torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 7 of 2870

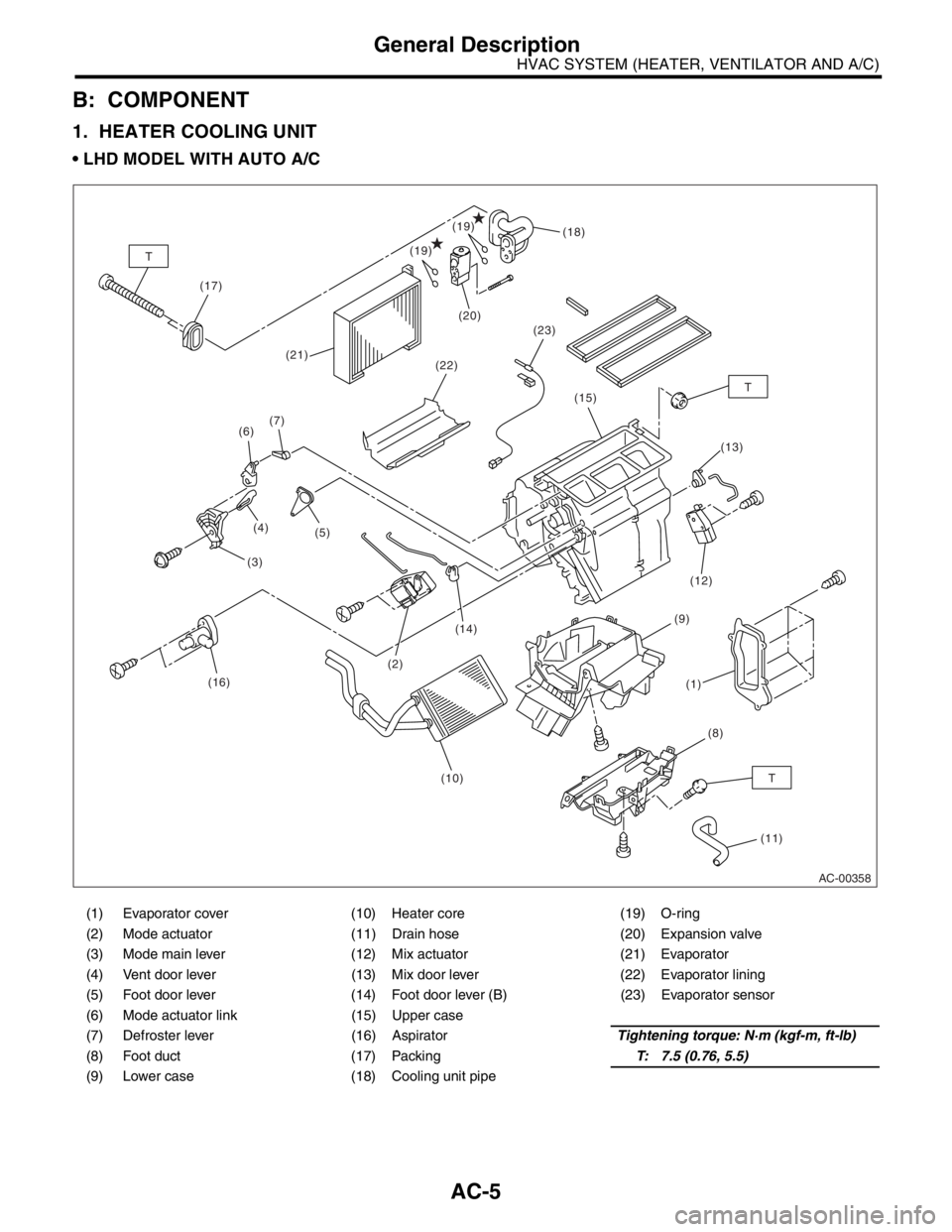

AC-5

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

B: COMPONENT

1. HEATER COOLING UNIT

LHD MODEL WITH AUTO A/C

(1) Evaporator cover (10) Heater core (19) O-ring

(2) Mode actuator (11) Drain hose (20) Expansion valve

(3) Mode main lever (12) Mix actuator (21) Evaporator

(4) Vent door lever (13) Mix door lever (22) Evaporator lining

(5) Foot door lever (14) Foot door lever (B) (23) Evaporator sensor

(6) Mode actuator link (15) Upper case

(7) Defroster lever (16) AspiratorTightening torque: N·m (kgf-m, ft-lb)

(8) Foot duct (17) PackingT: 7.5 (0.76, 5.5)

(9) Lower case (18) Cooling unit pipe

AC-00358

(1)

(9)

(8)

(10)

(18)

(12)(13)

(3)

(4)(5)

(2)

(6)(7)

(17)

(21)(19)

(20) (19)(22)

(23)

(14)(15)

T

T

T

(16)

(11)

Page 8 of 2870

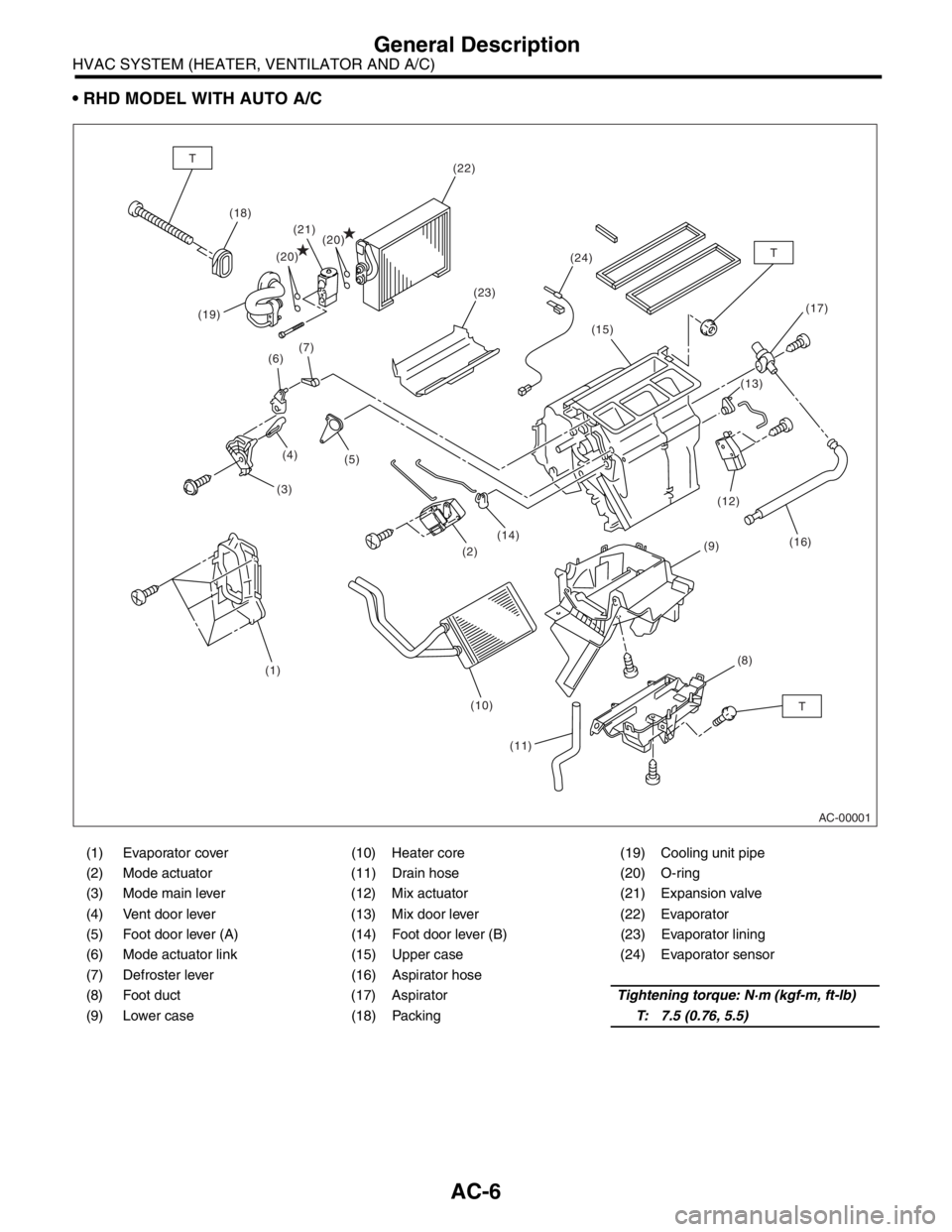

AC-6

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

RHD MODEL WITH AUTO A/C

(1) Evaporator cover (10) Heater core (19) Cooling unit pipe

(2) Mode actuator (11) Drain hose (20) O-ring

(3) Mode main lever (12) Mix actuator (21) Expansion valve

(4) Vent door lever (13) Mix door lever (22) Evaporator

(5) Foot door lever (A) (14) Foot door lever (B) (23) Evaporator lining

(6) Mode actuator link (15) Upper case (24) Evaporator sensor

(7) Defroster lever (16) Aspirator hose

(8) Foot duct (17) AspiratorTightening torque: N·m (kgf-m, ft-lb)

(9) Lower case (18) PackingT: 7.5 (0.76, 5.5)

AC-00001

(1)

(9)

(8)

(10)

(11)

(16) (19)

(12)(13)(3)

(4)(5)

(2)

(6)(7)

(18)

(22)

(20)(21)

(20)

(23)

(24)

(14)(15)

(17)

T

T

T

Page 9 of 2870

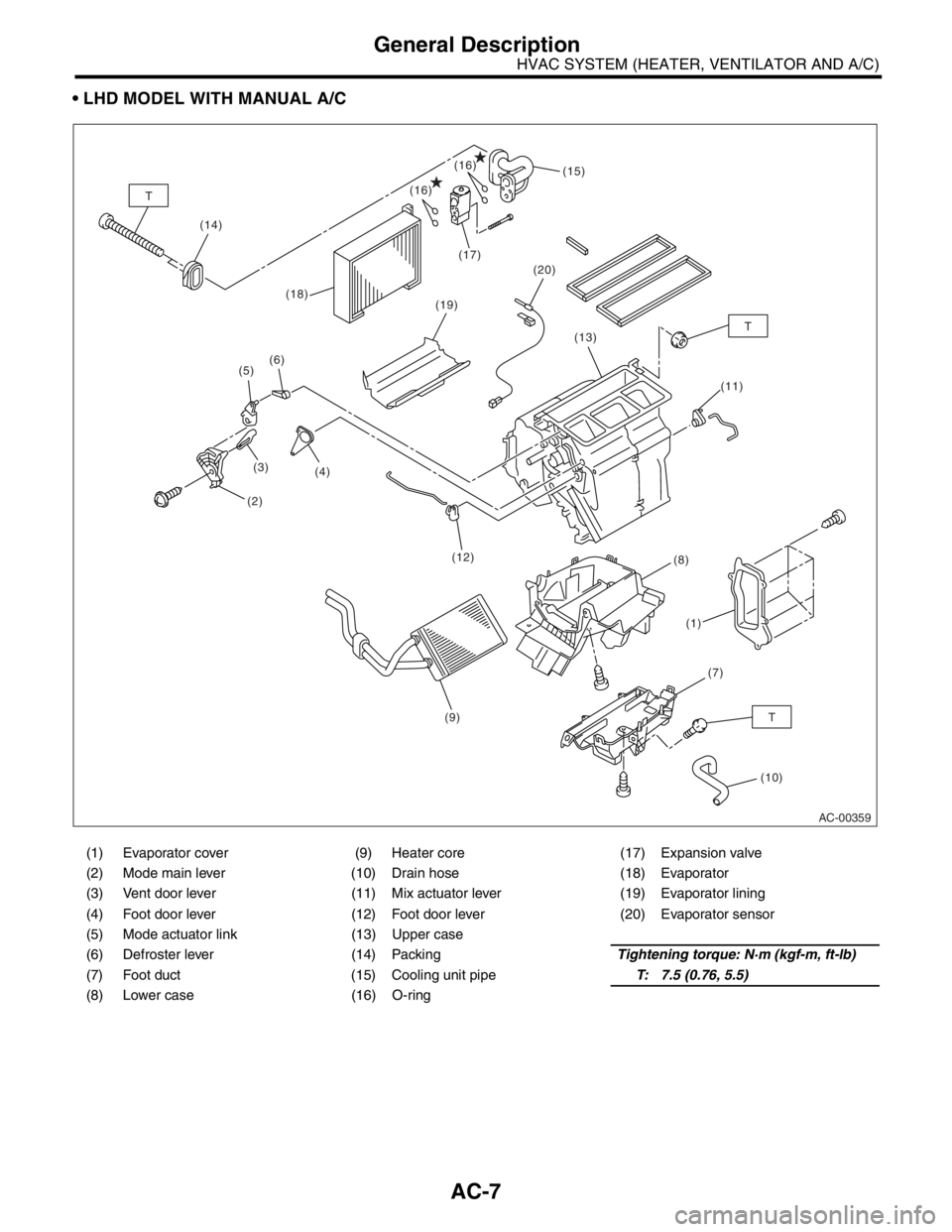

AC-7

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

LHD MODEL WITH MANUAL A/C

(1) Evaporator cover (9) Heater core (17) Expansion valve

(2) Mode main lever (10) Drain hose (18) Evaporator

(3) Vent door lever (11) Mix actuator lever (19) Evaporator lining

(4) Foot door lever (12) Foot door lever (20) Evaporator sensor

(5) Mode actuator link (13) Upper case

(6) Defroster lever (14) PackingTightening torque: N·m (kgf-m, ft-lb)

(7) Foot duct (15) Cooling unit pipeT: 7.5 (0.76, 5.5)

(8) Lower case (16) O-ring

AC-00359

(1)

(8)

(7)

(9)

(15)

(11)

(2)

(3)(4)

(5)(6)

(14)

(18)(16)

(17) (16)(19)

(20)

(12)(13)

T

T

T

(10)

Page 10 of 2870

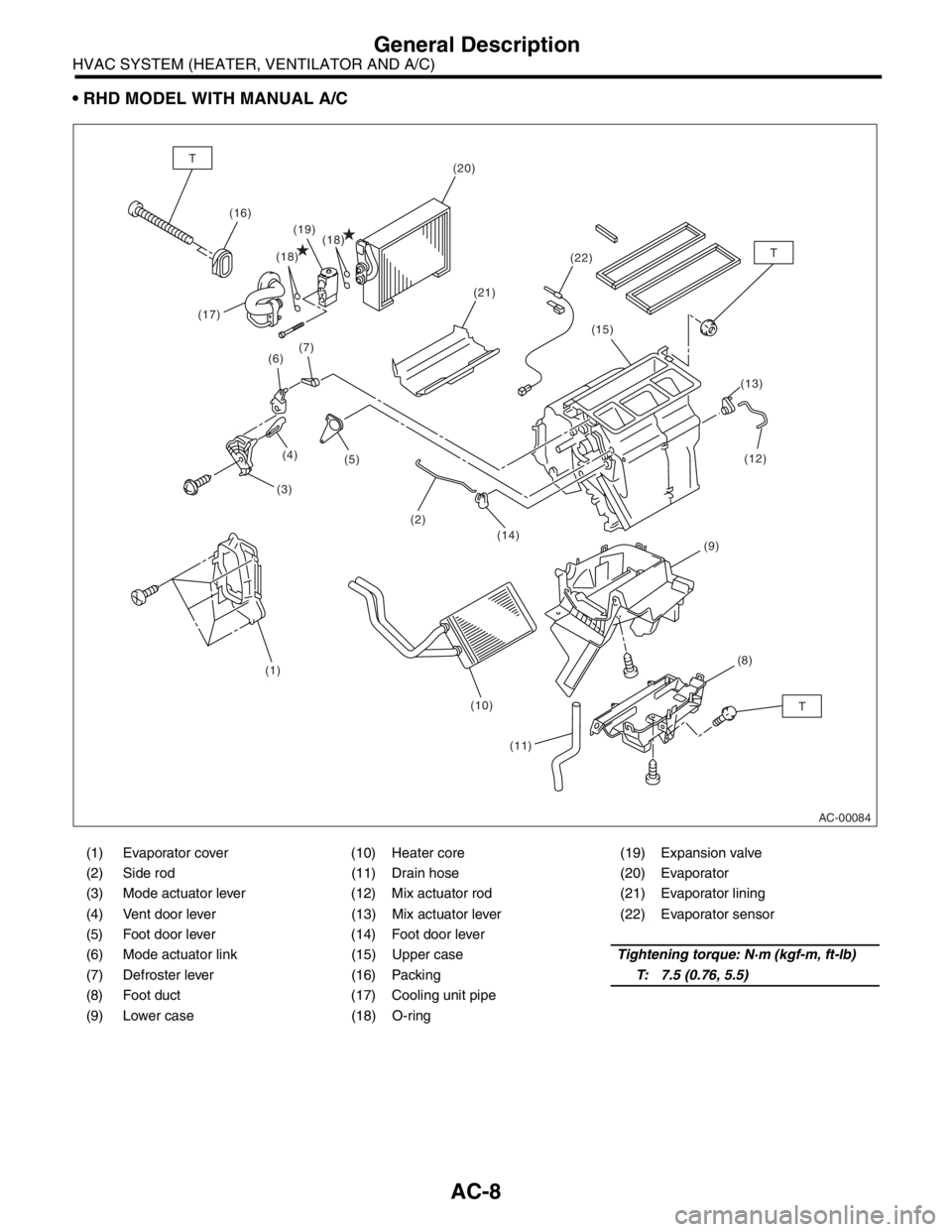

AC-8

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

RHD MODEL WITH MANUAL A/C

(1) Evaporator cover (10) Heater core (19) Expansion valve

(2) Side rod (11) Drain hose (20) Evaporator

(3) Mode actuator lever (12) Mix actuator rod (21) Evaporator lining

(4) Vent door lever (13) Mix actuator lever (22) Evaporator sensor

(5) Foot door lever (14) Foot door lever

(6) Mode actuator link (15) Upper caseTightening torque: N·m (kgf-m, ft-lb)

(7) Defroster lever (16) PackingT: 7.5 (0.76, 5.5)

(8) Foot duct (17) Cooling unit pipe

(9) Lower case (18) O-ring

AC-00084

(1)

(9)

(8)

(10)

(11)

(17)

(12) (13)

(3)

(4)(5)

(2)

(6)(7)

(16)

(20)

(18)(19)

(18)

(21)

(22)

(14)(15)

T

T

T

Page 18 of 2870

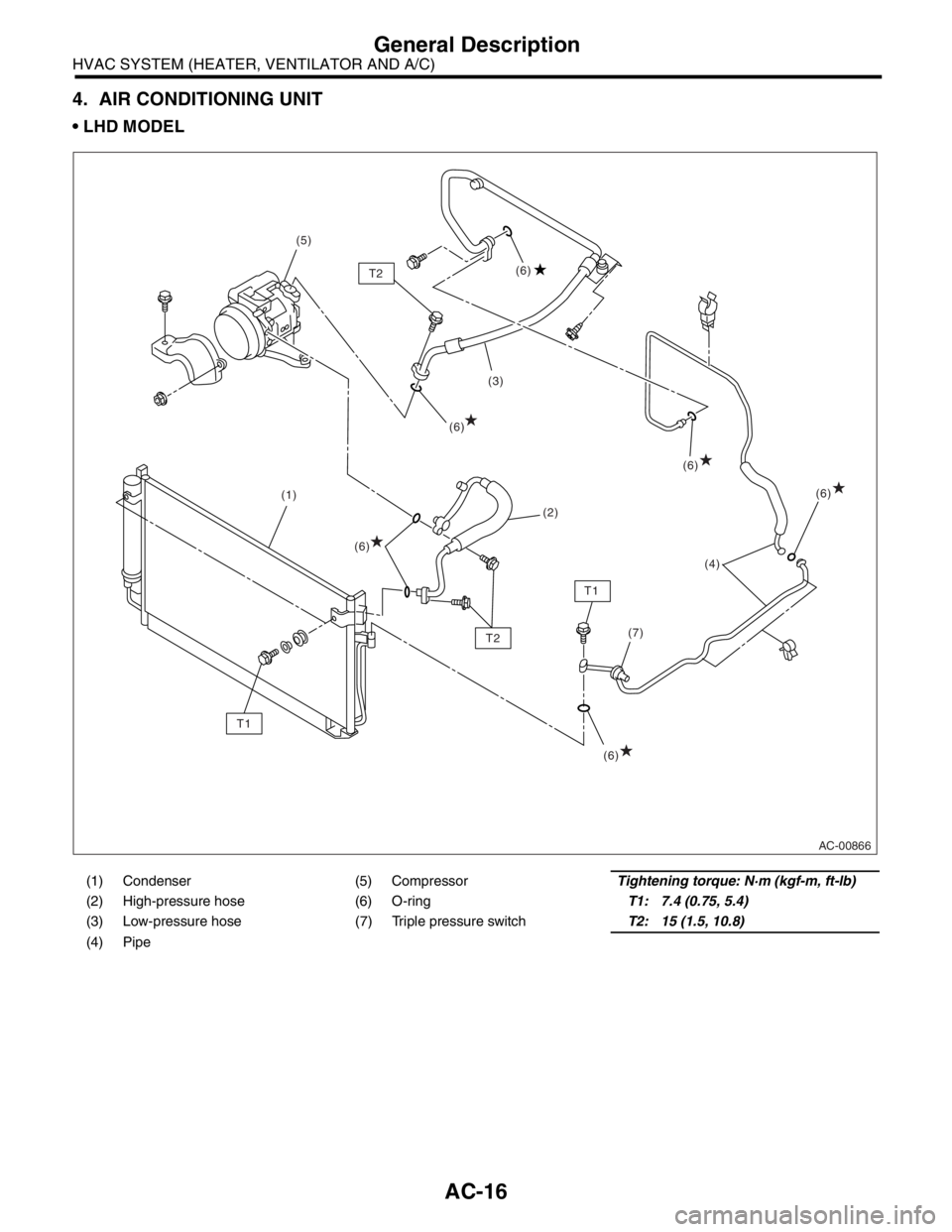

AC-16

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

4. AIR CONDITIONING UNIT

LHD MODEL

(1) Condenser (5) CompressorTightening torque: N·m (kgf-m, ft-lb)

(2) High-pressure hose (6) O-ringT1: 7.4 (0.75, 5.4)

(3) Low-pressure hose (7) Triple pressure switchT2: 15 (1.5, 10.8)

(4) Pipe

AC-00866

(1)(3)

(4)

(7) (5)

(2)

T1

T1T2(6) (6)

(6)(6)

(6) T2(6)

Page 19 of 2870

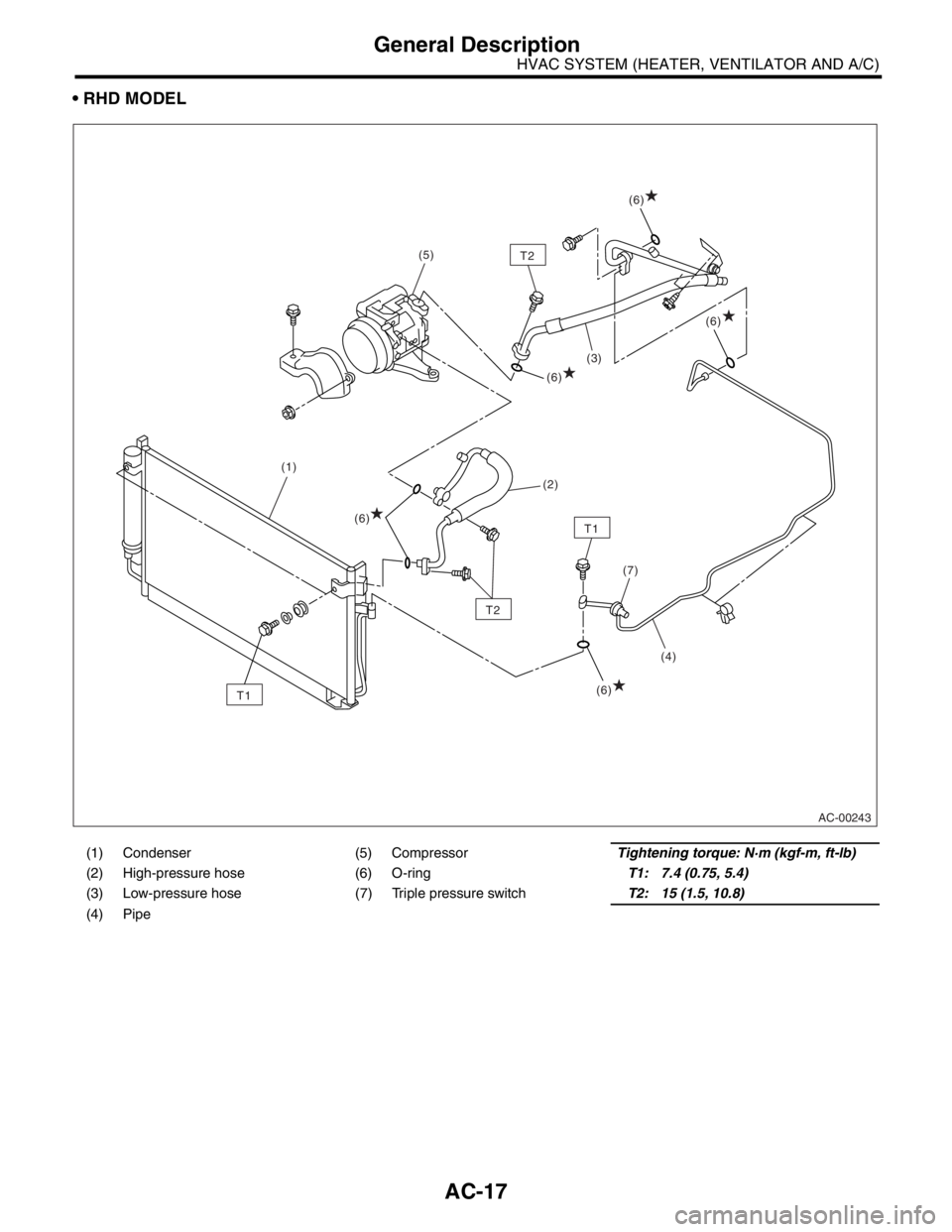

AC-17

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

RHD MODEL

(1) Condenser (5) CompressorTightening torque: N·m (kgf-m, ft-lb)

(2) High-pressure hose (6) O-ringT1: 7.4 (0.75, 5.4)

(3) Low-pressure hose (7) Triple pressure switchT2: 15 (1.5, 10.8)

(4) Pipe

AC-00243

(1)(3)

(4)

(7)

(5)

(2)

T1

T1

T2

(6)

(6)

(6)

(6)

(6)

T2

Page 20 of 2870

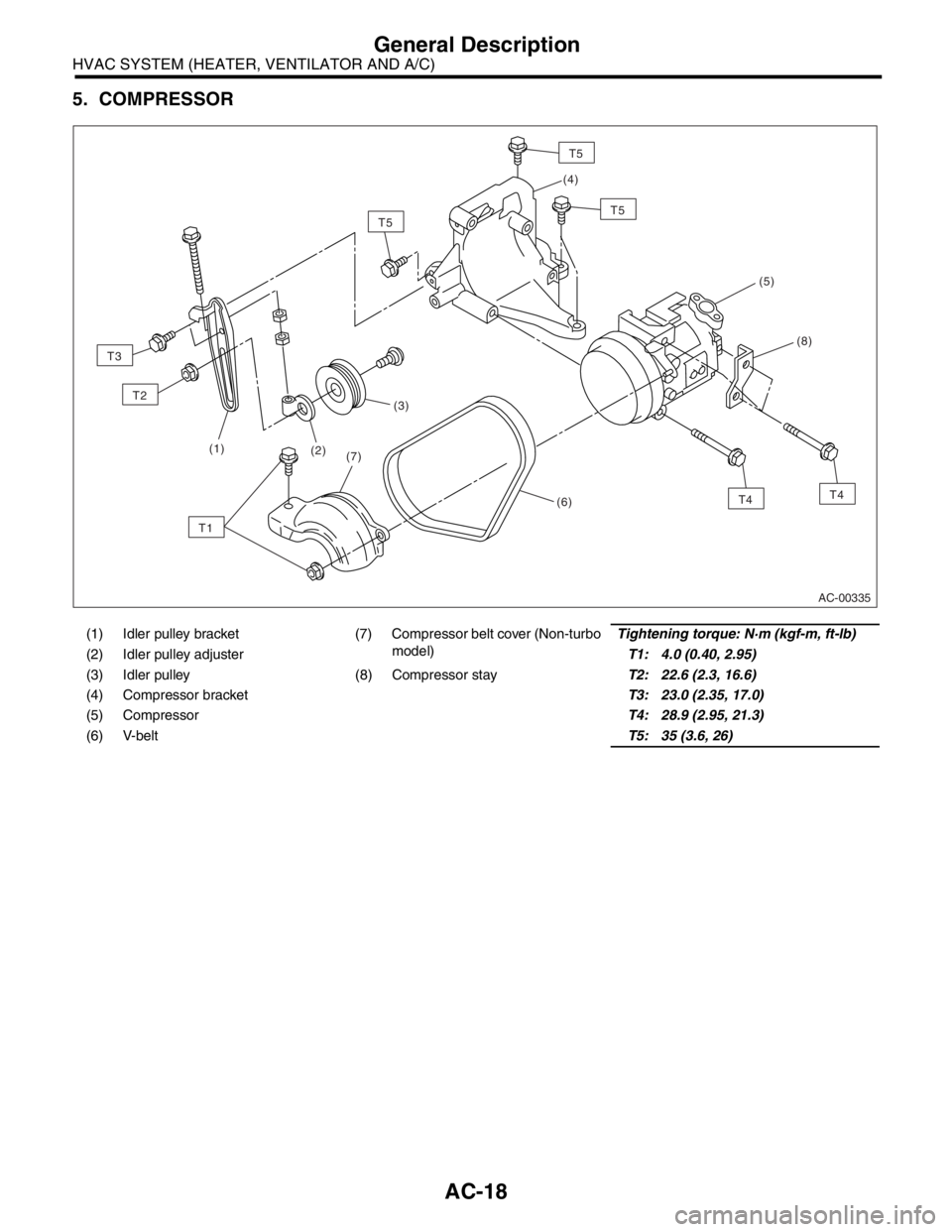

AC-18

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

5. COMPRESSOR

(1) Idler pulley bracket (7) Compressor belt cover (Non-turbo

model)Tightening torque: N·m (kgf-m, ft-lb)

(2) Idler pulley adjusterT1: 4.0 (0.40, 2.95)

(3) Idler pulley (8) Compressor stayT2: 22.6 (2.3, 16.6)

(4) Compressor bracketT3: 23.0 (2.35, 17.0)

(5) CompressorT4: 28.9 (2.95, 21.3)

(6) V-beltT5: 35 (3.6, 26)

AC-00335

(1)

(3)

(2)

(4)

(5)

(8)

(6)

(7)

T3

T2

T1

T5

T5

T5

T4T4

Page 23 of 2870

AC-21

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

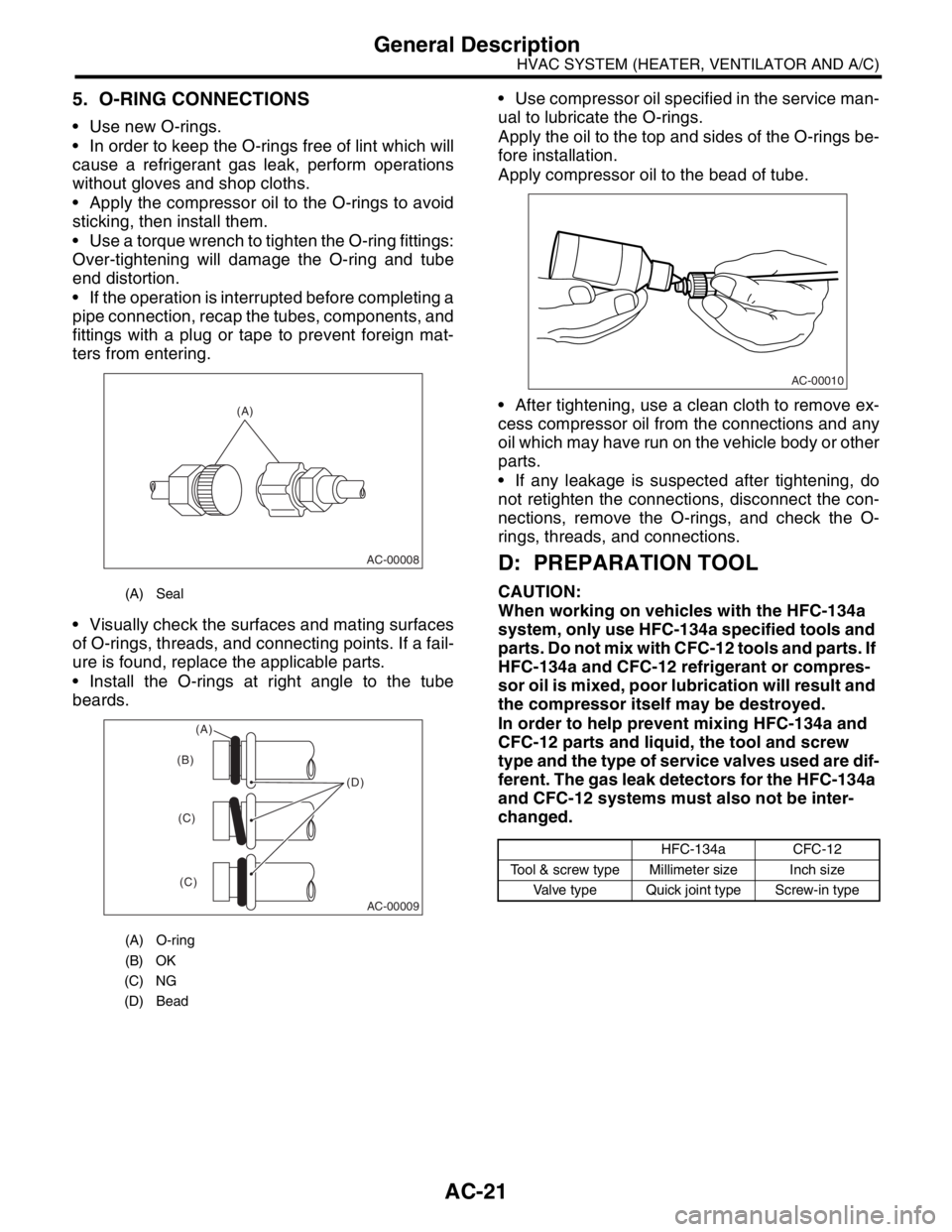

5. O-RING CONNECTIONS

Use new O-rings.

In order to keep the O-rings free of lint which will

cause a refrigerant gas leak, perform operations

without gloves and shop cloths.

Apply the compressor oil to the O-rings to avoid

sticking, then install them.

Use a torque wrench to tighten the O-ring fittings:

Over-tightening will damage the O-ring and tube

end distortion.

If the operation is interrupted before completing a

pipe connection, recap the tubes, components, and

fittings with a plug or tape to prevent foreign mat-

ters from entering.

Visually check the surfaces and mating surfaces

of O-rings, threads, and connecting points. If a fail-

ure is found, replace the applicable parts.

Install the O-rings at right angle to the tube

beards. Use compressor oil specified in the service man-

ual to lubricate the O-rings.

Apply the oil to the top and sides of the O-rings be-

fore installation.

Apply compressor oil to the bead of tube.

After tightening, use a clean cloth to remove ex-

cess compressor oil from the connections and any

oil which may have run on the vehicle body or other

parts.

If any leakage is suspected after tightening, do

not retighten the connections, disconnect the con-

nections, remove the O-rings, and check the O-

rings, threads, and connections.

D: PREPARATION TOOL

CAUTION:

When working on vehicles with the HFC-134a

system, only use HFC-134a specified tools and

parts. Do not mix with CFC-12 tools and parts. If

HFC-134a and CFC-12 refrigerant or compres-

sor oil is mixed, poor lubrication will result and

the compressor itself may be destroyed.

In order to help prevent mixing HFC-134a and

CFC-12 parts and liquid, the tool and screw

type and the type of service valves used are dif-

ferent. The gas leak detectors for the HFC-134a

and CFC-12 systems must also not be inter-

changed.(A) Seal

(A) O-ring

(B) OK

(C) NG

(D) Bead

(A)

AC-00008

AC-00009

(D) (B)

(C)

(C)

(A)

HFC-134a CFC-12

Tool & screw type Millimeter size Inch size

Valve type Quick joint type Screw-in type

AC-00010

Page 24 of 2870

AC-22

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

Illustration Tools and Equipment

Wrench

Va r i o u s WRENCHES will be required to service any A/C system. A 7 to

40 N·m (0.7 to 4.1 kgf-m, 5 to 30 ft-lb) torque wrench and various crow-

foot wrenches will be needed. Open end or flare nut wrenches will be

needed for back-up on the tube and hose fittings.

Applicator bottle

A small APPLICATOR BOTTLE is recommended to apply refrigerant

oil to the various parts. They can be available at a hardware or drug

store.

Manifold gauge set

A MANIFOLD GAUGE SET (with hoses) can be available at from

either a refrigerant supplier or an automotive equipment supplier.

Refrigerant recovery system

A REFRIGERANT RECOVERY SYSTEM is used for the recovery and

reuse of A/C system refrigerant after contaminants and moisture have

been removed from the refrigerant.

AC-00213

AC-00012

AC-00013

AC-00014

Page 34 of 2870

AC-32

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Blower Motor Unit Assembly

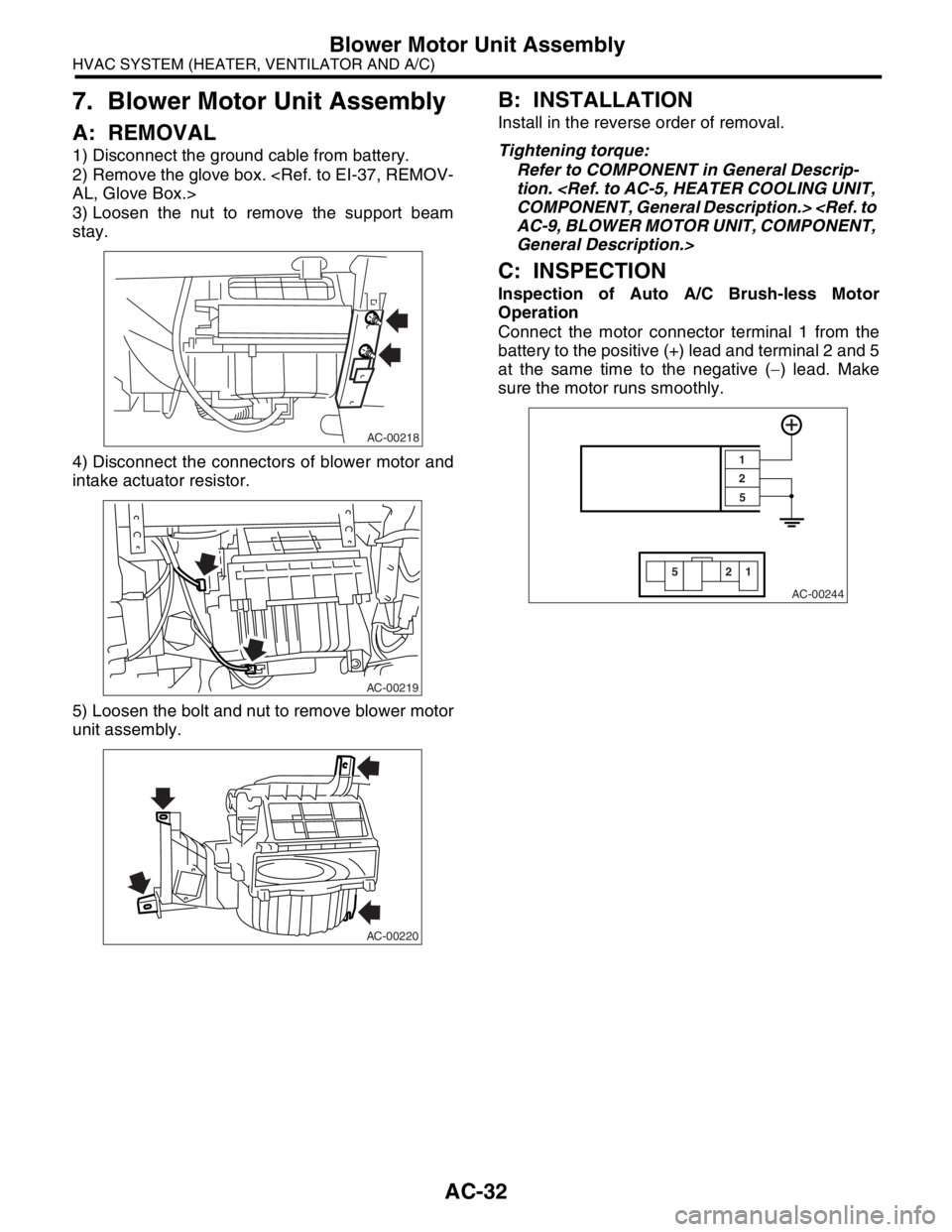

7. Blower Motor Unit Assembly

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the glove box.

3) Loosen the nut to remove the support beam

stay.

4) Disconnect the connectors of blower motor and

intake actuator resistor.

5) Loosen the bolt and nut to remove blower motor

unit assembly.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

General Description.>

C: INSPECTION

Inspection of Auto A/C Brush-less Motor

Operation

Connect the motor connector terminal 1 from the

battery to the positive (+) lead and terminal 2 and 5

at the same time to the negative (−) lead. Make

sure the motor runs smoothly.

AC-00218

AC-00219

AC-00220

AC-00244

22

55

1 1