O2 sensor SUBARU LEGACY 1999 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 22 of 1456

![SUBARU LEGACY 1999 Service User Guide 4) Connect connector to vent control solenoid

valve.

B2M0964

5) Connect two hoses to air filter.

B2M1888A

6) Install canister. <Ref. to 2-1 [W3A0].>

B2M1780

7) Lower the vehicle.

8) Connect battery gr SUBARU LEGACY 1999 Service User Guide 4) Connect connector to vent control solenoid

valve.

B2M0964

5) Connect two hoses to air filter.

B2M1888A

6) Install canister. <Ref. to 2-1 [W3A0].>

B2M1780

7) Lower the vehicle.

8) Connect battery gr](/img/17/57435/w960_57435-21.png)

4) Connect connector to vent control solenoid

valve.

B2M0964

5) Connect two hoses to air filter.

B2M1888A

6) Install canister.

B2M1780

7) Lower the vehicle.

8) Connect battery ground cable.

B2M1723

12. Main Fuel Level Sensor

A: REMOVAL

1) Release fuel pressure.

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Disconnect fuel delivery hose (A), return hose

(B) and jet pump hose (C).

B2M0954E

17

[W12A0]2-1SERVICE PROCEDURE

12. Main Fuel Level Sensor

Page 23 of 1456

![SUBARU LEGACY 1999 Service User Guide 4) Connect connector to vent control solenoid

valve.

B2M0964

5) Connect two hoses to air filter.

B2M1888A

6) Install canister. <Ref. to 2-1 [W3A0].>

B2M1780

7) Lower the vehicle.

8) Connect battery gr SUBARU LEGACY 1999 Service User Guide 4) Connect connector to vent control solenoid

valve.

B2M0964

5) Connect two hoses to air filter.

B2M1888A

6) Install canister. <Ref. to 2-1 [W3A0].>

B2M1780

7) Lower the vehicle.

8) Connect battery gr](/img/17/57435/w960_57435-22.png)

4) Connect connector to vent control solenoid

valve.

B2M0964

5) Connect two hoses to air filter.

B2M1888A

6) Install canister.

B2M1780

7) Lower the vehicle.

8) Connect battery ground cable.

B2M1723

12. Main Fuel Level Sensor

A: REMOVAL

1) Release fuel pressure.

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Disconnect fuel delivery hose (A), return hose

(B) and jet pump hose (C).

B2M0954E

17

[W12A0]2-1SERVICE PROCEDURE

12. Main Fuel Level Sensor

Page 24 of 1456

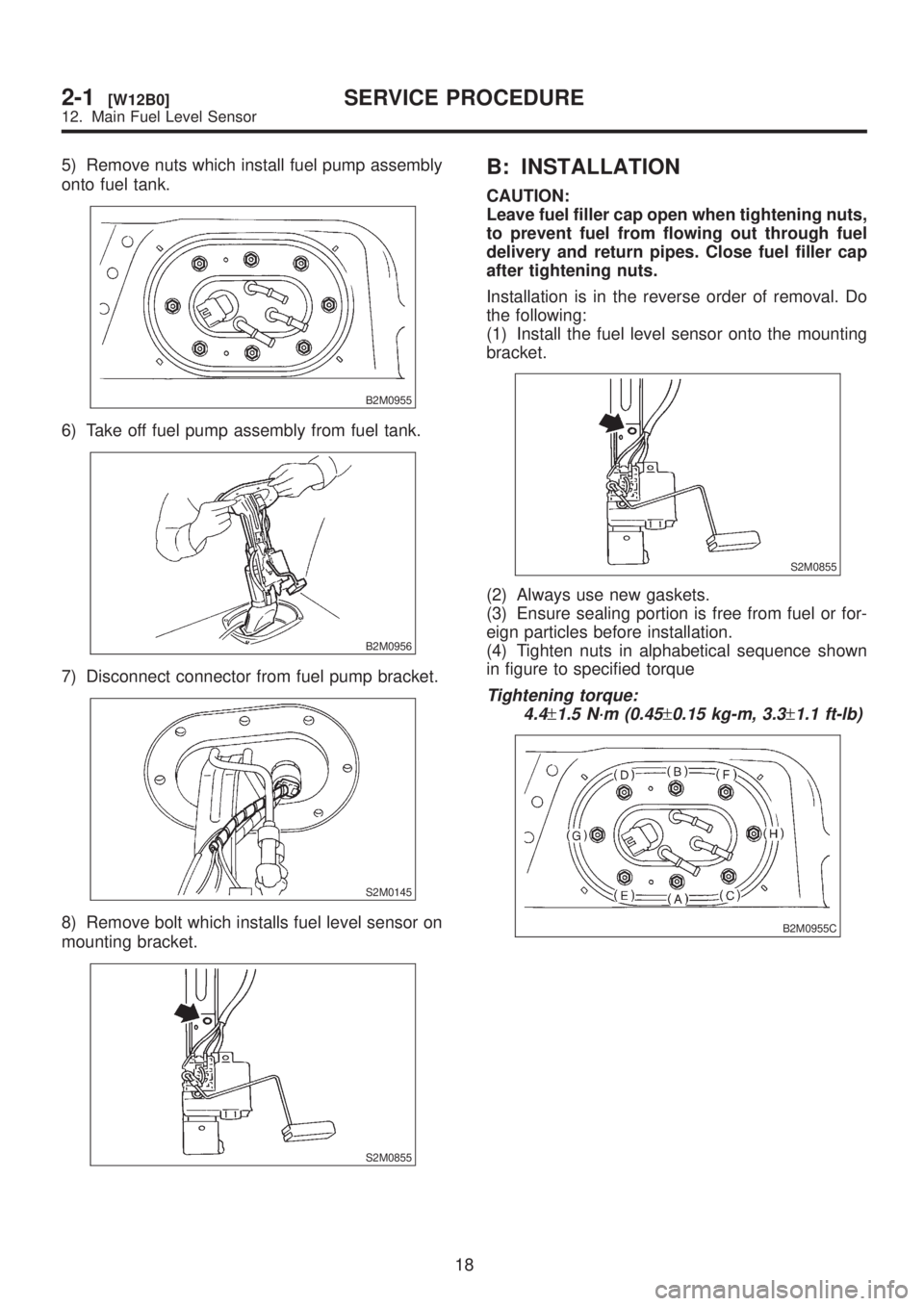

5) Remove nuts which install fuel pump assembly

onto fuel tank.

B2M0955

6) Take off fuel pump assembly from fuel tank.

B2M0956

7) Disconnect connector from fuel pump bracket.

S2M0145

8) Remove bolt which installs fuel level sensor on

mounting bracket.

S2M0855

B: INSTALLATION

CAUTION:

Leave fuel filler cap open when tightening nuts,

to prevent fuel from flowing out through fuel

delivery and return pipes. Close fuel filler cap

after tightening nuts.

Installation is in the reverse order of removal. Do

the following:

(1) Install the fuel level sensor onto the mounting

bracket.

S2M0855

(2) Always use new gaskets.

(3) Ensure sealing portion is free from fuel or for-

eign particles before installation.

(4) Tighten nuts in alphabetical sequence shown

in figure to specified torque

Tightening torque:

4.4

±1.5 N´m (0.45±0.15 kg-m, 3.3±1.1 ft-lb)

B2M0955C

18

2-1[W12B0]SERVICE PROCEDURE

12. Main Fuel Level Sensor

Page 26 of 1456

![SUBARU LEGACY 1999 Service User Guide 14. Sub Fuel Level Sensor

A: REMOVAL AND INSTALLATION

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M SUBARU LEGACY 1999 Service User Guide 14. Sub Fuel Level Sensor

A: REMOVAL AND INSTALLATION

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M](/img/17/57435/w960_57435-25.png)

14. Sub Fuel Level Sensor

A: REMOVAL AND INSTALLATION

1) Release fuel pressure.

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Remove service hole cover.

G2M0863

5) Disconnect connector from fuel sub meter, and

disconnect jet pump hose.

S2M0151

6) Remove bolts which install sub fuel level sensor

on fuel tank.

S2M0152

7) Remove sub fuel level sensor.

S2M0153

8) Installation is in the reverse order of removal.

Tightening torque:

T: 4.4

±1.5 N´m (0.45±0.15 kg-m, 3.3±1.1

ft-lb)

S2M0152A

20

2-1[W14A0]SERVICE PROCEDURE

14. Sub Fuel Level Sensor

Page 44 of 1456

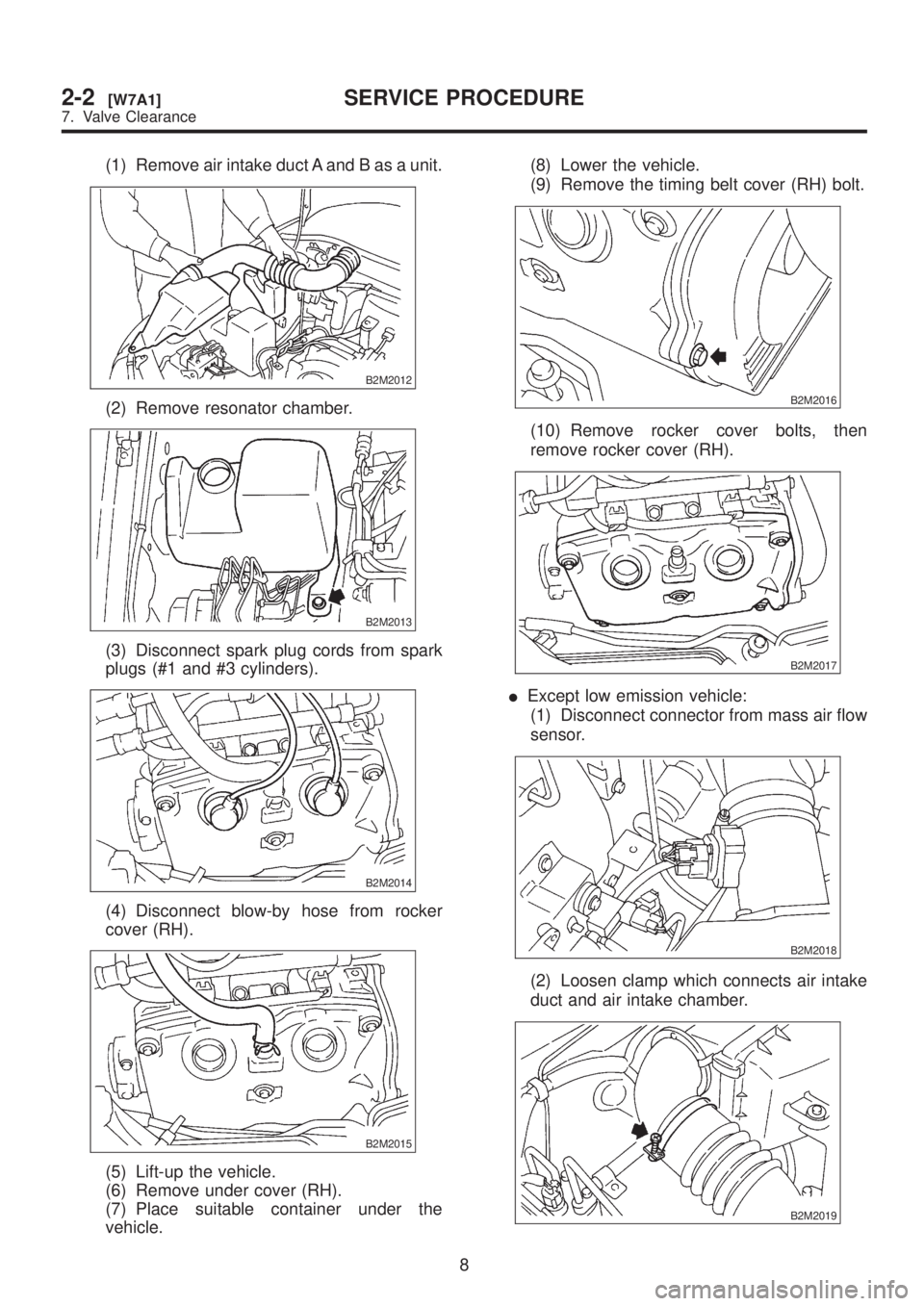

(1) Remove air intake duct A and B as a unit.

B2M2012

(2) Remove resonator chamber.

B2M2013

(3) Disconnect spark plug cords from spark

plugs (#1 and #3 cylinders).

B2M2014

(4) Disconnect blow-by hose from rocker

cover (RH).

B2M2015

(5) Lift-up the vehicle.

(6) Remove under cover (RH).

(7) Place suitable container under the

vehicle.(8) Lower the vehicle.

(9) Remove the timing belt cover (RH) bolt.

B2M2016

(10) Remove rocker cover bolts, then

remove rocker cover (RH).

B2M2017

IExcept low emission vehicle:

(1) Disconnect connector from mass air flow

sensor.

B2M2018

(2) Loosen clamp which connects air intake

duct and air intake chamber.

B2M2019

8

2-2[W7A1]SERVICE PROCEDURE

7. Valve Clearance

Page 47 of 1456

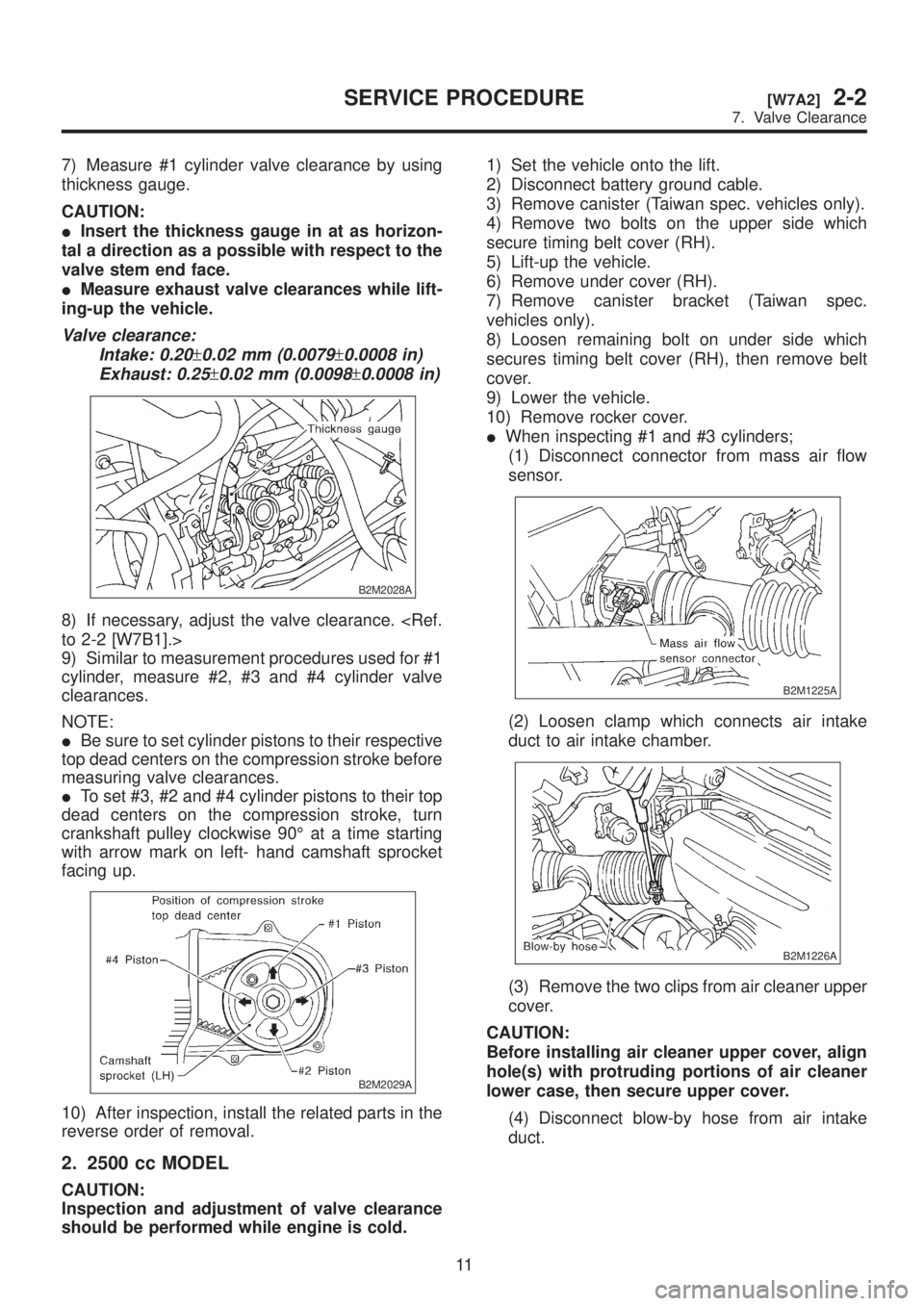

7) Measure #1 cylinder valve clearance by using

thickness gauge.

CAUTION:

IInsert the thickness gauge in at as horizon-

tal a direction as a possible with respect to the

valve stem end face.

IMeasure exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M2028A

8) If necessary, adjust the valve clearance.

9) Similar to measurement procedures used for #1

cylinder, measure #2, #3 and #4 cylinder valve

clearances.

NOTE:

IBe sure to set cylinder pistons to their respective

top dead centers on the compression stroke before

measuring valve clearances.

ITo set #3, #2 and #4 cylinder pistons to their top

dead centers on the compression stroke, turn

crankshaft pulley clockwise 90É at a time starting

with arrow mark on left- hand camshaft sprocket

facing up.

B2M2029A

10) After inspection, install the related parts in the

reverse order of removal.

2. 2500 cc MODEL

CAUTION:

Inspection and adjustment of valve clearance

should be performed while engine is cold.1) Set the vehicle onto the lift.

2) Disconnect battery ground cable.

3) Remove canister (Taiwan spec. vehicles only).

4) Remove two bolts on the upper side which

secure timing belt cover (RH).

5) Lift-up the vehicle.

6) Remove under cover (RH).

7) Remove canister bracket (Taiwan spec.

vehicles only).

8) Loosen remaining bolt on under side which

secures timing belt cover (RH), then remove belt

cover.

9) Lower the vehicle.

10) Remove rocker cover.

IWhen inspecting #1 and #3 cylinders;

(1) Disconnect connector from mass air flow

sensor.

B2M1225A

(2) Loosen clamp which connects air intake

duct to air intake chamber.

B2M1226A

(3) Remove the two clips from air cleaner upper

cover.

CAUTION:

Before installing air cleaner upper cover, align

hole(s) with protruding portions of air cleaner

lower case, then secure upper cover.

(4) Disconnect blow-by hose from air intake

duct.

11

[W7A2]2-2SERVICE PROCEDURE

7. Valve Clearance

Page 72 of 1456

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

5.7

±0.5 mm (0.224±0.020 in)

H2M2381A

3. BELT TENSION PULLEY

1) Check mating surfaces of timing belt and con-

tact point of adjuster rod for abnormal wear or

scratches. Replace automatic belt tension adjuster

assembly if faulty.

2) Check tension pulley for smooth rotation.

Replace if noise or excessive play is noted.

3) Check tension pulley for grease leakage.

4. BELT IDLER

1) Check belt idler for smooth rotation. Replace if

noise or excessive play is noted.

2) Check belt outer contacting surfaces of idler

pulley for abnormal wear and scratches.

3) Check belt idler for grease leakage.

5. CAMSHAFT AND CRANKSHAFT

SPROCKET

1) Check sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between

sprocket and key.

3) Check crankshaft sprocket notch for sensor for

damage and contamination of foreign matter.

C: INSTALLATION

1. CAMSHAFT AND CRANKSHAFT SPROCKET

B2M2598A

(1) Tensioner bracket

(2) Belt cover No. 2 (RH)

(3) Belt cover No. 2 (LH)

(4) Crankshaft sprocket(5) Camshaft sprocket No. 1

(6) Camshaft sprocket No. 2Tightening torque: N´m (kg-m, ft-lb)

T1:

5±1 (0.5±0.1, 3.6±0.7)

T2:25±3 (2.5±0.3, 18.1±2.2)

T3:78±5 (8.0±0.5, 57.9±3.6)

19

[W2C1]2-3aSERVICE PROCEDURE

2. Timing Belt

Page 73 of 1456

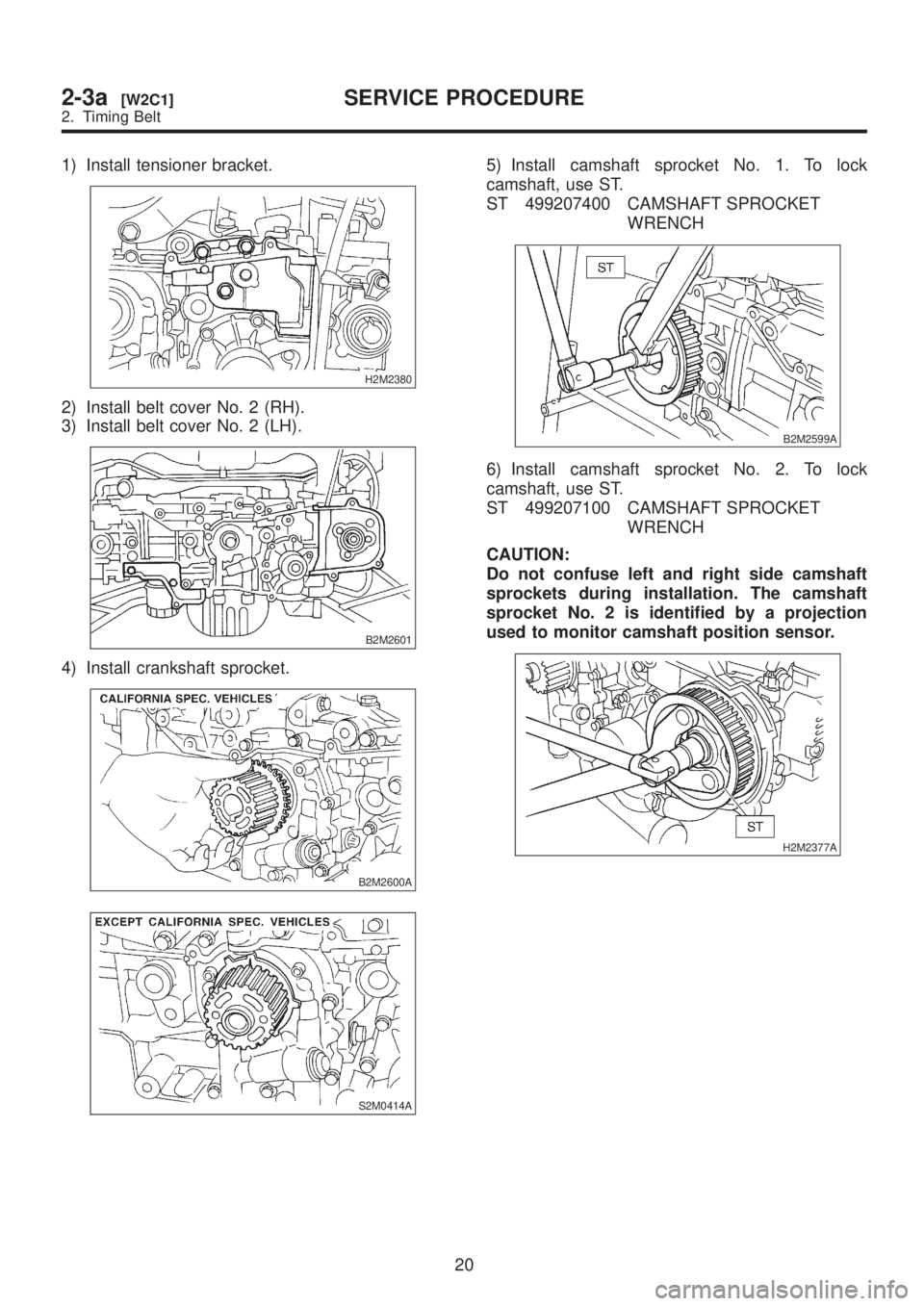

1) Install tensioner bracket.

H2M2380

2) Install belt cover No. 2 (RH).

3) Install belt cover No. 2 (LH).

B2M2601

4) Install crankshaft sprocket.

B2M2600A

S2M0414A

5) Install camshaft sprocket No. 1. To lock

camshaft, use ST.

ST 499207400 CAMSHAFT SPROCKET

WRENCH

B2M2599A

6) Install camshaft sprocket No. 2. To lock

camshaft, use ST.

ST 499207100 CAMSHAFT SPROCKET

WRENCH

CAUTION:

Do not confuse left and right side camshaft

sprockets during installation. The camshaft

sprocket No. 2 is identified by a projection

used to monitor camshaft position sensor.

H2M2377A

20

2-3a[W2C1]SERVICE PROCEDURE

2. Timing Belt

Page 86 of 1456

![SUBARU LEGACY 1999 Service User Guide 4. Camshaft

A: REMOVAL

1. RELATED PARTS

Remove timing belt, camshaft sprockets and

related parts. <Ref. to 2-3a [W2A0].>

2. CAMSHAFT (LH)

B2M2610A

(1) Bolt

(2) Oil level gauge guide(3) Camshaft cap

(4 SUBARU LEGACY 1999 Service User Guide 4. Camshaft

A: REMOVAL

1. RELATED PARTS

Remove timing belt, camshaft sprockets and

related parts. <Ref. to 2-3a [W2A0].>

2. CAMSHAFT (LH)

B2M2610A

(1) Bolt

(2) Oil level gauge guide(3) Camshaft cap

(4](/img/17/57435/w960_57435-85.png)

4. Camshaft

A: REMOVAL

1. RELATED PARTS

Remove timing belt, camshaft sprockets and

related parts.

2. CAMSHAFT (LH)

B2M2610A

(1) Bolt

(2) Oil level gauge guide(3) Camshaft cap

(4) Camshaft (LH)(5) Oil seal

(6) Plug

1) Remove camshaft position sensor.

CAUTION:

Do not damage the camshaft position sensor.

2) Remove oil level gauge guide attaching bolt.

3) Remove oil level gauge guide.

4) Remove camshaft position sensor support.

5) Remove camshaft cap.

(1) Remove valve rocker assembly.

B2M2606

(2) Remove bolts (a) through (b) in alphabetical

sequence.

B2M2612A

32

2-3a[W4A1]SERVICE PROCEDURE

4. Camshaft

Page 91 of 1456

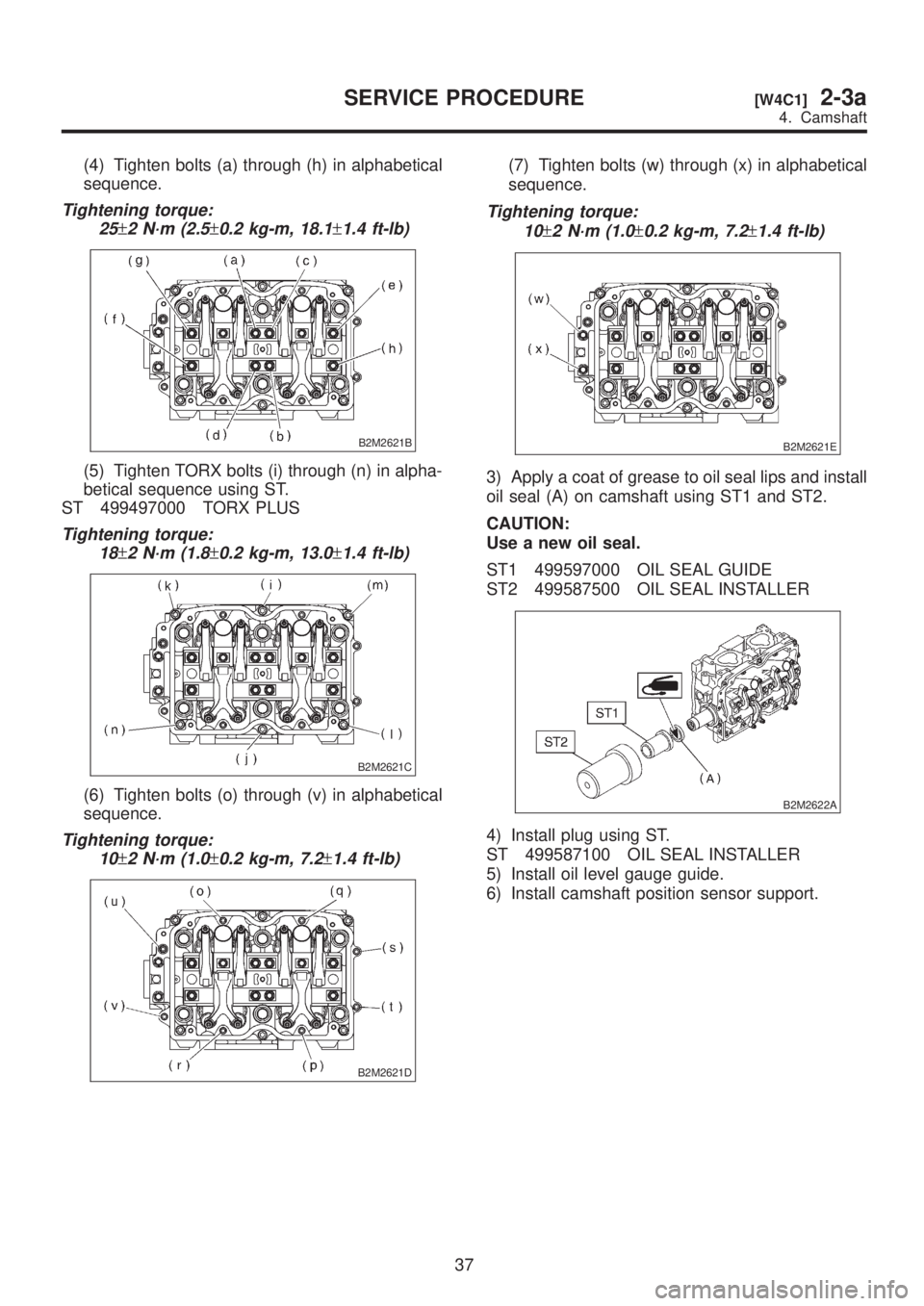

(4) Tighten bolts (a) through (h) in alphabetical

sequence.

Tightening torque:

25

±2 N´m (2.5±0.2 kg-m, 18.1±1.4 ft-lb)

B2M2621B

(5) Tighten TORX bolts (i) through (n) in alpha-

betical sequence using ST.

ST 499497000 TORX PLUS

Tightening torque:

18

±2 N´m (1.8±0.2 kg-m, 13.0±1.4 ft-lb)

B2M2621C

(6) Tighten bolts (o) through (v) in alphabetical

sequence.

Tightening torque:

10

±2 N´m (1.0±0.2 kg-m, 7.2±1.4 ft-lb)

B2M2621D

(7) Tighten bolts (w) through (x) in alphabetical

sequence.

Tightening torque:

10

±2 N´m (1.0±0.2 kg-m, 7.2±1.4 ft-lb)

B2M2621E

3) Apply a coat of grease to oil seal lips and install

oil seal (A) on camshaft using ST1 and ST2.

CAUTION:

Use a new oil seal.

ST1 499597000 OIL SEAL GUIDE

ST2 499587500 OIL SEAL INSTALLER

B2M2622A

4) Install plug using ST.

ST 499587100 OIL SEAL INSTALLER

5) Install oil level gauge guide.

6) Install camshaft position sensor support.

37

[W4C1]2-3aSERVICE PROCEDURE

4. Camshaft