check engine SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2678 of 2870

4AT(H4DOTC)-102

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

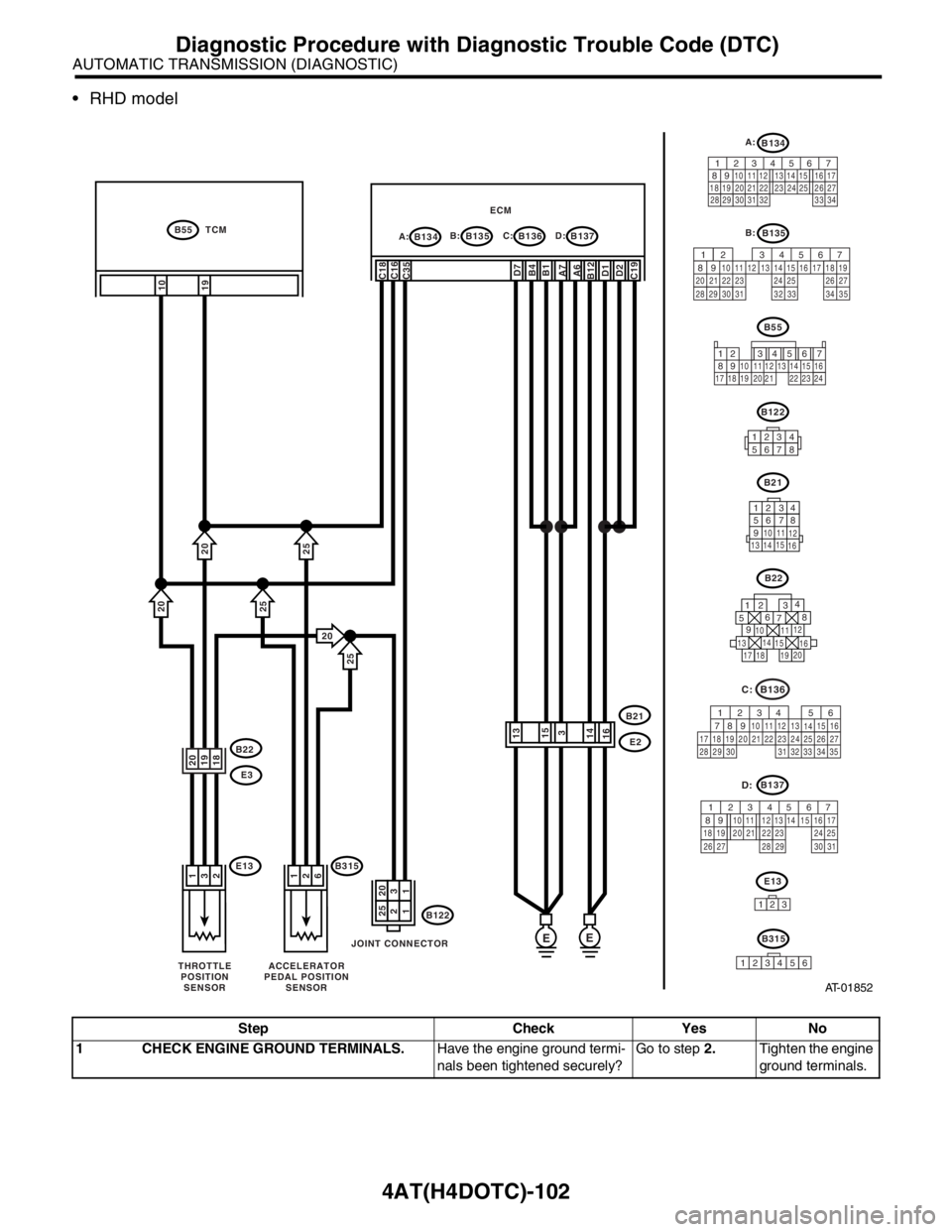

RHD model

Step Check Yes No

1 CHECK ENGINE GROUND TERMINALS.Have the engine ground termi-

nals been tightened securely?Go to step 2.Tighten the engine

ground terminals.

AT-01852

B55

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

E13

B122

B21

B134B55 TCM

A:B135 B:B137 D: ECMB136 C:

E2B22

E3

B21

13 1415

16

12 34

56 78

9

10

11

12

13161415

3

1

3

210

19

C18

C16

C35D2D1D7

B12B4C19A6 A7B1

EE

1225

1320

20

19

18

B22

1

234

56

78

9

1314

15

20

19 1716 10 111218

JOINT CONNECTOR

THROTTLE

POSITION

SENSOR

B3151

2

6

ACCELERATOR

PEDAL POSITION

SENSOR

123

E13

20

20

20

25

25

25

B315

1

23456

B136

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

C:

B137

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

D:

B122

12345678

B135 B:

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

B134 A:

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

Page 2679 of 2870

4AT(H4DOTC)-103

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

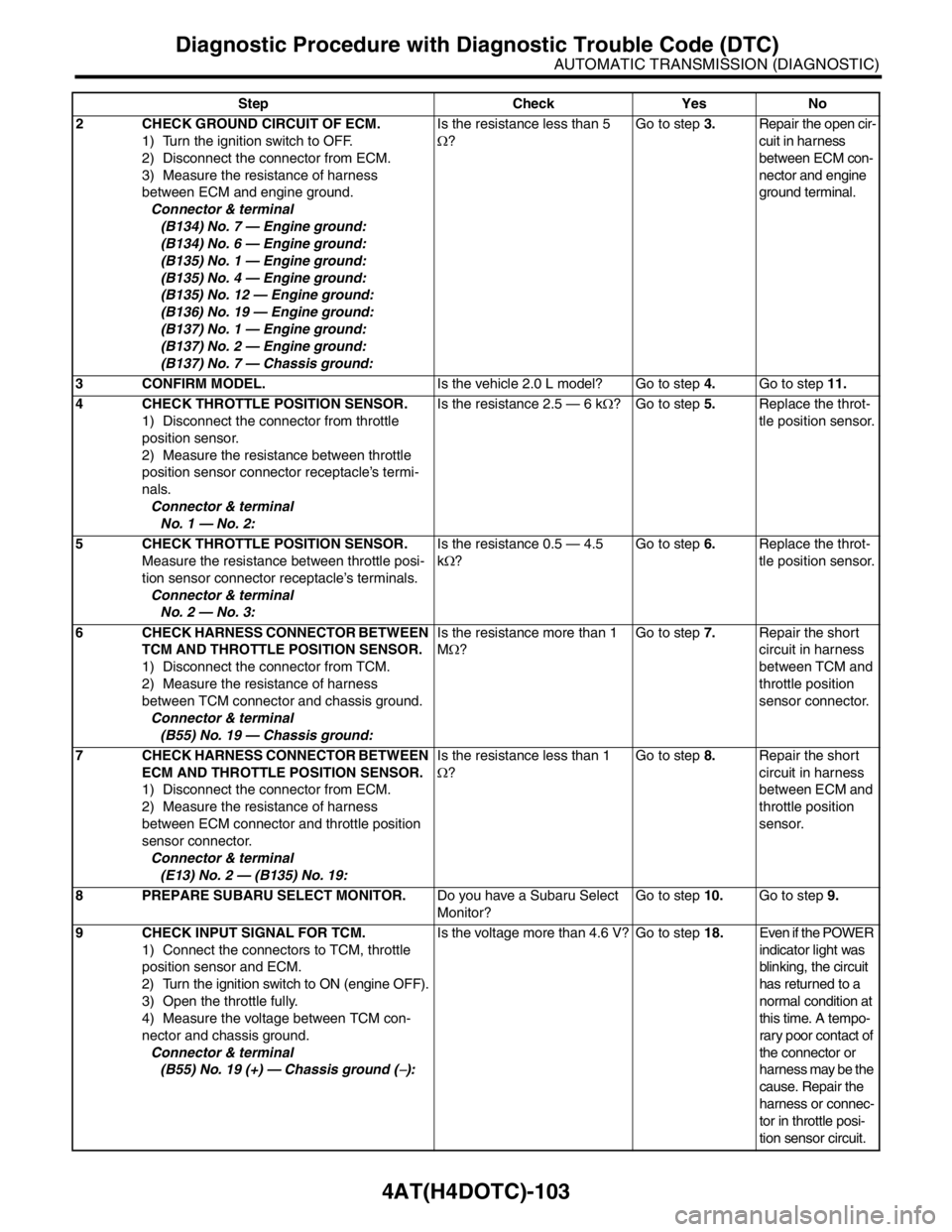

2 CHECK GROUND CIRCUIT OF ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance of harness

between ECM and engine ground.

Connector & terminal

(B134) No. 7 — Engine ground:

(B134) No. 6 — Engine ground:

(B135) No. 1 — Engine ground:

(B135) No. 4 — Engine ground:

(B135) No. 12 — Engine ground:

(B136) No. 19 — Engine ground:

(B137) No. 1 — Engine ground:

(B137) No. 2 — Engine ground:

(B137) No. 7 — Chassis ground:Is the resistance less than 5

Ω?Go to step 3.Repair the open cir-

cuit in harness

between ECM con-

nector and engine

ground terminal.

3 CONFIRM MODEL.Is the vehicle 2.0 L model? Go to step 4.Go to step 11.

4 CHECK THROTTLE POSITION SENSOR.

1) Disconnect the connector from throttle

position sensor.

2) Measure the resistance between throttle

position sensor connector receptacle’s termi-

nals.

Connector & terminal

No. 1 — No. 2:Is the resistance 2.5 — 6 kΩ? Go to step 5.Replace the throt-

tle position sensor.

5 CHECK THROTTLE POSITION SENSOR.

Measure the resistance between throttle posi-

tion sensor connector receptacle’s terminals.

Connector & terminal

No. 2 — No. 3:Is the resistance 0.5 — 4.5

kΩ?Go to step 6.Replace the throt-

tle position sensor.

6 CHECK HARNESS CONNECTOR BETWEEN

TCM AND THROTTLE POSITION SENSOR.

1) Disconnect the connector from TCM.

2) Measure the resistance of harness

between TCM connector and chassis ground.

Connector & terminal

(B55) No. 19 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 7.Repair the short

circuit in harness

between TCM and

throttle position

sensor connector.

7 CHECK HARNESS CONNECTOR BETWEEN

ECM AND THROTTLE POSITION SENSOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness

between ECM connector and throttle position

sensor connector.

Connector & terminal

(E13) No. 2 — (B135) No. 19:Is the resistance less than 1

Ω?Go to step 8.Repair the short

circuit in harness

between ECM and

throttle position

sensor.

8 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 10.Go to step 9.

9 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connectors to TCM, throttle

position sensor and ECM.

2) Turn the ignition switch to ON (engine OFF).

3) Open the throttle fully.

4) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (

−):Is the voltage more than 4.6 V? Go to step 18.Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in throttle posi-

tion sensor circuit. Step Check Yes No

Page 2680 of 2870

4AT(H4DOTC)-104

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

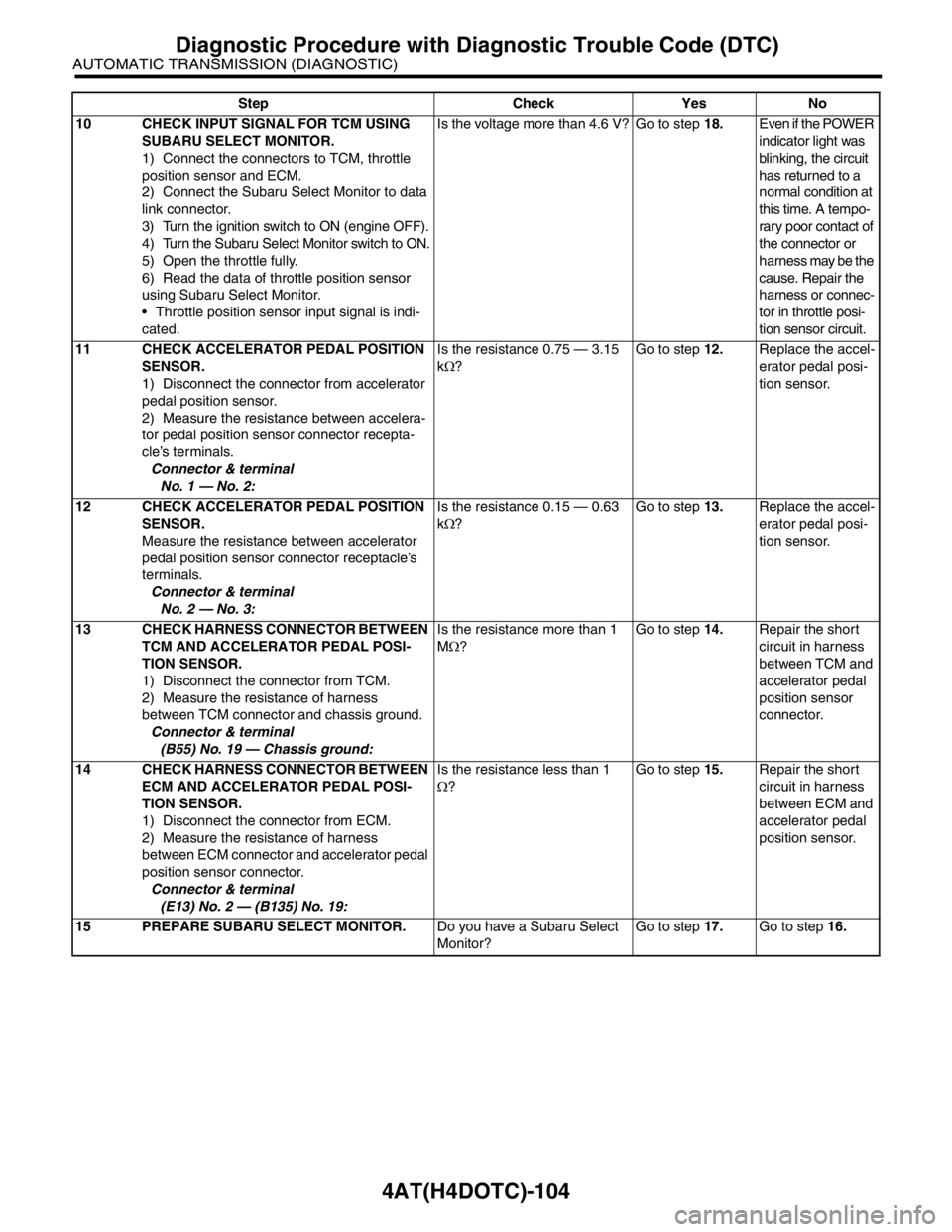

10 CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connectors to TCM, throttle

position sensor and ECM.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON (engine OFF).

4) Turn the Subaru Select Monitor switch to ON.

5) Open the throttle fully.

6) Read the data of throttle position sensor

using Subaru Select Monitor.

Throttle position sensor input signal is indi-

cated.Is the voltage more than 4.6 V? Go to step 18.Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in throttle posi-

tion sensor circuit.

11 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Disconnect the connector from accelerator

pedal position sensor.

2) Measure the resistance between accelera-

tor pedal position sensor connector recepta-

cle’s terminals.

Connector & terminal

No. 1 — No. 2:Is the resistance 0.75 — 3.15

kΩ?Go to step 12.Replace the accel-

erator pedal posi-

tion sensor.

12 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Measure the resistance between accelerator

pedal position sensor connector receptacle’s

terminals.

Connector & terminal

No. 2 — No. 3:Is the resistance 0.15 — 0.63

kΩ?Go to step 13.Replace the accel-

erator pedal posi-

tion sensor.

13 CHECK HARNESS CONNECTOR BETWEEN

TCM AND ACCELERATOR PEDAL POSI-

TION SENSOR.

1) Disconnect the connector from TCM.

2) Measure the resistance of harness

between TCM connector and chassis ground.

Connector & terminal

(B55) No. 19 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 14.Repair the short

circuit in harness

between TCM and

accelerator pedal

position sensor

connector.

14 CHECK HARNESS CONNECTOR BETWEEN

ECM AND ACCELERATOR PEDAL POSI-

TION SENSOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness

between ECM connector and accelerator pedal

position sensor connector.

Connector & terminal

(E13) No. 2 — (B135) No. 19:Is the resistance less than 1

Ω?Go to step 15.Repair the short

circuit in harness

between ECM and

accelerator pedal

position sensor.

15 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 17.Go to step 16. Step Check Yes No

Page 2681 of 2870

4AT(H4DOTC)-105

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

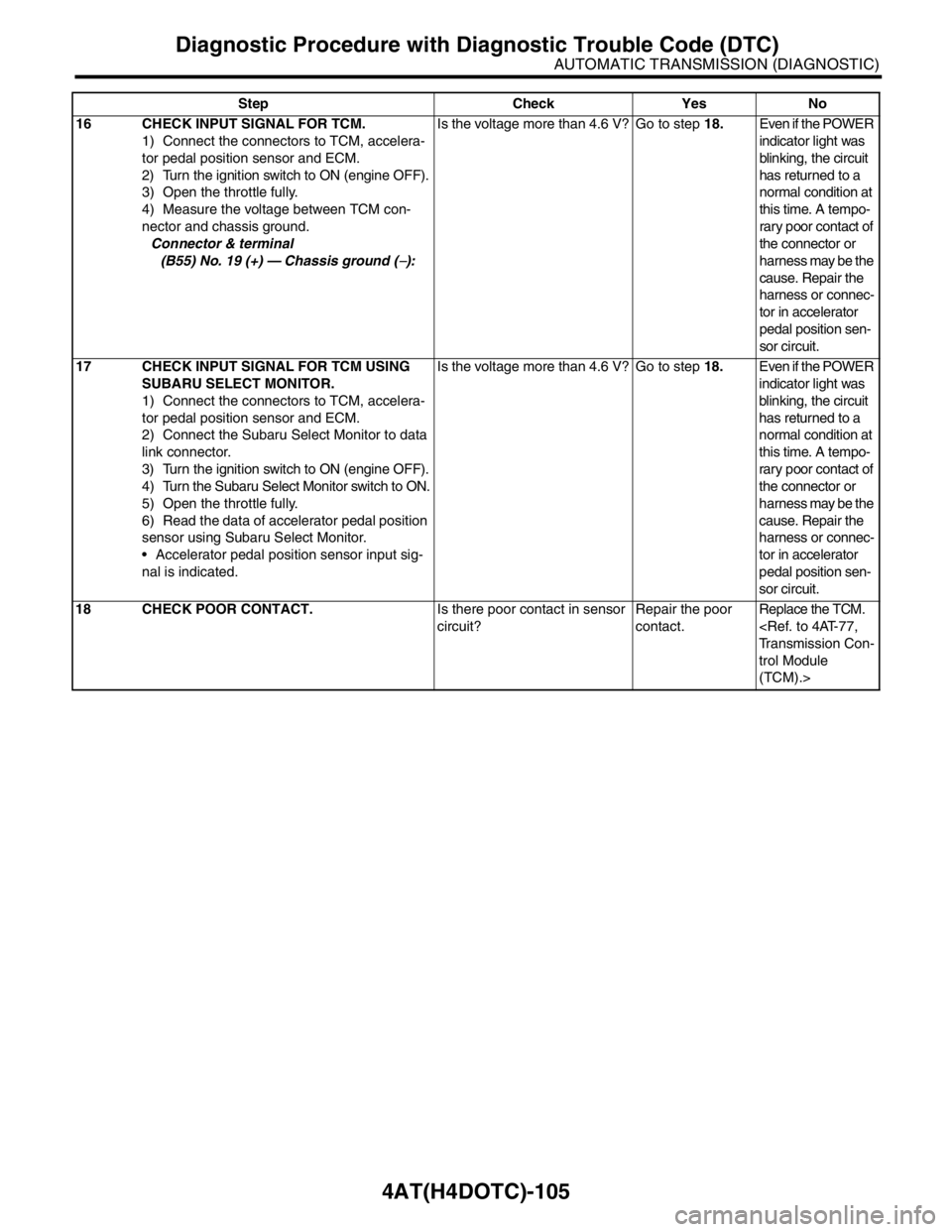

16 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connectors to TCM, accelera-

tor pedal position sensor and ECM.

2) Turn the ignition switch to ON (engine OFF).

3) Open the throttle fully.

4) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (

−):Is the voltage more than 4.6 V? Go to step 18.Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in accelerator

pedal position sen-

sor circuit.

17 CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connectors to TCM, accelera-

tor pedal position sensor and ECM.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON (engine OFF).

4) Turn the Subaru Select Monitor switch to ON.

5) Open the throttle fully.

6) Read the data of accelerator pedal position

sensor using Subaru Select Monitor.

Accelerator pedal position sensor input sig-

nal is indicated.Is the voltage more than 4.6 V? Go to step 18.Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in accelerator

pedal position sen-

sor circuit.

18 CHECK POOR CONTACT.Is there poor contact in sensor

circuit?Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No

Page 2694 of 2870

4AT(H4DOTC)-118

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

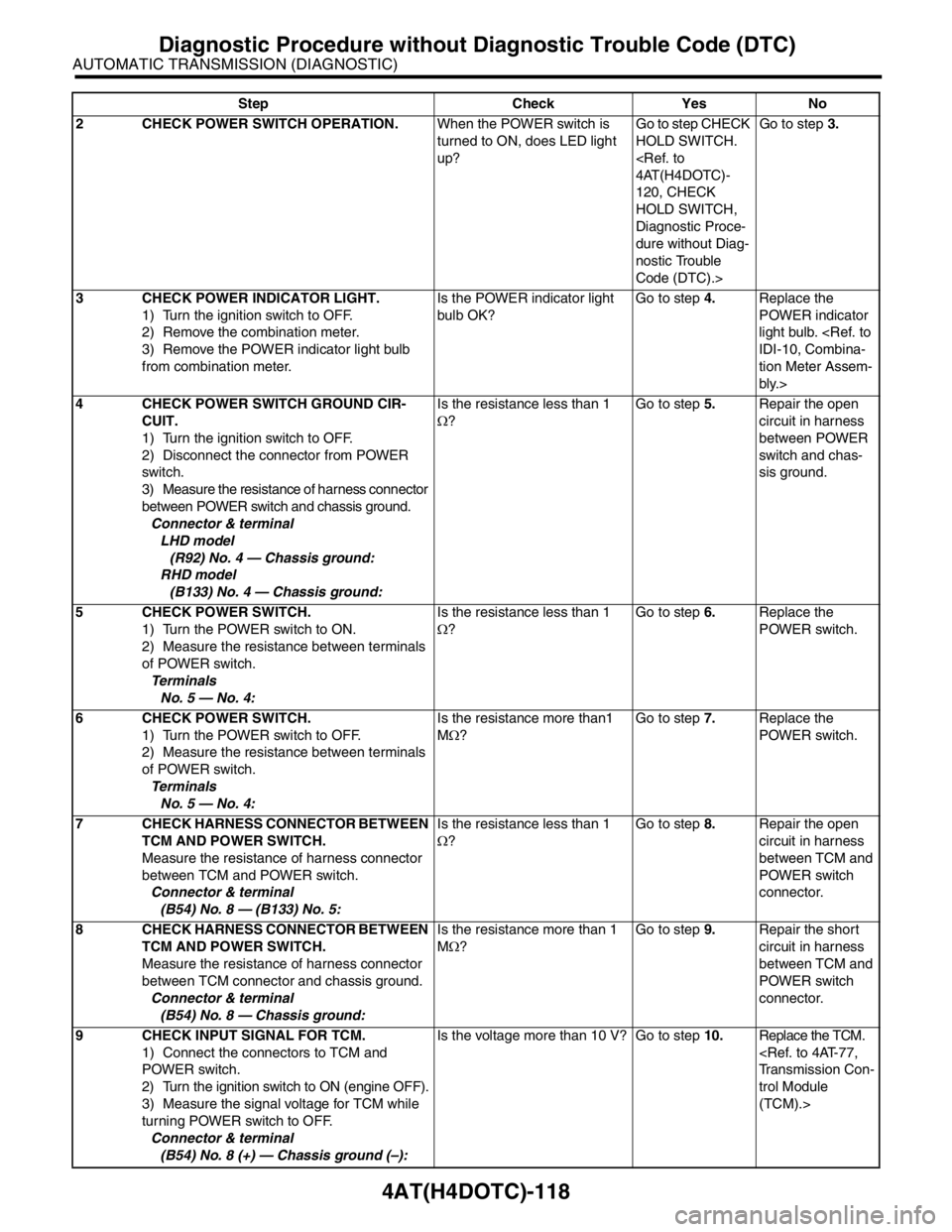

2 CHECK POWER SWITCH OPERATION.When the POWER switch is

turned to ON, does LED light

up?Go to step CHECK

HOLD SWITCH.

120, CHECK

HOLD SWITCH,

Diagnostic Proce-

dure without Diag-

nostic Trouble

Code (DTC).>Go to step 3.

3 CHECK POWER INDICATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Remove the POWER indicator light bulb

from combination meter.Is the POWER indicator light

bulb OK?Go to step 4.Replace the

POWER indicator

light bulb.

tion Meter Assem-

bly.>

4 CHECK POWER SWITCH GROUND CIR-

CUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from POWER

switch.

3) Measure the resistance of harness connector

between POWER switch and chassis ground.

Connector & terminal

LHD model

(R92) No. 4 — Chassis ground:

RHD model

(B133) No. 4 — Chassis ground:Is the resistance less than 1

Ω?Go to step 5.Repair the open

circuit in harness

between POWER

switch and chas-

sis ground.

5 CHECK POWER SWITCH.

1) Turn the POWER switch to ON.

2) Measure the resistance between terminals

of POWER switch.

Te r m i n a l s

No. 5 — No. 4:Is the resistance less than 1

Ω?Go to step 6.Replace the

POWER switch.

6 CHECK POWER SWITCH.

1) Turn the POWER switch to OFF.

2) Measure the resistance between terminals

of POWER switch.

Te r m i n a l s

No. 5 — No. 4:Is the resistance more than1

MΩ?Go to step 7.Replace the

POWER switch.

7 CHECK HARNESS CONNECTOR BETWEEN

TCM AND POWER SWITCH.

Measure the resistance of harness connector

between TCM and POWER switch.

Connector & terminal

(B54) No. 8 — (B133) No. 5:Is the resistance less than 1

Ω?Go to step 8.Repair the open

circuit in harness

between TCM and

POWER switch

connector.

8 CHECK HARNESS CONNECTOR BETWEEN

TCM AND POWER SWITCH.

Measure the resistance of harness connector

between TCM connector and chassis ground.

Connector & terminal

(B54) No. 8 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 9.Repair the short

circuit in harness

between TCM and

POWER switch

connector.

9 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connectors to TCM and

POWER switch.

2) Turn the ignition switch to ON (engine OFF).

3) Measure the signal voltage for TCM while

turning POWER switch to OFF.

Connector & terminal

(B54) No. 8 (+) — Chassis ground (–):Is the voltage more than 10 V? Go to step 10.Replace the TCM.

trol Module

(TCM).> Step Check Yes No

Page 2701 of 2870

4AT(H4DOTC)-125

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

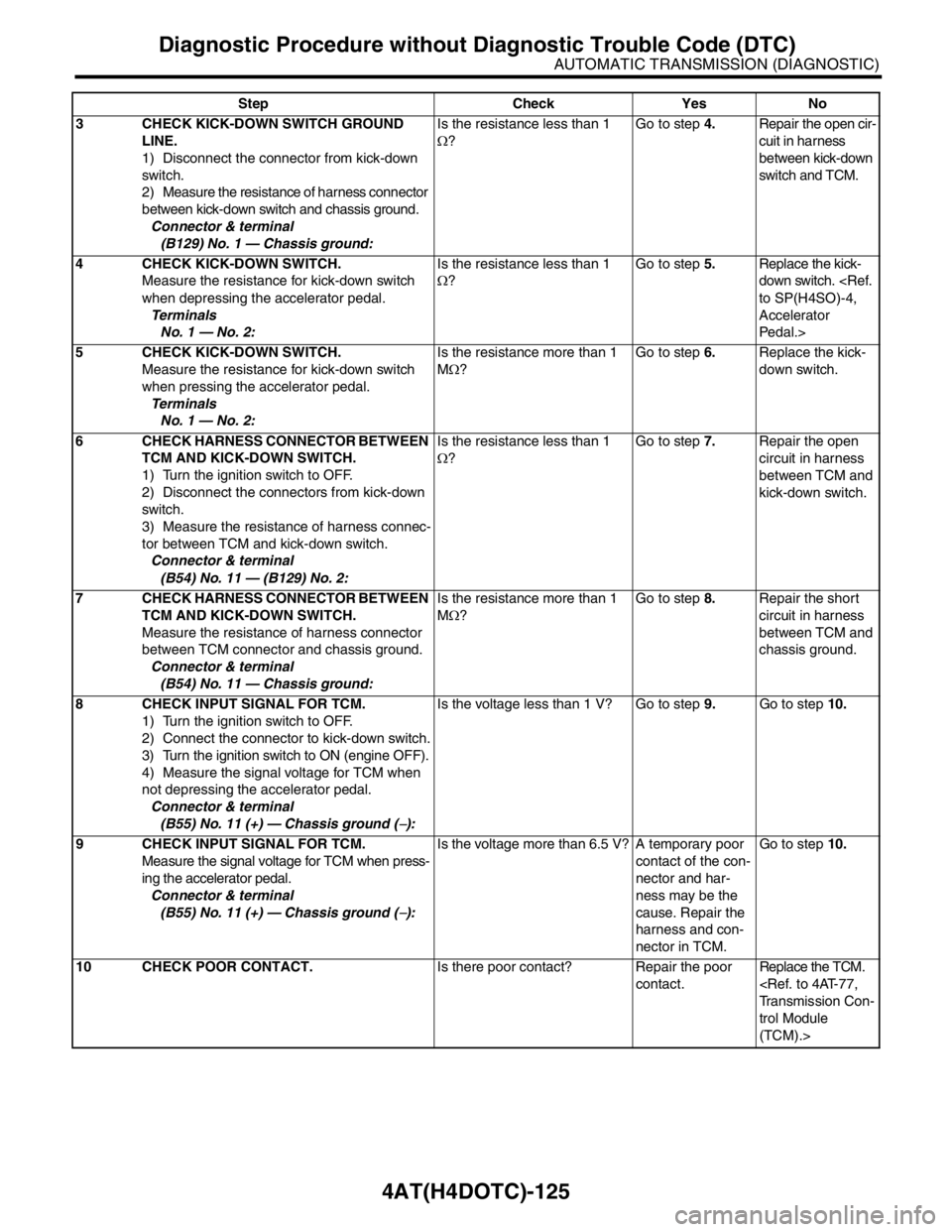

3 CHECK KICK-DOWN SWITCH GROUND

LINE.

1) Disconnect the connector from kick-down

switch.

2) Measure the resistance of harness connector

between kick-down switch and chassis ground.

Connector & terminal

(B129) No. 1 — Chassis ground:Is the resistance less than 1

Ω?Go to step 4.Repair the open cir-

cuit in harness

between kick-down

switch and TCM.

4 CHECK KICK-DOWN SWITCH.

Measure the resistance for kick-down switch

when depressing the accelerator pedal.

Te r m i n a l s

No. 1 — No. 2:Is the resistance less than 1

Ω?Go to step 5.Replace the kick-

down switch.

Accelerator

Pedal.>

5 CHECK KICK-DOWN SWITCH.

Measure the resistance for kick-down switch

when pressing the accelerator pedal.

Te r m i n a l s

No. 1 — No. 2:Is the resistance more than 1

MΩ?Go to step 6.Replace the kick-

down switch.

6 CHECK HARNESS CONNECTOR BETWEEN

TCM AND KICK-DOWN SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from kick-down

switch.

3) Measure the resistance of harness connec-

tor between TCM and kick-down switch.

Connector & terminal

(B54) No. 11 — (B129) No. 2:Is the resistance less than 1

Ω?Go to step 7.Repair the open

circuit in harness

between TCM and

kick-down switch.

7 CHECK HARNESS CONNECTOR BETWEEN

TCM AND KICK-DOWN SWITCH.

Measure the resistance of harness connector

between TCM connector and chassis ground.

Connector & terminal

(B54) No. 11 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 8.Repair the short

circuit in harness

between TCM and

chassis ground.

8 CHECK INPUT SIGNAL FOR TCM.

1) Turn the ignition switch to OFF.

2) Connect the connector to kick-down switch.

3) Turn the ignition switch to ON (engine OFF).

4) Measure the signal voltage for TCM when

not depressing the accelerator pedal.

Connector & terminal

(B55) No. 11 (+) — Chassis ground (

−):Is the voltage less than 1 V? Go to step 9.Go to step 10.

9 CHECK INPUT SIGNAL FOR TCM.

Measure the signal voltage for TCM when press-

ing the accelerator pedal.

Connector & terminal

(B55) No. 11 (+) — Chassis ground (

−):Is the voltage more than 6.5 V? A temporary poor

contact of the con-

nector and har-

ness may be the

cause. Repair the

harness and con-

nector in TCM.Go to step 10.

10 CHECK POOR CONTACT.Is there poor contact? Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No

Page 2743 of 2870

5MT-31

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Gear Oil

2. Transmission Gear Oil

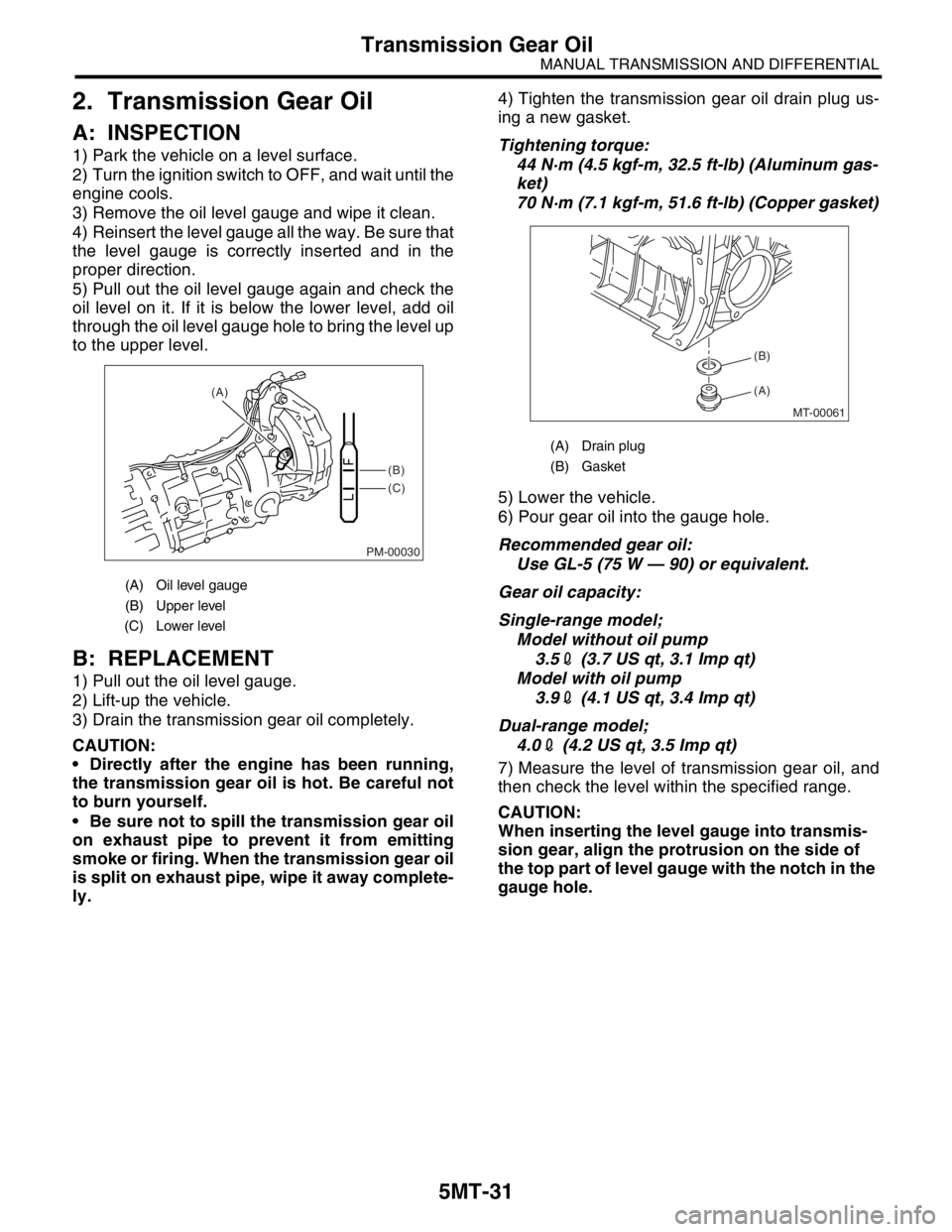

A: INSPECTION

1) Park the vehicle on a level surface.

2) Turn the ignition switch to OFF, and wait until the

engine cools.

3) Remove the oil level gauge and wipe it clean.

4) Reinsert the level gauge all the way. Be sure that

the level gauge is correctly inserted and in the

proper direction.

5) Pull out the oil level gauge again and check the

oil level on it. If it is below the lower level, add oil

through the oil level gauge hole to bring the level up

to the upper level.

B: REPLACEMENT

1) Pull out the oil level gauge.

2) Lift-up the vehicle.

3) Drain the transmission gear oil completely.

CAUTION:

Directly after the engine has been running,

the transmission gear oil is hot. Be careful not

to burn yourself.

Be sure not to spill the transmission gear oil

on exhaust pipe to prevent it from emitting

smoke or firing. When the transmission gear oil

is split on exhaust pipe, wipe it away complete-

ly.4) Tighten the transmission gear oil drain plug us-

ing a new gasket.

Tightening torque:

44 N·m (4.5 kgf-m, 32.5 ft-lb) (Aluminum gas-

ket)

70 N·m (7.1 kgf-m, 51.6 ft-lb) (Copper gasket)

5) Lower the vehicle.

6) Pour gear oil into the gauge hole.

Recommended gear oil:

Use GL-5 (75 W — 90) or equivalent.

Gear oil capacity:

Single-range model;

Model without oil pump

3.52 (3.7 US qt, 3.1 Imp qt)

Model with oil pump

3.92 (4.1 US qt, 3.4 Imp qt)

Dual-range model;

4.02 (4.2 US qt, 3.5 Imp qt)

7) Measure the level of transmission gear oil, and

then check the level within the specified range.

CAUTION:

When inserting the level gauge into transmis-

sion gear, align the protrusion on the side of

the top part of level gauge with the notch in the

gauge hole.

(A) Oil level gauge

(B) Upper level

(C) Lower level

PM-00030

(B)

(C) (A)

(A) Drain plug

(B) Gasket

MT-00061

(A) (B)

Page 2824 of 2870

5MT-111

MANUAL TRANSMISSION AND DIFFERENTIAL

General Diagnostic

26.General Diagnostic

A: INSPECTION

1. MANUAL TRANSMISSION

Symptom Possible cause Remedy

1. Gears are difficult to intermesh.

N

OTE:

The cause for difficulty in shifting gears

can be classified into two kinds: one is

malfunction of the gear shift system and

the other is malfunction of the transmis-

sion. However, if the operation is heavy

and engagement of the gears is difficult,

defective clutch disengagement may also

be responsible. Check whether the clutch

is correctly functioning, before checking

the gear shift system and transmission.(a) Worn, damaged or burred chamfer of

internal spline of sleeve and reverse

driven gearReplace.

(b) Worn, damaged or burred chamfer of

spline of gearsReplace.

(c) Worn or scratched bushings Replace.

(d) Incorrect contact between synchro-

nizer ring and gear cone or wear Correct or replace.

2. Gear slips out.

Gear slips out when coasting on rough

road.

Gear slips out during acceleration.(a) Defective pitching stopper adjustment Adjust.

(b) Loose engine mounting bolts Tighten or replace.

(c) Worn fork shifter, broken shifter fork

rail springReplace.

(d) Worn or damaged ball bearing Replace.

(e) Excessive clearance between splines

of synchronizer hub and synchronizer

sleeveReplace.

(f) Worn tooth step of synchronizer hub Replace.

(g) Worn 1st driven gear and driven shaft Replace.

(h) Worn 2nd driven gear and 2nd bush Replace.

(i) Worn reverse idler gear and bushing Replace.

3. Unusual noise comes from transmis-

sion.

N

OTE:

If an unusual noise is heard when the ve-

hicle is parked with its engine idling and if

the noise ceases when the clutch is disen-

gaged, it may be considered that the

noise comes from the transmission.(a) Insufficient or improper lubrication Lubricate or replace with specified oil.

(b) Worn or damaged gears and bearings

NOTE:

If the trouble is only wear of the tooth sur-

faces, merely a high roaring noise will oc-

cur at high speeds, but if any part is

broken, rhythmical knocking sound will be

heard even at low speeds.Replace.

Page 2825 of 2870

5MT-112

MANUAL TRANSMISSION AND DIFFERENTIAL

General Diagnostic

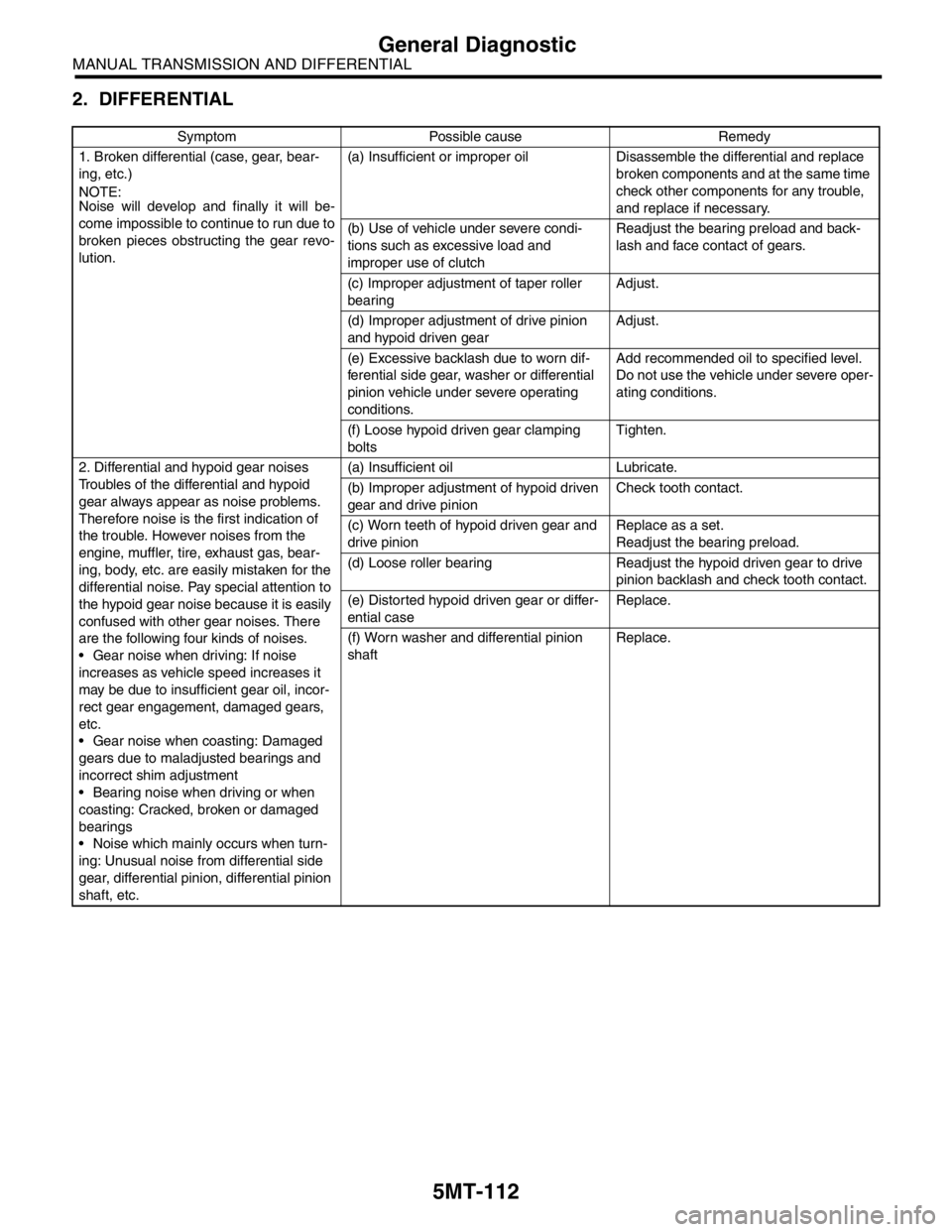

2. DIFFERENTIAL

Symptom Possible cause Remedy

1. Broken differential (case, gear, bear-

ing, etc.)

N

OTE:

Noise will develop and finally it will be-

come impossible to continue to run due to

broken pieces obstructing the gear revo-

lution. (a) Insufficient or improper oil Disassemble the differential and replace

broken components and at the same time

check other components for any trouble,

and replace if necessary.

(b) Use of vehicle under severe condi-

tions such as excessive load and

improper use of clutch Readjust the bearing preload and back-

lash and face contact of gears.

(c) Improper adjustment of taper roller

bearingAdjust.

(d) Improper adjustment of drive pinion

and hypoid driven gear Adjust.

(e) Excessive backlash due to worn dif-

ferential side gear, washer or differential

pinion vehicle under severe operating

conditions. Add recommended oil to specified level.

Do not use the vehicle under severe oper-

ating conditions.

(f) Loose hypoid driven gear clamping

boltsTighten.

2. Differential and hypoid gear noises

Troubles of the differential and hypoid

gear always appear as noise problems.

Therefore noise is the first indication of

the trouble. However noises from the

engine, muffler, tire, exhaust gas, bear-

ing, body, etc. are easily mistaken for the

differential noise. Pay special attention to

the hypoid gear noise because it is easily

confused with other gear noises. There

are the following four kinds of noises.

Gear noise when driving: If noise

increases as vehicle speed increases it

may be due to insufficient gear oil, incor-

rect gear engagement, damaged gears,

etc.

Gear noise when coasting: Damaged

gears due to maladjusted bearings and

incorrect shim adjustment

Bearing noise when driving or when

coasting: Cracked, broken or damaged

bearings

Noise which mainly occurs when turn-

ing: Unusual noise from differential side

gear, differential pinion, differential pinion

shaft, etc. (a) Insufficient oil Lubricate.

(b) Improper adjustment of hypoid driven

gear and drive pinionCheck tooth contact.

(c) Worn teeth of hypoid driven gear and

drive pinionReplace as a set.

Readjust the bearing preload.

(d) Loose roller bearing Readjust the hypoid driven gear to drive

pinion backlash and check tooth contact.

(e) Distorted hypoid driven gear or differ-

ential caseReplace.

(f) Worn washer and differential pinion

shaftReplace.

Page 2869 of 2870

CL-43

CLUTCH SYSTEM

General Diagnostic Table

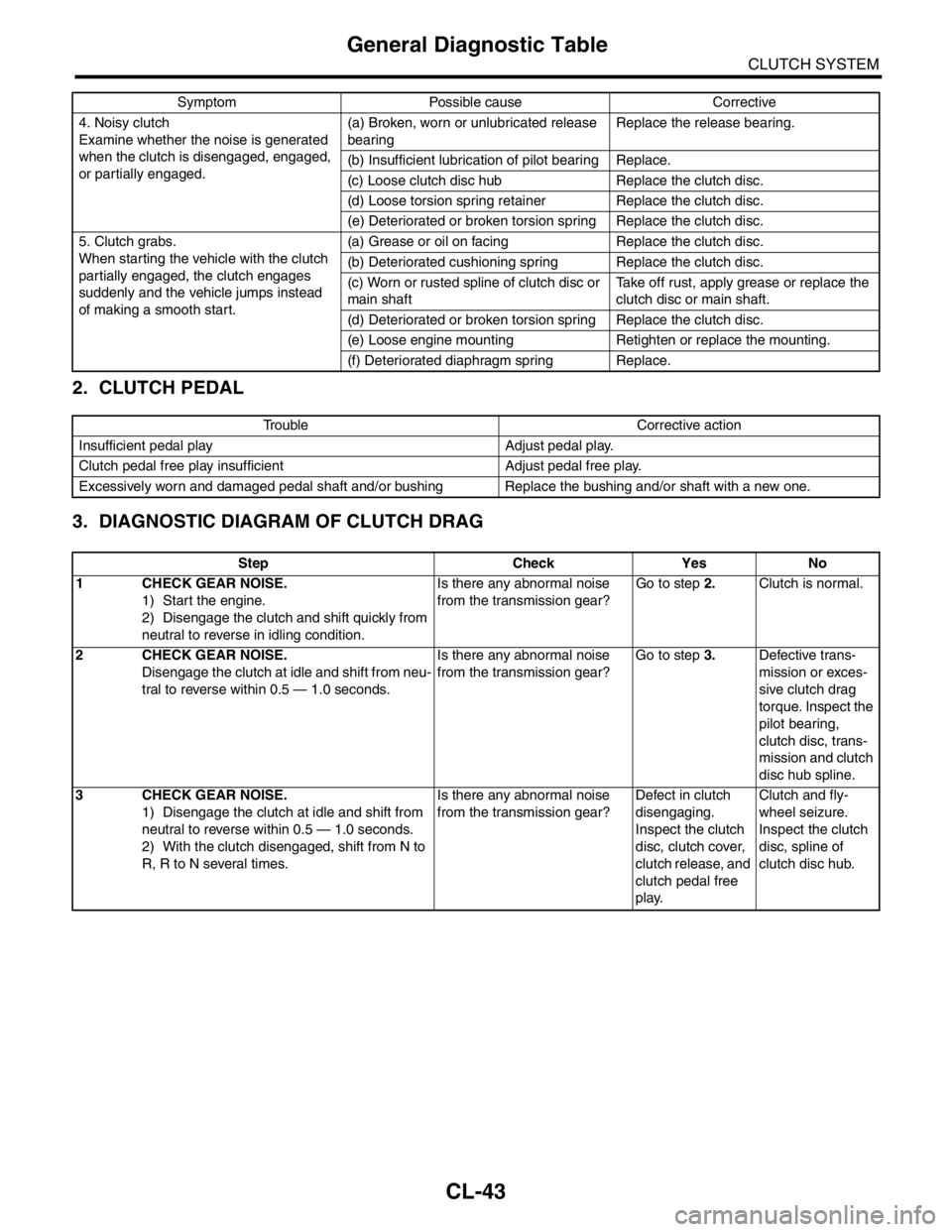

2. CLUTCH PEDAL

3. DIAGNOSTIC DIAGRAM OF CLUTCH DRAG

4. Noisy clutch

Examine whether the noise is generated

when the clutch is disengaged, engaged,

or partially engaged.(a) Broken, worn or unlubricated release

bearingReplace the release bearing.

(b) Insufficient lubrication of pilot bearing Replace.

(c) Loose clutch disc hub Replace the clutch disc.

(d) Loose torsion spring retainer Replace the clutch disc.

(e) Deteriorated or broken torsion spring Replace the clutch disc.

5. Clutch grabs.

When starting the vehicle with the clutch

partially engaged, the clutch engages

suddenly and the vehicle jumps instead

of making a smooth start.(a) Grease or oil on facing Replace the clutch disc.

(b) Deteriorated cushioning spring Replace the clutch disc.

(c) Worn or rusted spline of clutch disc or

main shaftTake off rust, apply grease or replace the

clutch disc or main shaft.

(d) Deteriorated or broken torsion spring Replace the clutch disc.

(e) Loose engine mounting Retighten or replace the mounting.

(f) Deteriorated diaphragm spring Replace.

Trouble Corrective action

Insufficient pedal play Adjust pedal play.

Clutch pedal free play insufficient Adjust pedal free play.

Excessively worn and damaged pedal shaft and/or bushing Replace the bushing and/or shaft with a new one.

Step Check Yes No

1 CHECK GEAR NOISE.

1) Start the engine.

2) Disengage the clutch and shift quickly from

neutral to reverse in idling condition.Is there any abnormal noise

from the transmission gear?Go to step 2.Clutch is normal.

2 CHECK GEAR NOISE.

Disengage the clutch at idle and shift from neu-

tral to reverse within 0.5 — 1.0 seconds.Is there any abnormal noise

from the transmission gear?Go to step 3.Defective trans-

mission or exces-

sive clutch drag

torque. Inspect the

pilot bearing,

clutch disc, trans-

mission and clutch

disc hub spline.

3 CHECK GEAR NOISE.

1) Disengage the clutch at idle and shift from

neutral to reverse within 0.5 — 1.0 seconds.

2) With the clutch disengaged, shift from N to

R, R to N several times.Is there any abnormal noise

from the transmission gear?Defect in clutch

disengaging.

Inspect the clutch

disc, clutch cover,

clutch release, and

clutch pedal free

play.Clutch and fly-

wheel seizure.

Inspect the clutch

disc, spline of

clutch disc hub. Symptom Possible cause Corrective