ECU SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 22 of 2870

AC-20

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

C: CAUTION

1. HFC-134a A/C SYSTEM

The cooling system components for the HFC-

134a system such as the refrigerant and compres-

sor oil are different from the old conventional HFC-

12 system components and they are incompatible

with each other.

Vehicles with the HFC-134a system can be iden-

tified by the label (A) attached to the vehicle.

Before maintenance, check which A/C system is in-

stalled in the vehicle.

2. COMPRESSOR OIL

HFC-134a compressor oil has no compatibility

with that for R12 system.

Use only the manufacturer-authorized compres-

sor oil for the HFC-134a system; only use

ZXL200PG.

Do not mix multiple compressor oils.

If HFC-12 compressor oil is used in a HFC-134a A/

C system, the compressor may become stuck due

to poor lubrication, or the refrigerant may leak due

to swelling of rubber parts.

On the other hand, if HFC-134a compressor oil is

used in a HFC-12 A/C system, the durability of the

A/C system will be lowered.

HFC-134a compressor oil is very hygroscopic.

When replacing or installing/removing A/C parts,

immediately isolate the oil from the atmosphere us-

ing a plug or tape. In order to avoid moisture, store

the oil in a container with its cap securely closed.

3. REFRIGERANT

The HFC-12 refrigerant cannot be used in the

HFC-134a A/C system. The HFC-134a refrigerant,

also, cannot be used in the HFC-12 A/C system.

If an incorrect or no refrigerant is used, poor lu-

brication will result and the compressor itself may

be damaged.

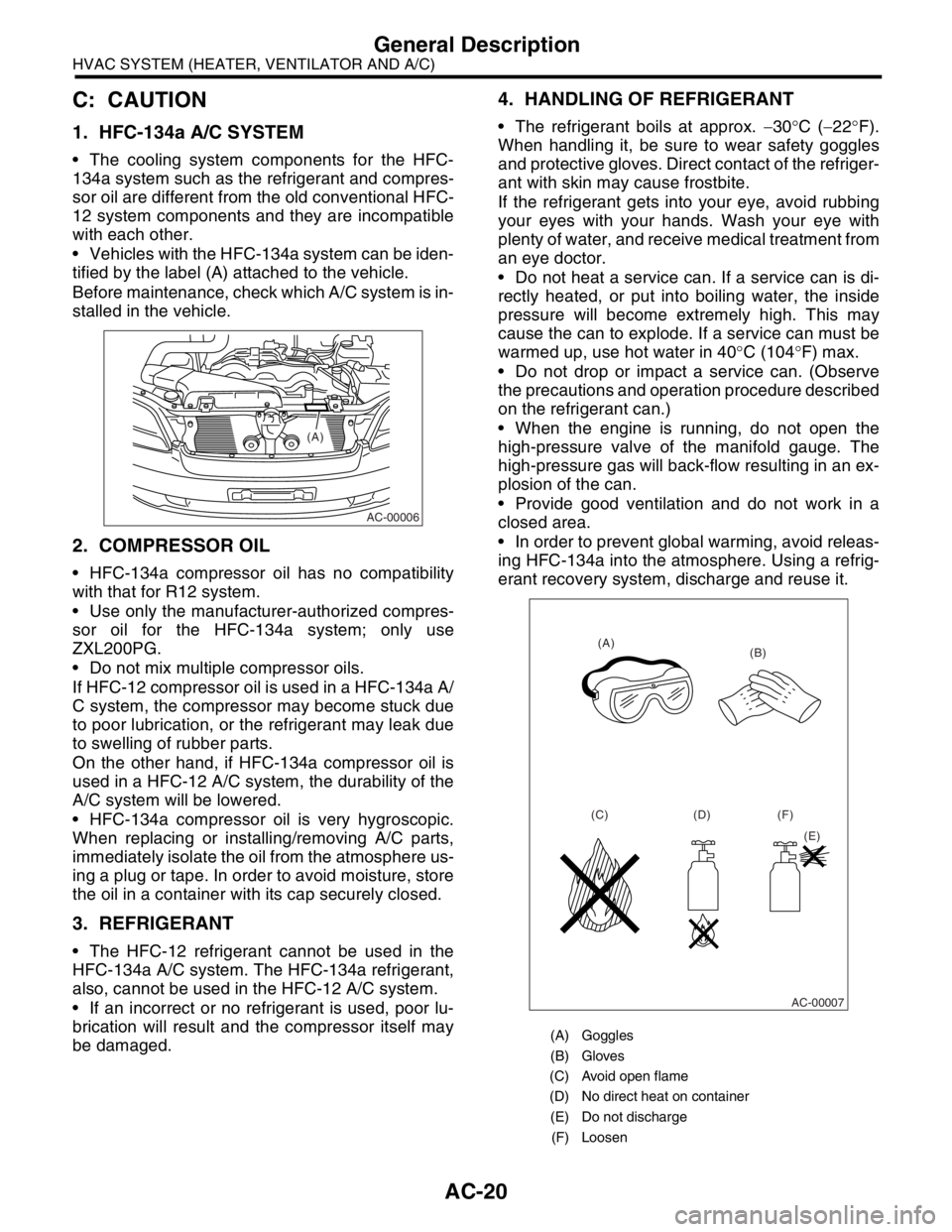

4. HANDLING OF REFRIGERANT

The refrigerant boils at approx. −30°C (−22°F).

When handling it, be sure to wear safety goggles

and protective gloves. Direct contact of the refriger-

ant with skin may cause frostbite.

If the refrigerant gets into your eye, avoid rubbing

your eyes with your hands. Wash your eye with

plenty of water, and receive medical treatment from

an eye doctor.

Do not heat a service can. If a service can is di-

rectly heated, or put into boiling water, the inside

pressure will become extremely high. This may

cause the can to explode. If a service can must be

warmed up, use hot water in 40°C (104°F) max.

Do not drop or impact a service can. (Observe

the precautions and operation procedure described

on the refrigerant can.)

When the engine is running, do not open the

high-pressure valve of the manifold gauge. The

high-pressure gas will back-flow resulting in an ex-

plosion of the can.

Provide good ventilation and do not work in a

closed area.

In order to prevent global warming, avoid releas-

ing HFC-134a into the atmosphere. Using a refrig-

erant recovery system, discharge and reuse it.

AC-00006

(A)

(A) Goggles

(B) Gloves

(C) Avoid open flame

(D) No direct heat on container

(E) Do not discharge

(F) Loosen

(A)

(B)

(C) (D)

(E) (F)

AC-00007

Page 29 of 2870

AC-27

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Charging Procedure

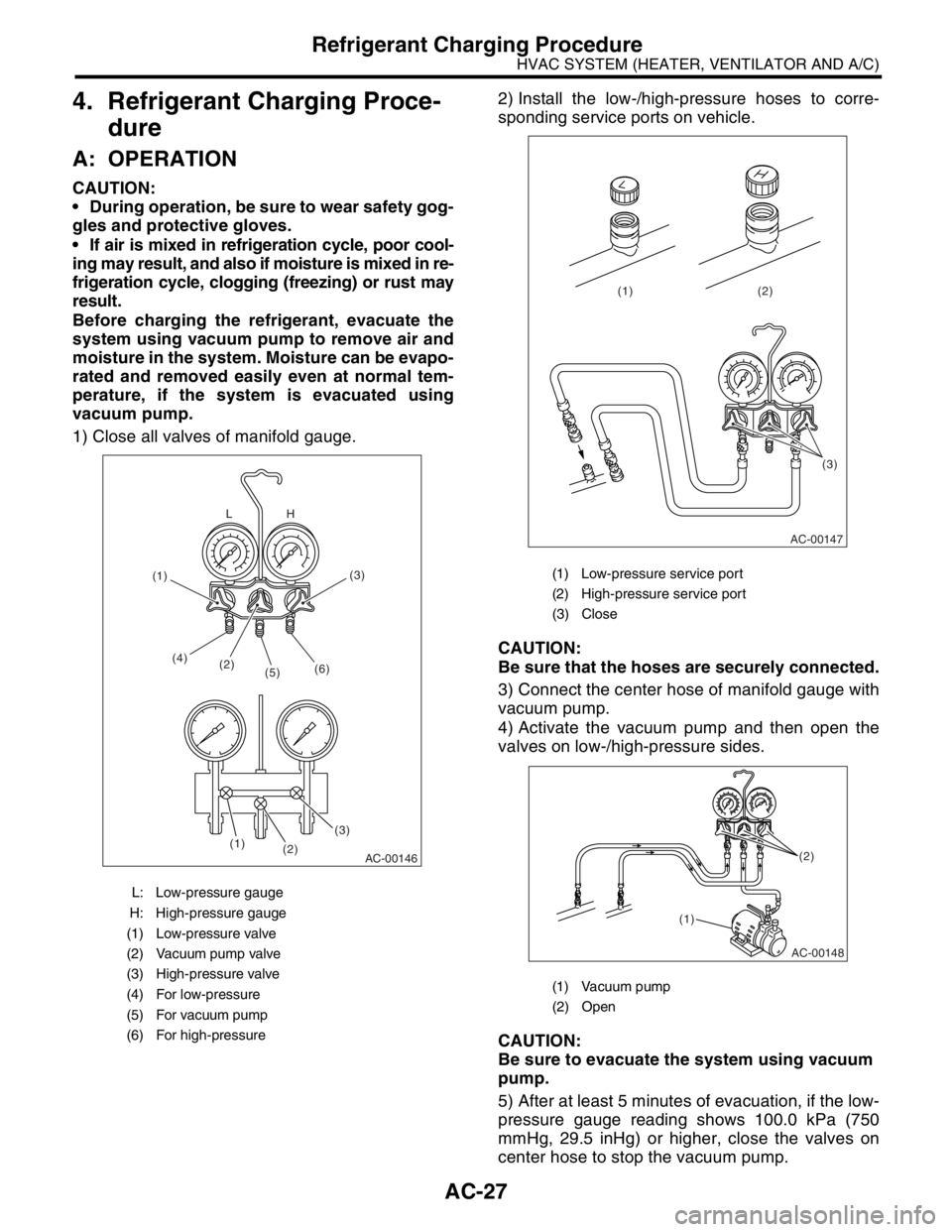

4. Refrigerant Charging Proce-

dure

A: OPERATION

CAUTION:

During operation, be sure to wear safety gog-

gles and protective gloves.

If air is mixed in refrigeration cycle, poor cool-

ing may result, and also if moisture is mixed in re-

frigeration cycle, clogging (freezing) or rust may

result.

Before charging the refrigerant, evacuate the

system using vacuum pump to remove air and

moisture in the system. Moisture can be evapo-

rated and removed easily even at normal tem-

perature, if the system is evacuated using

vacuum pump.

1) Close all valves of manifold gauge.2) Install the low-/high-pressure hoses to corre-

sponding service ports on vehicle.

CAUTION:

Be sure that the hoses are securely connected.

3) Connect the center hose of manifold gauge with

vacuum pump.

4) Activate the vacuum pump and then open the

valves on low-/high-pressure sides.

CAUTION:

Be sure to evacuate the system using vacuum

pump.

5) After at least 5 minutes of evacuation, if the low-

pressure gauge reading shows 100.0 kPa (750

mmHg, 29.5 inHg) or higher, close the valves on

center hose to stop the vacuum pump.

L: Low-pressure gauge

H: High-pressure gauge

(1) Low-pressure valve

(2) Vacuum pump valve

(3) High-pressure valve

(4) For low-pressure

(5) For vacuum pump

(6) For high-pressure

AC-00146

(2) (4)

(5)(6)

(3)(3)

(2) (1)H L

(1)

(1) Low-pressure service port

(2) High-pressure service port

(3) Close

(1) Vacuum pump

(2) Open

AC-00147

(3) (2) (1)

AC-00148

(1)(2)

Page 41 of 2870

AC-39

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Heater Cooling Unit

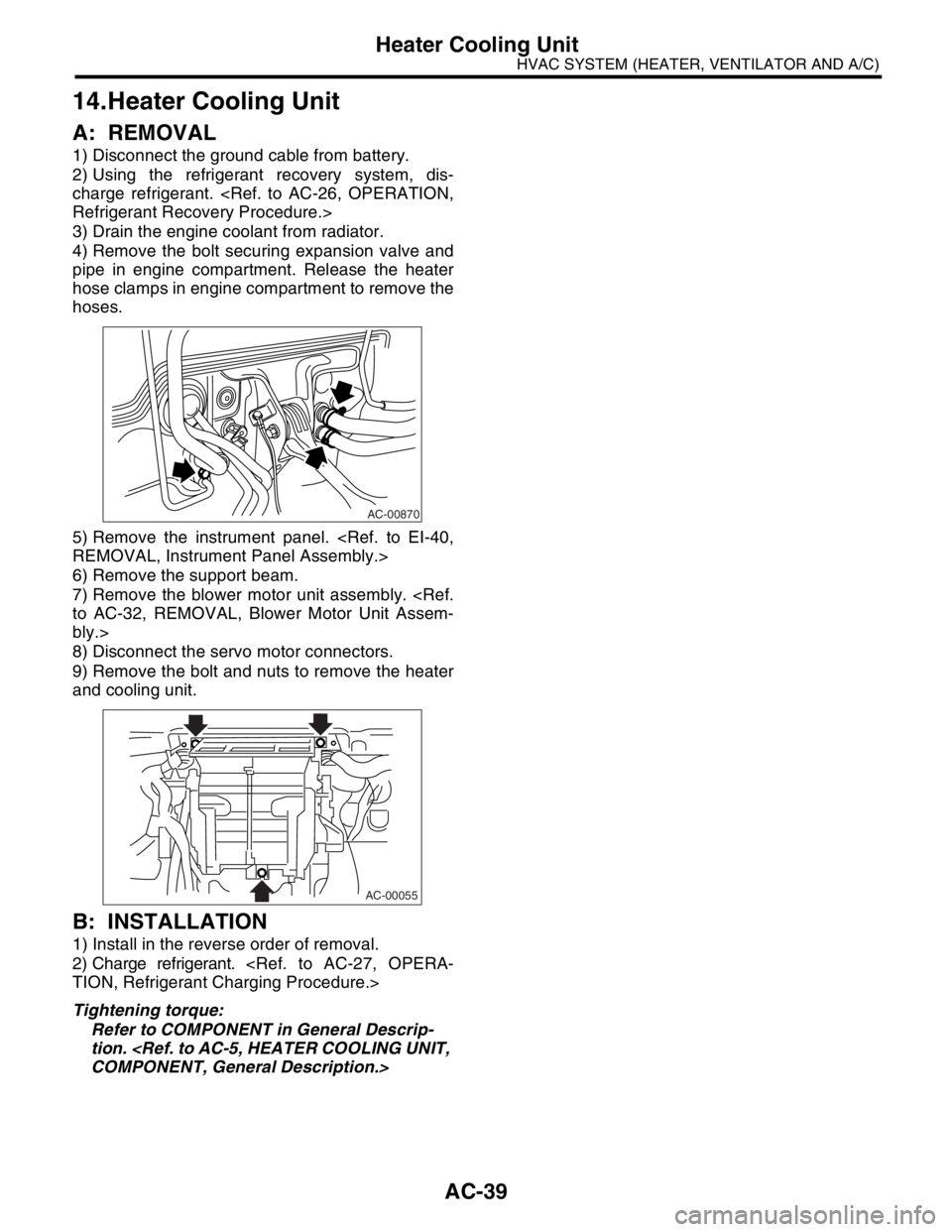

14.Heater Cooling Unit

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Using the refrigerant recovery system, dis-

charge refrigerant.

3) Drain the engine coolant from radiator.

4) Remove the bolt securing expansion valve and

pipe in engine compartment. Release the heater

hose clamps in engine compartment to remove the

hoses.

5) Remove the instrument panel.

6) Remove the support beam.

7) Remove the blower motor unit assembly.

bly.>

8) Disconnect the servo motor connectors.

9) Remove the bolt and nuts to remove the heater

and cooling unit.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

AC-00870

AC-00055

Page 55 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 99 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 104 of 2870

AB-4

AIRBAG SYSTEM

General Description

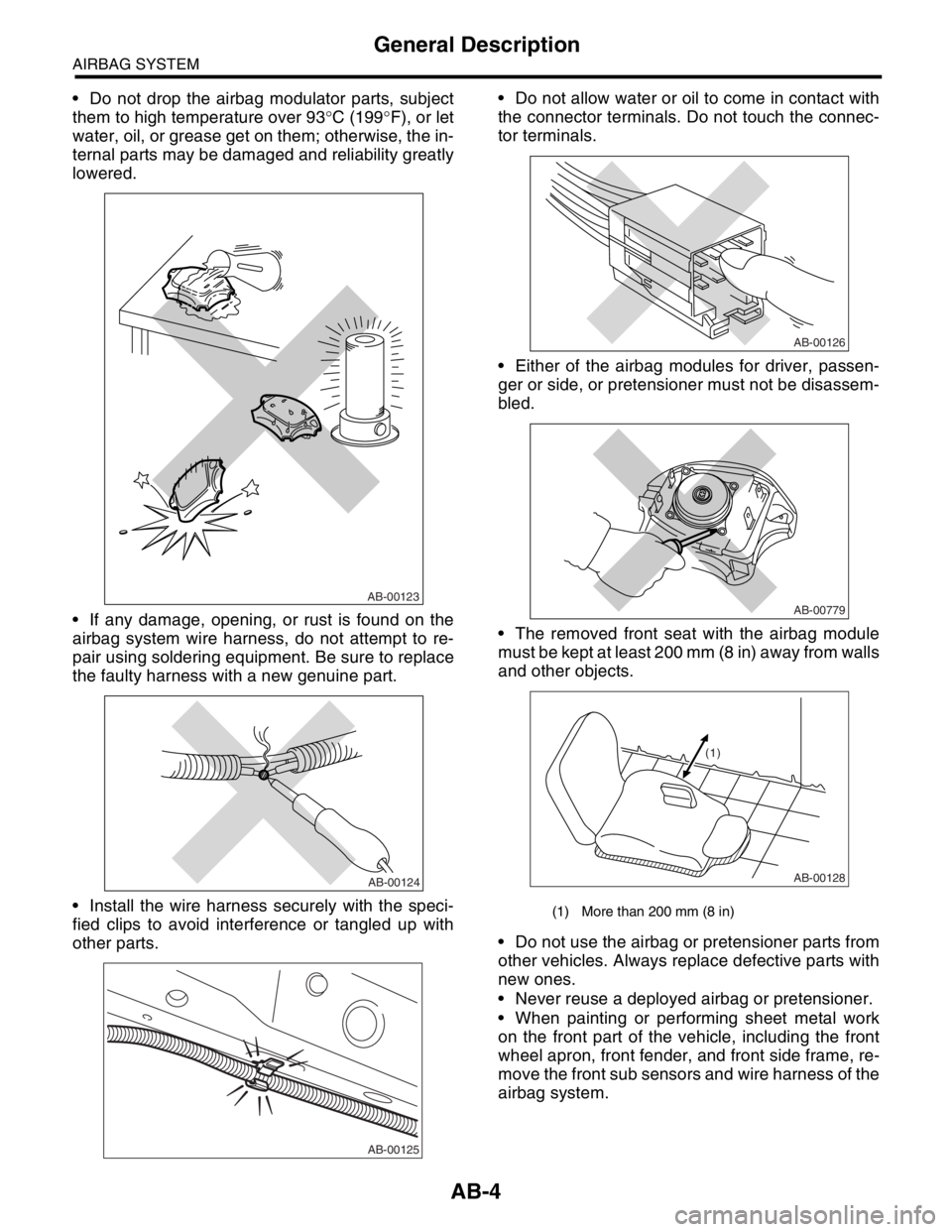

Do not drop the airbag modulator parts, subject

them to high temperature over 93°C (199°F), or let

water, oil, or grease get on them; otherwise, the in-

ternal parts may be damaged and reliability greatly

lowered.

If any damage, opening, or rust is found on the

airbag system wire harness, do not attempt to re-

pair using soldering equipment. Be sure to replace

the faulty harness with a new genuine part.

Install the wire harness securely with the speci-

fied clips to avoid interference or tangled up with

other parts. Do not allow water or oil to come in contact with

the connector terminals. Do not touch the connec-

tor terminals.

Either of the airbag modules for driver, passen-

ger or side, or pretensioner must not be disassem-

bled.

The removed front seat with the airbag module

must be kept at least 200 mm (8 in) away from walls

and other objects.

Do not use the airbag or pretensioner parts from

other vehicles. Always replace defective parts with

new ones.

Never reuse a deployed airbag or pretensioner.

When painting or performing sheet metal work

on the front part of the vehicle, including the front

wheel apron, front fender, and front side frame, re-

move the front sub sensors and wire harness of the

airbag system.

AB-00123

AB-00124

AB-00125

(1) More than 200 mm (8 in)

AB-00126

AB-00779

AB-00128

(1)

Page 111 of 2870

AB-11

AIRBAG SYSTEM

Airbag Connector

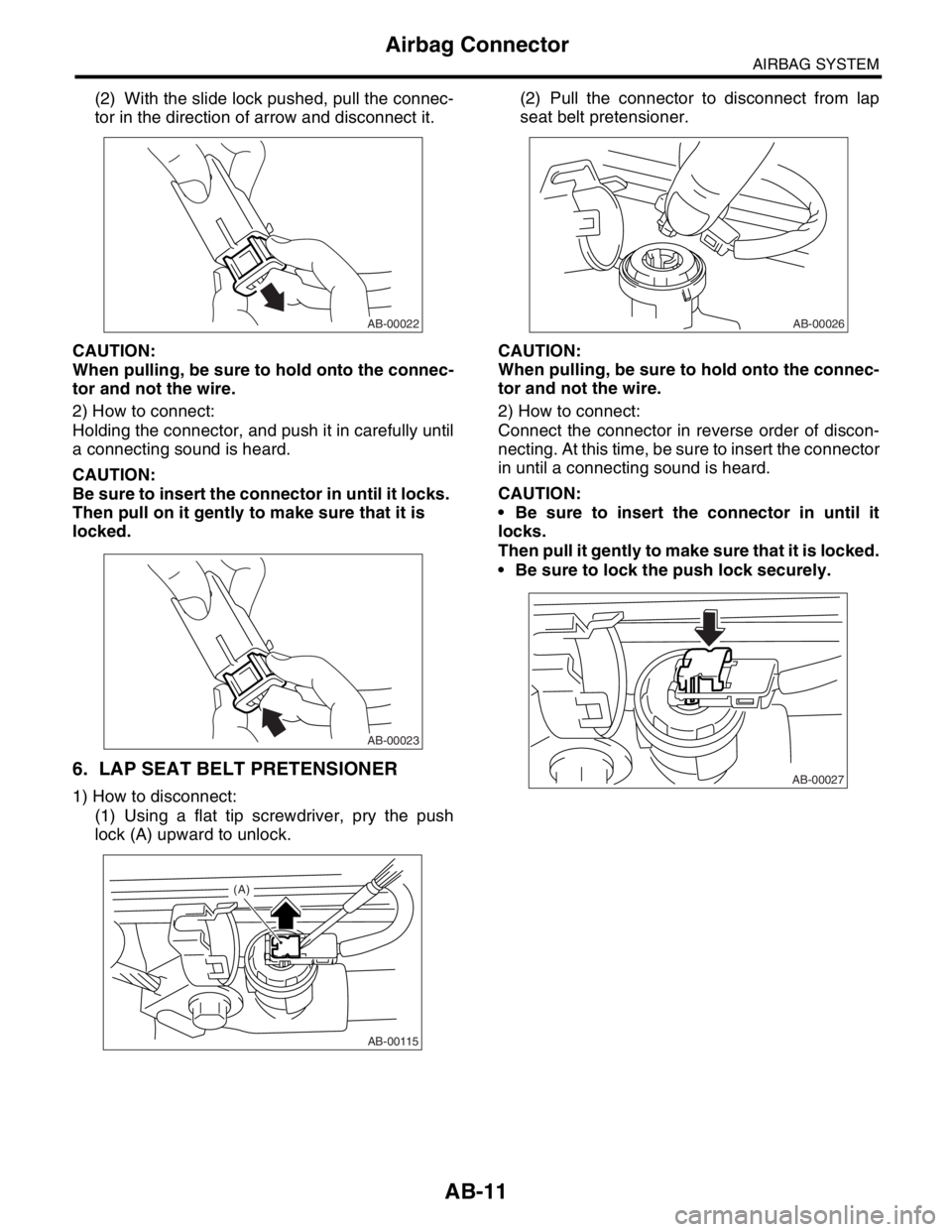

(2) With the slide lock pushed, pull the connec-

tor in the direction of arrow and disconnect it.

CAUTION:

When pulling, be sure to hold onto the connec-

tor and not the wire.

2) How to connect:

Holding the connector, and push it in carefully until

a connecting sound is heard.

CAUTION:

Be sure to insert the connector in until it locks.

Then pull on it gently to make sure that it is

locked.

6. LAP SEAT BELT PRETENSIONER

1) How to disconnect:

(1) Using a flat tip screwdriver, pry the push

lock (A) upward to unlock.(2) Pull the connector to disconnect from lap

seat belt pretensioner.

CAUTION:

When pulling, be sure to hold onto the connec-

tor and not the wire.

2) How to connect:

Connect the connector in reverse order of discon-

necting. At this time, be sure to insert the connector

in until a connecting sound is heard.

CAUTION:

Be sure to insert the connector in until it

locks.

Then pull it gently to make sure that it is locked.

Be sure to lock the push lock securely.

AB-00022

AB-00023

AB-00115

(A)

AB-00026

AB-00027

Page 117 of 2870

AB-17

AIRBAG SYSTEM

Side Airbag Module

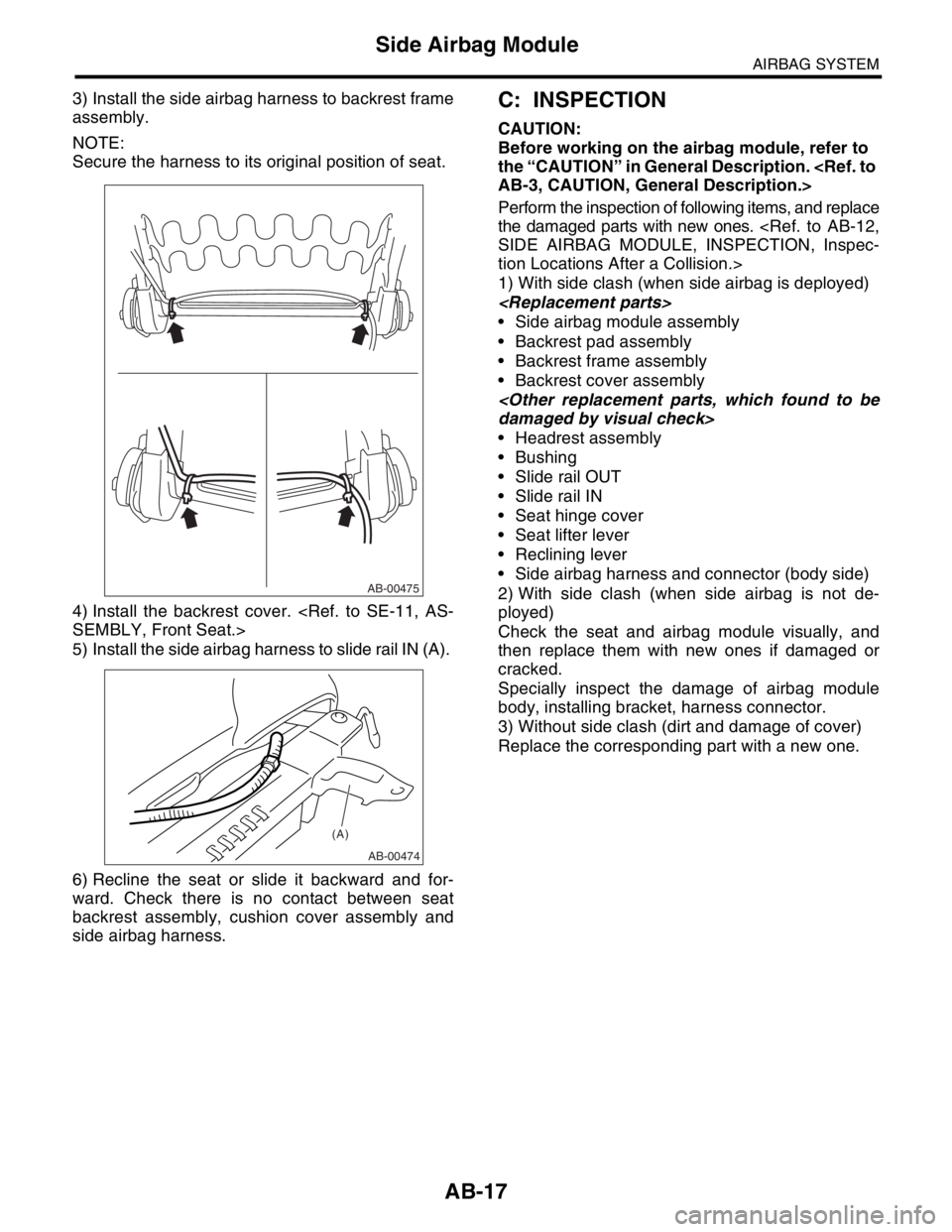

3) Install the side airbag harness to backrest frame

assembly.

NOTE:

Secure the harness to its original position of seat.

4) Install the backrest cover.

5) Install the side airbag harness to slide rail IN (A).

6) Recline the seat or slide it backward and for-

ward. Check there is no contact between seat

backrest assembly, cushion cover assembly and

side airbag harness. C: INSPECTION

CAUTION:

Before working on the airbag module, refer to

the “CAUTION” in General Description.

Perform the inspection of following items, and replace

the damaged parts with new ones.

tion Locations After a Collision.>

1) With side clash (when side airbag is deployed)

Side airbag module assembly

Backrest pad assembly

Backrest frame assembly

Backrest cover assembly

Headrest assembly

Bushing

Slide rail OUT

Slide rail IN

Seat hinge cover

Seat lifter lever

Reclining lever

Side airbag harness and connector (body side)

2) With side clash (when side airbag is not de-

ployed)

Check the seat and airbag module visually, and

then replace them with new ones if damaged or

cracked.

Specially inspect the damage of airbag module

body, installing bracket, harness connector.

3) Without side clash (dirt and damage of cover)

Replace the corresponding part with a new one.

AB-00475

AB-00474

(A)

Page 123 of 2870

AB-23

AIRBAG SYSTEM

Airbag Module Disposal (Deployment Processing On Vehicle)

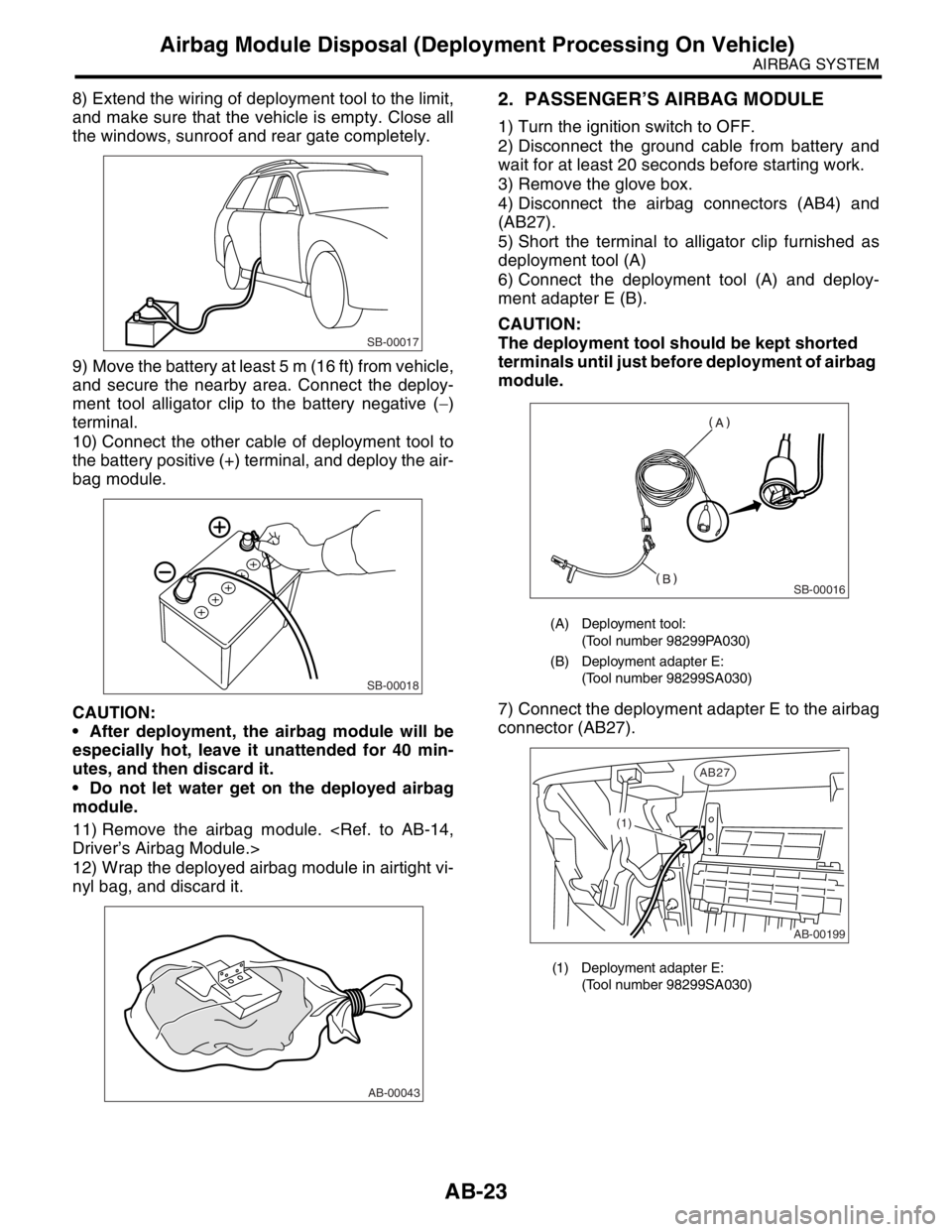

8) Extend the wiring of deployment tool to the limit,

and make sure that the vehicle is empty. Close all

the windows, sunroof and rear gate completely.

9) Move the battery at least 5 m (16 ft) from vehicle,

and secure the nearby area. Connect the deploy-

ment tool alligator clip to the battery negative (−)

terminal.

10) Connect the other cable of deployment tool to

the battery positive (+) terminal, and deploy the air-

bag module.

CAUTION:

After deployment, the airbag module will be

especially hot, leave it unattended for 40 min-

utes, and then discard it.

Do not let water get on the deployed airbag

module.

11) Remove the airbag module.

12) Wrap the deployed airbag module in airtight vi-

nyl bag, and discard it.2. PASSENGER’S AIRBAG MODULE

1) Turn the ignition switch to OFF.

2) Disconnect the ground cable from battery and

wait for at least 20 seconds before starting work.

3) Remove the glove box.

4) Disconnect the airbag connectors (AB4) and

(AB27).

5) Short the terminal to alligator clip furnished as

deployment tool (A)

6) Connect the deployment tool (A) and deploy-

ment adapter E (B).

CAUTION:

The deployment tool should be kept shorted

terminals until just before deployment of airbag

module.

7) Connect the deployment adapter E to the airbag

connector (AB27).

SB-00017

SB-00018

AB-00043

(A) Deployment tool:

(Tool number 98299PA030)

(B) Deployment adapter E:

(Tool number 98299SA030)

(1) Deployment adapter E:

(Tool number 98299SA030)

SB-00016

AB-00199

AB27

(1)