check engine SUBARU LEGACY 1999 Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 916 of 1456

4. LACK OF BOOSTING ACTION CHECK

Turn off engine, and set the vacuum gauge read-

ing at ª0º. Then, check the fluid pressure when

brake pedal is depressed. The pressure must be

greater than the standard value listed below.

Brake pedal force147N (15 kg,

33 lb)294N (30kg, 66

lb)

Models without ABS785 kPa (8

kg/cm

2,114

psi)2,158 kPa (22

kg/cm2, 313 psi)

Models with ABS588 kPa (6

kg/cm

2, 85 psi)1,667 kPa (17

kg/cm2, 242 psi)

5. BOOSTING ACTION CHECK

Set the vacuum gauge reading at 66.7 kPa (500

mmHg, 19.69 inHg) by running engine. Then,

check the fluid pressure when brake pedal is

depressed. The pressure must be greater than the

standard value listed below.

Brake pedal force147N (15 kg,

33 lb)294N (30kg, 66

lb)

Models without ABS5,492 kPa (56

kg/cm

2, 796

psi)8,434 kPa (86

kg/cm2, 1,223 psi)

Models with ABS5,394 kPa (55

kg/cm

2,782 psi)10,003 kPa (102

kg/cm2, 1,450 psi)

7. Brake Hose

A: REMOVAL

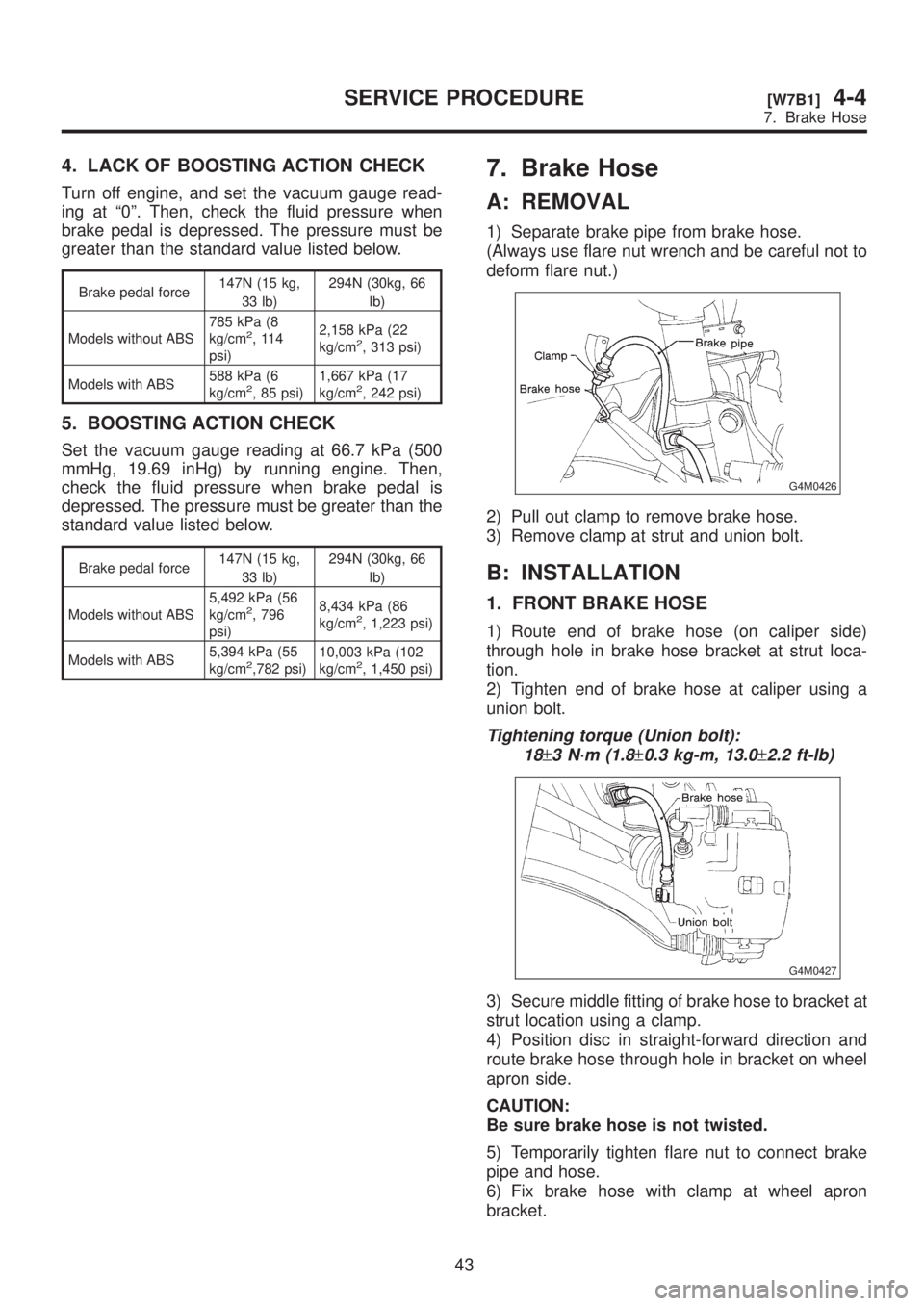

1) Separate brake pipe from brake hose.

(Always use flare nut wrench and be careful not to

deform flare nut.)

G4M0426

2) Pull out clamp to remove brake hose.

3) Remove clamp at strut and union bolt.

B: INSTALLATION

1. FRONT BRAKE HOSE

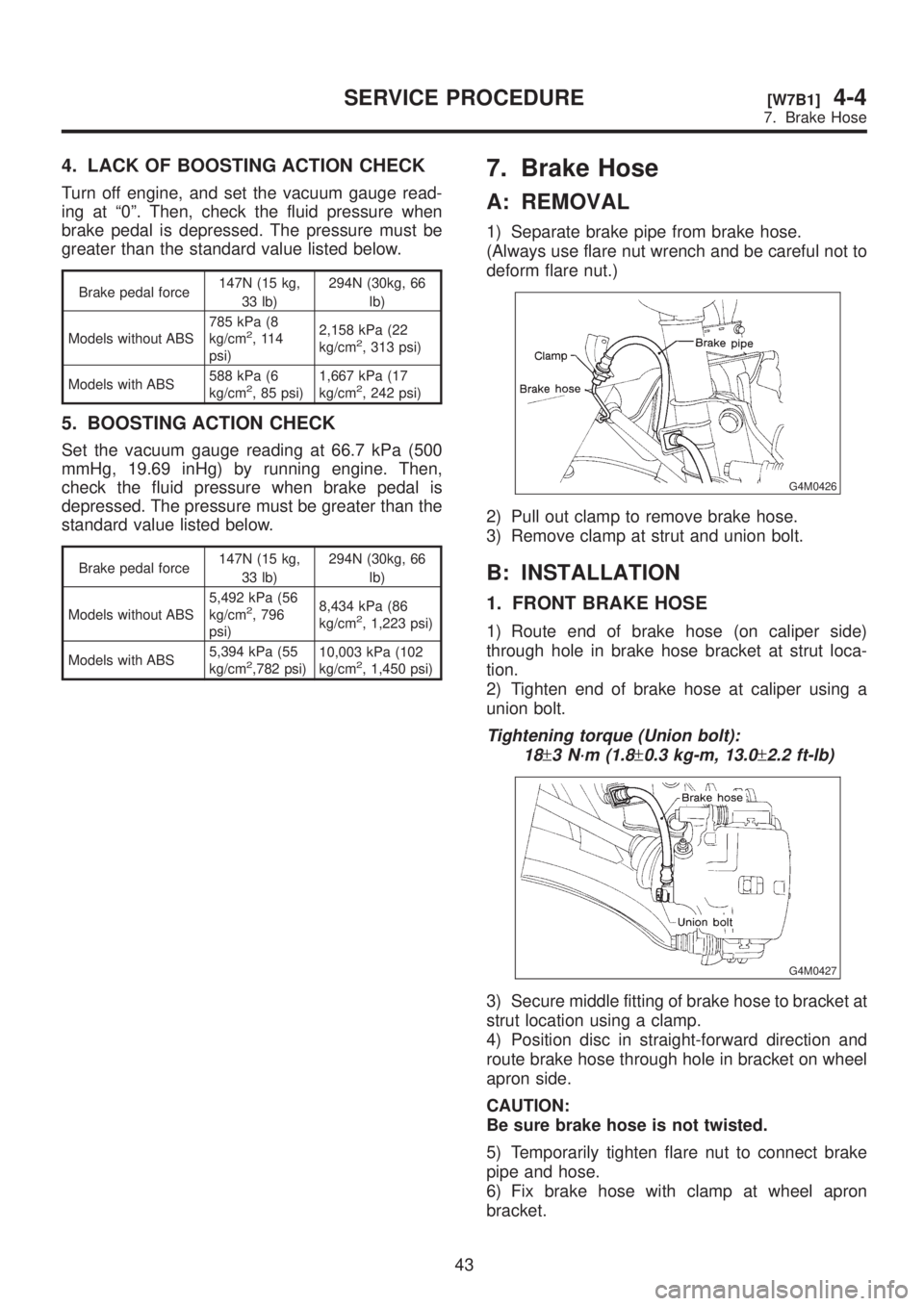

1) Route end of brake hose (on caliper side)

through hole in brake hose bracket at strut loca-

tion.

2) Tighten end of brake hose at caliper using a

union bolt.

Tightening torque (Union bolt):

18

±3 N´m (1.8±0.3 kg-m, 13.0±2.2 ft-lb)

G4M0427

3) Secure middle fitting of brake hose to bracket at

strut location using a clamp.

4) Position disc in straight-forward direction and

route brake hose through hole in bracket on wheel

apron side.

CAUTION:

Be sure brake hose is not twisted.

5) Temporarily tighten flare nut to connect brake

pipe and hose.

6) Fix brake hose with clamp at wheel apron

bracket.

43

[W7B1]4-4SERVICE PROCEDURE

7. Brake Hose

Page 917 of 1456

4. LACK OF BOOSTING ACTION CHECK

Turn off engine, and set the vacuum gauge read-

ing at ª0º. Then, check the fluid pressure when

brake pedal is depressed. The pressure must be

greater than the standard value listed below.

Brake pedal force147N (15 kg,

33 lb)294N (30kg, 66

lb)

Models without ABS785 kPa (8

kg/cm

2,114

psi)2,158 kPa (22

kg/cm2, 313 psi)

Models with ABS588 kPa (6

kg/cm

2, 85 psi)1,667 kPa (17

kg/cm2, 242 psi)

5. BOOSTING ACTION CHECK

Set the vacuum gauge reading at 66.7 kPa (500

mmHg, 19.69 inHg) by running engine. Then,

check the fluid pressure when brake pedal is

depressed. The pressure must be greater than the

standard value listed below.

Brake pedal force147N (15 kg,

33 lb)294N (30kg, 66

lb)

Models without ABS5,492 kPa (56

kg/cm

2, 796

psi)8,434 kPa (86

kg/cm2, 1,223 psi)

Models with ABS5,394 kPa (55

kg/cm

2,782 psi)10,003 kPa (102

kg/cm2, 1,450 psi)

7. Brake Hose

A: REMOVAL

1) Separate brake pipe from brake hose.

(Always use flare nut wrench and be careful not to

deform flare nut.)

G4M0426

2) Pull out clamp to remove brake hose.

3) Remove clamp at strut and union bolt.

B: INSTALLATION

1. FRONT BRAKE HOSE

1) Route end of brake hose (on caliper side)

through hole in brake hose bracket at strut loca-

tion.

2) Tighten end of brake hose at caliper using a

union bolt.

Tightening torque (Union bolt):

18

±3 N´m (1.8±0.3 kg-m, 13.0±2.2 ft-lb)

G4M0427

3) Secure middle fitting of brake hose to bracket at

strut location using a clamp.

4) Position disc in straight-forward direction and

route brake hose through hole in bracket on wheel

apron side.

CAUTION:

Be sure brake hose is not twisted.

5) Temporarily tighten flare nut to connect brake

pipe and hose.

6) Fix brake hose with clamp at wheel apron

bracket.

43

[W7B1]4-4SERVICE PROCEDURE

7. Brake Hose

Page 918 of 1456

7) While holding hexagonal part of brake hose fit-

ting with a wrench, tighten flare nut to the specified

torque.

Tightening torque (Brake pipe flare nut):

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

8) Bleed air from the brake system.

2. REAR BRAKE HOSE

1) Pass brake hose through the hole of bracket,

and lightly tighten flare nut to connect brake pipe.

2) Insert clamp upward to fix brake hose.

3) While holding hexagonal part of brake hose fit-

ting with a wrench, tighten flare nut to the specified

torque.

Tightening torque (Brake pipe flare nut):

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

4) Bleed air from the brake system.

8. Hill Holder

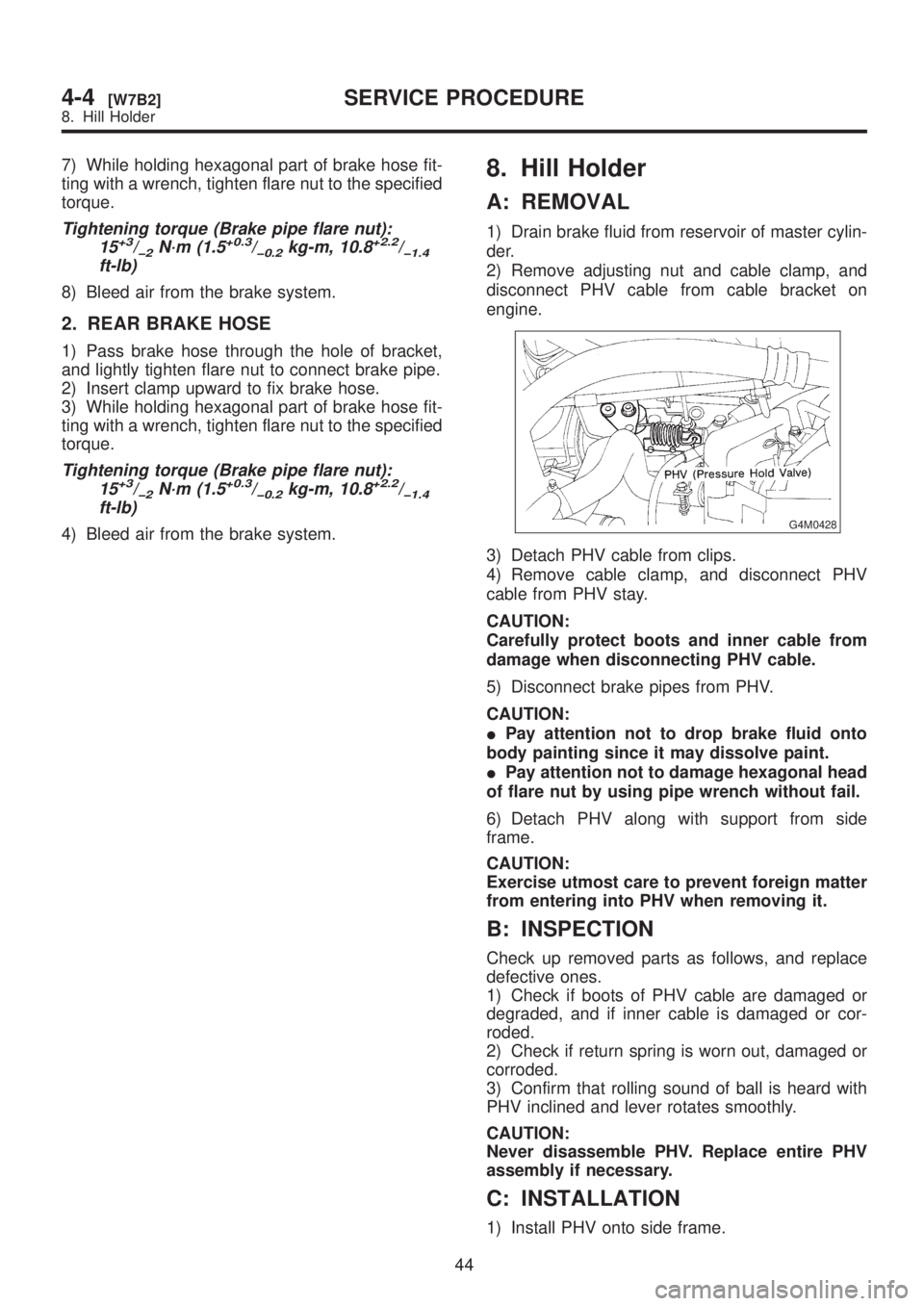

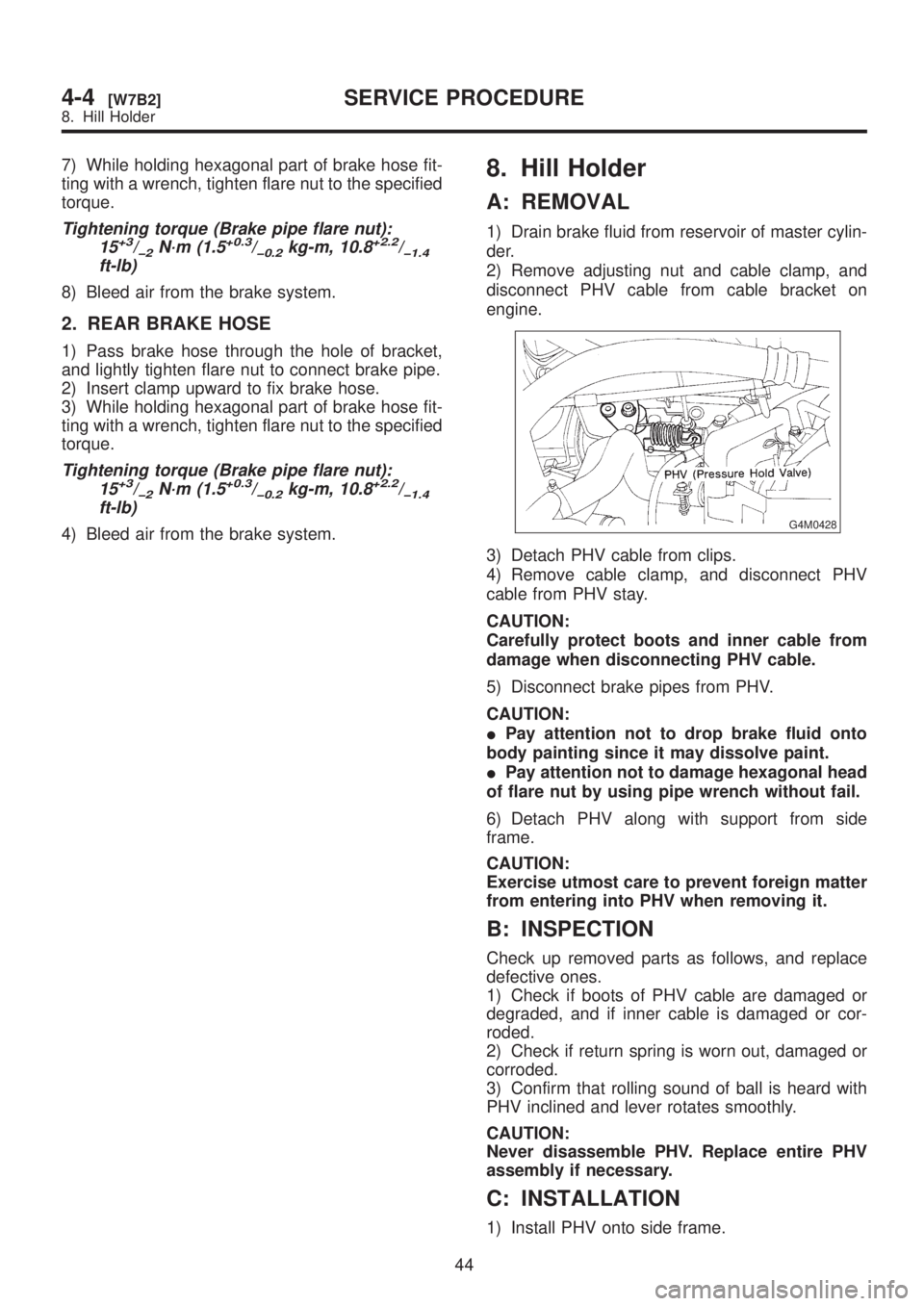

A: REMOVAL

1) Drain brake fluid from reservoir of master cylin-

der.

2) Remove adjusting nut and cable clamp, and

disconnect PHV cable from cable bracket on

engine.

G4M0428

3) Detach PHV cable from clips.

4) Remove cable clamp, and disconnect PHV

cable from PHV stay.

CAUTION:

Carefully protect boots and inner cable from

damage when disconnecting PHV cable.

5) Disconnect brake pipes from PHV.

CAUTION:

IPay attention not to drop brake fluid onto

body painting since it may dissolve paint.

IPay attention not to damage hexagonal head

of flare nut by using pipe wrench without fail.

6) Detach PHV along with support from side

frame.

CAUTION:

Exercise utmost care to prevent foreign matter

from entering into PHV when removing it.

B: INSPECTION

Check up removed parts as follows, and replace

defective ones.

1) Check if boots of PHV cable are damaged or

degraded, and if inner cable is damaged or cor-

roded.

2) Check if return spring is worn out, damaged or

corroded.

3) Confirm that rolling sound of ball is heard with

PHV inclined and lever rotates smoothly.

CAUTION:

Never disassemble PHV. Replace entire PHV

assembly if necessary.

C: INSTALLATION

1) Install PHV onto side frame.

44

4-4[W7B2]SERVICE PROCEDURE

8. Hill Holder

Page 919 of 1456

7) While holding hexagonal part of brake hose fit-

ting with a wrench, tighten flare nut to the specified

torque.

Tightening torque (Brake pipe flare nut):

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

8) Bleed air from the brake system.

2. REAR BRAKE HOSE

1) Pass brake hose through the hole of bracket,

and lightly tighten flare nut to connect brake pipe.

2) Insert clamp upward to fix brake hose.

3) While holding hexagonal part of brake hose fit-

ting with a wrench, tighten flare nut to the specified

torque.

Tightening torque (Brake pipe flare nut):

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

4) Bleed air from the brake system.

8. Hill Holder

A: REMOVAL

1) Drain brake fluid from reservoir of master cylin-

der.

2) Remove adjusting nut and cable clamp, and

disconnect PHV cable from cable bracket on

engine.

G4M0428

3) Detach PHV cable from clips.

4) Remove cable clamp, and disconnect PHV

cable from PHV stay.

CAUTION:

Carefully protect boots and inner cable from

damage when disconnecting PHV cable.

5) Disconnect brake pipes from PHV.

CAUTION:

IPay attention not to drop brake fluid onto

body painting since it may dissolve paint.

IPay attention not to damage hexagonal head

of flare nut by using pipe wrench without fail.

6) Detach PHV along with support from side

frame.

CAUTION:

Exercise utmost care to prevent foreign matter

from entering into PHV when removing it.

B: INSPECTION

Check up removed parts as follows, and replace

defective ones.

1) Check if boots of PHV cable are damaged or

degraded, and if inner cable is damaged or cor-

roded.

2) Check if return spring is worn out, damaged or

corroded.

3) Confirm that rolling sound of ball is heard with

PHV inclined and lever rotates smoothly.

CAUTION:

Never disassemble PHV. Replace entire PHV

assembly if necessary.

C: INSTALLATION

1) Install PHV onto side frame.

44

4-4[W7B2]SERVICE PROCEDURE

8. Hill Holder

Page 925 of 1456

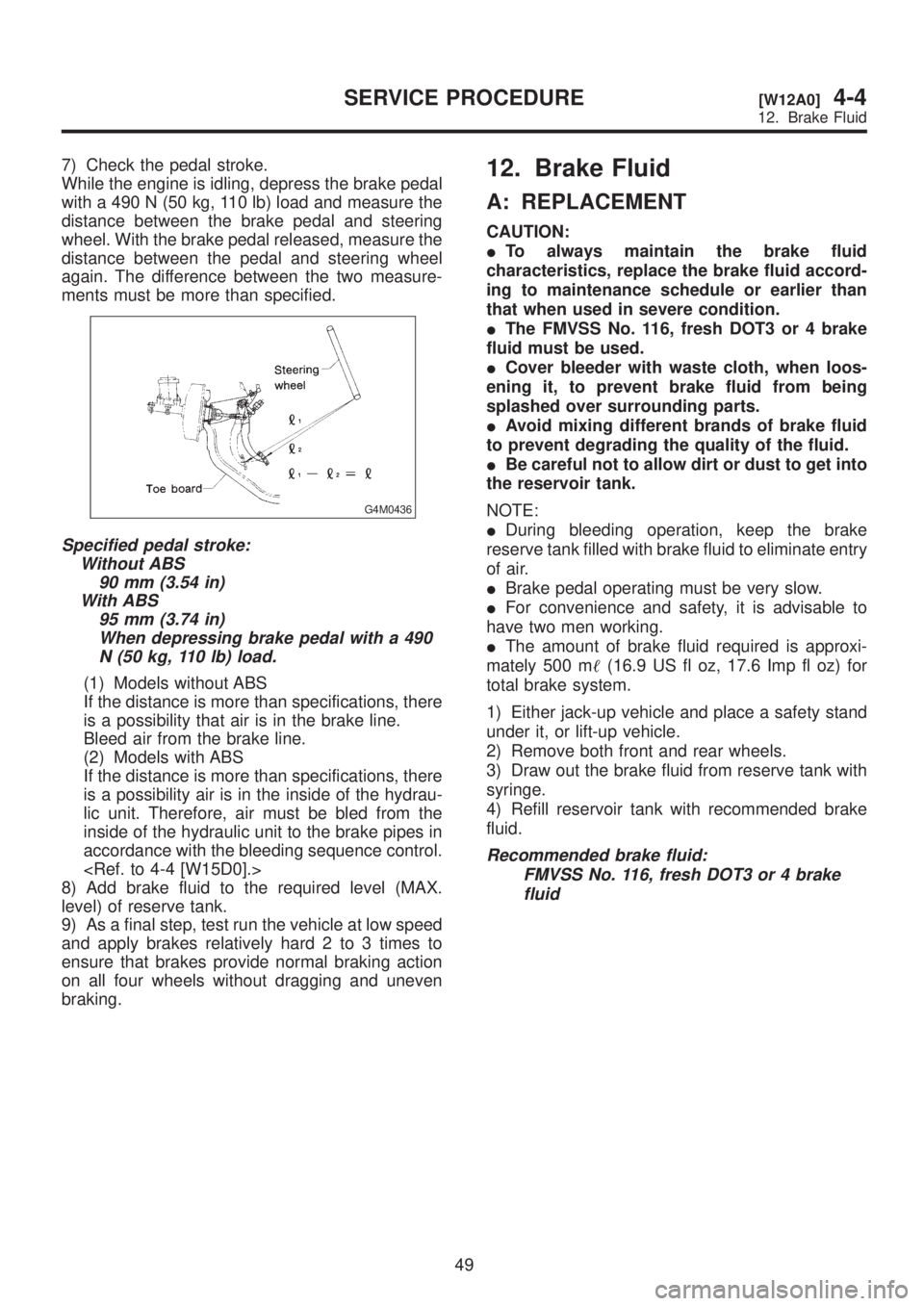

7) Check the pedal stroke.

While the engine is idling, depress the brake pedal

with a 490 N (50 kg, 110 lb) load and measure the

distance between the brake pedal and steering

wheel. With the brake pedal released, measure the

distance between the pedal and steering wheel

again. The difference between the two measure-

ments must be more than specified.

G4M0436

Specified pedal stroke:

Without ABS

90 mm (3.54 in)

With ABS

95 mm (3.74 in)

When depressing brake pedal with a 490

N (50 kg, 110 lb) load.

(1) Models without ABS

If the distance is more than specifications, there

is a possibility that air is in the brake line.

Bleed air from the brake line.

(2) Models with ABS

If the distance is more than specifications, there

is a possibility air is in the inside of the hydrau-

lic unit. Therefore, air must be bled from the

inside of the hydraulic unit to the brake pipes in

accordance with the bleeding sequence control.

8) Add brake fluid to the required level (MAX.

level) of reserve tank.

9) As a final step, test run the vehicle at low speed

and apply brakes relatively hard 2 to 3 times to

ensure that brakes provide normal braking action

on all four wheels without dragging and uneven

braking.

12. Brake Fluid

A: REPLACEMENT

CAUTION:

ITo always maintain the brake fluid

characteristics, replace the brake fluid accord-

ing to maintenance schedule or earlier than

that when used in severe condition.

IThe FMVSS No. 116, fresh DOT3 or 4 brake

fluid must be used.

ICover bleeder with waste cloth, when loos-

ening it, to prevent brake fluid from being

splashed over surrounding parts.

IAvoid mixing different brands of brake fluid

to prevent degrading the quality of the fluid.

IBe careful not to allow dirt or dust to get into

the reservoir tank.

NOTE:

IDuring bleeding operation, keep the brake

reserve tank filled with brake fluid to eliminate entry

of air.

IBrake pedal operating must be very slow.

IFor convenience and safety, it is advisable to

have two men working.

IThe amount of brake fluid required is approxi-

mately 500 m(16.9 US fl oz, 17.6 Imp fl oz) for

total brake system.

1) Either jack-up vehicle and place a safety stand

under it, or lift-up vehicle.

2) Remove both front and rear wheels.

3) Draw out the brake fluid from reserve tank with

syringe.

4) Refill reservoir tank with recommended brake

fluid.

Recommended brake fluid:

FMVSS No. 116, fresh DOT3 or 4 brake

fluid

49

[W12A0]4-4SERVICE PROCEDURE

12. Brake Fluid

Page 926 of 1456

7) Check the pedal stroke.

While the engine is idling, depress the brake pedal

with a 490 N (50 kg, 110 lb) load and measure the

distance between the brake pedal and steering

wheel. With the brake pedal released, measure the

distance between the pedal and steering wheel

again. The difference between the two measure-

ments must be more than specified.

G4M0436

Specified pedal stroke:

Without ABS

90 mm (3.54 in)

With ABS

95 mm (3.74 in)

When depressing brake pedal with a 490

N (50 kg, 110 lb) load.

(1) Models without ABS

If the distance is more than specifications, there

is a possibility that air is in the brake line.

Bleed air from the brake line.

(2) Models with ABS

If the distance is more than specifications, there

is a possibility air is in the inside of the hydrau-

lic unit. Therefore, air must be bled from the

inside of the hydraulic unit to the brake pipes in

accordance with the bleeding sequence control.

8) Add brake fluid to the required level (MAX.

level) of reserve tank.

9) As a final step, test run the vehicle at low speed

and apply brakes relatively hard 2 to 3 times to

ensure that brakes provide normal braking action

on all four wheels without dragging and uneven

braking.

12. Brake Fluid

A: REPLACEMENT

CAUTION:

ITo always maintain the brake fluid

characteristics, replace the brake fluid accord-

ing to maintenance schedule or earlier than

that when used in severe condition.

IThe FMVSS No. 116, fresh DOT3 or 4 brake

fluid must be used.

ICover bleeder with waste cloth, when loos-

ening it, to prevent brake fluid from being

splashed over surrounding parts.

IAvoid mixing different brands of brake fluid

to prevent degrading the quality of the fluid.

IBe careful not to allow dirt or dust to get into

the reservoir tank.

NOTE:

IDuring bleeding operation, keep the brake

reserve tank filled with brake fluid to eliminate entry

of air.

IBrake pedal operating must be very slow.

IFor convenience and safety, it is advisable to

have two men working.

IThe amount of brake fluid required is approxi-

mately 500 m(16.9 US fl oz, 17.6 Imp fl oz) for

total brake system.

1) Either jack-up vehicle and place a safety stand

under it, or lift-up vehicle.

2) Remove both front and rear wheels.

3) Draw out the brake fluid from reserve tank with

syringe.

4) Refill reservoir tank with recommended brake

fluid.

Recommended brake fluid:

FMVSS No. 116, fresh DOT3 or 4 brake

fluid

49

[W12A0]4-4SERVICE PROCEDURE

12. Brake Fluid

Page 929 of 1456

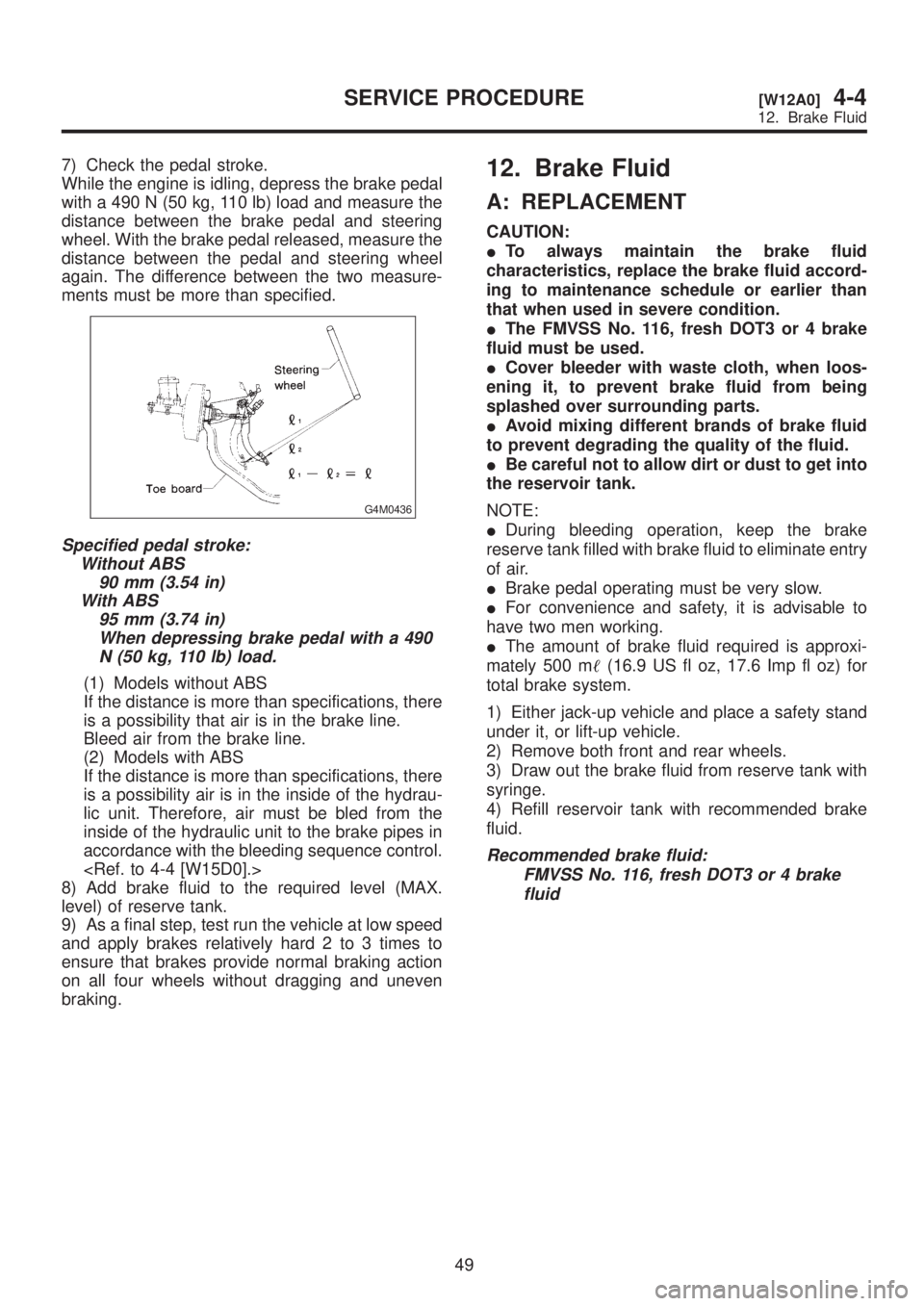

14. ABS Sensor

A: REMOVAL

1. FRONT ABS SENSOR

1) Disconnect front ABS sensor connector located

in engine compartment.

2) Remove bolts which secure sensor harness to

strut.

B4M0079A

3) Remove bolts which secure sensor harness to

body.

B4M1181A

4) Remove bolts which secure front ABS sensor to

housing, and remove front ABS sensor.

CAUTION:

IBe careful not to damage pole piece located

at tip of the sensor and teeth faces during

removal.

IDo not pull sensor harness during removal.

B4M1183A

5) Remove front disc brake caliper and disc rotor

from housing after removing front tire.6) Remove front drive shaft and housing and hub

assembly.

7) Remove tone wheel while removing hub from

housing and hub assembly.

CAUTION:

Be careful not to damage teeth faces of tone

wheel during removal.

G4M0444

2. REAR ABS SENSOR

1) Remove rear seat and disconnect rear ABS

sensor connector.

2) Remove rear sensor harness bracket from rear

trailing link and bracket.

3) Remove rear ABS sensor from rear back plate.

B4M1182A

4) Remove rear tone wheel while removing hub

from housing and hub assembly.

CAUTION:

IBe careful not to damage pole piece located

at tip of the sensor and teeth faces during

removal.

IDo not pull sensor harness during removal.

B: INSPECTION

1. ABS SENSOR

1) Check pole piece of ABS sensor for foreign par-

ticles or damage. If necessary, clean pole piece or

replace ABS sensor.

52

4-4[W14A1]SERVICE PROCEDURE

14. ABS Sensor

Page 933 of 1456

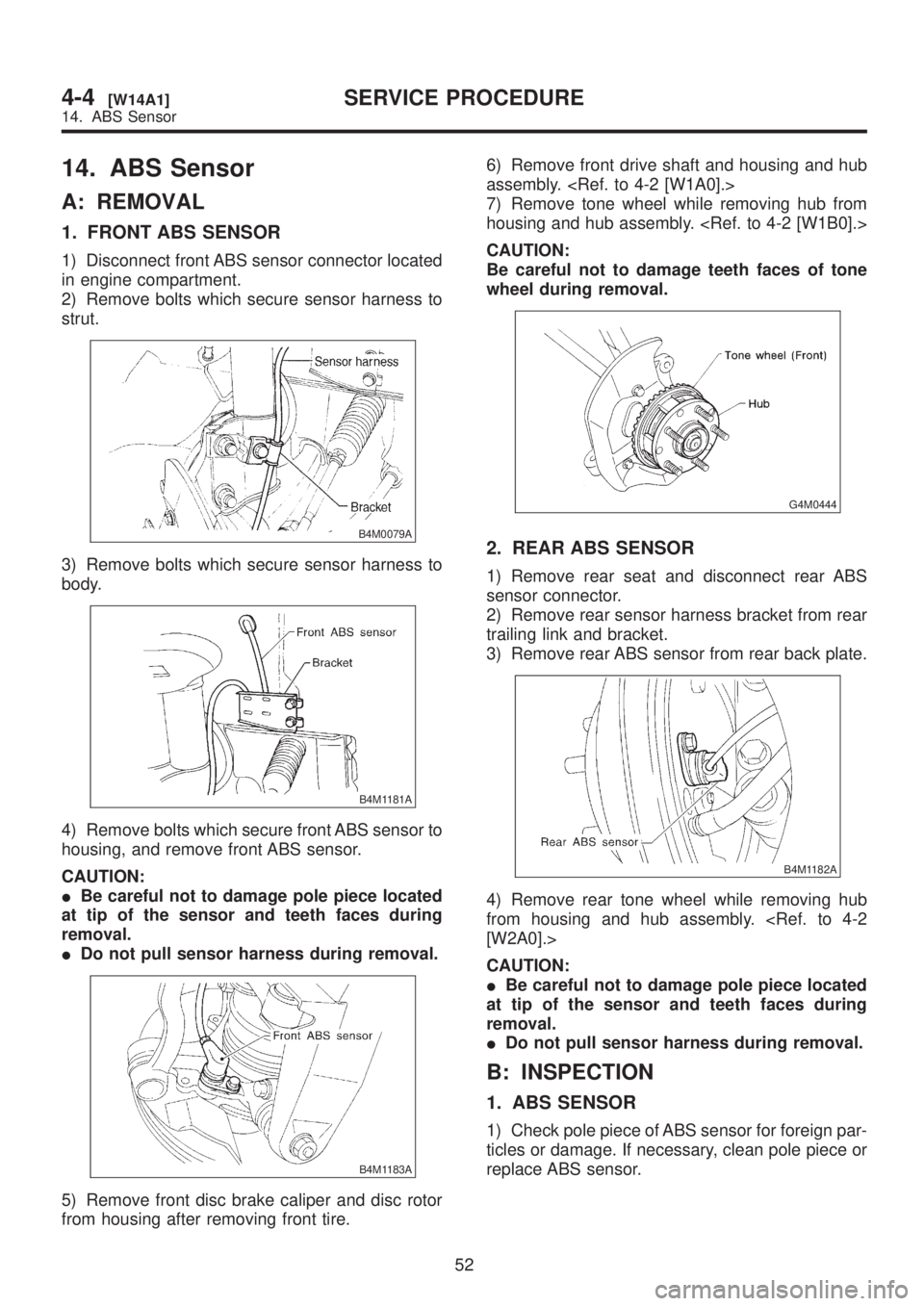

7) Disconnect brake pipes from ABSCM&H/U.

CAUTION:

Wrap brake pipes with vinyl bag to avoid spill-

ing brake fluid on vehicle body.

8) Remove ABSCM&H/U from engine compart-

ment.

CAUTION:

IABSCM&H/U cannot be disassembled. Do

not attempt to loosen bolts and nuts.

IDo not drop or bump ABSCM&H/U.

IDo not turn the ABSCM&H/U upside down or

place it on its side.

IBe careful to prevent foreign particles from

getting into ABSCM&H/U.

IApply a coat of rust-preventive wax (Nippeco

LT or GB) to bracket attaching bolt after tight-

ening.

IDo not pull harness disconnecting harness

connector.

B4M1222

B: INSPECTION

1) Check connected and fixed condition of con-

nector.

2) Check specifications of the mark with

ABSCM&H/U.

Mark Model

C5 AWD AT

C6 AWD MT

B4M1248A

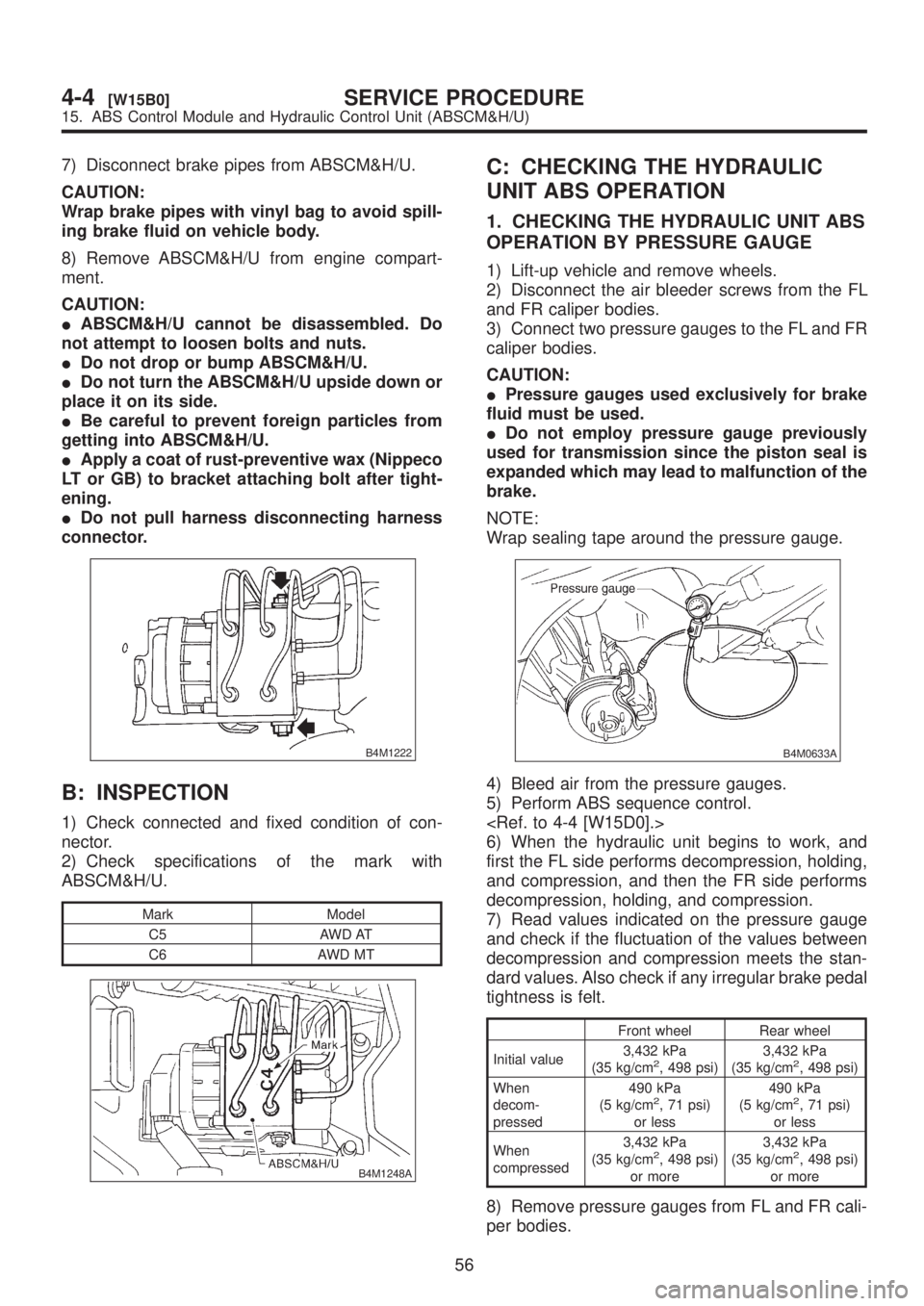

C: CHECKING THE HYDRAULIC

UNIT ABS OPERATION

1. CHECKING THE HYDRAULIC UNIT ABS

OPERATION BY PRESSURE GAUGE

1) Lift-up vehicle and remove wheels.

2) Disconnect the air bleeder screws from the FL

and FR caliper bodies.

3) Connect two pressure gauges to the FL and FR

caliper bodies.

CAUTION:

IPressure gauges used exclusively for brake

fluid must be used.

IDo not employ pressure gauge previously

used for transmission since the piston seal is

expanded which may lead to malfunction of the

brake.

NOTE:

Wrap sealing tape around the pressure gauge.

B4M0633A

4) Bleed air from the pressure gauges.

5) Perform ABS sequence control.

6) When the hydraulic unit begins to work, and

first the FL side performs decompression, holding,

and compression, and then the FR side performs

decompression, holding, and compression.

7) Read values indicated on the pressure gauge

and check if the fluctuation of the values between

decompression and compression meets the stan-

dard values. Also check if any irregular brake pedal

tightness is felt.

Front wheel Rear wheel

Initial value3,432 kPa

(35 kg/cm

2, 498 psi)3,432 kPa

(35 kg/cm2, 498 psi)

When

decom-

pressed490 kPa

(5 kg/cm

2, 71 psi)

or less490 kPa

(5 kg/cm2, 71 psi)

or less

When

compressed3,432 kPa

(35 kg/cm

2, 498 psi)

or more3,432 kPa

(35 kg/cm2, 498 psi)

or more

8) Remove pressure gauges from FL and FR cali-

per bodies.

56

4-4[W15B0]SERVICE PROCEDURE

15. ABS Control Module and Hydraulic Control Unit (ABSCM&H/U)

Page 934 of 1456

9) Remove air bleeder screws from the RL and RR

caliper bodies.

10) Connect the air bleeder screws to the FL and

FR caliper bodies.

11) Connect two pressure gauges to the RL and

RR caliper bodies.

12) Bleed air from the pressure gauges and the FL

and FR caliper bodies.

13) Perform ABS sequence control.

14) When the hydraulic unit begins to work, at first

the RR side performs decompression, holding, and

compression, and then the RL side performs

decompression, holding, and compression.

15) Read values indicated on the pressure

gauges and check if they meet the standard value.

16) After checking, remove the pressure gauges

from caliper bodies.

17) Connect the air bleeder screws to RL and RR

caliper bodies.

18) Bleed air from brake line.

2. CHECKING THE HYDRAULIC UNIT ABS

OPERATION WITH BRAKE TESTER

1) In the case of AWD AT vehicles, install a spare

fuse with the FWD connector in the engine com-

partment to simulate FWD vehicles.

G4M0462

2) Prepare for operating ABS sequence control.

3) Set the front wheels or rear wheels on the brake

tester and set the select lever's position at ªneu-

tralº.

G4M0464

4) Operate the brake tester.5) Perform ABS sequence control.

6) Hydraulic unit begins to work; and check the

following working sequence.

(1) The FL wheel performs decompression,

holding, and compression in sequence, and

subsequently the FR wheel repeats the cycle.

(2) The RR wheel performs decompression,

holding, and compression in sequence, and

subsequently the RL wheel repeats the cycle.

7) Read values indicated on the brake tester and

check if the fluctuation of values, when decom-

pressed and compressed, meet the standard val-

ues.

Front wheel Rear wheel

Initial value981 N

(100 kg, 221 lb)981 N

(100 kg, 221 lb)

When

decompressed490 N

(50 kg, 110 lb)

or less490 N

(50 kg, 110 lb)

or less

When

compressed981 N

(100 kg, 221 lb)

or more981 N

(100 kg, 221 lb)

or more

8) After checking, also check if any irregular brake

pedal tightness is felt.

D: ABS SEQUENCE CONTROL

1) Under the ABS sequence control, after the

hydraulic unit solenoid valve is driven, the opera-

tion of the hydraulic unit can be checked by means

of the brake tester or pressure gauge.

2) ABS sequence control can be started by diag-

nosis connector or select monitor.

1. OPERATIONAL GUIDELINES OF THE

ABS SEQUENCE CONTROL WITH

DIAGNOSIS CONNECTOR

1) Connect diagnosis terminals to terminals No. 3

and No. 6 of the diagnosis connector beside driv-

er's seat heater unit.

B4M0082D

2) Set the speed of all wheels at 4 km/h (2 MPH)

or less.

3) Turn ignition switch OFF.

57

[W15D1]4-4SERVICE PROCEDURE

15. ABS Control Module and Hydraulic Control Unit (ABSCM&H/U)

Page 935 of 1456

4) Within 0.5 seconds after the ABS warning light

goes out, depress the brake pedal and hold it

immediately after ignition switch is turned to ON.

CAUTION:

Do not depress the clutch pedal.

NOTE:

IWhen the ignition switch is set to on, the brake

pedal must not be depressed.

IEngine must not operate.

5) After completion of ABS sequence control, turn

ignition switch OFF.

2. OPERATIONAL GUIDELINES OF THE

ABS SEQUENCE CONTROL WITH

SELECT MONITOR

NOTE:

IIn the event of any trouble, the sequence con-

trol may not be operative. In such a case, activate

the sequence control, referring to ªOPERATIONAL

GUIDELINES OF THE ABS SEQUENCE CON-

TROL WITH DIAGNOSIS CONNECTORº.

IWhen the diagnosis terminal is connected to the

diagnosis connector, the sequence control will not

operate.

1) Connect select monitor to data link connector

beside driver's seat instrument panel lower cover.

2) Turn ignition switch ON.

3) Turn select monitor switch ON.

4) Put select monitor to {ABS/TCS} mode.

5) When {Function check sequence} is selected,

`ABS sequence control' will start.

6) The message `Press Brake Pedal Firmly' is dis-

played as follows:

(1) When using the brake tester, depress brake

pedal with braking force of 981 N (100 kg, 221

lb).

(2) When using the pressure gauge, depress

brake pedal so as to make the pressure gauge

indicate 3,432 kPa (35 kg/cm

2, 498 psi).

CAUTION:

Do not depress the clutch pedal.

7) When the message ªPress YESº is displayed,

press YES key.

8) Operation points will be displayed on select

monitor.

3. CONDITIONS FOR COMPLETION OF

ABS SEQUENCE CONTROL

When the following conditions develop, the ABS

sequence control stops and ABS operation is

returned to the normal control mode.

1) When the speed of at least one wheel reaches

10 km/h (6 MPH).

2) When terminal No. 3 or No. 6 are separated

from diagnosis terminals. (When select monitor is

not used.)

3) When the brake pedal is released during

sequence control and the braking lamp switch is

set to off.

4) When brake pedal is depressed after ignition

key is turned to ON, and before ABS warning light

goes out. (When select monitor is not used.)

5) When brake pedal is not depressed after igni-

tion key is turned to ON, and within 0.5 seconds

after ABS warning light goes out. (When select

monitor is not used.)

6) After completion of the sequence control.

7) When malfunction is detected. (When select

monitor is used.)

58

4-4[W15D2]SERVICE PROCEDURE

15. ABS Control Module and Hydraulic Control Unit (ABSCM&H/U)