air box SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 59 of 2870

AC-3

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

General Description

2. General Description

A: CAUTION

1) Never connect the battery in reverse polarity.

Auto A/C control module may be destroyed instant-

ly.

2) Do not disconnect the battery terminals while the

engine is running.

A large counter electromotive force will be generat-

ed in the generator, and this voltage may damage

electronic parts such as auto A/C control module,

etc.

3) Before disconnecting the connectors of each

sensor and the auto A/C control module, be sure to

turn off the ignition switch.

Auto A/C control module may be damaged.

4) Every A/C-related part is a precision part. Do not

drop them.

5) Airbag system wiring harness is routed near the

A/C control panel (auto A/C control module) and

junction box.

CAUTION:

For airbag system, yellow-colored wiring har-

ness and connectors are all used. Do not use

the electrical test equipment on these circuits.

Be careful not to damage the airbag system

wiring harness when servicing the A/C control

panel (auto A/C control module) and junction

box.

B: INSPECTION

Before performing the diagnosis, check the follow-

ing items which might affect A/C system problems.

1. BATTERY

1) Measure battery voltage and specific gravity of

electrolyte.

Standard voltage: 12 V

Specific gravity: More than 1.260

2) Check the condition of the fuses for A/C system

power supply and other fuses.

3) Check the condition of harness and harness

connector connections.

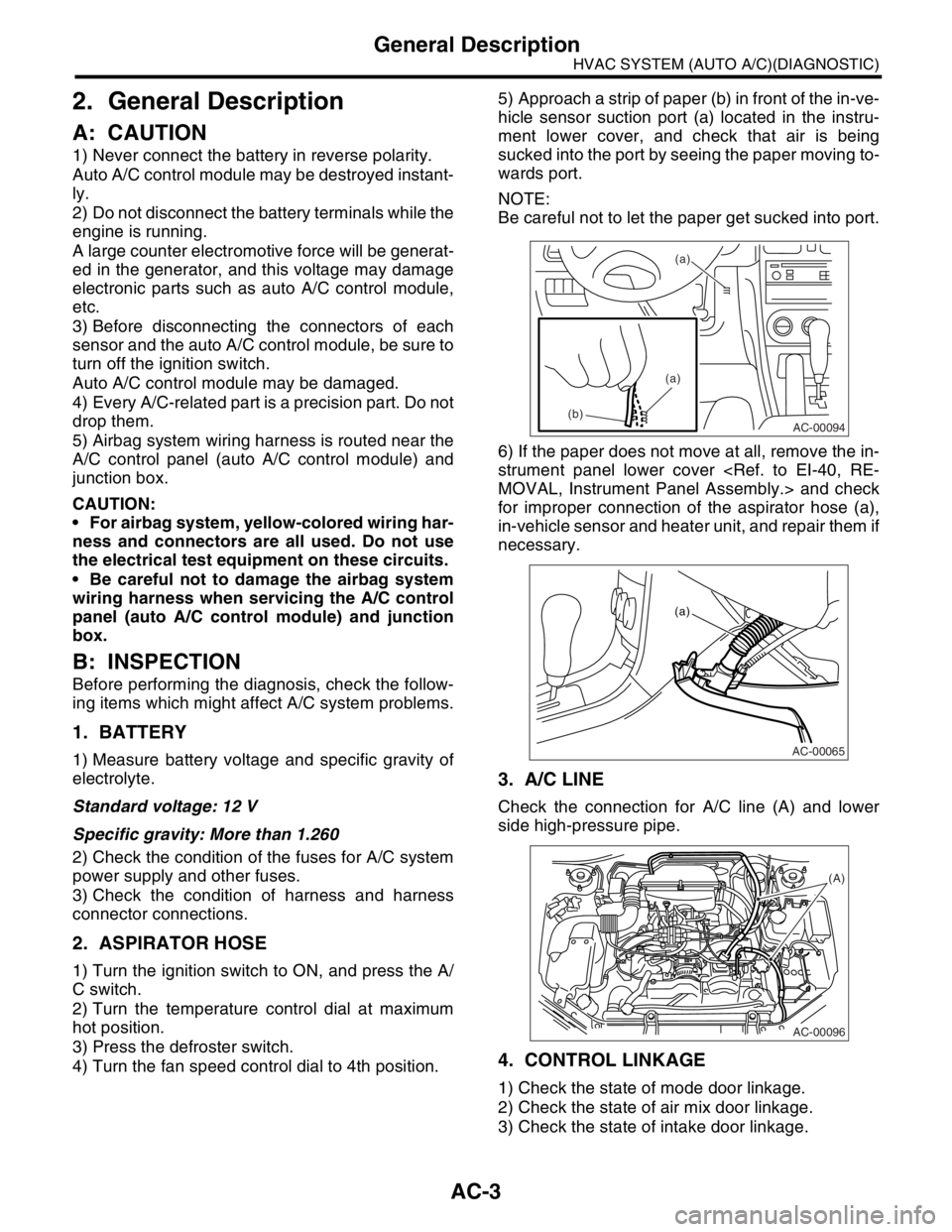

2. ASPIRATOR HOSE

1) Turn the ignition switch to ON, and press the A/

C switch.

2) Turn the temperature control dial at maximum

hot position.

3) Press the defroster switch.

4) Turn the fan speed control dial to 4th position.5) Approach a strip of paper (b) in front of the in-ve-

hicle sensor suction port (a) located in the instru-

ment lower cover, and check that air is being

sucked into the port by seeing the paper moving to-

wards port.

NOTE:

Be careful not to let the paper get sucked into port.

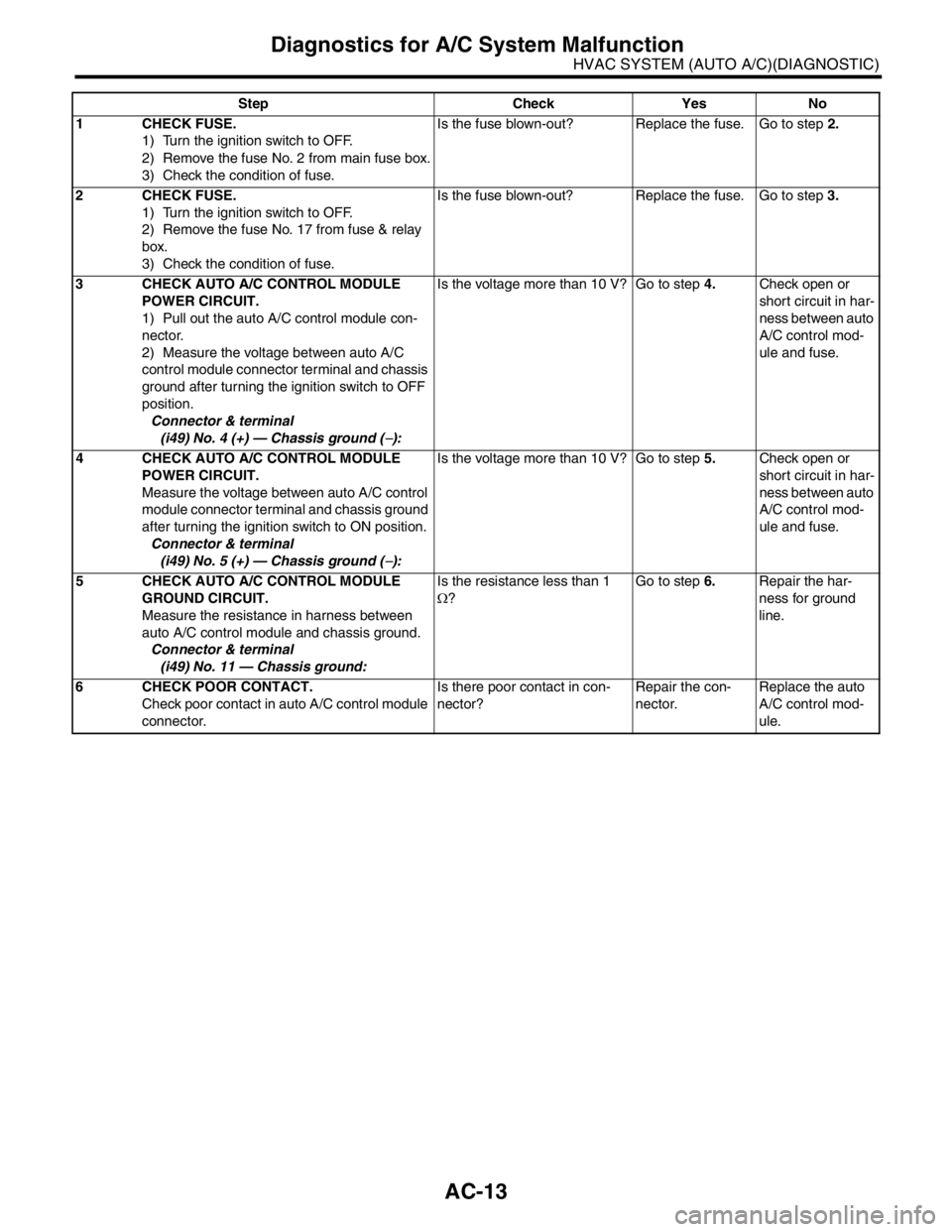

6) If the paper does not move at all, remove the in-

strument panel lower cover

for improper connection of the aspirator hose (a),

in-vehicle sensor and heater unit, and repair them if

necessary.

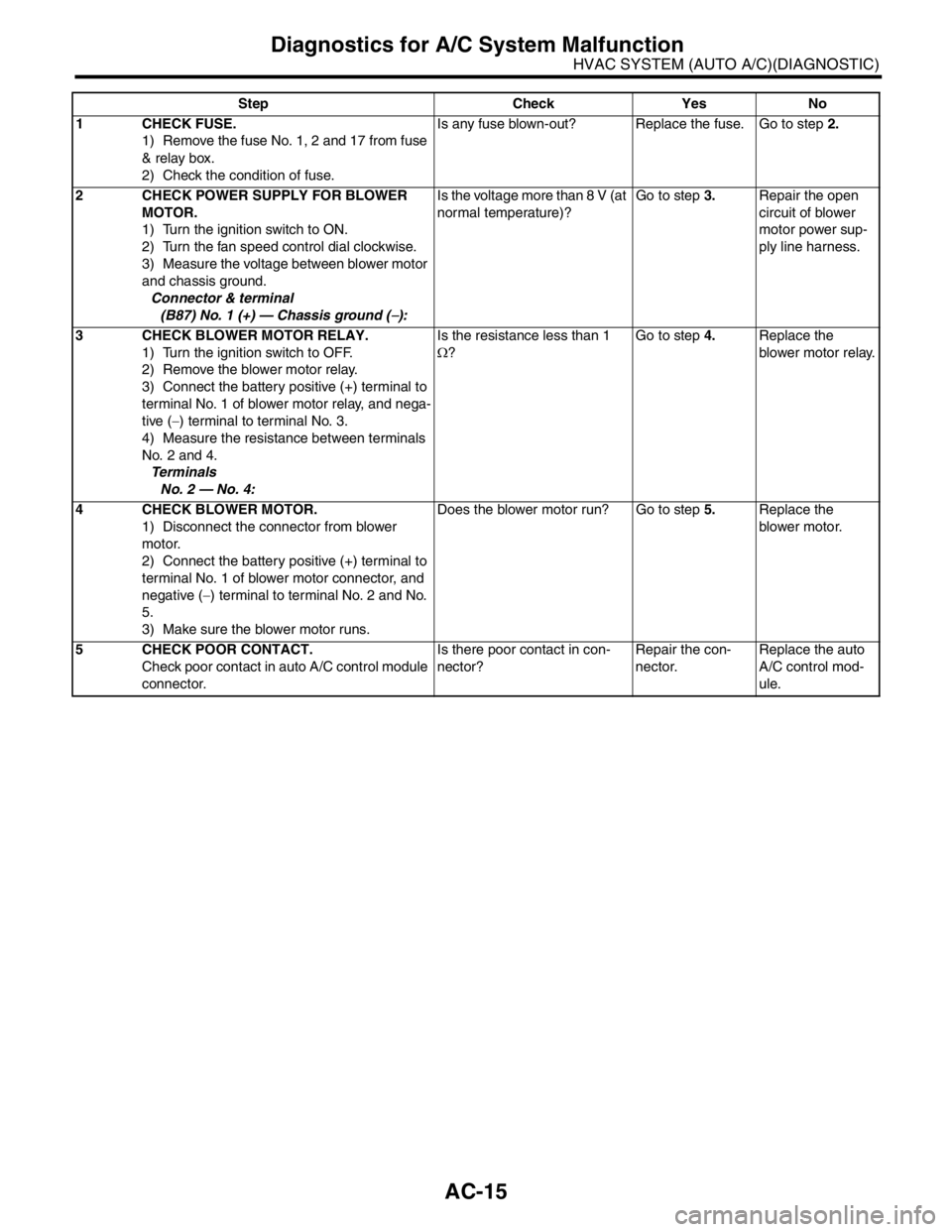

3. A/C LINE

Check the connection for A/C line (A) and lower

side high-pressure pipe.

4. CONTROL LINKAGE

1) Check the state of mode door linkage.

2) Check the state of air mix door linkage.

3) Check the state of intake door linkage.

AC-00094

(a)

(a)

(b)

AC-00065

(a)

AC-00096

(A)

Page 69 of 2870

AC-13

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

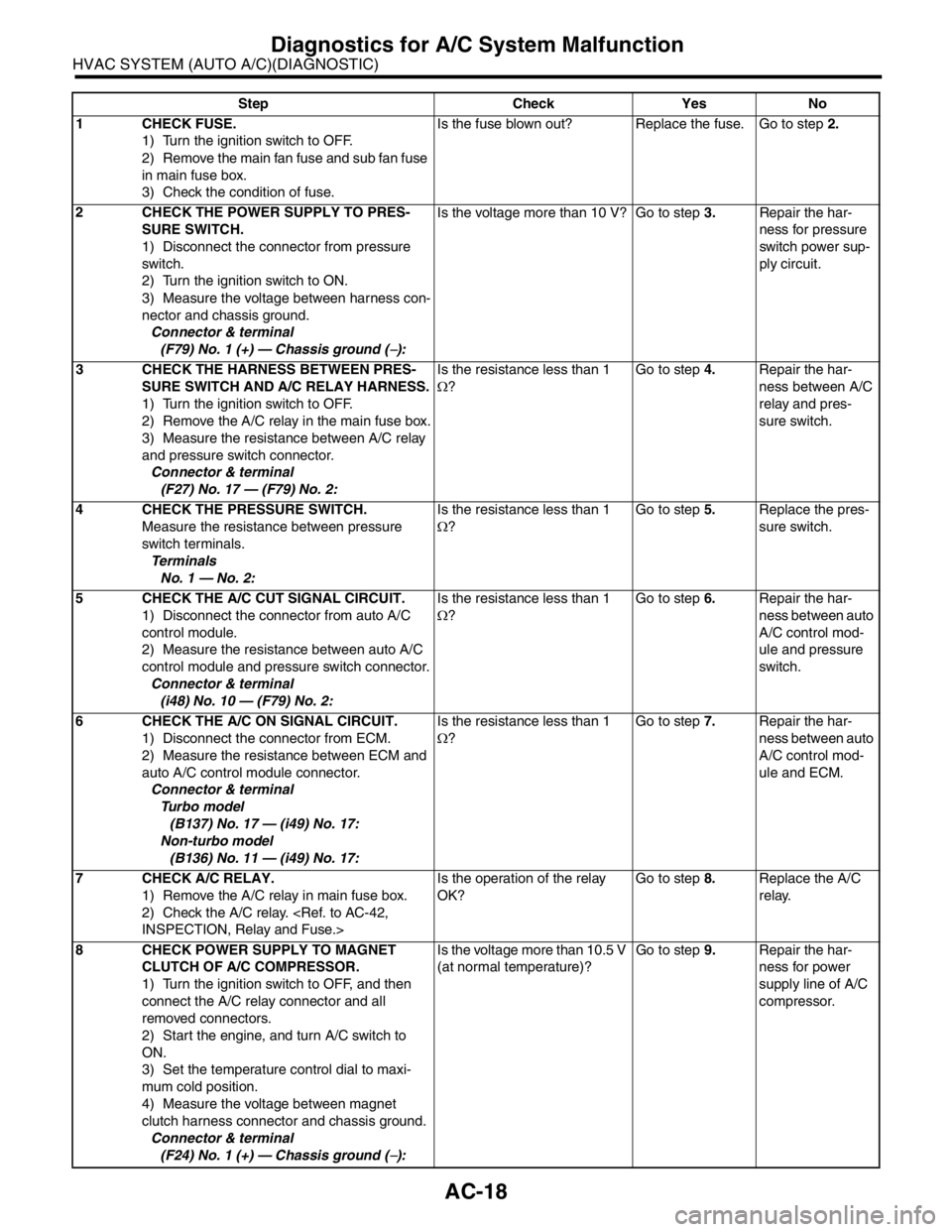

Step Check Yes No

1 CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the fuse No. 2 from main fuse box.

3) Check the condition of fuse.Is the fuse blown-out? Replace the fuse. Go to step 2.

2 CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the fuse No. 17 from fuse & relay

box.

3) Check the condition of fuse.Is the fuse blown-out? Replace the fuse. Go to step 3.

3 CHECK AUTO A/C CONTROL MODULE

POWER CIRCUIT.

1) Pull out the auto A/C control module con-

nector.

2) Measure the voltage between auto A/C

control module connector terminal and chassis

ground after turning the ignition switch to OFF

position.

Connector & terminal

(i49) No. 4 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 4.Check open or

short circuit in har-

ness between auto

A/C control mod-

ule and fuse.

4 CHECK AUTO A/C CONTROL MODULE

POWER CIRCUIT.

Measure the voltage between auto A/C control

module connector terminal and chassis ground

after turning the ignition switch to ON position.

Connector & terminal

(i49) No. 5 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 5.Check open or

short circuit in har-

ness between auto

A/C control mod-

ule and fuse.

5 CHECK AUTO A/C CONTROL MODULE

GROUND CIRCUIT.

Measure the resistance in harness between

auto A/C control module and chassis ground.

Connector & terminal

(i49) No. 11 — Chassis ground:Is the resistance less than 1

Ω?Go to step 6.Repair the har-

ness for ground

line.

6 CHECK POOR CONTACT.

Check poor contact in auto A/C control module

connector.Is there poor contact in con-

nector?Repair the con-

nector.Replace the auto

A/C control mod-

ule.

Page 71 of 2870

AC-15

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

Step Check Yes No

1 CHECK FUSE.

1) Remove the fuse No. 1, 2 and 17 from fuse

& relay box.

2) Check the condition of fuse.Is any fuse blown-out? Replace the fuse. Go to step 2.

2 CHECK POWER SUPPLY FOR BLOWER

MOTOR.

1) Turn the ignition switch to ON.

2) Turn the fan speed control dial clockwise.

3) Measure the voltage between blower motor

and chassis ground.

Connector & terminal

(B87) No. 1 (+) — Chassis ground (

−):Is the voltage more than 8 V (at

normal temperature)?Go to step 3.Repair the open

circuit of blower

motor power sup-

ply line harness.

3 CHECK BLOWER MOTOR RELAY.

1) Turn the ignition switch to OFF.

2) Remove the blower motor relay.

3) Connect the battery positive (+) terminal to

terminal No. 1 of blower motor relay, and nega-

tive (−) terminal to terminal No. 3.

4) Measure the resistance between terminals

No. 2 and 4.

Te r m i n a l s

No. 2 — No. 4:Is the resistance less than 1

Ω?Go to step 4.Replace the

blower motor relay.

4 CHECK BLOWER MOTOR.

1) Disconnect the connector from blower

motor.

2) Connect the battery positive (+) terminal to

terminal No. 1 of blower motor connector, and

negative (−) terminal to terminal No. 2 and No.

5.

3) Make sure the blower motor runs.Does the blower motor run? Go to step 5.Replace the

blower motor.

5 CHECK POOR CONTACT.

Check poor contact in auto A/C control module

connector.Is there poor contact in con-

nector?Repair the con-

nector.Replace the auto

A/C control mod-

ule.

Page 74 of 2870

AC-18

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

Step Check Yes No

1 CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the main fan fuse and sub fan fuse

in main fuse box.

3) Check the condition of fuse.Is the fuse blown out? Replace the fuse. Go to step 2.

2 CHECK THE POWER SUPPLY TO PRES-

SURE SWITCH.

1) Disconnect the connector from pressure

switch.

2) Turn the ignition switch to ON.

3) Measure the voltage between harness con-

nector and chassis ground.

Connector & terminal

(F79) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 3.Repair the har-

ness for pressure

switch power sup-

ply circuit.

3 CHECK THE HARNESS BETWEEN PRES-

SURE SWITCH AND A/C RELAY HARNESS.

1) Turn the ignition switch to OFF.

2) Remove the A/C relay in the main fuse box.

3) Measure the resistance between A/C relay

and pressure switch connector.

Connector & terminal

(F27) No. 17 — (F79) No. 2:Is the resistance less than 1

Ω?Go to step 4.Repair the har-

ness between A/C

relay and pres-

sure switch.

4 CHECK THE PRESSURE SWITCH.

Measure the resistance between pressure

switch terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance less than 1

Ω?Go to step 5.Replace the pres-

sure switch.

5 CHECK THE A/C CUT SIGNAL CIRCUIT.

1) Disconnect the connector from auto A/C

control module.

2) Measure the resistance between auto A/C

control module and pressure switch connector.

Connector & terminal

(i48) No. 10 — (F79) No. 2:Is the resistance less than 1

Ω?Go to step 6.Repair the har-

ness between auto

A/C control mod-

ule and pressure

switch.

6 CHECK THE A/C ON SIGNAL CIRCUIT.

1) Disconnect the connector from ECM.

2) Measure the resistance between ECM and

auto A/C control module connector.

Connector & terminal

Turbo model

(B137) No. 17 — (i49) No. 17:

Non-turbo model

(B136) No. 11 — (i49) No. 17:Is the resistance less than 1

Ω?Go to step 7.Repair the har-

ness between auto

A/C control mod-

ule and ECM.

7 CHECK A/C RELAY.

1) Remove the A/C relay in main fuse box.

2) Check the A/C relay.

OK?Go to step 8.Replace the A/C

relay.

8 CHECK POWER SUPPLY TO MAGNET

CLUTCH OF A/C COMPRESSOR.

1) Turn the ignition switch to OFF, and then

connect the A/C relay connector and all

removed connectors.

2) Start the engine, and turn A/C switch to

ON.

3) Set the temperature control dial to maxi-

mum cold position.

4) Measure the voltage between magnet

clutch harness connector and chassis ground.

Connector & terminal

(F24) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10.5 V

(at normal temperature)?Go to step 9.Repair the har-

ness for power

supply line of A/C

compressor.

Page 94 of 2870

AC-38

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

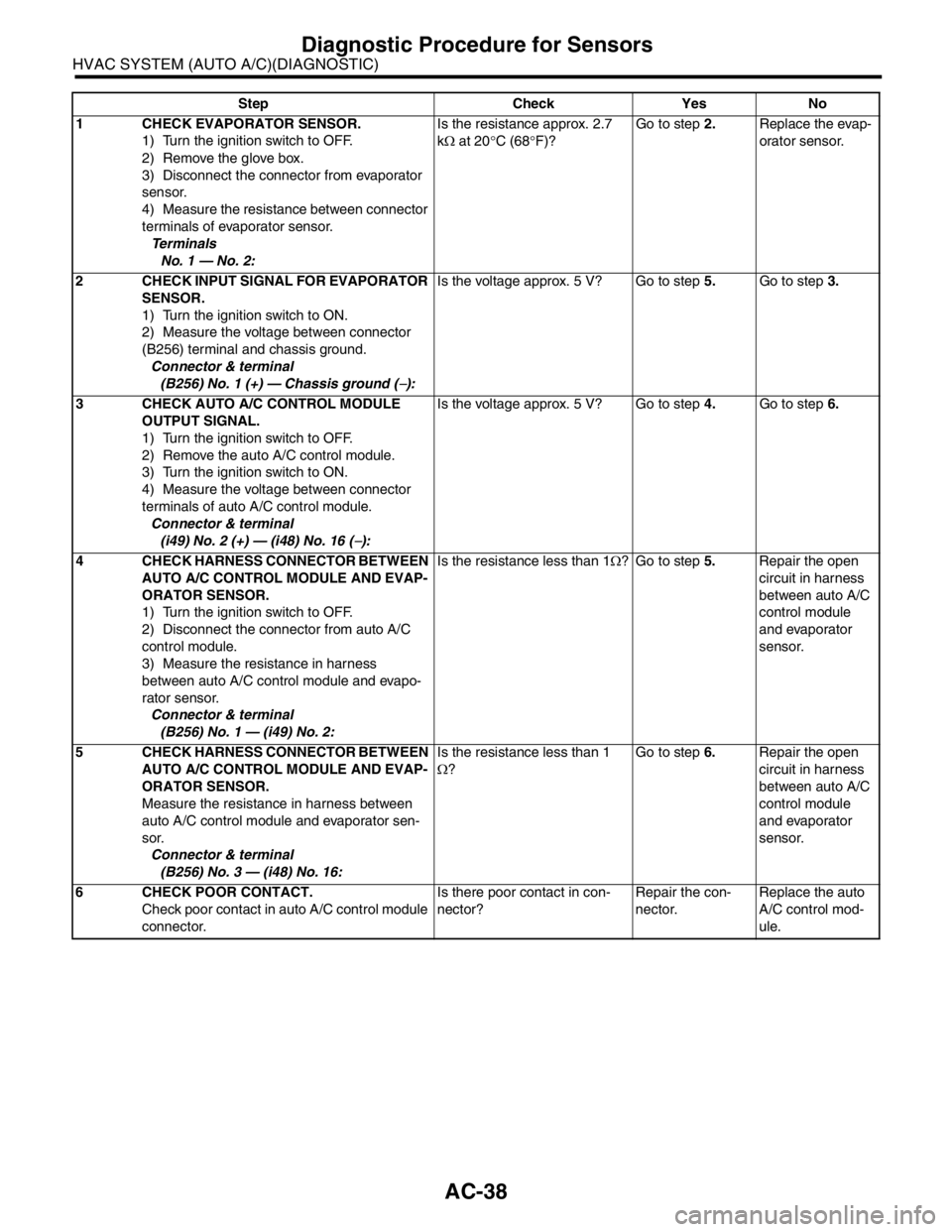

Diagnostic Procedure for Sensors

Step Check Yes No

1 CHECK EVAPORATOR SENSOR.

1) Turn the ignition switch to OFF.

2) Remove the glove box.

3) Disconnect the connector from evaporator

sensor.

4) Measure the resistance between connector

terminals of evaporator sensor.

Te r m i n a l s

No. 1 — No. 2:Is the resistance approx. 2.7

kΩ at 20°C (68°F)?Go to step 2.Replace the evap-

orator sensor.

2 CHECK INPUT SIGNAL FOR EVAPORATOR

SENSOR.

1) Turn the ignition switch to ON.

2) Measure the voltage between connector

(B256) terminal and chassis ground.

Connector & terminal

(B256) No. 1 (+) — Chassis ground (

−):Is the voltage approx. 5 V? Go to step 5.Go to step 3.

3 CHECK AUTO A/C CONTROL MODULE

OUTPUT SIGNAL.

1) Turn the ignition switch to OFF.

2) Remove the auto A/C control module.

3) Turn the ignition switch to ON.

4) Measure the voltage between connector

terminals of auto A/C control module.

Connector & terminal

(i49) No. 2 (+) — (i48) No. 16 (

−):Is the voltage approx. 5 V? Go to step 4.Go to step 6.

4 CHECK HARNESS CONNECTOR BETWEEN

AUTO A/C CONTROL MODULE AND EVAP-

ORATOR SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from auto A/C

control module.

3) Measure the resistance in harness

between auto A/C control module and evapo-

rator sensor.

Connector & terminal

(B256) No. 1 — (i49) No. 2:Is the resistance less than 1Ω? Go to step 5.Repair the open

circuit in harness

between auto A/C

control module

and evaporator

sensor.

5 CHECK HARNESS CONNECTOR BETWEEN

AUTO A/C CONTROL MODULE AND EVAP-

ORATOR SENSOR.

Measure the resistance in harness between

auto A/C control module and evaporator sen-

sor.

Connector & terminal

(B256) No. 3 — (i48) No. 16:Is the resistance less than 1

Ω?Go to step 6.Repair the open

circuit in harness

between auto A/C

control module

and evaporator

sensor.

6 CHECK POOR CONTACT.

Check poor contact in auto A/C control module

connector.Is there poor contact in con-

nector?Repair the con-

nector.Replace the auto

A/C control mod-

ule.

Page 115 of 2870

AB-15

AIRBAG SYSTEM

Passenger’s Airbag Module

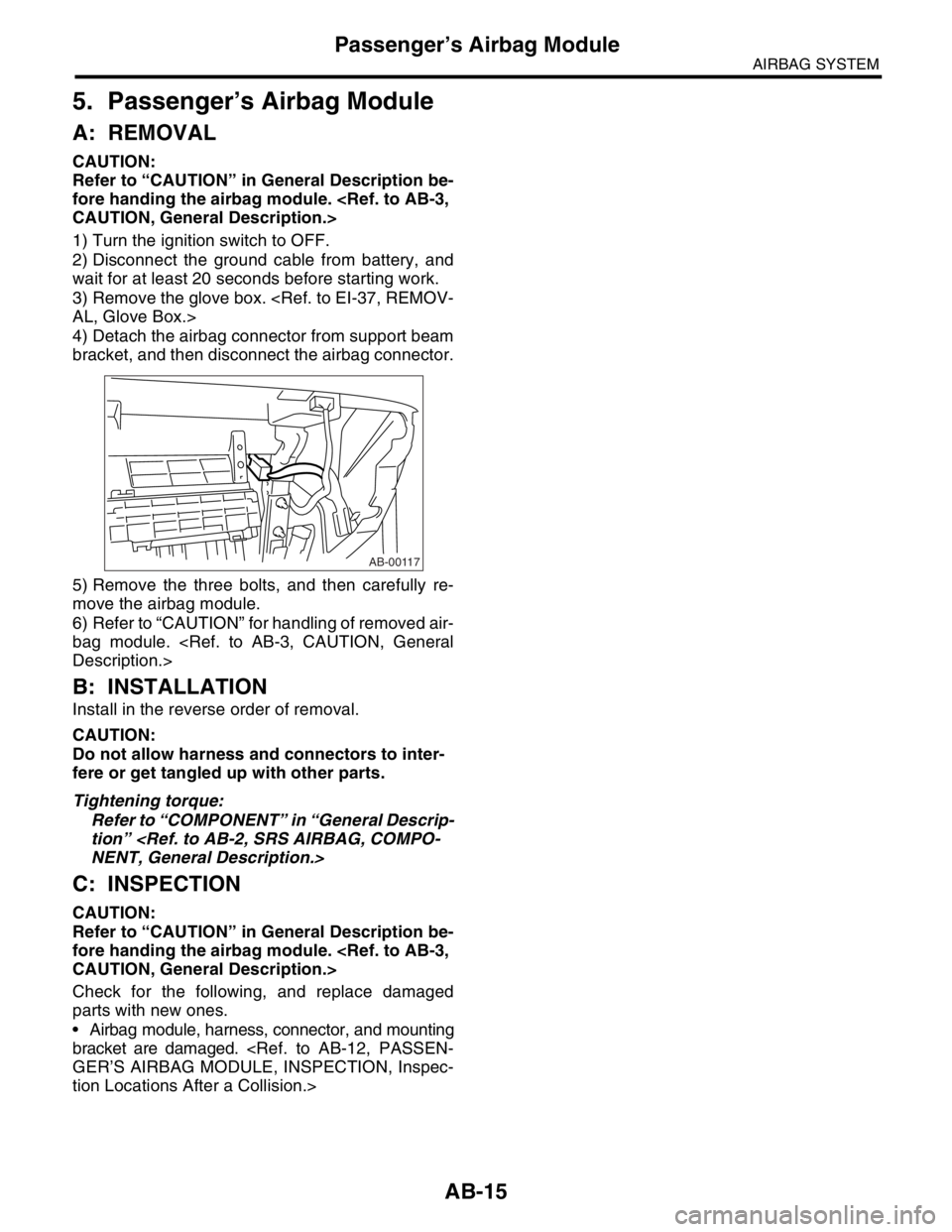

5. Passenger’s Airbag Module

A: REMOVAL

CAUTION:

Refer to “CAUTION” in General Description be-

fore handing the airbag module.

1) Turn the ignition switch to OFF.

2) Disconnect the ground cable from battery, and

wait for at least 20 seconds before starting work.

3) Remove the glove box.

4) Detach the airbag connector from support beam

bracket, and then disconnect the airbag connector.

5) Remove the three bolts, and then carefully re-

move the airbag module.

6) Refer to “CAUTION” for handling of removed air-

bag module.

B: INSTALLATION

Install in the reverse order of removal.

CAUTION:

Do not allow harness and connectors to inter-

fere or get tangled up with other parts.

Tightening torque:

Refer to “COMPONENT” in “General Descrip-

tion”

C: INSPECTION

CAUTION:

Refer to “CAUTION” in General Description be-

fore handing the airbag module.

Check for the following, and replace damaged

parts with new ones.

Airbag module, harness, connector, and mounting

bracket are damaged.

tion Locations After a Collision.>

AB-00117

Page 118 of 2870

AB-18

AIRBAG SYSTEM

Airbag Control Module

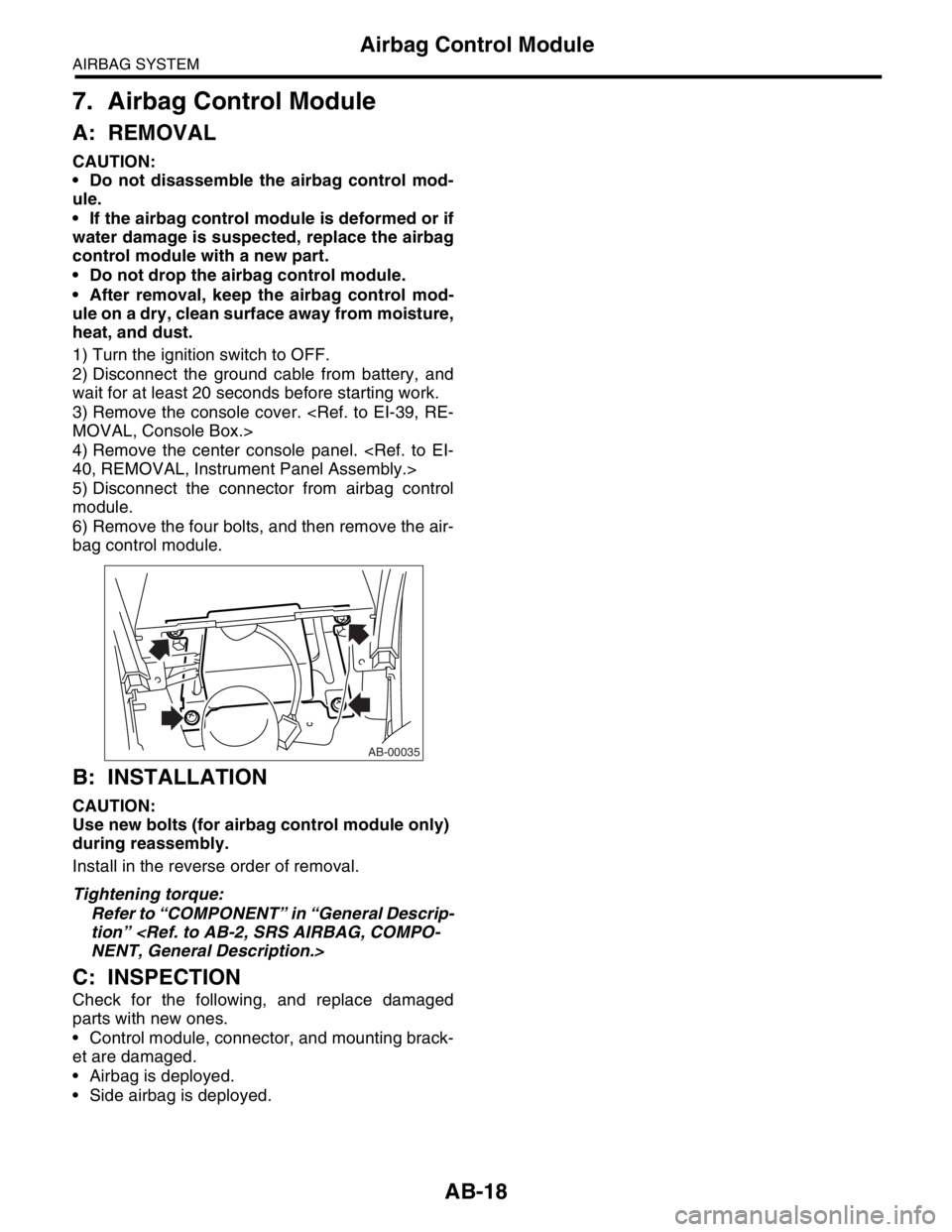

7. Airbag Control Module

A: REMOVAL

CAUTION:

Do not disassemble the airbag control mod-

ule.

If the airbag control module is deformed or if

water damage is suspected, replace the airbag

control module with a new part.

Do not drop the airbag control module.

After removal, keep the airbag control mod-

ule on a dry, clean surface away from moisture,

heat, and dust.

1) Turn the ignition switch to OFF.

2) Disconnect the ground cable from battery, and

wait for at least 20 seconds before starting work.

3) Remove the console cover.

4) Remove the center console panel.

5) Disconnect the connector from airbag control

module.

6) Remove the four bolts, and then remove the air-

bag control module.

B: INSTALLATION

CAUTION:

Use new bolts (for airbag control module only)

during reassembly.

Install in the reverse order of removal.

Tightening torque:

Refer to “COMPONENT” in “General Descrip-

tion”

C: INSPECTION

Check for the following, and replace damaged

parts with new ones.

Control module, connector, and mounting brack-

et are damaged.

Airbag is deployed.

Side airbag is deployed.

AB-00035

Page 123 of 2870

AB-23

AIRBAG SYSTEM

Airbag Module Disposal (Deployment Processing On Vehicle)

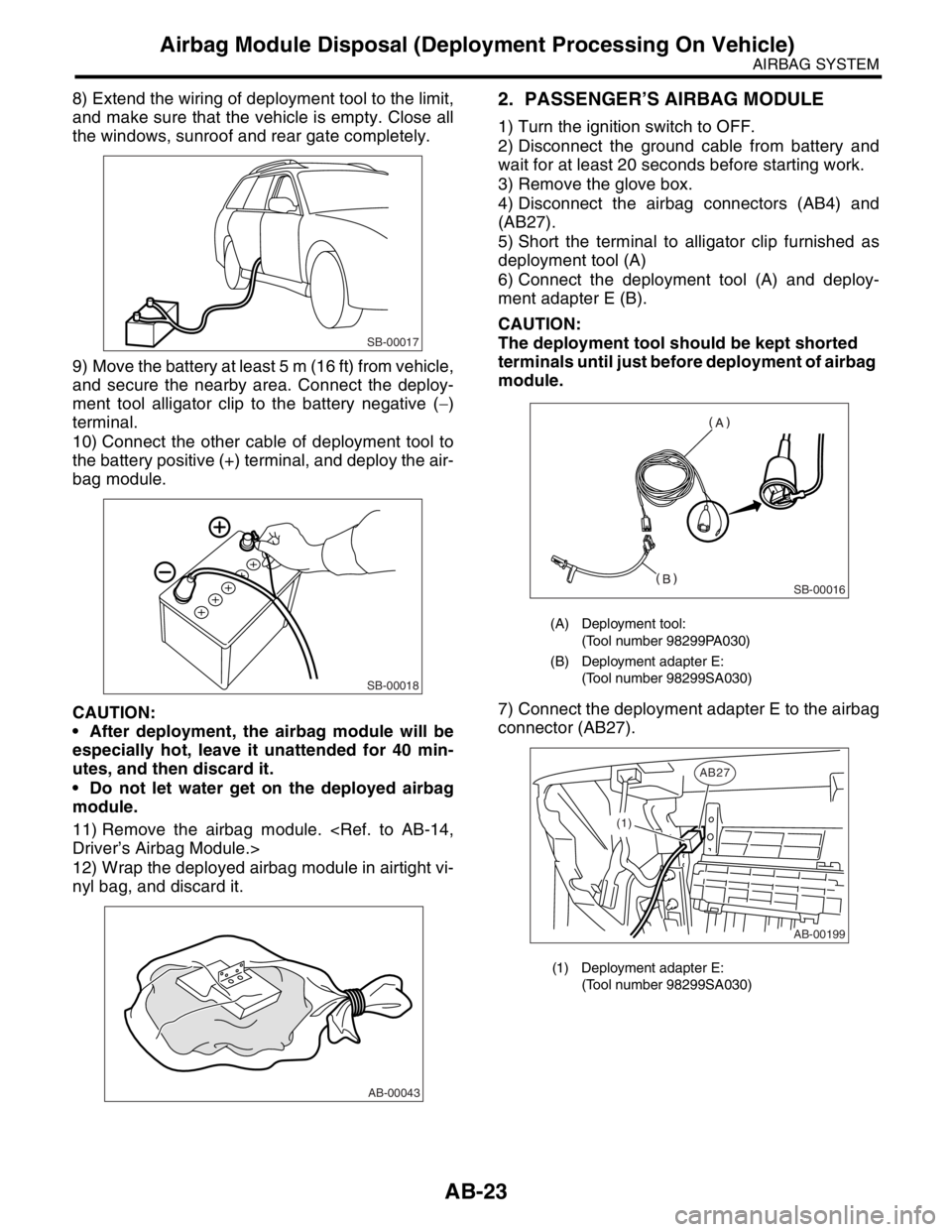

8) Extend the wiring of deployment tool to the limit,

and make sure that the vehicle is empty. Close all

the windows, sunroof and rear gate completely.

9) Move the battery at least 5 m (16 ft) from vehicle,

and secure the nearby area. Connect the deploy-

ment tool alligator clip to the battery negative (−)

terminal.

10) Connect the other cable of deployment tool to

the battery positive (+) terminal, and deploy the air-

bag module.

CAUTION:

After deployment, the airbag module will be

especially hot, leave it unattended for 40 min-

utes, and then discard it.

Do not let water get on the deployed airbag

module.

11) Remove the airbag module.

12) Wrap the deployed airbag module in airtight vi-

nyl bag, and discard it.2. PASSENGER’S AIRBAG MODULE

1) Turn the ignition switch to OFF.

2) Disconnect the ground cable from battery and

wait for at least 20 seconds before starting work.

3) Remove the glove box.

4) Disconnect the airbag connectors (AB4) and

(AB27).

5) Short the terminal to alligator clip furnished as

deployment tool (A)

6) Connect the deployment tool (A) and deploy-

ment adapter E (B).

CAUTION:

The deployment tool should be kept shorted

terminals until just before deployment of airbag

module.

7) Connect the deployment adapter E to the airbag

connector (AB27).

SB-00017

SB-00018

AB-00043

(A) Deployment tool:

(Tool number 98299PA030)

(B) Deployment adapter E:

(Tool number 98299SA030)

(1) Deployment adapter E:

(Tool number 98299SA030)

SB-00016

AB-00199

AB27

(1)

Page 168 of 2870

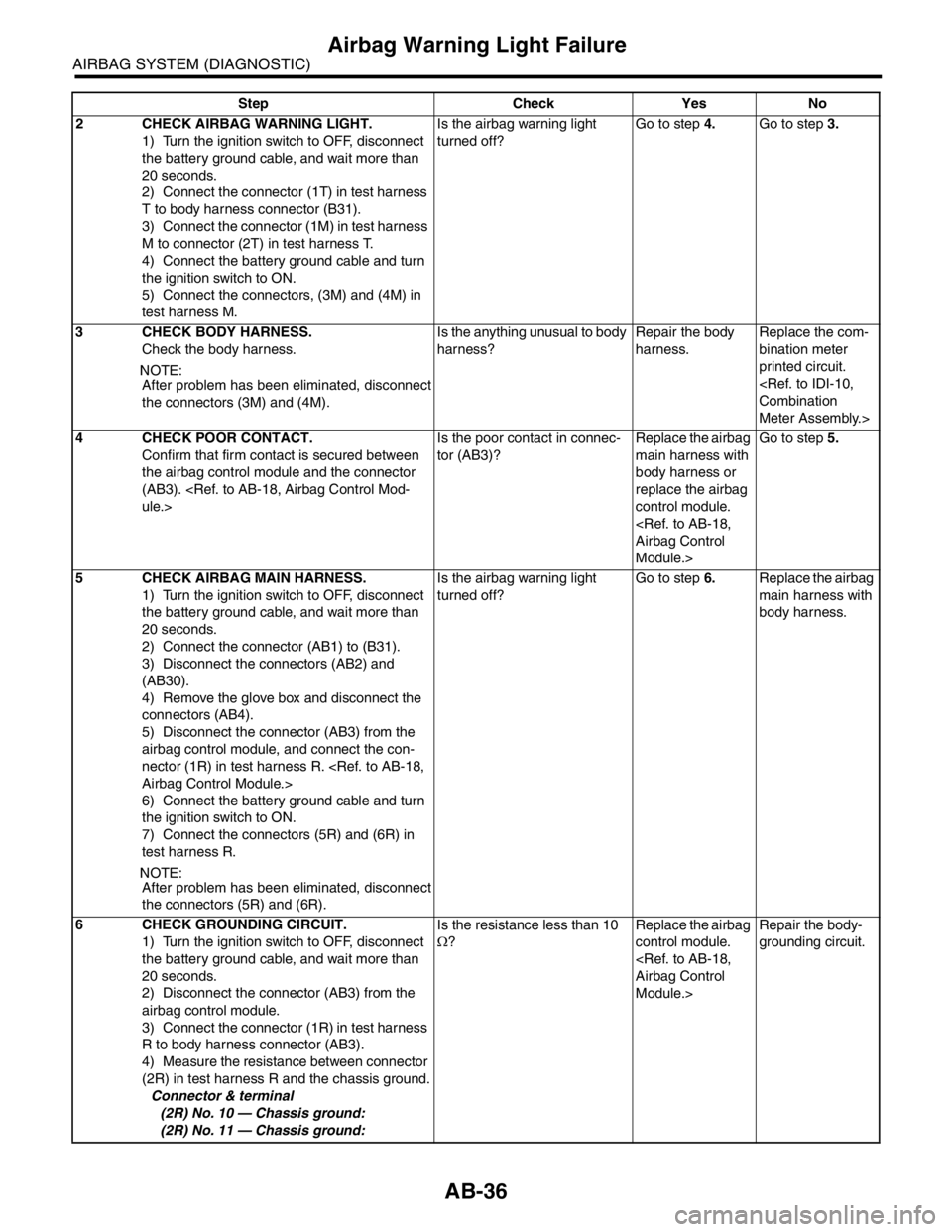

AB-36

AIRBAG SYSTEM (DIAGNOSTIC)

Airbag Warning Light Failure

2 CHECK AIRBAG WARNING LIGHT.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Connect the connector (1T) in test harness

T to body harness connector (B31).

3) Connect the connector (1M) in test harness

M to connector (2T) in test harness T.

4) Connect the battery ground cable and turn

the ignition switch to ON.

5) Connect the connectors, (3M) and (4M) in

test harness M.Is the airbag warning light

turned off?Go to step 4.Go to step 3.

3 CHECK BODY HARNESS.

Check the body harness.

N

OTE:

After problem has been eliminated, disconnect

the connectors (3M) and (4M).Is the anything unusual to body

harness? Repair the body

harness.Replace the com-

bination meter

printed circuit.

Meter Assembly.>

4 CHECK POOR CONTACT.

Confirm that firm contact is secured between

the airbag control module and the connector

(AB3).

tor (AB3)?Replace the airbag

main harness with

body harness or

replace the airbag

control module.

Module.>Go to step 5.

5 CHECK AIRBAG MAIN HARNESS.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Connect the connector (AB1) to (B31).

3) Disconnect the connectors (AB2) and

(AB30).

4) Remove the glove box and disconnect the

connectors (AB4).

5) Disconnect the connector (AB3) from the

airbag control module, and connect the con-

nector (1R) in test harness R.

6) Connect the battery ground cable and turn

the ignition switch to ON.

7) Connect the connectors (5R) and (6R) in

test harness R.

N

OTE:

After problem has been eliminated, disconnect

the connectors (5R) and (6R).Is the airbag warning light

turned off?Go to step 6.Replace the airbag

main harness with

body harness.

6 CHECK GROUNDING CIRCUIT.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Disconnect the connector (AB3) from the

airbag control module.

3) Connect the connector (1R) in test harness

R to body harness connector (AB3).

4) Measure the resistance between connector

(2R) in test harness R and the chassis ground.

Connector & terminal

(2R) No. 10 — Chassis ground:

(2R) No. 11 — Chassis ground: Is the resistance less than 10

Ω?Replace the airbag

control module.

Module.>Repair the body-

grounding circuit. Step Check Yes No

Page 170 of 2870

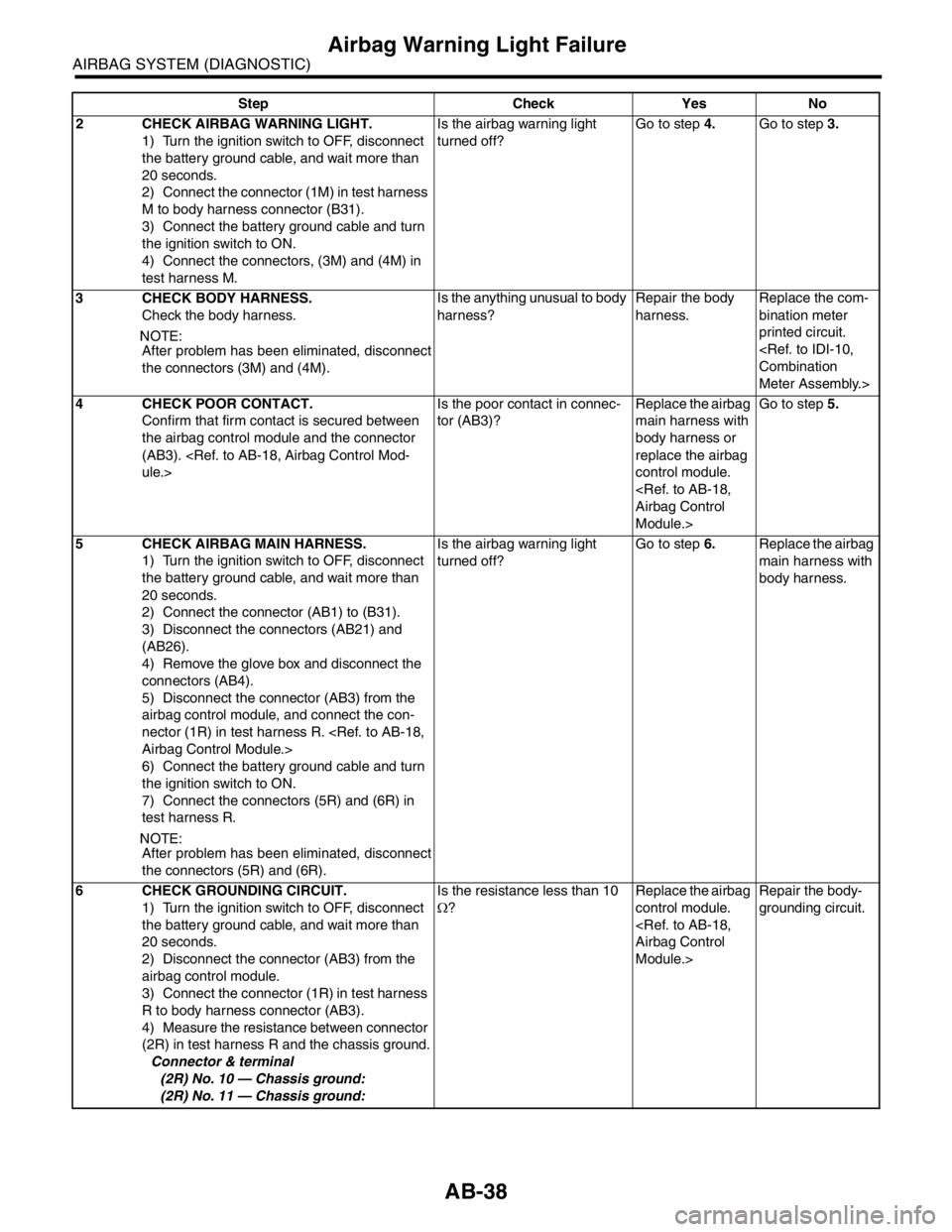

AB-38

AIRBAG SYSTEM (DIAGNOSTIC)

Airbag Warning Light Failure

2 CHECK AIRBAG WARNING LIGHT.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Connect the connector (1M) in test harness

M to body harness connector (B31).

3) Connect the battery ground cable and turn

the ignition switch to ON.

4) Connect the connectors, (3M) and (4M) in

test harness M.Is the airbag warning light

turned off?Go to step 4.Go to step 3.

3 CHECK BODY HARNESS.

Check the body harness.

N

OTE:

After problem has been eliminated, disconnect

the connectors (3M) and (4M).Is the anything unusual to body

harness?Repair the body

harness.Replace the com-

bination meter

printed circuit.

Meter Assembly.>

4 CHECK POOR CONTACT.

Confirm that firm contact is secured between

the airbag control module and the connector

(AB3).

tor (AB3)? Replace the airbag

main harness with

body harness or

replace the airbag

control module.

Module.>Go to step 5.

5 CHECK AIRBAG MAIN HARNESS.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Connect the connector (AB1) to (B31).

3) Disconnect the connectors (AB21) and

(AB26).

4) Remove the glove box and disconnect the

connectors (AB4).

5) Disconnect the connector (AB3) from the

airbag control module, and connect the con-

nector (1R) in test harness R.

6) Connect the battery ground cable and turn

the ignition switch to ON.

7) Connect the connectors (5R) and (6R) in

test harness R.

N

OTE:

After problem has been eliminated, disconnect

the connectors (5R) and (6R).Is the airbag warning light

turned off? Go to step 6.Replace the airbag

main harness with

body harness.

6 CHECK GROUNDING CIRCUIT.

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Disconnect the connector (AB3) from the

airbag control module.

3) Connect the connector (1R) in test harness

R to body harness connector (AB3).

4) Measure the resistance between connector

(2R) in test harness R and the chassis ground.

Connector & terminal

(2R) No. 10 — Chassis ground:

(2R) No. 11 — Chassis ground: Is the resistance less than 10

Ω?Replace the airbag

control module.

Module.>Repair the body-

grounding circuit. Step Check Yes No