod further 270° counterclockwise

to lengthen (arrow direction as shown in the figure).

9) Move the clevis pin in lateral direction to ensure

it moves smoothly.

10) Tighten the push rod lock nut.

Tightening torque :

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

11) Measure the full stroke amount of clutch pedal

again.

Specified clutch pedal full stroke: A

125 — 130 mm (4.92 — 5.12 in)

12) Install the clutch switch.

(A) Stopper bolt

(A) Clutch pedal

(B) Brake pedal

CL-00134

(A)

CL-00085

(A)

(B)

Page 2867 of 2870

CL-41

CLUTCH SYSTEM

Clutch Switch

11.Clutch Switch

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the instrument panel lower cover.

3) Disconnect the connector from clutch switch.

4) Remove the clutch switch.

B: INSTALLATION

1) Install the clutch switch and clutch pedal stopper

so that the gap between them is 0 mm (0 in).

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

2) Measure stroke of clutch pedal.

Specified clutch pedal full stroke: A

130 — 135 mm (5.12 — 5.31 in)

3) If the clutch pedal stroke is out of specification,

adjust the stroke.

4) Connect clutch switch connector.

C: INSPECTION

Check the clutch switch continuity. If continuity is

not as specified, replace the switch.

(1) Disconnect the clutch switch connector.

(2) Measure the resistance between 1 and 2 of

switch terminal.

Terminals/Specified resistance

When clutch pedal depressed:

1 — 2/Less than 1

Ω

Terminals/Specified resistance

When clutch pedal not depressed:

1 — 2/More than 1 M

Ω

D: ADJUSTMENT

Refer to “ADJUSTMENT” for clutch pedal.

(A) Clutch switch

(B) Stopper

(C) 0 mm (0 in)

(A) Clutch (Full stroke condition)

(B) Scale

(C) Seat

(A)

(B) (C)

CL-00133

CL-00078(A)(B)(C)A

CL-00084

21

Page 2869 of 2870

CL-43

CLUTCH SYSTEM

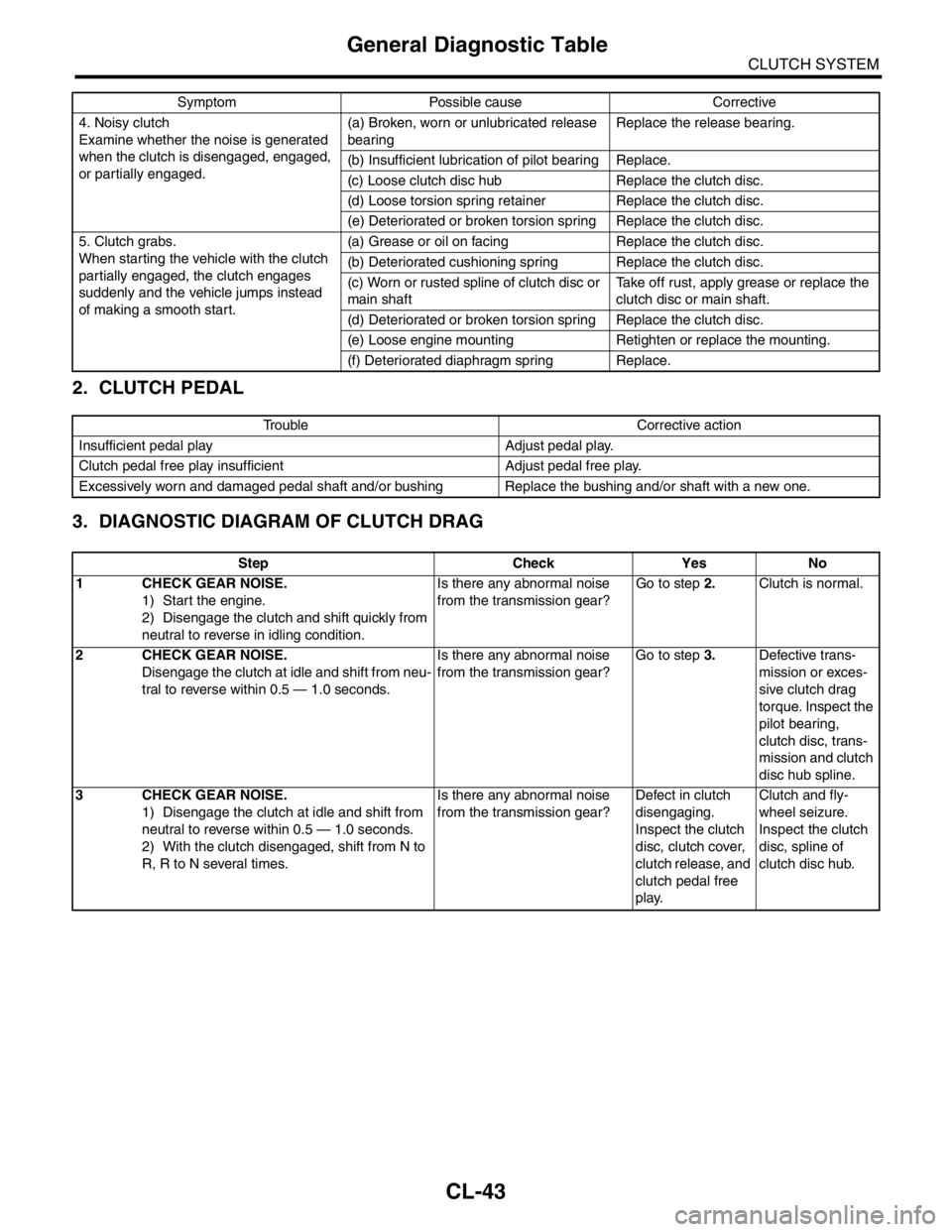

General Diagnostic Table

2. CLUTCH PEDAL

3. DIAGNOSTIC DIAGRAM OF CLUTCH DRAG

4. Noisy clutch

Examine whether the noise is generated

when the clutch is disengaged, engaged,

or partially engaged.(a) Broken, worn or unlubricated release

bearingReplace the release bearing.

(b) Insufficient lubrication of pilot bearing Replace.

(c) Loose clutch disc hub Replace the clutch disc.

(d) Loose torsion spring retainer Replace the clutch disc.

(e) Deteriorated or broken torsion spring Replace the clutch disc.

5. Clutch grabs.

When starting the vehicle with the clutch

partially engaged, the clutch engages

suddenly and the vehicle jumps instead

of making a smooth start.(a) Grease or oil on facing Replace the clutch disc.

(b) Deteriorated cushioning spring Replace the clutch disc.

(c) Worn or rusted spline of clutch disc or

main shaftTake off rust, apply grease or replace the

clutch disc or main shaft.

(d) Deteriorated or broken torsion spring Replace the clutch disc.

(e) Loose engine mounting Retighten or replace the mounting.

(f) Deteriorated diaphragm spring Replace.

Trouble Corrective action

Insufficient pedal play Adjust pedal play.

Clutch pedal free play insufficient Adjust pedal free play.

Excessively worn and damaged pedal shaft and/or bushing Replace the bushing and/or shaft with a new one.

Step Check Yes No

1 CHECK GEAR NOISE.

1) Start the engine.

2) Disengage the clutch and shift quickly from

neutral to reverse in idling condition.Is there any abnormal noise

from the transmission gear?Go to step 2.Clutch is normal.

2 CHECK GEAR NOISE.

Disengage the clutch at idle and shift from neu-

tral to reverse within 0.5 — 1.0 seconds.Is there any abnormal noise

from the transmission gear?Go to step 3.Defective trans-

mission or exces-

sive clutch drag

torque. Inspect the

pilot bearing,

clutch disc, trans-

mission and clutch

disc hub spline.

3 CHECK GEAR NOISE.

1) Disengage the clutch at idle and shift from

neutral to reverse within 0.5 — 1.0 seconds.

2) With the clutch disengaged, shift from N to

R, R to N several times.Is there any abnormal noise

from the transmission gear?Defect in clutch

disengaging.

Inspect the clutch

disc, clutch cover,

clutch release, and

clutch pedal free

play.Clutch and fly-

wheel seizure.

Inspect the clutch

disc, spline of

clutch disc hub. Symptom Possible cause Corrective