tire size SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 128 of 2870

AB-28

AIRBAG SYSTEM

Disposal of Airbag Module (Deploying After Removal from Vehicle)

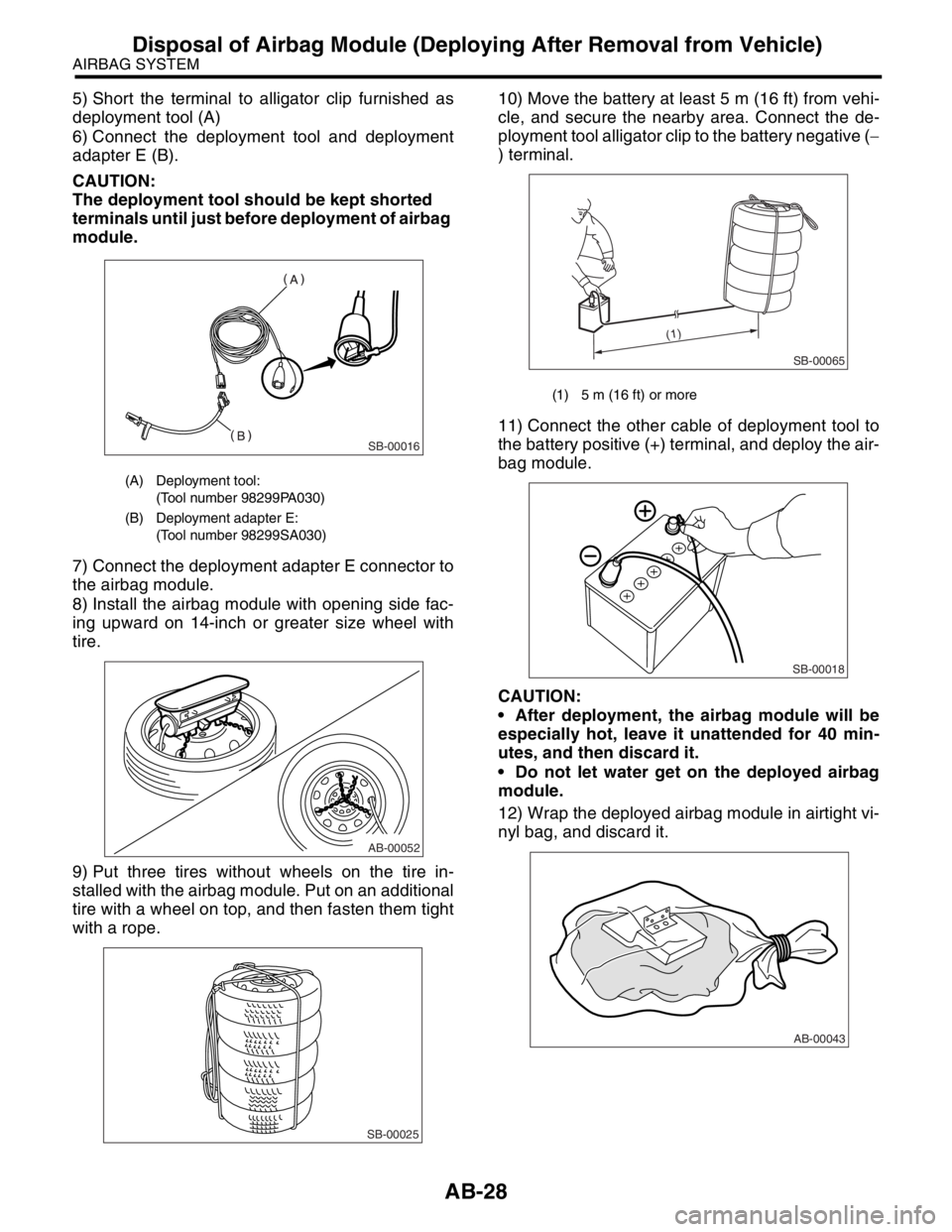

5) Short the terminal to alligator clip furnished as

deployment tool (A)

6) Connect the deployment tool and deployment

adapter E (B).

CAUTION:

The deployment tool should be kept shorted

terminals until just before deployment of airbag

module.

7) Connect the deployment adapter E connector to

the airbag module.

8) Install the airbag module with opening side fac-

ing upward on 14-inch or greater size wheel with

tire.

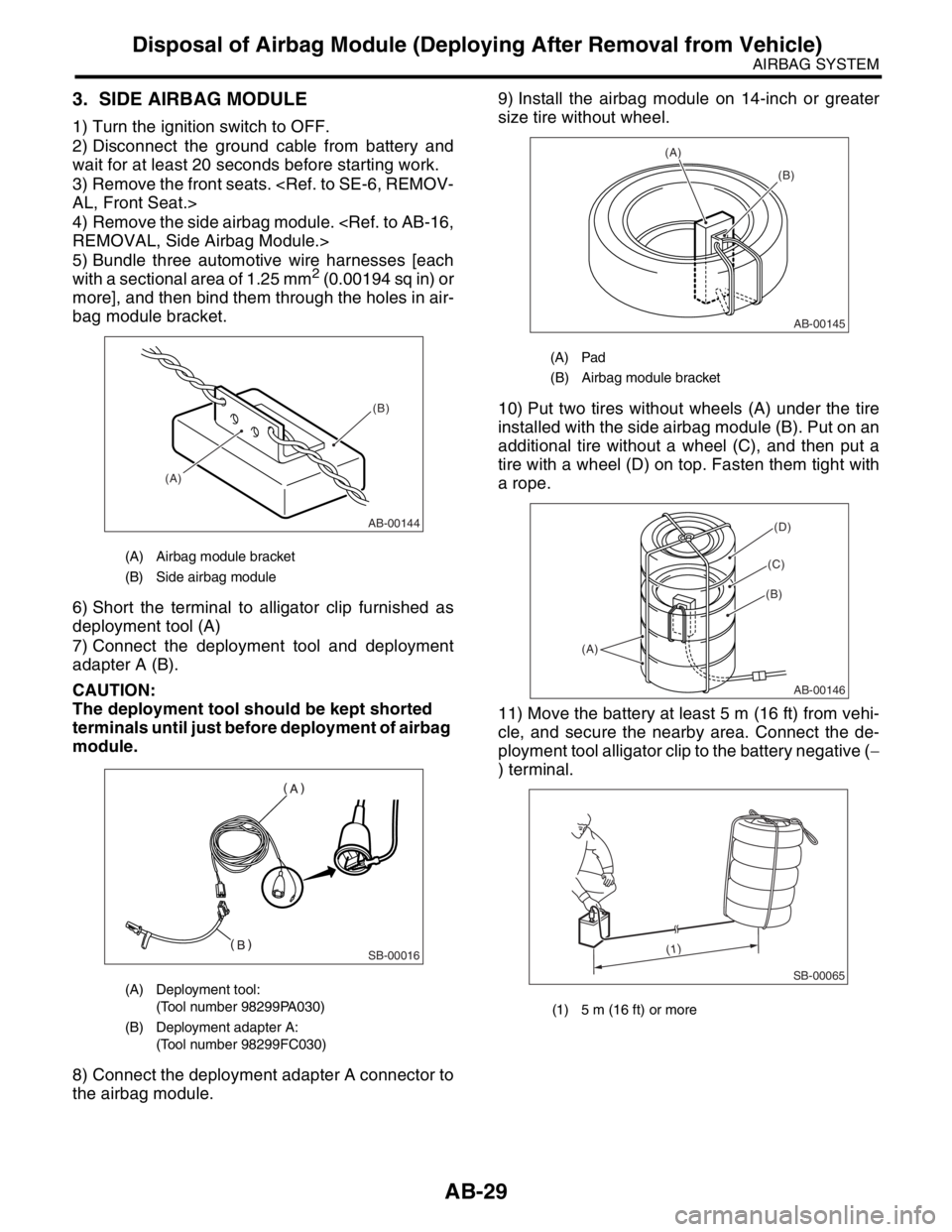

9) Put three tires without wheels on the tire in-

stalled with the airbag module. Put on an additional

tire with a wheel on top, and then fasten them tight

with a rope.10) Move the battery at least 5 m (16 ft) from vehi-

cle, and secure the nearby area. Connect the de-

ployment tool alligator clip to the battery negative (−

) terminal.

11) Connect the other cable of deployment tool to

the battery positive (+) terminal, and deploy the air-

bag module.

CAUTION:

After deployment, the airbag module will be

especially hot, leave it unattended for 40 min-

utes, and then discard it.

Do not let water get on the deployed airbag

module.

12) Wrap the deployed airbag module in airtight vi-

nyl bag, and discard it.

(A) Deployment tool:

(Tool number 98299PA030)

(B) Deployment adapter E:

(Tool number 98299SA030)

SB-00016

AB-00052

SB-00025

(1) 5 m (16 ft) or more

SB-00065

(1)

SB-00018

AB-00043

Page 129 of 2870

AB-29

AIRBAG SYSTEM

Disposal of Airbag Module (Deploying After Removal from Vehicle)

3. SIDE AIRBAG MODULE

1) Turn the ignition switch to OFF.

2) Disconnect the ground cable from battery and

wait for at least 20 seconds before starting work.

3) Remove the front seats.

4) Remove the side airbag module.

5) Bundle three automotive wire harnesses [each

with a sectional area of 1.25 mm

2 (0.00194 sq in) or

more], and then bind them through the holes in air-

bag module bracket.

6) Short the terminal to alligator clip furnished as

deployment tool (A)

7) Connect the deployment tool and deployment

adapter A (B).

CAUTION:

The deployment tool should be kept shorted

terminals until just before deployment of airbag

module.

8) Connect the deployment adapter A connector to

the airbag module.9) Install the airbag module on 14-inch or greater

size tire without wheel.

10) Put two tires without wheels (A) under the tire

installed with the side airbag module (B). Put on an

additional tire without a wheel (C), and then put a

tire with a wheel (D) on top. Fasten them tight with

a rope.

11) Move the battery at least 5 m (16 ft) from vehi-

cle, and secure the nearby area. Connect the de-

ployment tool alligator clip to the battery negative (−

) terminal.

(A) Airbag module bracket

(B) Side airbag module

(A) Deployment tool:

(Tool number 98299PA030)

(B) Deployment adapter A:

(Tool number 98299FC030)

AB-00144

(A)(B)

SB-00016

(A) Pad

(B) Airbag module bracket

(1) 5 m (16 ft) or more

AB-00145

(A)

(B)

AB-00146

(A)

(B)

(C)

(D)

SB-00065

(1)

Page 693 of 2870

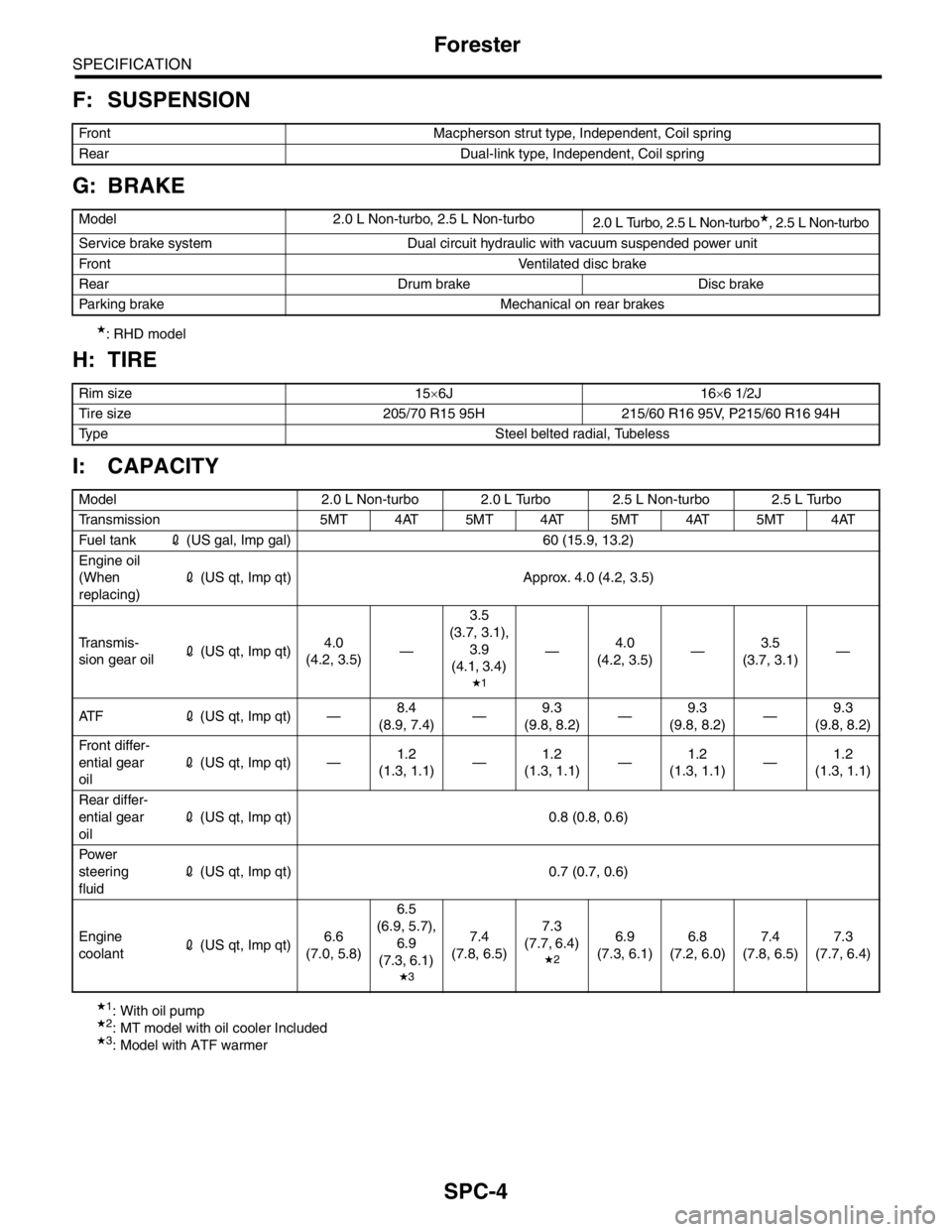

SPC-4

SPECIFICATION

Forester

F: SUSPENSION

G: BRAKE

★: RHD model

H: TIRE

I: CAPACITY

★1: With oil pump★2: MT model with oil cooler Included★3: Model with ATF warmer Front Macpherson strut type, Independent, Coil spring

Rear Dual-link type, Independent, Coil spring

Model 2.0 L Non-turbo, 2.5 L Non-turbo

2.0 L Turbo, 2.5 L Non-turbo

★, 2.5 L Non-turbo

Service brake system Dual circuit hydraulic with vacuum suspended power unit

Front Ventilated disc brake

Rear Drum brake Disc brake

Parking brake Mechanical on rear brakes

Rim size 15×6J 16×6 1/2J

Tire size 205/70 R15 95H 215/60 R16 95V, P215/60 R16 94H

Type Steel belted radial, Tubeless

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Tr a n s m i s s i o n 5 M T 4 AT 5 M T 4 AT 5 M T 4 AT 5 M T 4 AT

Fuel tank2 (US gal, Imp gal) 60 (15.9, 13.2)

Engine oil

(When

replacing)2 (US qt, Imp qt) Approx. 4.0 (4.2, 3.5)

Tr a n s m i s -

sion gear oil2 (US qt, Imp qt)4.0

(4.2, 3.5)—3.5

(3.7, 3.1),

3.9

(4.1, 3.4)

★1

—4.0

(4.2, 3.5)—3.5

(3.7, 3.1)—

AT F2 (US qt, Imp qt) —8.4

(8.9, 7.4)—9.3

(9.8, 8.2)—9.3

(9.8, 8.2)—9.3

(9.8, 8.2)

Front differ-

ential gear

oil2 (US qt, Imp qt) —1.2

(1.3, 1.1)—1.2

(1.3, 1.1)—1.2

(1.3, 1.1)—1.2

(1.3, 1.1)

Rear differ-

ential gear

oil2 (US qt, Imp qt) 0.8 (0.8, 0.6)

Pow er

steering

fluid2 (US qt, Imp qt) 0.7 (0.7, 0.6)

Engine

coolant2 (US qt, Imp qt)6.6

(7.0, 5.8)6.5

(6.9, 5.7),

6.9

(7.3, 6.1)

★3

7.4

(7.8, 6.5)7.3

(7.7, 6.4)

★2

6.9

(7.3, 6.1)6.8

(7.2, 6.0)7.4

(7.8, 6.5)7.3

(7.7, 6.4)

Page 728 of 2870

PI-5

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

1. APPEARANCE CHECK

1) If the vehicle is covered with protective coating,

visually check the vehicle body for damage and

dents.

2) If there is no protective coating, check the body

paints for small areas of damage or stains and re-

pair as necessary.

3) Check the window glass, door glass, and lights

for any cracks or damage and repair or replace the

parts as necessary.

4) Check the plated parts, such as the grilles and

door knobs, for damage or loss of gloss and repair

or replace the parts as necessary.

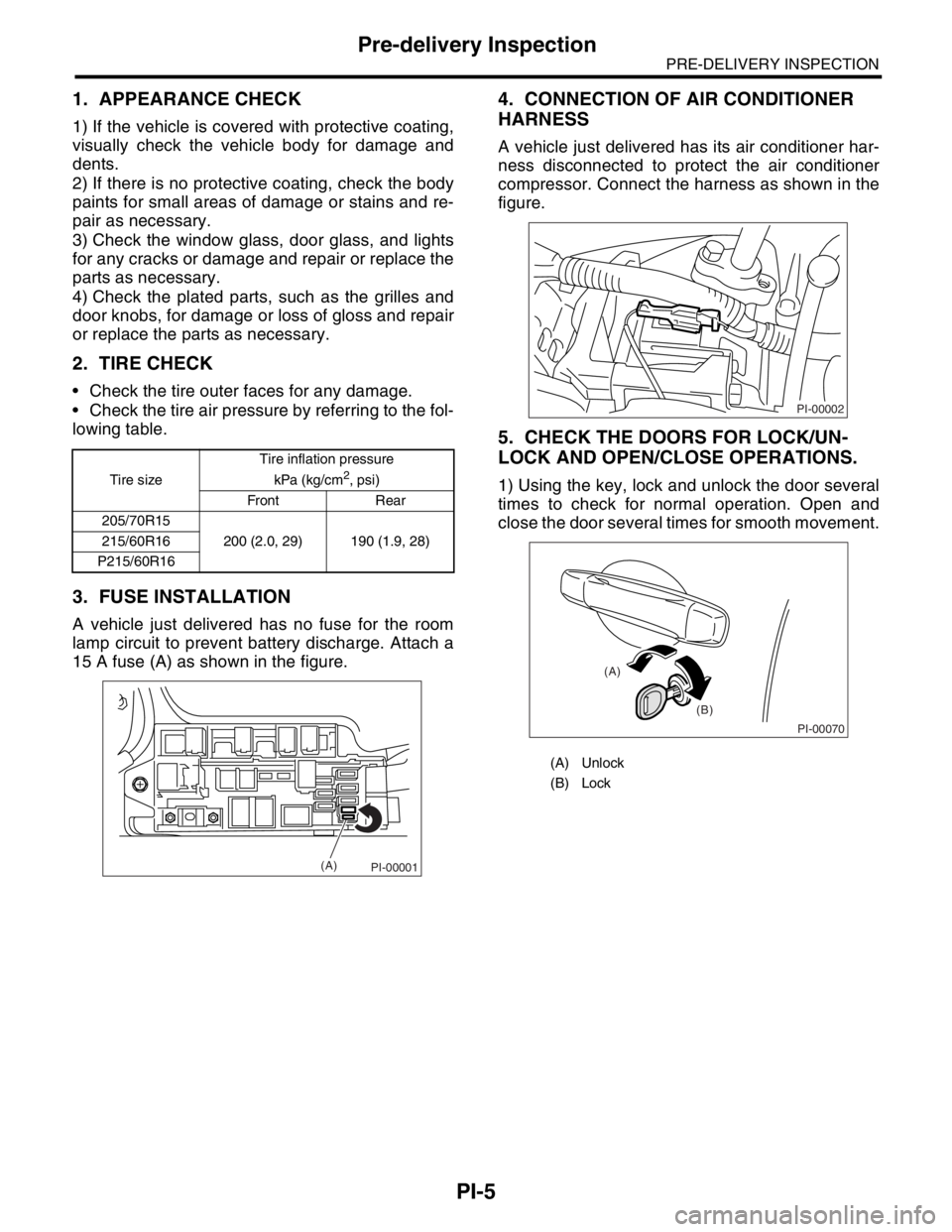

2. TIRE CHECK

Check the tire outer faces for any damage.

Check the tire air pressure by referring to the fol-

lowing table.

3. FUSE INSTALLATION

A vehicle just delivered has no fuse for the room

lamp circuit to prevent battery discharge. Attach a

15 A fuse (A) as shown in the figure.

4. CONNECTION OF AIR CONDITIONER

HARNESS

A vehicle just delivered has its air conditioner har-

ness disconnected to protect the air conditioner

compressor. Connect the harness as shown in the

figure.

5. CHECK THE DOORS FOR LOCK/UN-

LOCK AND OPEN/CLOSE OPERATIONS.

1) Using the key, lock and unlock the door several

times to check for normal operation. Open and

close the door several times for smooth movement.Tire sizeTire inflation pressure

kPa (kg/cm2, psi)

Front Rear

205/70R15

200 (2.0, 29) 190 (1.9, 28) 215/60R16

P215/60R16

PI-00001(A)

(A) Unlock

(B) Lock

PI-00002

PI-00070

(A)

(B)