front brake SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 665 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE6

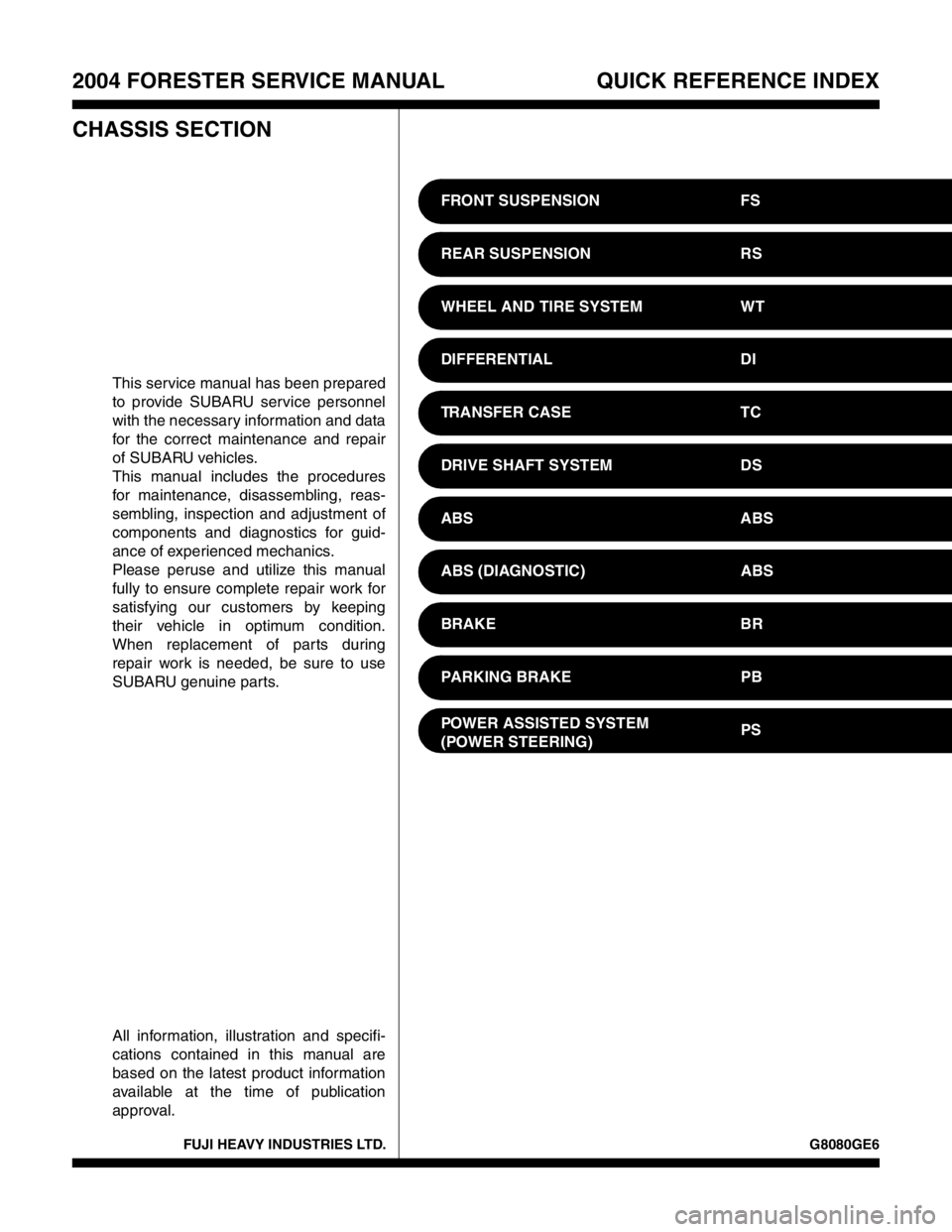

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

CHASSIS SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.FRONT SUSPENSION FS

REAR SUSPENSION RS

WHEEL AND TIRE SYSTEM WT

DIFFERENTIAL DI

TRANSFER CASE TC

DRIVE SHAFT SYSTEM DS

ABS ABS

ABS (DIAGNOSTIC) ABS

BRAKE BR

PARKING BRAKE PB

POWER ASSISTED SYSTEM

(POWER STEERING)PS

Page 693 of 2870

SPC-4

SPECIFICATION

Forester

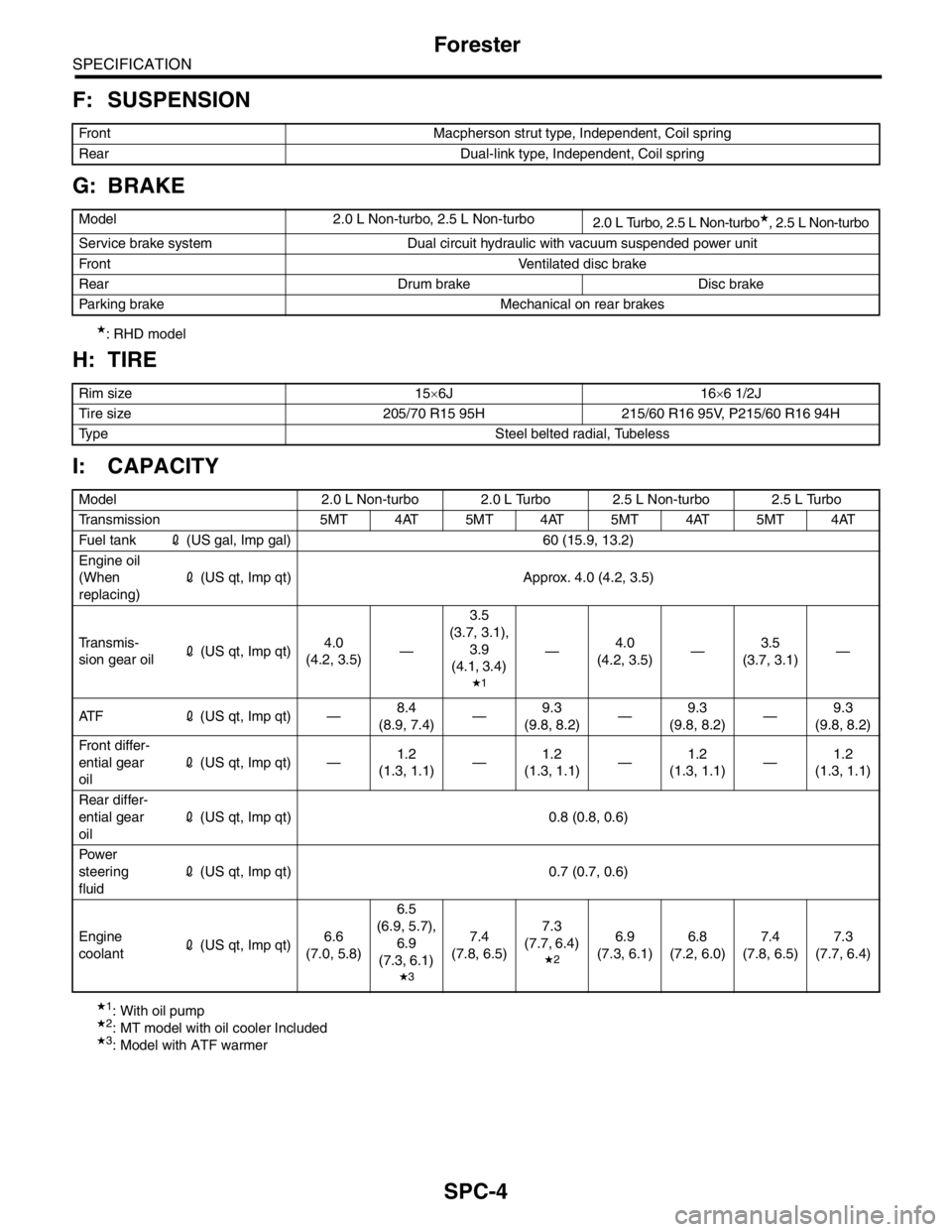

F: SUSPENSION

G: BRAKE

★: RHD model

H: TIRE

I: CAPACITY

★1: With oil pump★2: MT model with oil cooler Included★3: Model with ATF warmer Front Macpherson strut type, Independent, Coil spring

Rear Dual-link type, Independent, Coil spring

Model 2.0 L Non-turbo, 2.5 L Non-turbo

2.0 L Turbo, 2.5 L Non-turbo

★, 2.5 L Non-turbo

Service brake system Dual circuit hydraulic with vacuum suspended power unit

Front Ventilated disc brake

Rear Drum brake Disc brake

Parking brake Mechanical on rear brakes

Rim size 15×6J 16×6 1/2J

Tire size 205/70 R15 95H 215/60 R16 95V, P215/60 R16 94H

Type Steel belted radial, Tubeless

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Tr a n s m i s s i o n 5 M T 4 AT 5 M T 4 AT 5 M T 4 AT 5 M T 4 AT

Fuel tank2 (US gal, Imp gal) 60 (15.9, 13.2)

Engine oil

(When

replacing)2 (US qt, Imp qt) Approx. 4.0 (4.2, 3.5)

Tr a n s m i s -

sion gear oil2 (US qt, Imp qt)4.0

(4.2, 3.5)—3.5

(3.7, 3.1),

3.9

(4.1, 3.4)

★1

—4.0

(4.2, 3.5)—3.5

(3.7, 3.1)—

AT F2 (US qt, Imp qt) —8.4

(8.9, 7.4)—9.3

(9.8, 8.2)—9.3

(9.8, 8.2)—9.3

(9.8, 8.2)

Front differ-

ential gear

oil2 (US qt, Imp qt) —1.2

(1.3, 1.1)—1.2

(1.3, 1.1)—1.2

(1.3, 1.1)—1.2

(1.3, 1.1)

Rear differ-

ential gear

oil2 (US qt, Imp qt) 0.8 (0.8, 0.6)

Pow er

steering

fluid2 (US qt, Imp qt) 0.7 (0.7, 0.6)

Engine

coolant2 (US qt, Imp qt)6.6

(7.0, 5.8)6.5

(6.9, 5.7),

6.9

(7.3, 6.1)

★3

7.4

(7.8, 6.5)7.3

(7.7, 6.4)

★2

6.9

(7.3, 6.1)6.8

(7.2, 6.0)7.4

(7.8, 6.5)7.3

(7.7, 6.4)

Page 720 of 2870

RM-5

RECOMMENDED MATERIAL

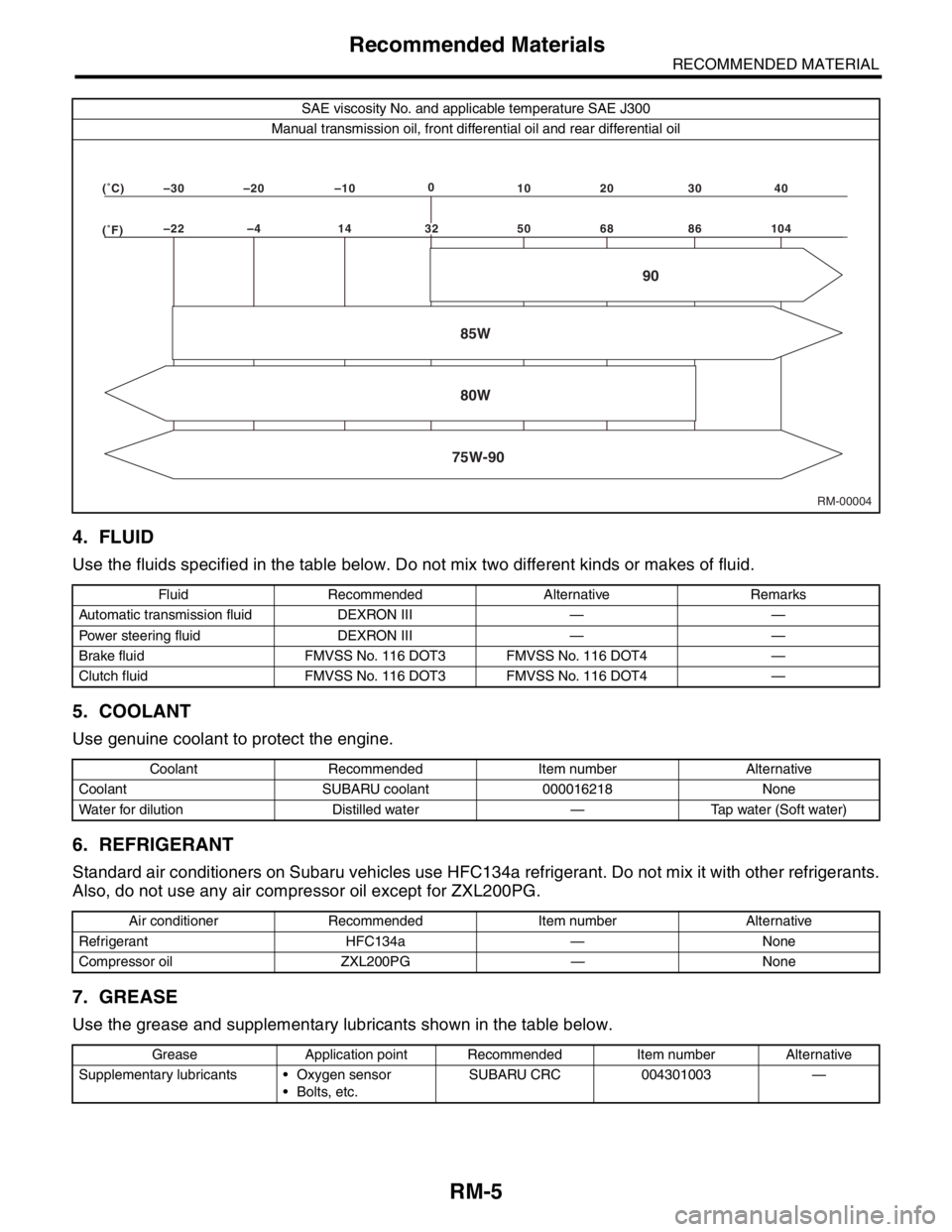

Recommended Materials

4. FLUID

Use the fluids specified in the table below. Do not mix two different kinds or makes of fluid.

5. COOLANT

Use genuine coolant to protect the engine.

6. REFRIGERANT

Standard air conditioners on Subaru vehicles use HFC134a refrigerant. Do not mix it with other refrigerants.

Also, do not use any air compressor oil except for ZXL200PG.

7. GREASE

Use the grease and supplementary lubricants shown in the table below.

SAE viscosity No. and applicable temperature SAE J300

Manual transmission oil, front differential oil and rear differential oil

Fluid Recommended Alternative Remarks

Automatic transmission fluid DEXRON III — —

Power steering fluid DEXRON III — —

Brake fluid FMVSS No. 116 DOT3 FMVSS No. 116 DOT4 —

Clutch fluid FMVSS No. 116 DOT3 FMVSS No. 116 DOT4 —

Coolant Recommended Item number Alternative

Coolant SUBARU coolant 000016218 None

Water for dilution Distilled water — Tap water (Soft water)

Air conditioner Recommended Item number Alternative

Refrigerant HFC134a — None

Compressor oil ZXL200PG — None

Grease Application point Recommended Item number Alternative

Supplementary lubricants Oxygen sensor

Bolts, etc.SUBARU CRC 004301003 —

RM-00004 (�F)–22 –4 14 50 68 86 104 (�C)–30 –20 –100

10 20 30 40

85W

75W-9080W90

32

Page 721 of 2870

RM-6

RECOMMENDED MATERIAL

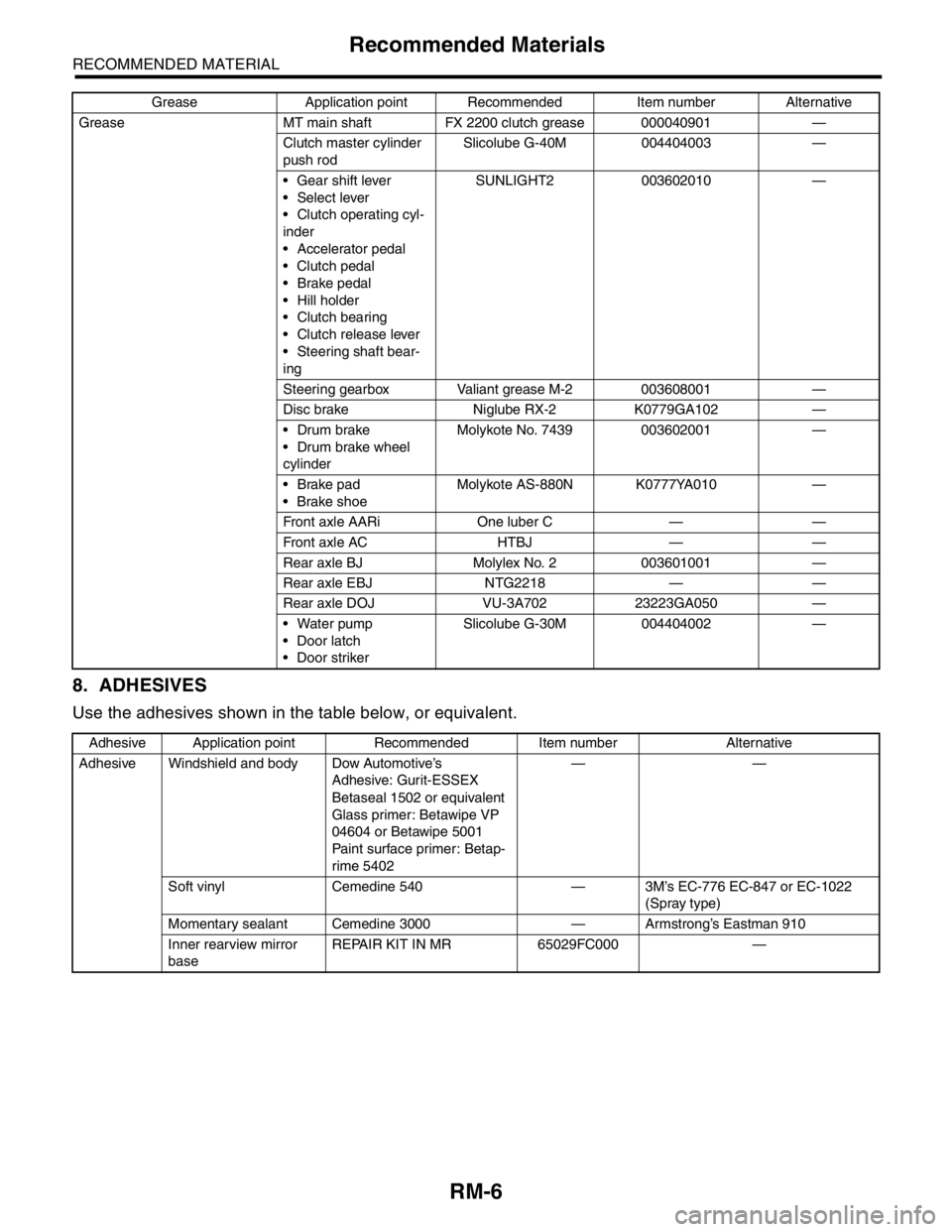

Recommended Materials

8. ADHESIVES

Use the adhesives shown in the table below, or equivalent.

Grease MT main shaft FX 2200 clutch grease 000040901 —

Clutch master cylinder

push rodSlicolube G-40M 004404003 —

Gear shift lever

Select lever

Clutch operating cyl-

inder

Accelerator pedal

Clutch pedal

Brake pedal

Hill holder

Clutch bearing

Clutch release lever

Steering shaft bear-

ingSUNLIGHT2 003602010 —

Steering gearbox Valiant grease M-2 003608001 —

Disc brake Niglube RX-2 K0779GA102 —

Drum brake

Drum brake wheel

cylinderMolykote No. 7439 003602001 —

Brake pad

Brake shoeMolykote AS-880N K0777YA010 —

Front axle AARi One luber C — —

Front axle AC HTBJ — —

Rear axle BJ Molylex No. 2 003601001 —

Rear axle EBJ NTG2218 — —

Rear axle DOJ VU-3A702 23223GA050 —

Water pump

Door latch

Door strikerSlicolube G-30M 004404002 —

Adhesive Application point Recommended Item number Alternative

Adhesive Windshield and body Dow Automotive’s

Adhesive: Gurit-ESSEX

Betaseal 1502 or equivalent

Glass primer: Betawipe VP

04604 or Betawipe 5001

Paint surface primer: Betap-

rime 5402——

Soft vinyl Cemedine 540 — 3M’s EC-776 EC-847 or EC-1022

(Spray type)

Momentary sealant Cemedine 3000 — Armstrong’s Eastman 910

Inner rearview mirror

baseREPAIR KIT IN MR 65029FC000 — Grease Application point Recommended Item number Alternative

Page 726 of 2870

PI-3

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

B: PDI PROCEDURE

Follow the procedures shown in the table below.

Static Checks Just After Vehicle Receipt

Step Check point

1. Appearance check (1) If the vehicle is covered with protective coating, visually check the vehicle

body for damage and dents. If the protective coating has been removed,

visually check the body paints for small areas of damage or stains.

(2) Visually check the glass and light lenses for any damage and cracks or

excessive gaps to the body sheet metal.

(3) Visually check the plated parts for any damage.

2. Tire check (1) Check the tires for damage, abnormal conditions, and dents on the

wheels.

(2) Check the tire air pressure.

3. Fuse installation If the vehicle is about to be delivered to the customer, attach a room light

fuse.

4. Connection of air conditioner harness If the vehicle is about to be delivered to the customer, connect the air condi-

tioner harness.

5. Check the doors for lock/unlock and open/close

operations.(1) Using the key, check if the door can be locked and unlocked normally.

(2) Open and close all doors to see that there are no abnormal conditions.

6. Operation check of double lock Check that the double lock operates normally.

7. Operation check of the child safety lock system. Check the child safety lock system operates normally.

8. Check the rear gate for lock/unlock and open/

close operations.(1) Check if the rear gate can be unlocked normally from the emergency

door.

(2) Open and close the rear gate to see that there are no abnormal condi-

tions.

(3) Operate the power door locking switch to check that the rear gate is

locked and unlocked normally.

9. Operation check of fuel lid opener lock release

leverOperate the fuel lid opener to check that the fuel lid is unlocked normally.

10. Accessory check Check that the following accessories are provided:

Owner’s manual

Warranty booklet

Service booklet

Spare key

Jack

Tool set

Spare tire

11. Operation check of hood lock release system Operate the hood lock release lever to check that the hood opens normally.

12. Battery Check the battery for any abnormal conditions such as rust and trace of bat-

tery fluid leaks.

13. Brake fluid Check the fluid amount.

14. Engine oil Check the oil amount.

15. Transmission fluid (1) Check the fluid amount.

(2) For AT, check the front differential oil.

16. AT front differential oil Check the AT front differential oil amount.

17. Coolant Check the coolant amount.

18. Clutch fluid Check the clutch fluid amount.

19. Window washer fluid Check the window washer fluid amount.

20. Hood latch check Check that the hood is closed and latched securely.

21. Keyless entry system Check that the keyless entry system operates normally.

22. Security system Check that the security system operates normally.

23. Seat (1) Check the seat surfaces for smears or dirt.

(2) Check the seat installation conditions and functionality.

24. Seat belt Check the seat belt installation conditions and functionality.

25. Wheel alignment Check that the wheel alignments are properly adjusted.

Page 727 of 2870

PI-4

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

Checks with the Engine Running

Dynamic Test with the Vehicle Running

Checks after Dynamic Test

Step Check point

26. Test mode connectors Test mode connectors

27. Starting condition Start the engine and check that the engine starts smoothly.

28. Exhaust system Check that the exhaust noise is normal and no leaks are found.

29. Indicator light Check that all the indicator lights operate normally.

30. Clock Check that the clock operates normally.

31. Radio Check that the radio system operates normally.

32. Front accessory power supply socket Check that the front accessory power supply socket operates normally.

33. Lighting system Check that the lighting systems operate normally.

34. Window washer Check that the window washer system operates normally.

35. Wiper Check that the wiper system operates normally.

36. Power window operation check Check the power window for correct operations.

Step Check point

37. Brake test Check that the foot brake operates normally.

38. Parking brake Check that the parking brake operates normally.

39. AT shift control Check the AT shift patterns are correct.

40. Heater & ventilation Check that the heater & ventilation system operates normally.

41. Air conditioner Check that the air conditioner operates normally.

42. Speed control Check that the speed control operates normally.

Step Check point

43. ATF level Check that the ATF level is normal.

44. Power steering fluid level Check that the power steering fluid level is normal.

45. Fluid leak check Check for fluid/oil leaks.

46. Water leak check Spray the vehicle with water and check for water leaks.

47. Appearance check 2 (1) Remove the protective coating (wrap guard).(if any)

(2) Check the body paints for damage and smears.

(3) Check the plated parts for damage and rust.

Page 734 of 2870

PI-11

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

29.CLOCK

Check the clock for normal operations and enough

accuracy.

30.RADIO

Check the radio for full functionality and normal

noise level. Also check the CD unit operations.

31.FRONT ACCESSORY POWER SUPPLY

SOCKET

Check the front accessory power supply socket op-

erations.

32.LIGHTING SYSTEM

Check the headlight operations.

Check the brake light operations.

Check the other lights for normal operations.

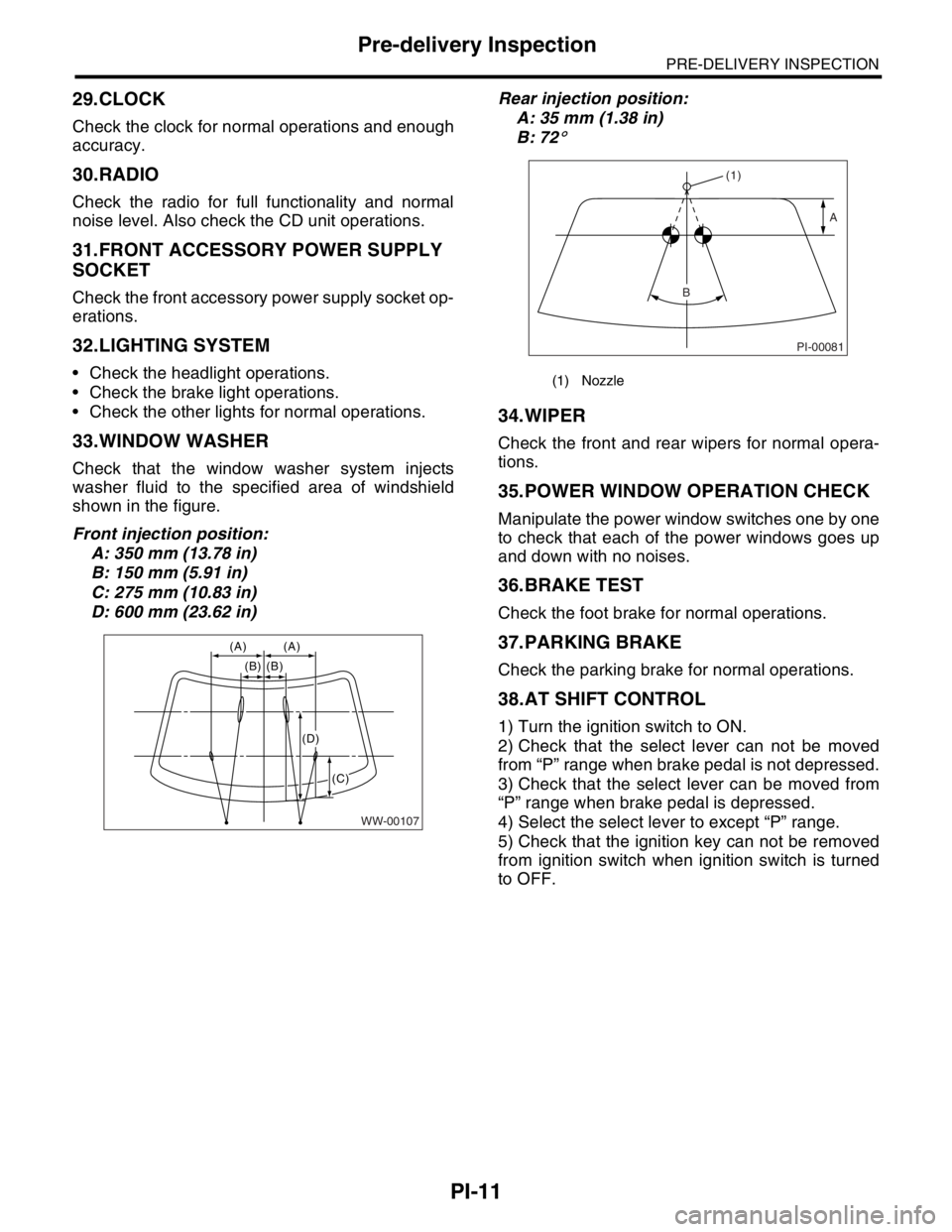

33.WINDOW WASHER

Check that the window washer system injects

washer fluid to the specified area of windshield

shown in the figure.

Front injection position:

A: 350 mm (13.78 in)

B: 150 mm (5.91 in)

C: 275 mm (10.83 in)

D: 600 mm (23.62 in)Rear injection position:

A: 35 mm (1.38 in)

B: 72

°

34.WIPER

Check the front and rear wipers for normal opera-

tions.

35.POWER WINDOW OPERATION CHECK

Manipulate the power window switches one by one

to check that each of the power windows goes up

and down with no noises.

36.BRAKE TEST

Check the foot brake for normal operations.

37.PARKING BRAKE

Check the parking brake for normal operations.

38.AT SHIFT CONTROL

1) Turn the ignition switch to ON.

2) Check that the select lever can not be moved

from “P” range when brake pedal is not depressed.

3) Check that the select lever can be moved from

“P” range when brake pedal is depressed.

4) Select the select lever to except “P” range.

5) Check that the ignition key can not be removed

from ignition switch when ignition switch is turned

to OFF.

WW-00107

(A) (A)

(B) (B)

(C)

(D)

(1) Nozzle

PI-00081

(1)

A

B

Page 738 of 2870

PERIODIC MAINTENANCE SERVICE

PM

Page

1. General Description ....................................................................................2

2. Schedule .....................................................................................................3

3. Engine Oil....................................................................................................7

4. Engine Oil Filter...........................................................................................9

5. Spark Plugs ...............................................................................................10

6. V-belt .........................................................................................................11

7. Timing Belt ................................................................................................13

8. Fuel Line ...................................................................................................17

9. Fuel Filter ..................................................................................................18

10. Air Cleaner Element ..................................................................................19

11. Cooling System .........................................................................................20

12. Engine Coolant..........................................................................................21

13. Clutch System ...........................................................................................23

14. Transmission Gear Oil ..............................................................................24

15. Hill-holder System .....................................................................................25

16. ATF ...........................................................................................................26

17. Front & Rear Differential Oil ......................................................................28

18. Brake Line .................................................................................................30

19. Brake Fluid ................................................................................................32

20. Disc Brake Pads and Discs .......................................................................33

21. Brake Linings and Drums ..........................................................................34

22. Suspension ...............................................................................................36

23. Wheel Bearing...........................................................................................38

24. Axle Boots & Joints ...................................................................................39

25. Tire Rotation..............................................................................................40

26. Steering System (Power Steering) ............................................................41

Page 740 of 2870

PM-3

PERIODIC MAINTENANCE SERVICE

Schedule

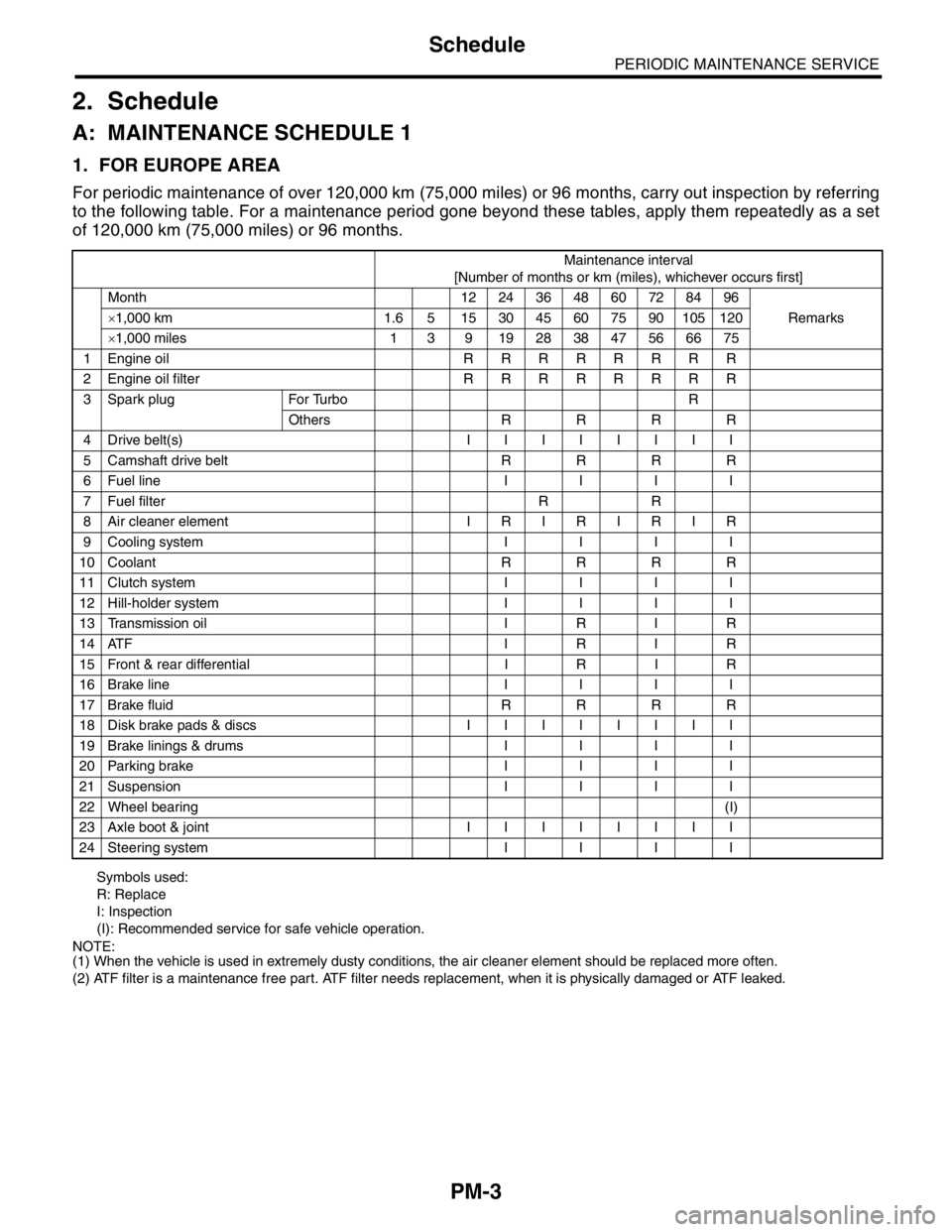

2. Schedule

A: MAINTENANCE SCHEDULE 1

1. FOR EUROPE AREA

For periodic maintenance of over 120,000 km (75,000 miles) or 96 months, carry out inspection by referring

to the following table. For a maintenance period gone beyond these tables, apply them repeatedly as a set

of 120,000 km (75,000 miles) or 96 months.

Symbols used:

R: Replace

I: Inspection

(I): Recommended service for safe vehicle operation.

N

OTE:

(1) When the vehicle is used in extremely dusty conditions, the air cleaner element should be replaced more often.

(2) ATF filter is a maintenance free part. ATF filter needs replacement, when it is physically damaged or ATF leaked.Maintenance interval

[Number of months or km (miles), whichever occurs first]

Month 1224364860728496

Remarks ×1,000 km 1.6 5 15 30 45 60 75 90 105 120

×1,000 miles 1 3 9 19 28 38 47 56 66 75

1Engine oil RRRRRRRR

2Engine oil filter RRRRRRRR

3 Spark plug For Turbo R

Others RRRR

4Drive belt(s) IIIIIIII

5Camshaft drive belt RRRR

6Fuel line IIII

7 Fuel filter R R

8 Air cleaner element I R I R I R I R

9Cooling system IIII

10Coolant RRRR

11Clutch system IIII

12Hill-holder system IIII

13 Transmission oil I R I R

14 ATF I R I R

15 Front & rear differential I R I R

16Brake line IIII

17Brake fluid RRRR

18Disk brake pads & discs IIIIIIII

19Brake linings & drums IIII

20Parking brake IIII

21Suspension IIII

22 Wheel bearing(I)

23Axle boot & joint IIIIIIII

24Steering system IIII

Page 741 of 2870

PM-4

PERIODIC MAINTENANCE SERVICE

Schedule

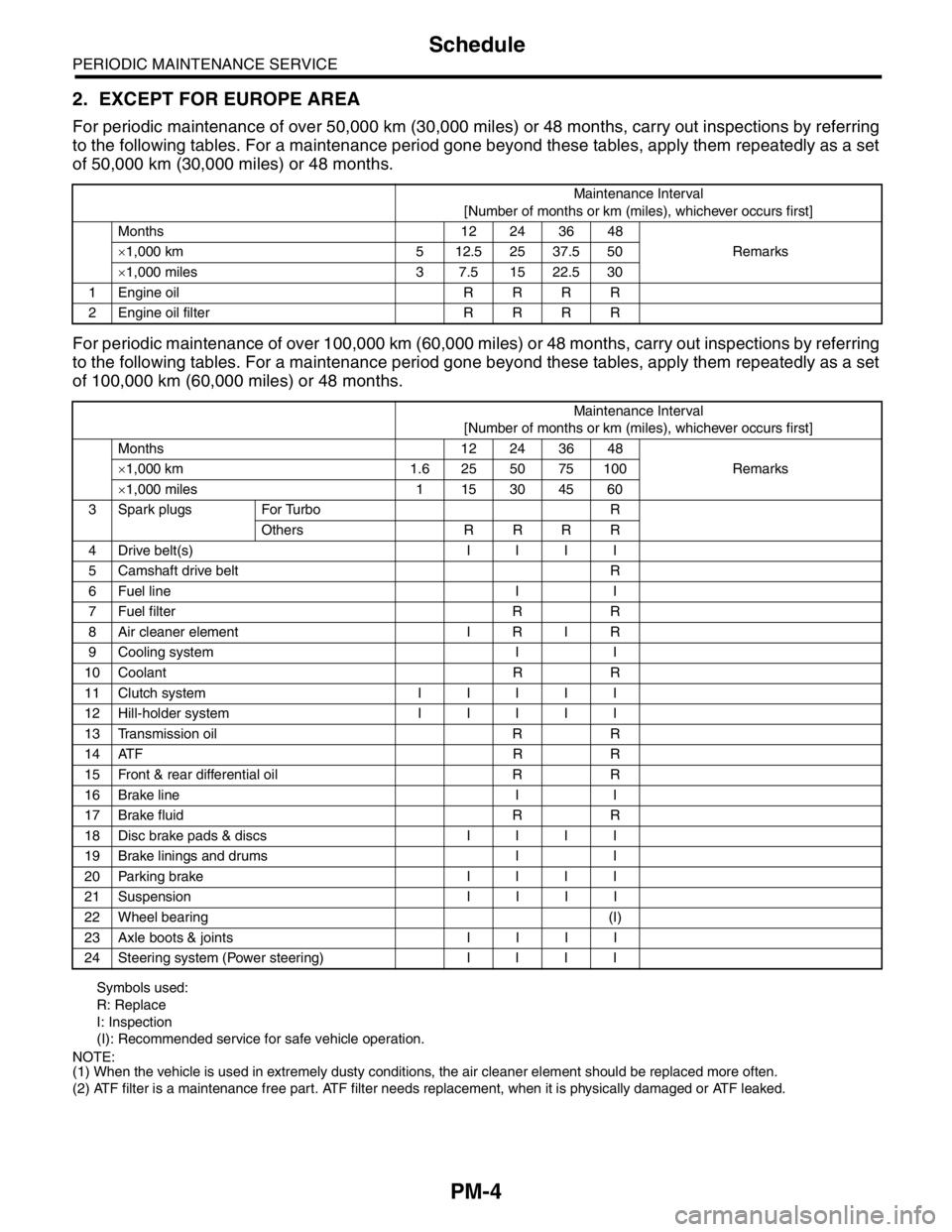

2. EXCEPT FOR EUROPE AREA

For periodic maintenance of over 50,000 km (30,000 miles) or 48 months, carry out inspections by referring

to the following tables. For a maintenance period gone beyond these tables, apply them repeatedly as a set

of 50,000 km (30,000 miles) or 48 months.

For periodic maintenance of over 100,000 km (60,000 miles) or 48 months, carry out inspections by referring

to the following tables. For a maintenance period gone beyond these tables, apply them repeatedly as a set

of 100,000 km (60,000 miles) or 48 months.

Symbols used:

R: Replace

I: Inspection

(I): Recommended service for safe vehicle operation.

N

OTE:

(1) When the vehicle is used in extremely dusty conditions, the air cleaner element should be replaced more often.

(2) ATF filter is a maintenance free part. ATF filter needs replacement, when it is physically damaged or ATF leaked.Maintenance Interval

[Number of months or km (miles), whichever occurs first]

Months 12 24 36 48

Remarks ×1,000 km 5 12.5 25 37.5 50

×1,000 miles 3 7.5 15 22.5 30

1 Engine oil R R R R

2 Engine oil filter R R R R

Maintenance Interval

[Number of months or km (miles), whichever occurs first]

Months 12 24 36 48

Remarks ×1,000 km 1.6 25 50 75 100

×1,000 miles 1 15 30 45 60

3 Spark plugs For Turbo R

Others R R R R

4Drive belt(s) IIII

5 Camshaft drive belt R

6 Fuel line I I

7 Fuel filter R R

8 Air cleaner element I R I R

9 Cooling system I I

10 Coolant R R

11 Clutch system I I I I I

12 Hill-holder system I I I I I

13 Transmission oil R R

14 ATF R R

15 Front & rear differential oil R R

16 Brake line I I

17 Brake fluid R R

18 Disc brake pads & discs I I I I

19 Brake linings and drums I I

20 Parking brake I I I I

21 Suspension I I I I

22 Wheel bearing (I)

23 Axle boots & joints I I I I

24 Steering system (Power steering) I I I I