O2 sensor SUBARU LEGACY 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 94 of 1456

![SUBARU LEGACY 1999 Service Owners Manual 5. Cylinder Head

A: REMOVAL

1. RELATED PARTS

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Drain engine coolant. <Ref. to 2-5 [W1A0].>

3) Remove V-belt(s).

4) Remove generator and bracket.

5) Rem SUBARU LEGACY 1999 Service Owners Manual 5. Cylinder Head

A: REMOVAL

1. RELATED PARTS

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Drain engine coolant. <Ref. to 2-5 [W1A0].>

3) Remove V-belt(s).

4) Remove generator and bracket.

5) Rem](/img/17/57435/w960_57435-93.png)

5. Cylinder Head

A: REMOVAL

1. RELATED PARTS

1) Release fuel pressure.

2) Drain engine coolant.

3) Remove V-belt(s).

4) Remove generator and bracket.

5) Remove A/C compressor and bracket. (With

A/C model)6) Disconnect spark plug cords.

7) Remove connector bracket attaching bolt.

8) Remove camshaft position sensor and cam-

shaft position sensor support.

9) Disconnect oil pressure switch connector.

10) Disconnect blow-by hose.

11) Remove intake manifold.

2. CYLINDER HEAD

B2M2627A

(1) Rocker cover

(2) Cylinder head bolt(3) Cylinder head

(4) Cylinder head gasket

1) Remove timing belt, camshaft sprocket and

related parts.

2) Remove oil level gauge guide attaching bolt

(left hand only) and oil level gauge guide.

3) Remove rocker cover.

40

2-3a[W5A1]SERVICE PROCEDURE

5. Cylinder Head

Page 104 of 1456

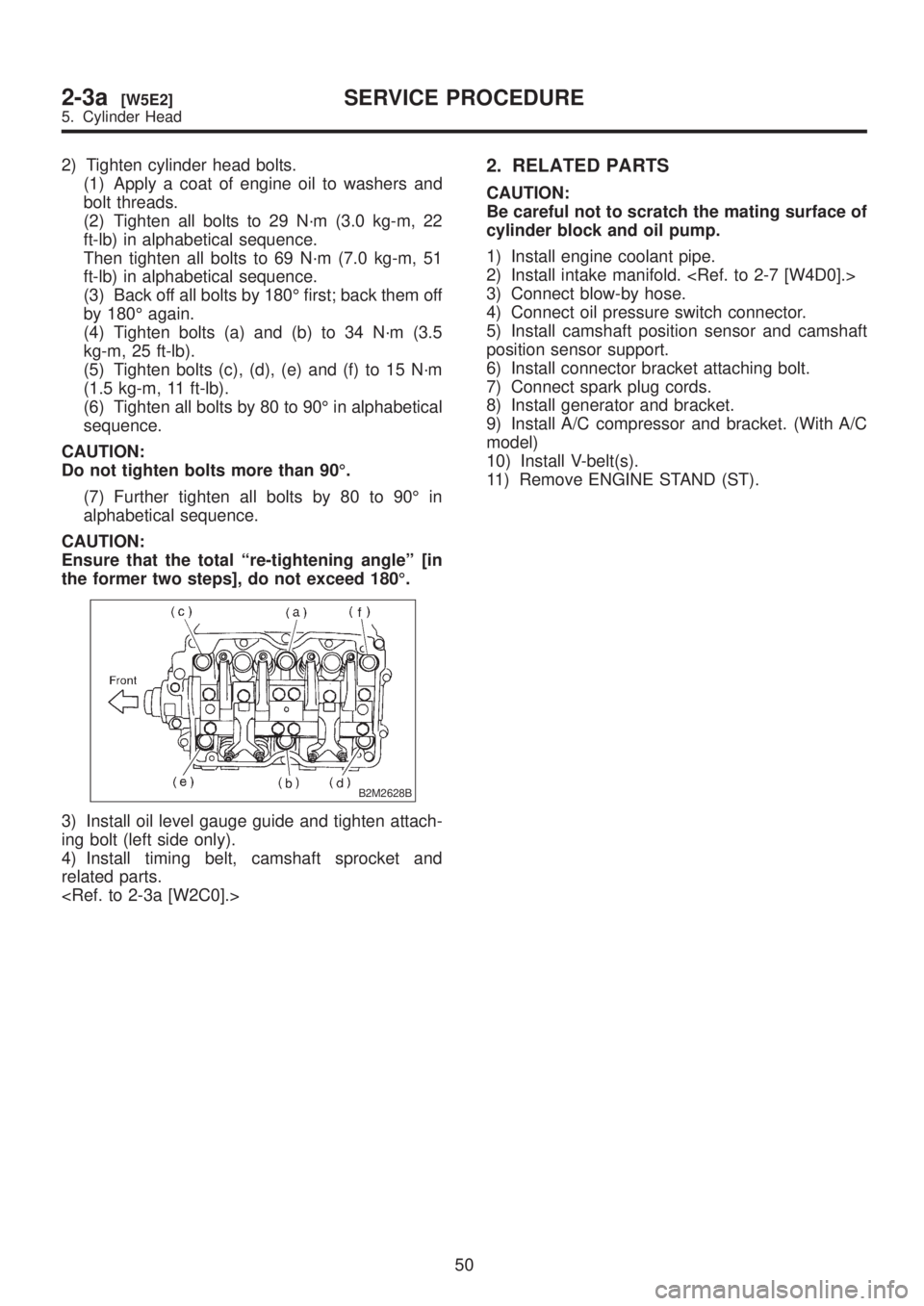

2) Tighten cylinder head bolts.

(1) Apply a coat of engine oil to washers and

bolt threads.

(2) Tighten all bolts to 29 N´m (3.0 kg-m, 22

ft-lb) in alphabetical sequence.

Then tighten all bolts to 69 N´m (7.0 kg-m, 51

ft-lb) in alphabetical sequence.

(3) Back off all bolts by 180É first; back them off

by 180É again.

(4) Tighten bolts (a) and (b) to 34 N´m (3.5

kg-m, 25 ft-lb).

(5) Tighten bolts (c), (d), (e) and (f) to 15 N´m

(1.5 kg-m, 11 ft-lb).

(6) Tighten all bolts by 80 to 90É in alphabetical

sequence.

CAUTION:

Do not tighten bolts more than 90É.

(7) Further tighten all bolts by 80 to 90É in

alphabetical sequence.

CAUTION:

Ensure that the total ªre-tightening angleº [in

the former two steps], do not exceed 180É.

B2M2628B

3) Install oil level gauge guide and tighten attach-

ing bolt (left side only).

4) Install timing belt, camshaft sprocket and

related parts.

2. RELATED PARTS

CAUTION:

Be careful not to scratch the mating surface of

cylinder block and oil pump.

1) Install engine coolant pipe.

2) Install intake manifold.

3) Connect blow-by hose.

4) Connect oil pressure switch connector.

5) Install camshaft position sensor and camshaft

position sensor support.

6) Install connector bracket attaching bolt.

7) Connect spark plug cords.

8) Install generator and bracket.

9) Install A/C compressor and bracket. (With A/C

model)

10) Install V-belt(s).

11) Remove ENGINE STAND (ST).

50

2-3a[W5E2]SERVICE PROCEDURE

5. Cylinder Head

Page 151 of 1456

(1) Slowly press the adjuster rod down to the

end surface of the cylinder. Repeat this motion

2 or 3 times.

(2) With the adjuster rod moved all the way up,

apply a pressure of 294 N (30 kg, 66 lb) to it.

Check adjuster rod stiffness.

(3) If the adjuster rod is not stiff and moves

down, replace the automatic belt tension

adjuster assembly with a new one.

CAUTION:

IAlways use a vertical type pressing tool to

move the adjuster rod down.

IDo not use a lateral type vise.

IPush adjuster rod vertically.

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

5.7

±0.5 mm (0.224±0.020 in)

H2M2381A

3. BELT TENSION PULLEY

1) Check mating surfaces of timing belt and con-

tact point of adjuster rod for abnormal wear or

scratches. Replace belt tension pulley if faulty.

2) Check belt tension pulley for smooth rotation.

Replace if noise or excessive play is noted.

3) Check belt tension pulley for grease leakage.

4. BELT IDLER

1) Check idler for smooth rotation. Replace if

noise or excessive play is noted.

2) Check outer contacting surfaces of idler pulley

for abnormal wear and scratches.

3) Check idler for grease leakage.

5. SPROCKET

1) Check sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between

sprocket and key.

3) Check crankshaft sprocket notch for sensor for

damage and contamination of foreign matter.

20

2-3b[W2B3]SERVICE PROCEDURE

2. Timing Belt

Page 161 of 1456

![SUBARU LEGACY 1999 Service Owners Manual 3. Camshaft

A: REMOVAL

1. RELATED PARTS

Remove timing belt, camshaft sprockets and related parts.

<Ref. to 2-3b [W2A0].>

2. CAMSHAFT

S2M0298A

(1) Spark plug cord

(2) Rocker cover (LH)

(3) Rocker cover SUBARU LEGACY 1999 Service Owners Manual 3. Camshaft

A: REMOVAL

1. RELATED PARTS

Remove timing belt, camshaft sprockets and related parts.

<Ref. to 2-3b [W2A0].>

2. CAMSHAFT

S2M0298A

(1) Spark plug cord

(2) Rocker cover (LH)

(3) Rocker cover](/img/17/57435/w960_57435-160.png)

3. Camshaft

A: REMOVAL

1. RELATED PARTS

Remove timing belt, camshaft sprockets and related parts.

2. CAMSHAFT

S2M0298A

(1) Spark plug cord

(2) Rocker cover (LH)

(3) Rocker cover gasket (LH)(4) Intake camshaft cap (LH)

(5) Intake camshaft (LH)

(6) Exhaust camshaft cap (LH)(7) Exhaust camshaft (LH)

1) Remove camshaft position sensor (LH side

only).

2) Remove spark plug cord.

3) Remove rocker cover and gasket.4) Loosen intake camshaft cap bolts equally, a

little at a time in alphabetical sequence shown in

figure.

B2M1393B

5) Remove camshaft caps and intake camshaft.

30

2-3b[W3A1]SERVICE PROCEDURE

3. Camshaft

Page 166 of 1456

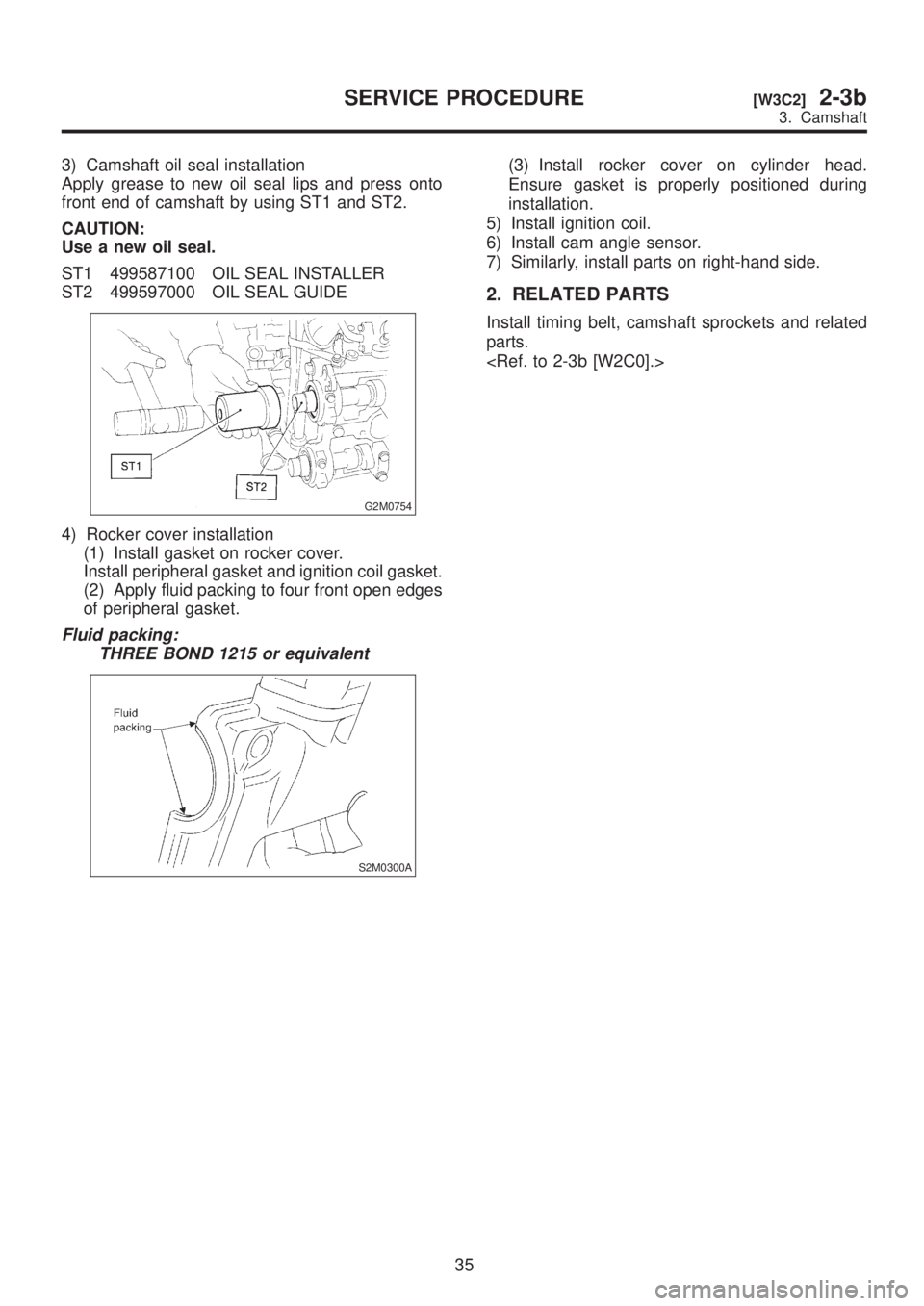

3) Camshaft oil seal installation

Apply grease to new oil seal lips and press onto

front end of camshaft by using ST1 and ST2.

CAUTION:

Use a new oil seal.

ST1 499587100 OIL SEAL INSTALLER

ST2 499597000 OIL SEAL GUIDE

G2M0754

4) Rocker cover installation

(1) Install gasket on rocker cover.

Install peripheral gasket and ignition coil gasket.

(2) Apply fluid packing to four front open edges

of peripheral gasket.

Fluid packing:

THREE BOND 1215 or equivalent

S2M0300A

(3) Install rocker cover on cylinder head.

Ensure gasket is properly positioned during

installation.

5) Install ignition coil.

6) Install cam angle sensor.

7) Similarly, install parts on right-hand side.

2. RELATED PARTS

Install timing belt, camshaft sprockets and related

parts.

35

[W3C2]2-3bSERVICE PROCEDURE

3. Camshaft

Page 167 of 1456

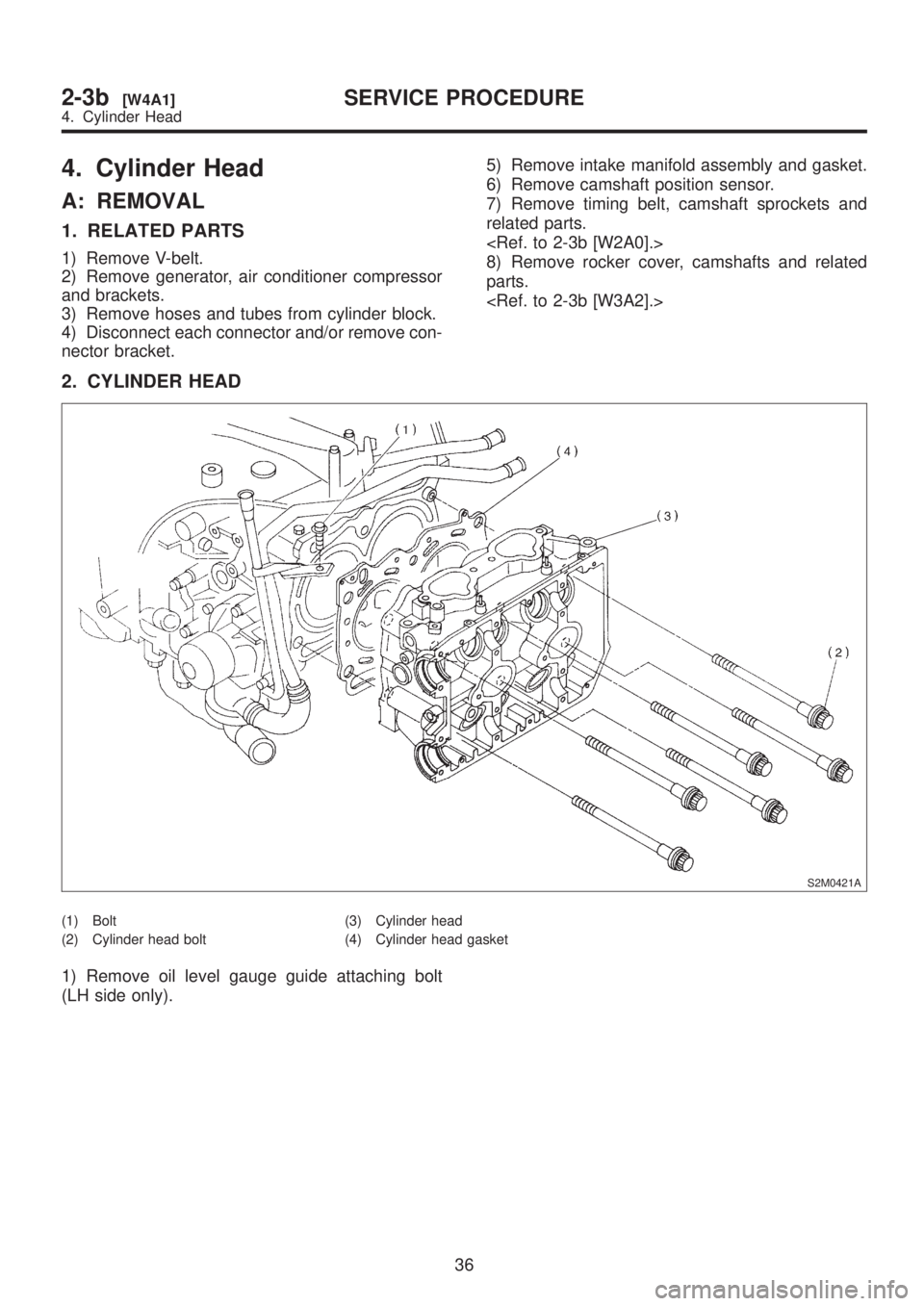

4. Cylinder Head

A: REMOVAL

1. RELATED PARTS

1) Remove V-belt.

2) Remove generator, air conditioner compressor

and brackets.

3) Remove hoses and tubes from cylinder block.

4) Disconnect each connector and/or remove con-

nector bracket.5) Remove intake manifold assembly and gasket.

6) Remove camshaft position sensor.

7) Remove timing belt, camshaft sprockets and

related parts.

8) Remove rocker cover, camshafts and related

parts.

2. CYLINDER HEAD

S2M0421A

(1) Bolt

(2) Cylinder head bolt(3) Cylinder head

(4) Cylinder head gasket

1) Remove oil level gauge guide attaching bolt

(LH side only).

36

2-3b[W4A1]SERVICE PROCEDURE

4. Cylinder Head

Page 178 of 1456

![SUBARU LEGACY 1999 Service Owners Manual 3) Install camshaft sprockets, timing belt and related parts.

<Ref. to 2-3b [W2C1].>

S2M0303

4) Install intake manifold.

CAUTION:

Use new gaskets.

G2M0774

5) Install camshaft position sensor. Use dry SUBARU LEGACY 1999 Service Owners Manual 3) Install camshaft sprockets, timing belt and related parts.

<Ref. to 2-3b [W2C1].>

S2M0303

4) Install intake manifold.

CAUTION:

Use new gaskets.

G2M0774

5) Install camshaft position sensor. Use dry](/img/17/57435/w960_57435-177.png)

3) Install camshaft sprockets, timing belt and related parts.

S2M0303

4) Install intake manifold.

CAUTION:

Use new gaskets.

G2M0774

5) Install camshaft position sensor. Use dry com-

pressed air to remove foreign particles before

installing sensor.

6) Connect each connector and/or install connec-

tor bracket.

7) Connect hoses and tubes to cylinder block.

8) Install brackets, generator and air conditioner

compressor.

9) Install V-belt.

47

[W4E2]2-3bSERVICE PROCEDURE

4. Cylinder Head

Page 212 of 1456

![SUBARU LEGACY 1999 Service Owners Manual 1. Oil Pump

A: REMOVAL

1) Disconnect battery ground cable.

G6M0095

2) Lift-up the vehicle.

3) Remove under cover.

B2M0014

4) Drain coolant. <Ref. to 2-5 [W1A0].>

B2M0015A

5) Remove radiator. <Ref. to SUBARU LEGACY 1999 Service Owners Manual 1. Oil Pump

A: REMOVAL

1) Disconnect battery ground cable.

G6M0095

2) Lift-up the vehicle.

3) Remove under cover.

B2M0014

4) Drain coolant. <Ref. to 2-5 [W1A0].>

B2M0015A

5) Remove radiator. <Ref. to](/img/17/57435/w960_57435-211.png)

1. Oil Pump

A: REMOVAL

1) Disconnect battery ground cable.

G6M0095

2) Lift-up the vehicle.

3) Remove under cover.

B2M0014

4) Drain coolant.

B2M0015A

5) Remove radiator.

S2M0033

6) Lower the vehicle.

7) Remove crankshaft position sensor.

B2M1252A

8) Remove camshaft position sensor.

G2M0417

9) Remove V-belts.

G2M0286

10) Remove rear side V-belt tensioner.

S2M0113

6

2-4[W1A0]SERVICE PROCEDURE

1. Oil Pump

Page 218 of 1456

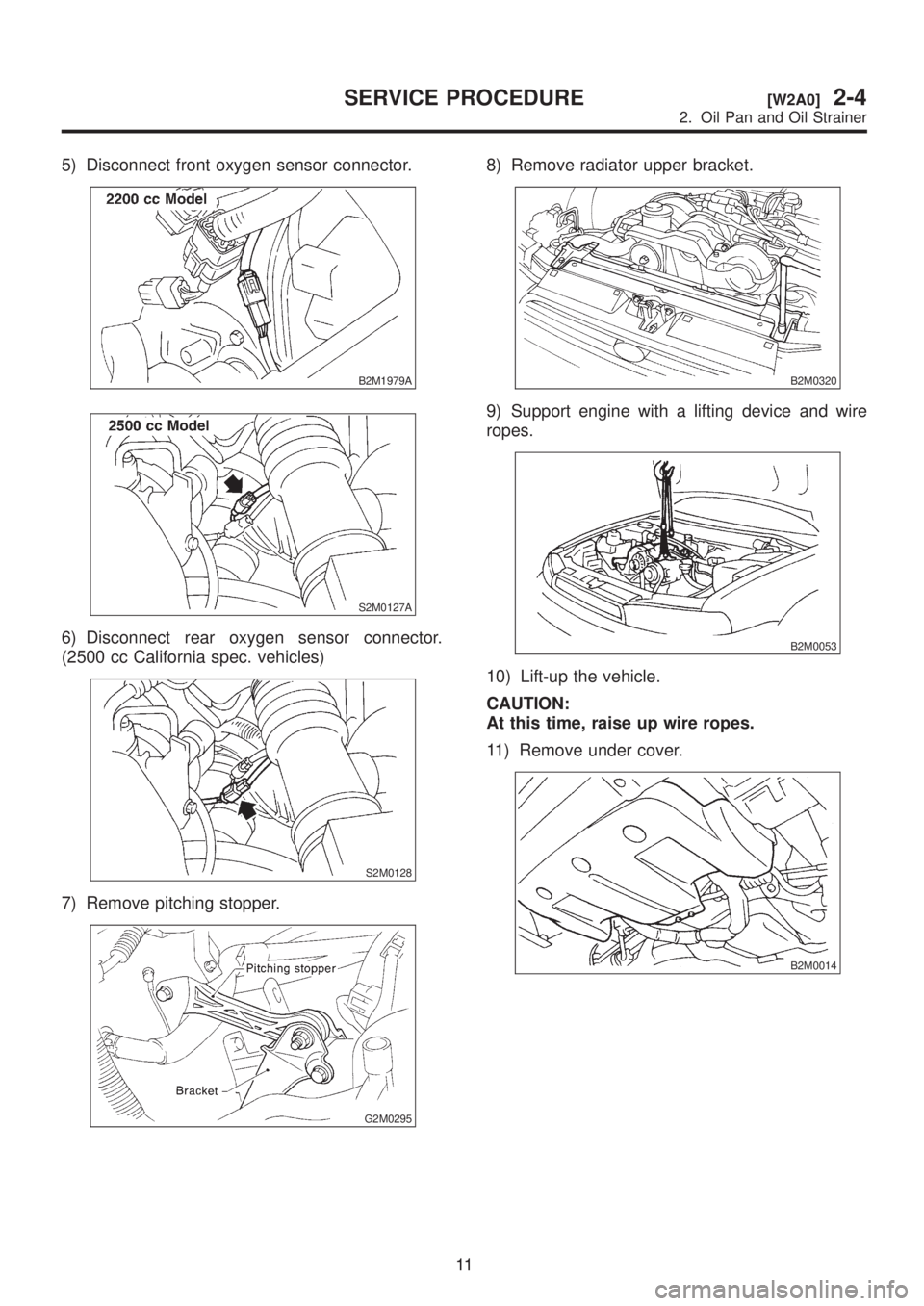

5) Disconnect front oxygen sensor connector.

B2M1979A

S2M0127A

6) Disconnect rear oxygen sensor connector.

(2500 cc California spec. vehicles)

S2M0128

7) Remove pitching stopper.

G2M0295

8) Remove radiator upper bracket.

B2M0320

9) Support engine with a lifting device and wire

ropes.

B2M0053

10) Lift-up the vehicle.

CAUTION:

At this time, raise up wire ropes.

11) Remove under cover.

B2M0014

11

[W2A0]2-4SERVICE PROCEDURE

2. Oil Pan and Oil Strainer

Page 222 of 1456

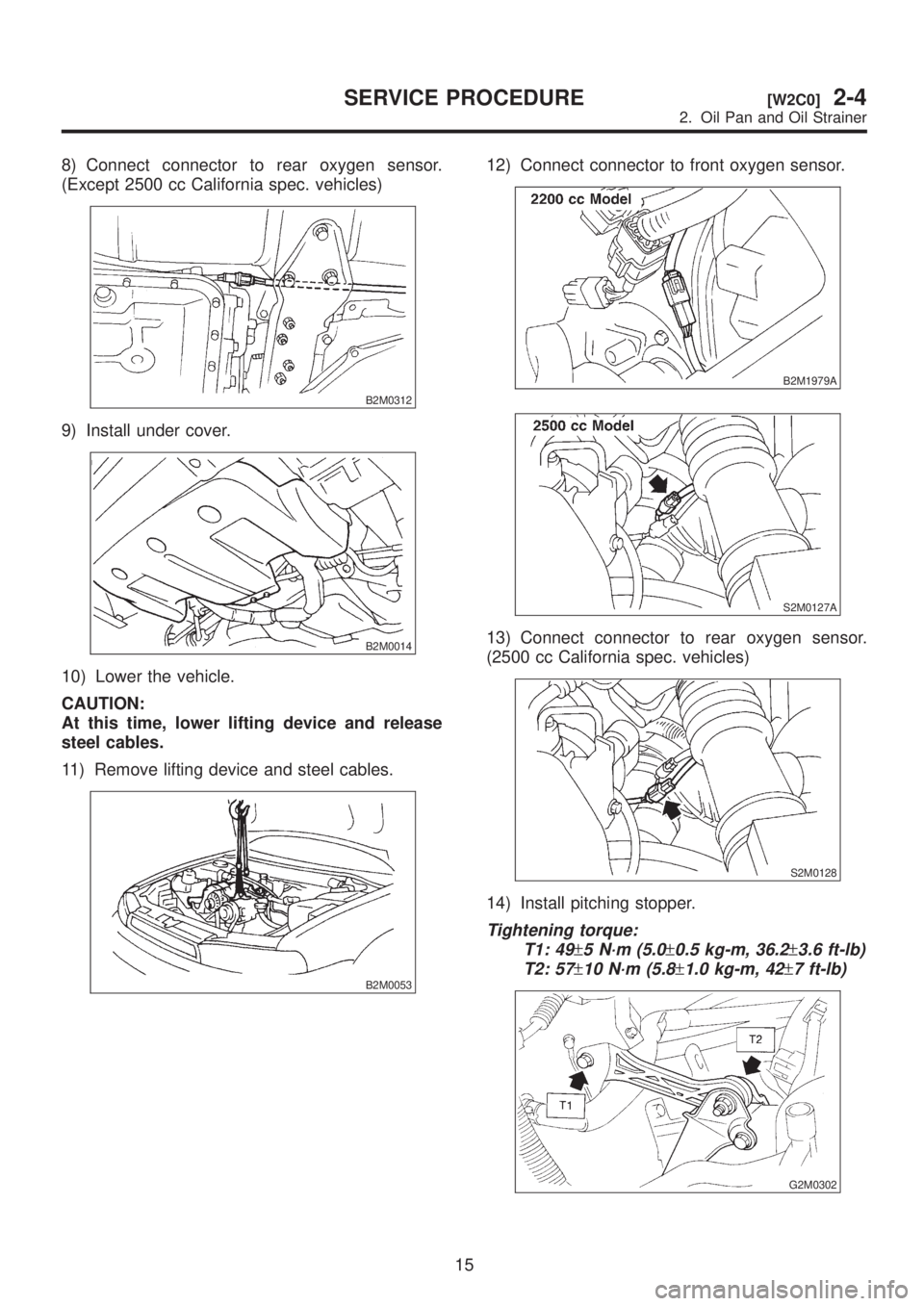

8) Connect connector to rear oxygen sensor.

(Except 2500 cc California spec. vehicles)

B2M0312

9) Install under cover.

B2M0014

10) Lower the vehicle.

CAUTION:

At this time, lower lifting device and release

steel cables.

11) Remove lifting device and steel cables.

B2M0053

12) Connect connector to front oxygen sensor.

B2M1979A

S2M0127A

13) Connect connector to rear oxygen sensor.

(2500 cc California spec. vehicles)

S2M0128

14) Install pitching stopper.

Tightening torque:

T1: 49

±5 N´m (5.0±0.5 kg-m, 36.2±3.6 ft-lb)

T2: 57

±10 N´m (5.8±1.0 kg-m, 42±7 ft-lb)

G2M0302

15

[W2C0]2-4SERVICE PROCEDURE

2. Oil Pan and Oil Strainer