spark plugs SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 738 of 2870

PERIODIC MAINTENANCE SERVICE

PM

Page

1. General Description ....................................................................................2

2. Schedule .....................................................................................................3

3. Engine Oil....................................................................................................7

4. Engine Oil Filter...........................................................................................9

5. Spark Plugs ...............................................................................................10

6. V-belt .........................................................................................................11

7. Timing Belt ................................................................................................13

8. Fuel Line ...................................................................................................17

9. Fuel Filter ..................................................................................................18

10. Air Cleaner Element ..................................................................................19

11. Cooling System .........................................................................................20

12. Engine Coolant..........................................................................................21

13. Clutch System ...........................................................................................23

14. Transmission Gear Oil ..............................................................................24

15. Hill-holder System .....................................................................................25

16. ATF ...........................................................................................................26

17. Front & Rear Differential Oil ......................................................................28

18. Brake Line .................................................................................................30

19. Brake Fluid ................................................................................................32

20. Disc Brake Pads and Discs .......................................................................33

21. Brake Linings and Drums ..........................................................................34

22. Suspension ...............................................................................................36

23. Wheel Bearing...........................................................................................38

24. Axle Boots & Joints ...................................................................................39

25. Tire Rotation..............................................................................................40

26. Steering System (Power Steering) ............................................................41

Page 741 of 2870

PM-4

PERIODIC MAINTENANCE SERVICE

Schedule

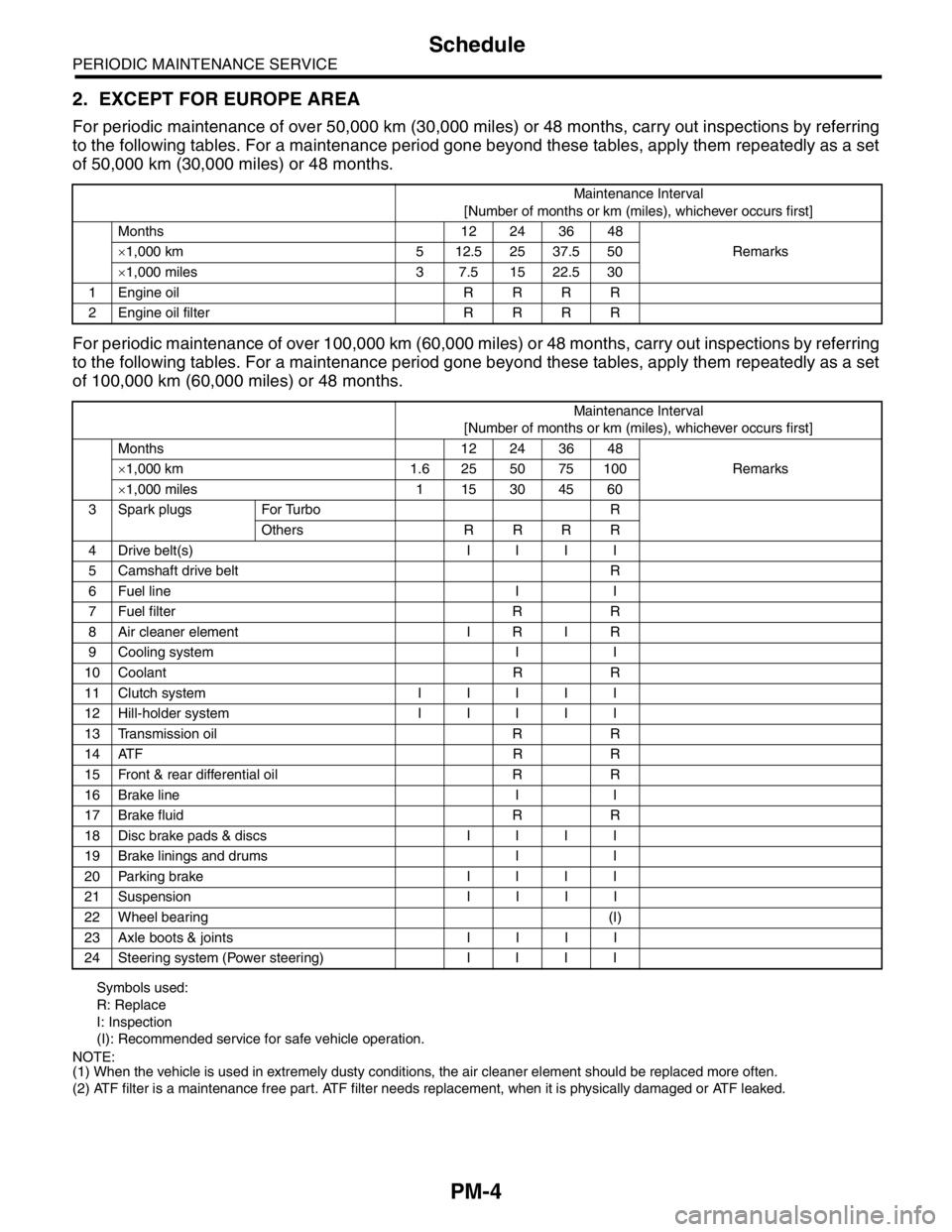

2. EXCEPT FOR EUROPE AREA

For periodic maintenance of over 50,000 km (30,000 miles) or 48 months, carry out inspections by referring

to the following tables. For a maintenance period gone beyond these tables, apply them repeatedly as a set

of 50,000 km (30,000 miles) or 48 months.

For periodic maintenance of over 100,000 km (60,000 miles) or 48 months, carry out inspections by referring

to the following tables. For a maintenance period gone beyond these tables, apply them repeatedly as a set

of 100,000 km (60,000 miles) or 48 months.

Symbols used:

R: Replace

I: Inspection

(I): Recommended service for safe vehicle operation.

N

OTE:

(1) When the vehicle is used in extremely dusty conditions, the air cleaner element should be replaced more often.

(2) ATF filter is a maintenance free part. ATF filter needs replacement, when it is physically damaged or ATF leaked.Maintenance Interval

[Number of months or km (miles), whichever occurs first]

Months 12 24 36 48

Remarks ×1,000 km 5 12.5 25 37.5 50

×1,000 miles 3 7.5 15 22.5 30

1 Engine oil R R R R

2 Engine oil filter R R R R

Maintenance Interval

[Number of months or km (miles), whichever occurs first]

Months 12 24 36 48

Remarks ×1,000 km 1.6 25 50 75 100

×1,000 miles 1 15 30 45 60

3 Spark plugs For Turbo R

Others R R R R

4Drive belt(s) IIII

5 Camshaft drive belt R

6 Fuel line I I

7 Fuel filter R R

8 Air cleaner element I R I R

9 Cooling system I I

10 Coolant R R

11 Clutch system I I I I I

12 Hill-holder system I I I I I

13 Transmission oil R R

14 ATF R R

15 Front & rear differential oil R R

16 Brake line I I

17 Brake fluid R R

18 Disc brake pads & discs I I I I

19 Brake linings and drums I I

20 Parking brake I I I I

21 Suspension I I I I

22 Wheel bearing (I)

23 Axle boots & joints I I I I

24 Steering system (Power steering) I I I I

Page 747 of 2870

PM-10

PERIODIC MAINTENANCE SERVICE

Spark Plugs

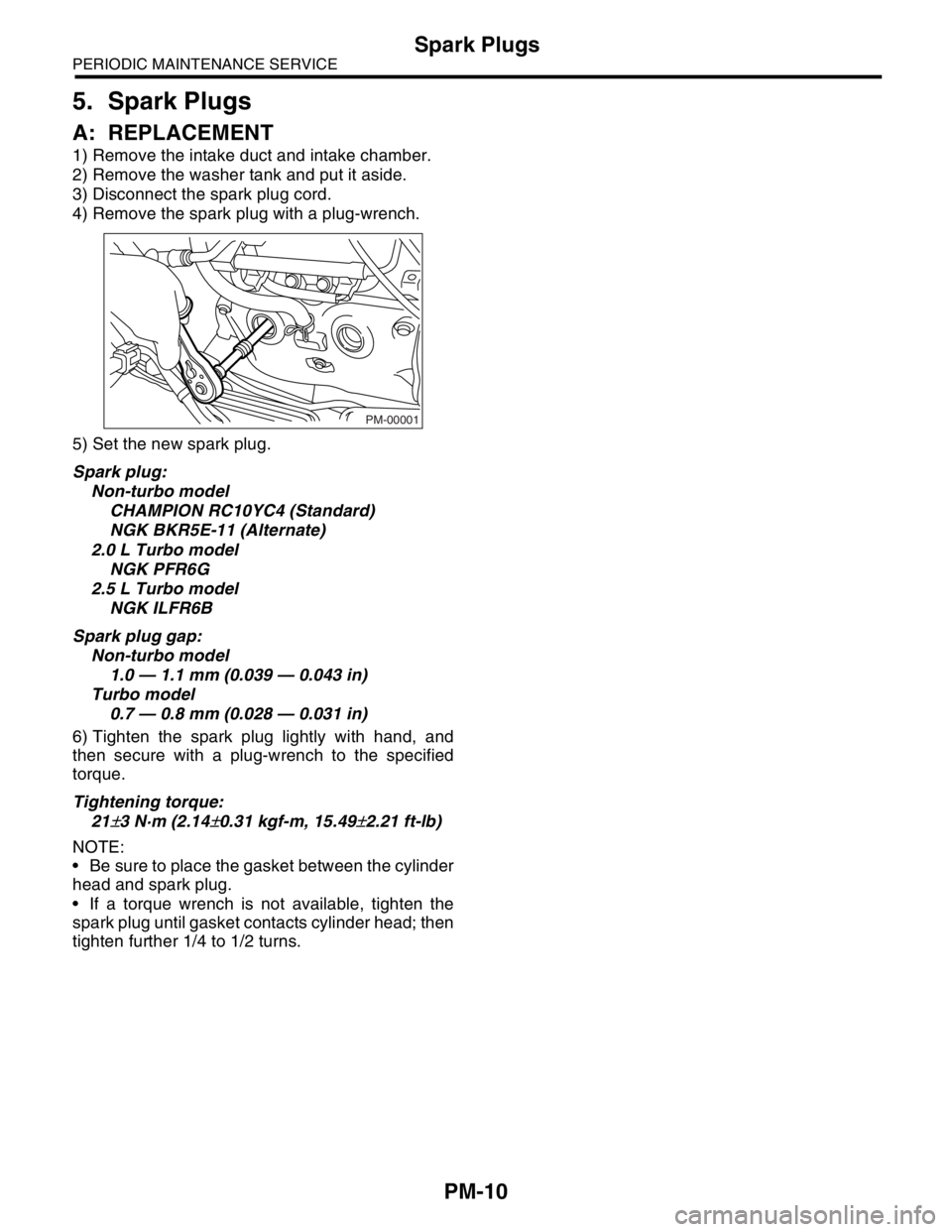

5. Spark Plugs

A: REPLACEMENT

1) Remove the intake duct and intake chamber.

2) Remove the washer tank and put it aside.

3) Disconnect the spark plug cord.

4) Remove the spark plug with a plug-wrench.

5) Set the new spark plug.

Spark plug:

Non-turbo model

CHAMPION RC10YC4 (Standard)

NGK BKR5E-11 (Alternate)

2.0 L Turbo model

NGK PFR6G

2.5 L Turbo model

NGK ILFR6B

Spark plug gap:

Non-turbo model

1.0 — 1.1 mm (0.039 — 0.043 in)

Turbo model

0.7 — 0.8 mm (0.028 — 0.031 in)

6) Tighten the spark plug lightly with hand, and

then secure with a plug-wrench to the specified

torque.

Tightening torque:

21

±3 N·m (2.14±0.31 kgf-m, 15.49±2.21 ft-lb)

NOTE:

Be sure to place the gasket between the cylinder

head and spark plug.

If a torque wrench is not available, tighten the

spark plug until gasket contacts cylinder head; then

tighten further 1/4 to 1/2 turns.

PM-00001

Page 797 of 2870

FU(H4SO)-15

FUEL INJECTION (FUEL SYSTEM)

Intake Manifold

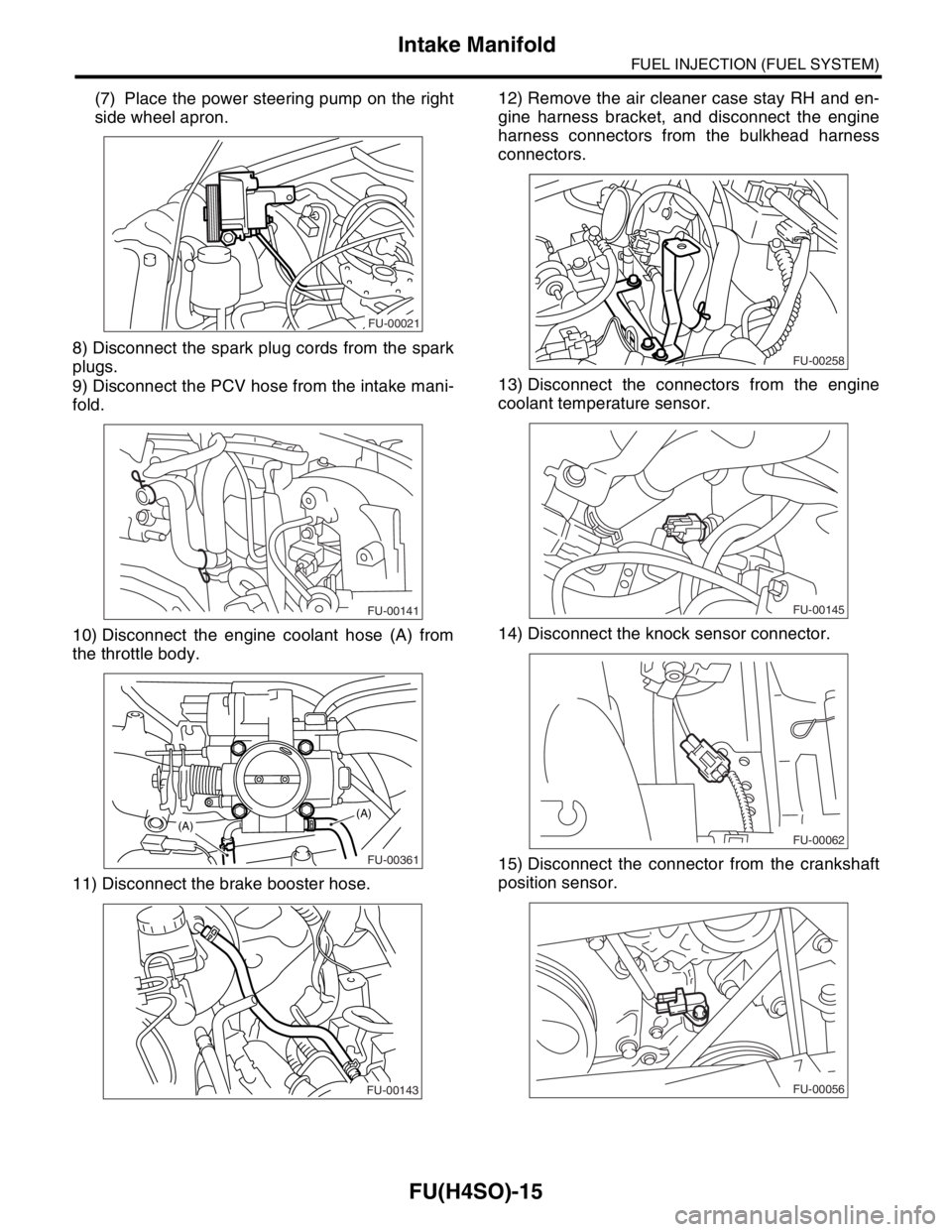

(7) Place the power steering pump on the right

side wheel apron.

8) Disconnect the spark plug cords from the spark

plugs.

9) Disconnect the PCV hose from the intake mani-

fold.

10) Disconnect the engine coolant hose (A) from

the throttle body.

11) Disconnect the brake booster hose.12) Remove the air cleaner case stay RH and en-

gine harness bracket, and disconnect the engine

harness connectors from the bulkhead harness

connectors.

13) Disconnect the connectors from the engine

coolant temperature sensor.

14) Disconnect the knock sensor connector.

15) Disconnect the connector from the crankshaft

position sensor.

FU-00021

FU-00141

FU-00361

(A)(A)

FU-00143

FU-00258

FU-00145

FU-00062

FU-00056

Page 800 of 2870

FU(H4SO)-18

FUEL INJECTION (FUEL SYSTEM)

Intake Manifold

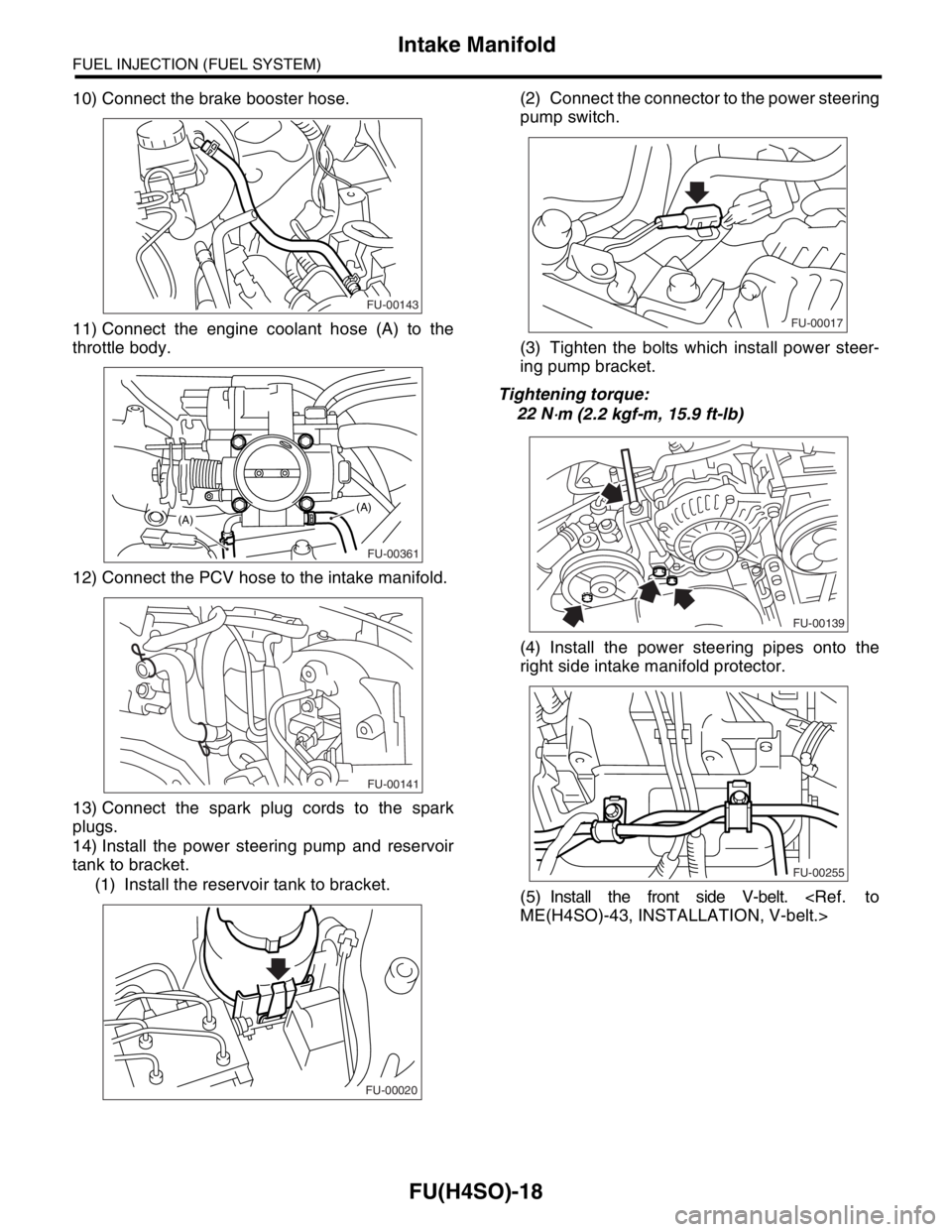

10) Connect the brake booster hose.

11) Connect the engine coolant hose (A) to the

throttle body.

12) Connect the PCV hose to the intake manifold.

13) Connect the spark plug cords to the spark

plugs.

14) Install the power steering pump and reservoir

tank to bracket.

(1) Install the reservoir tank to bracket.(2) Connect the connector to the power steering

pump switch.

(3) Tighten the bolts which install power steer-

ing pump bracket.

Tightening torque:

22 N

⋅m (2.2 kgf-m, 15.9 ft-lb)

(4) Install the power steering pipes onto the

right side intake manifold protector.

(5) Install the front side V-belt.

FU-00143

FU-00361

(A)(A)

FU-00141

FU-00020

FU-00017

FU-00139

FU-00255

Page 817 of 2870

FU(H4SO)-35

FUEL INJECTION (FUEL SYSTEM)

Fuel Injector

13.Fuel Injector

A: REMOVAL

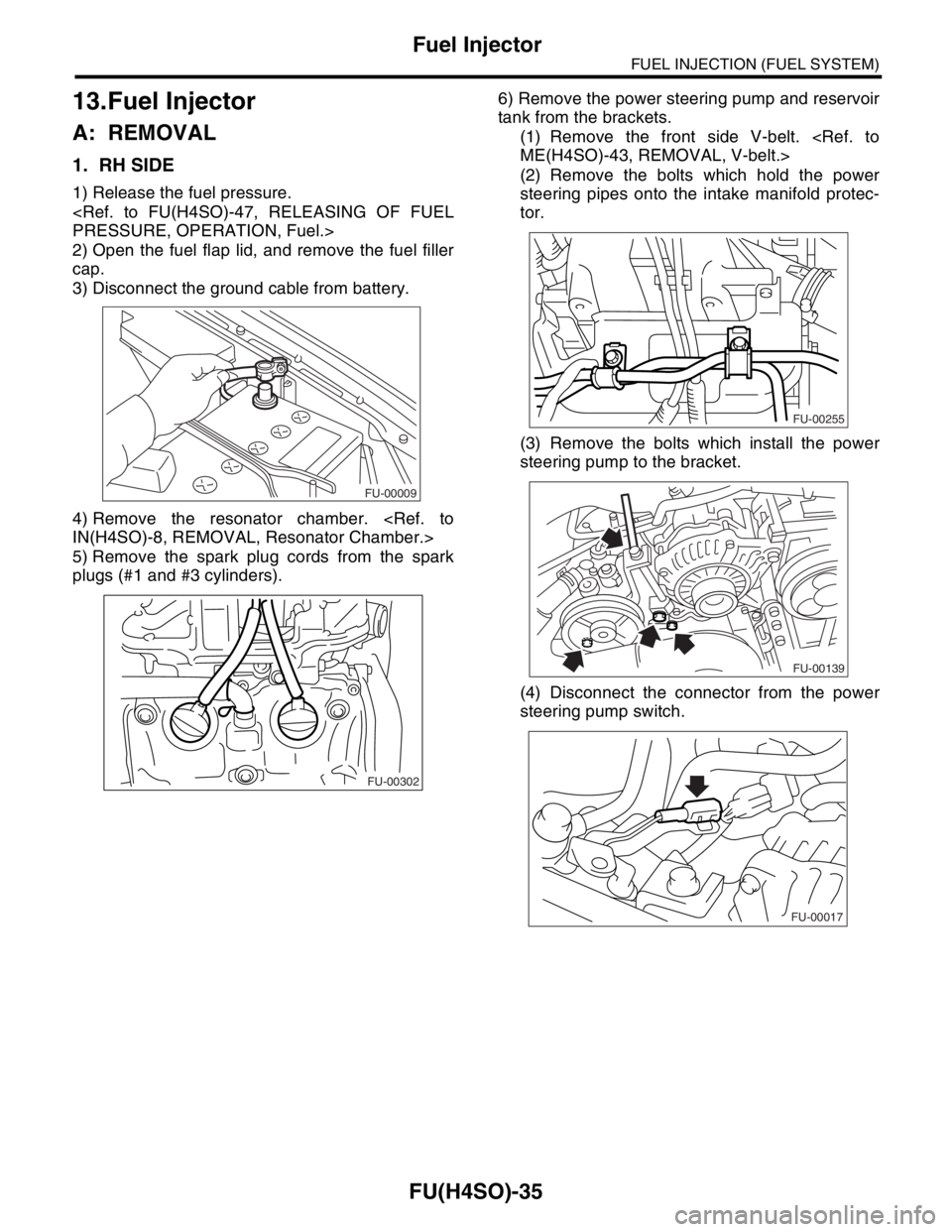

1. RH SIDE

1) Release the fuel pressure.

2) Open the fuel flap lid, and remove the fuel filler

cap.

3) Disconnect the ground cable from battery.

4) Remove the resonator chamber.

5) Remove the spark plug cords from the spark

plugs (#1 and #3 cylinders).6) Remove the power steering pump and reservoir

tank from the brackets.

(1) Remove the front side V-belt.

(2) Remove the bolts which hold the power

steering pipes onto the intake manifold protec-

tor.

(3) Remove the bolts which install the power

steering pump to the bracket.

(4) Disconnect the connector from the power

steering pump switch.

FU-00009

FU-00302

FU-00255

FU-00139

FU-00017

Page 819 of 2870

FU(H4SO)-37

FUEL INJECTION (FUEL SYSTEM)

Fuel Injector

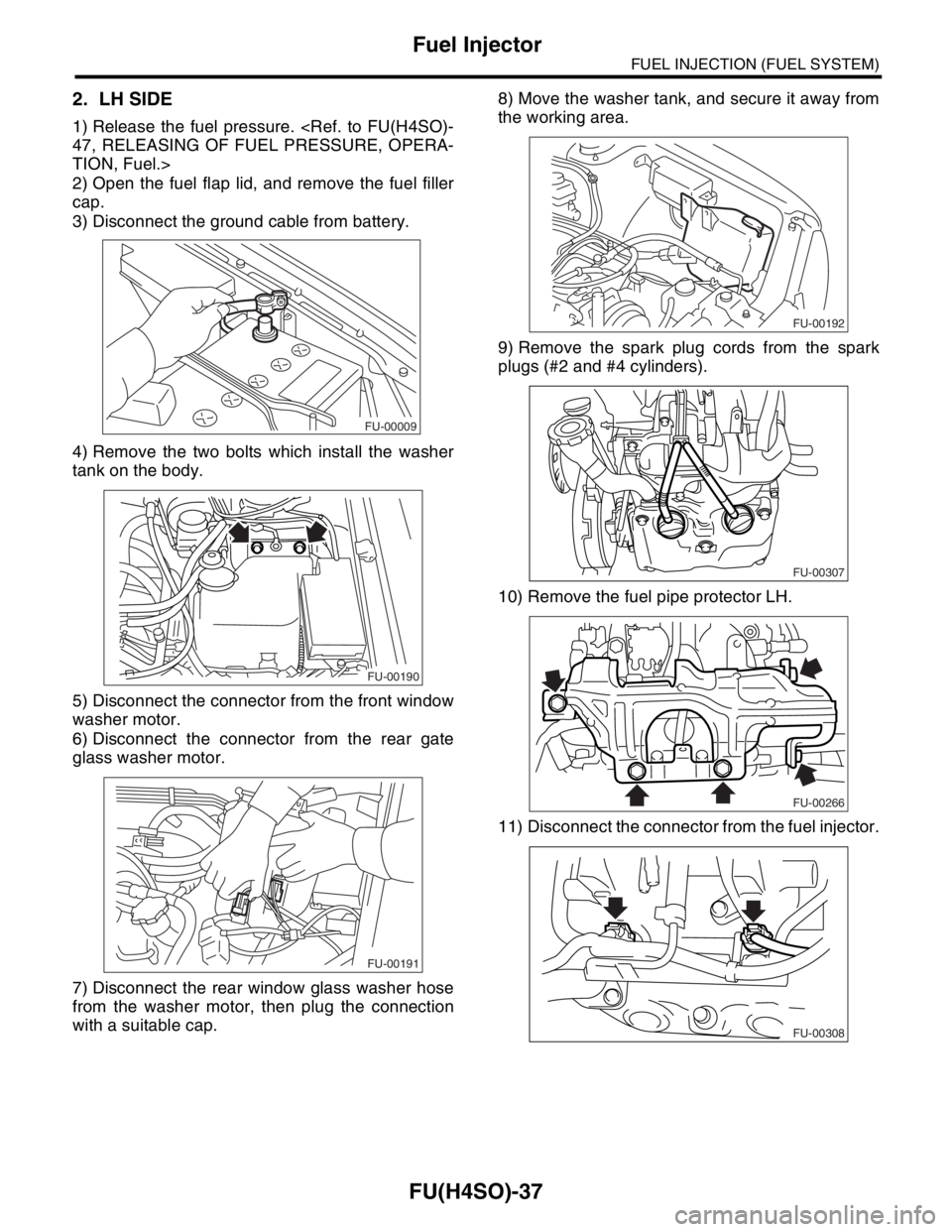

2. LH SIDE

1) Release the fuel pressure.

TION, Fuel.>

2) Open the fuel flap lid, and remove the fuel filler

cap.

3) Disconnect the ground cable from battery.

4) Remove the two bolts which install the washer

tank on the body.

5) Disconnect the connector from the front window

washer motor.

6) Disconnect the connector from the rear gate

glass washer motor.

7) Disconnect the rear window glass washer hose

from the washer motor, then plug the connection

with a suitable cap.8) Move the washer tank, and secure it away from

the working area.

9) Remove the spark plug cords from the spark

plugs (#2 and #4 cylinders).

10) Remove the fuel pipe protector LH.

11) Disconnect the connector from the fuel injector.

FU-00009

FU-00190

FU-00191

FU-00192

FU-00307

FU-00266

FU-00308

Page 894 of 2870

ME(H4SO)-25

MECHANICAL

Compression

2. Compression

A: INSPECTION

CAUTION:

After warming-up, engine becomes very hot. Be

careful not to burn yourself during measure-

ment.

1) After warming-up the engine, turn the ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Release the fuel pressure.

TION, Fuel.>

4) Remove all the spark plugs.

5) Fully open the throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against spark

plug hole.

NOTE:

When using a screw-in type compression gauge,

the screw (put into cylinder head spark plug hole)

should be less than 18 mm (0.71 in) long.

8) Crank the engine by means of starter motor, and

then read the maximum value on the gauge when

the pointer is steady.

9) Perform at least two measurements per cylinder,

and make sure that the values are correct.

Compression (350 rpm and fully open throttle):

Standard;

1,275 kPa (13.0 kgf/cm

2, 185 psi)

Limit;

1,020 kPa (10.4 kgf/cm

2, 148 psi)

Difference between cylinders;

49 kPa (0.5 kgf/cm

2, 7 psi), or less

ME-00192

Page 895 of 2870

ME(H4SO)-26

MECHANICAL

Idle Speed

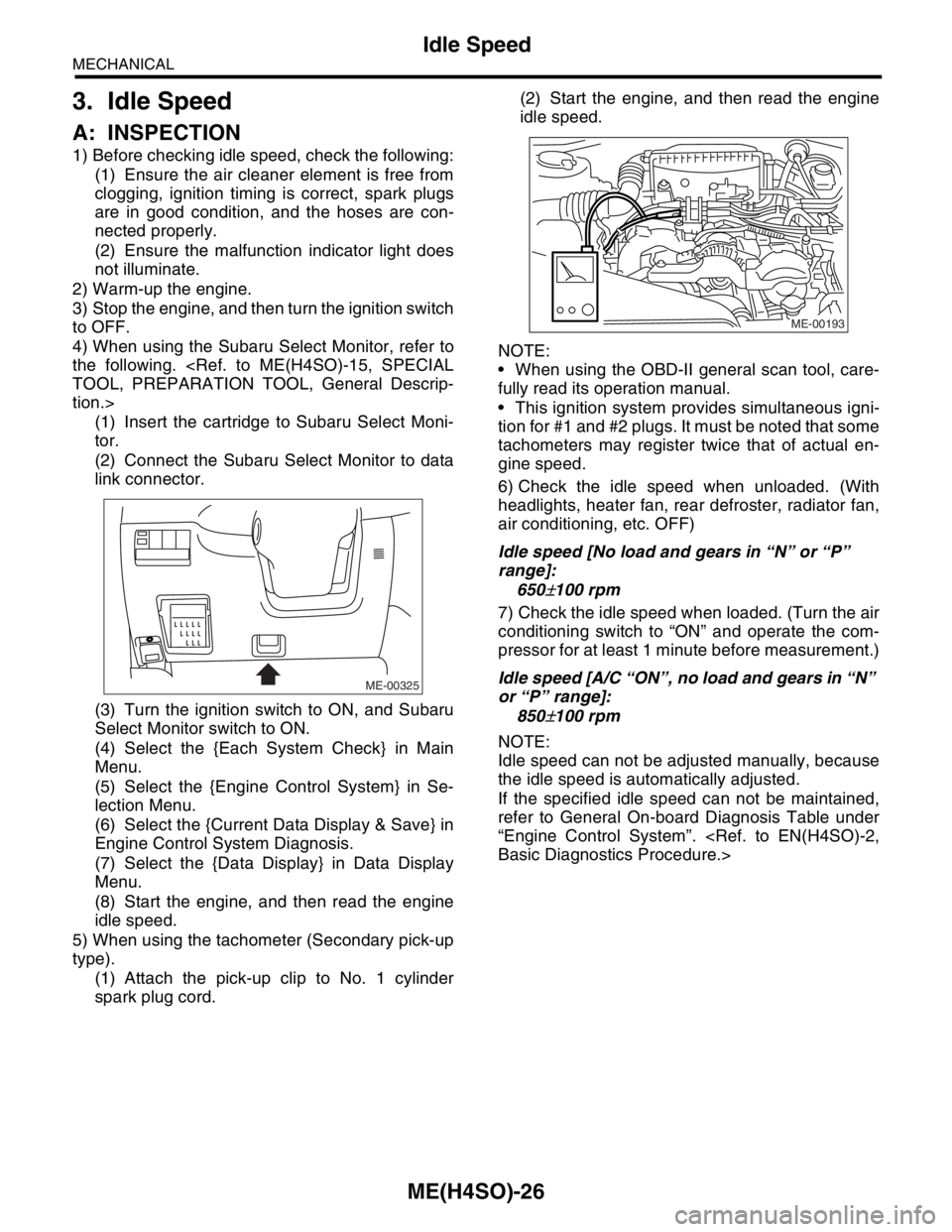

3. Idle Speed

A: INSPECTION

1) Before checking idle speed, check the following:

(1) Ensure the air cleaner element is free from

clogging, ignition timing is correct, spark plugs

are in good condition, and the hoses are con-

nected properly.

(2) Ensure the malfunction indicator light does

not illuminate.

2) Warm-up the engine.

3) Stop the engine, and then turn the ignition switch

to OFF.

4) When using the Subaru Select Monitor, refer to

the following.

tion.>

(1) Insert the cartridge to Subaru Select Moni-

tor.

(2) Connect the Subaru Select Monitor to data

link connector.

(3) Turn the ignition switch to ON, and Subaru

Select Monitor switch to ON.

(4) Select the {Each System Check} in Main

Menu.

(5) Select the {Engine Control System} in Se-

lection Menu.

(6) Select the {Current Data Display & Save} in

Engine Control System Diagnosis.

(7) Select the {Data Display} in Data Display

Menu.

(8) Start the engine, and then read the engine

idle speed.

5) When using the tachometer (Secondary pick-up

type).

(1) Attach the pick-up clip to No. 1 cylinder

spark plug cord.(2) Start the engine, and then read the engine

idle speed.

NOTE:

When using the OBD-II general scan tool, care-

fully read its operation manual.

This ignition system provides simultaneous igni-

tion for #1 and #2 plugs. It must be noted that some

tachometers may register twice that of actual en-

gine speed.

6) Check the idle speed when unloaded. (With

headlights, heater fan, rear defroster, radiator fan,

air conditioning, etc. OFF)

Idle speed [No load and gears in “N” or “P”

range]:

650

±100 rpm

7) Check the idle speed when loaded. (Turn the air

conditioning switch to “ON” and operate the com-

pressor for at least 1 minute before measurement.)

Idle speed [A/C “ON”, no load and gears in “N”

or “P” range]:

850

±100 rpm

NOTE:

Idle speed can not be adjusted manually, because

the idle speed is automatically adjusted.

If the specified idle speed can not be maintained,

refer to General On-board Diagnosis Table under

“Engine Control System”.

ME-00325

ME-00193

Page 900 of 2870

ME(H4SO)-31

MECHANICAL

Valve Clearance

8. Valve Clearance

A: INSPECTION

NOTE:

Inspection and adjustment of the valve clearance

should be performed while engine is cold.

1) Set the vehicle on a lift.

2) Lift-up the vehicle.

3) Remove the under cover.

4) Lower the vehicle.

5) Disconnect the ground cable from battery.

6) Remove the belt cover (LH).

7) When inspecting the #1 and #3 cylinders:

(1) Disconnect the spark plug cords from spark

plugs RH side.

(2) Disconnect the PCV hose from rocker cover

(RH).

(3) Remove the bolts, and then remove the

rocker cover (RH).

8) When inspecting the #2 and #4 cylinders:

(1) Disconnect the spark plug cords from spark

plugs (LH Side)

(2) Disconnect the PCV hose from rocker cover

(LH).

(3) Remove the bolts, and then remove the

rocker cover (LH).

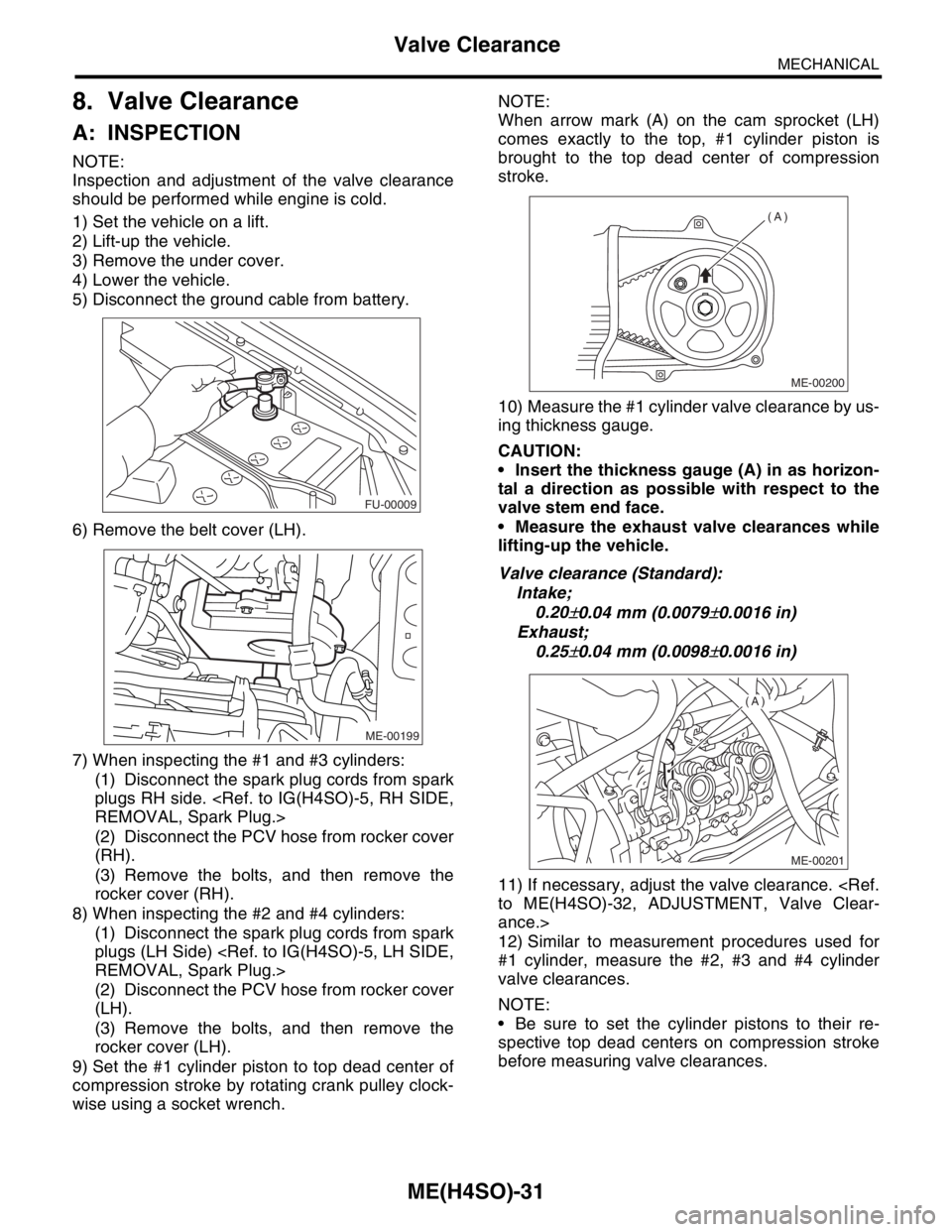

9) Set the #1 cylinder piston to top dead center of

compression stroke by rotating crank pulley clock-

wise using a socket wrench.NOTE:

When arrow mark (A) on the cam sprocket (LH)

comes exactly to the top, #1 cylinder piston is

brought to the top dead center of compression

stroke.

10) Measure the #1 cylinder valve clearance by us-

ing thickness gauge.

CAUTION:

Insert the thickness gauge (A) in as horizon-

tal a direction as possible with respect to the

valve stem end face.

Measure the exhaust valve clearances while

lifting-up the vehicle.

Valve clearance (Standard):

Intake;

0.20

±0.04 mm (0.0079±0.0016 in)

Exhaust;

0.25

±0.04 mm (0.0098±0.0016 in)

11) If necessary, adjust the valve clearance.

ance.>

12) Similar to measurement procedures used for

#1 cylinder, measure the #2, #3 and #4 cylinder

valve clearances.

NOTE:

Be sure to set the cylinder pistons to their re-

spective top dead centers on compression stroke

before measuring valve clearances.

FU-00009

ME-00199

ME-00200

(A)

ME-00201

(A)