check engine SUBARU LEGACY 1999 Service Manual PDF

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1226 of 1456

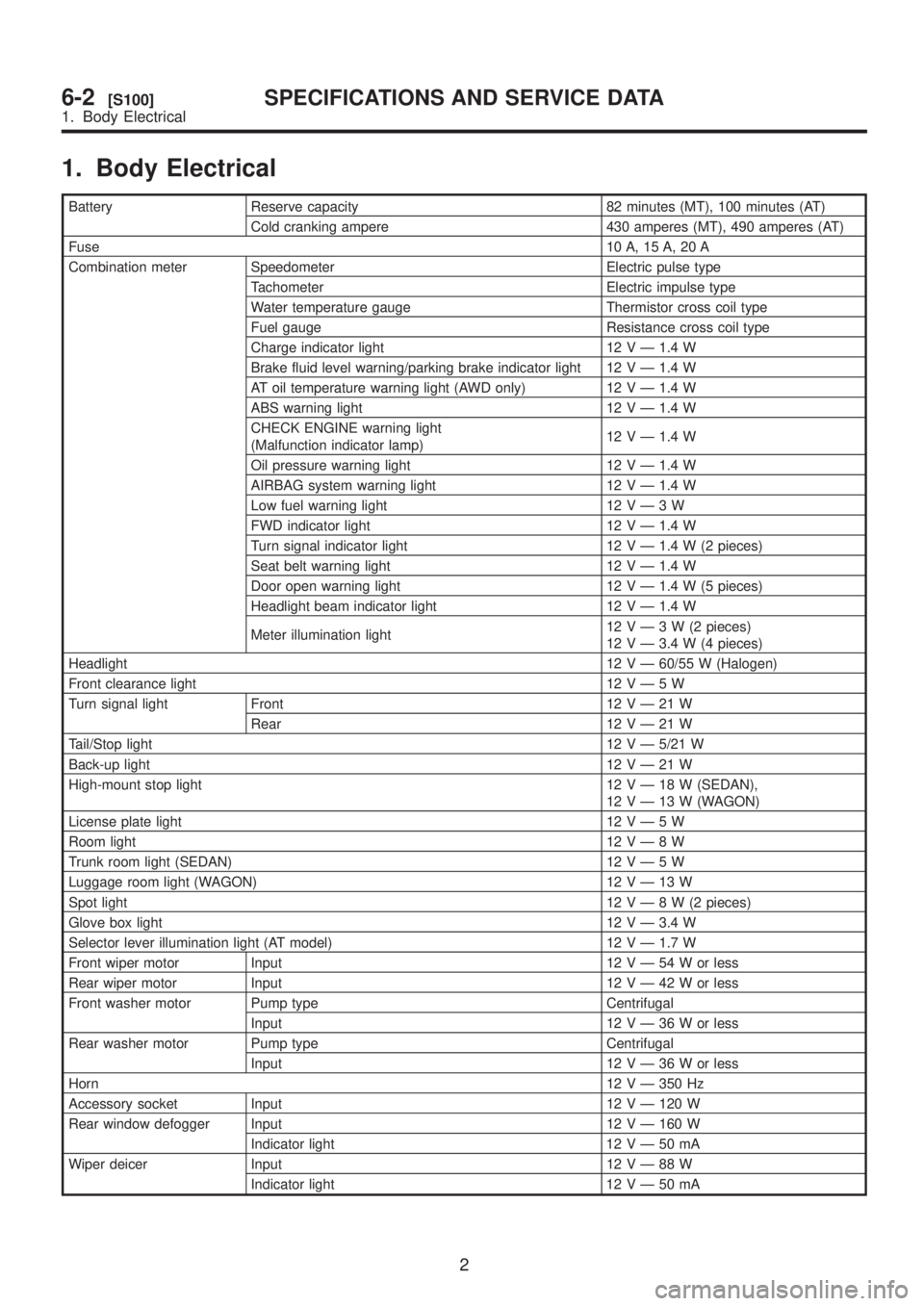

1. Body Electrical

Battery Reserve capacity 82 minutes (MT), 100 minutes (AT)

Cold cranking ampere 430 amperes (MT), 490 amperes (AT)

Fuse10 A, 15 A, 20 A

Combination meter Speedometer Electric pulse type

Tachometer Electric impulse type

Water temperature gauge Thermistor cross coil type

Fuel gauge Resistance cross coil type

Charge indicator light 12 V Ð 1.4 W

Brake fluid level warning/parking brake indicator light 12 V Ð 1.4 W

AT oil temperature warning light (AWD only) 12 V Ð 1.4 W

ABS warning light 12 V Ð 1.4 W

CHECK ENGINE warning light

(Malfunction indicator lamp)12 V Ð 1.4 W

Oil pressure warning light 12 V Ð 1.4 W

AIRBAG system warning light 12 V Ð 1.4 W

Low fuel warning light 12VÐ3W

FWD indicator light 12 V Ð 1.4 W

Turn signal indicator light 12 V Ð 1.4 W (2 pieces)

Seat belt warning light 12 V Ð 1.4 W

Door open warning light 12 V Ð 1.4 W (5 pieces)

Headlight beam indicator light 12 V Ð 1.4 W

Meter illumination light12VÐ3W(2pieces)

12 V Ð 3.4 W (4 pieces)

Headlight12 V Ð 60/55 W (Halogen)

Front clearance light 12VÐ5W

Turn signal light Front 12VÐ21W

Rear 12VÐ21W

Tail/Stop light12 V Ð 5/21 W

Back-up light12VÐ21W

High-mount stop light 12VÐ18W(SEDAN),

12VÐ13W(WAGON)

License plate light 12VÐ5W

Room light12VÐ8W

Trunk room light (SEDAN) 12VÐ5W

Luggage room light (WAGON) 12VÐ13W

Spot light12VÐ8W(2pieces)

Glove box light 12 V Ð 3.4 W

Selector lever illumination light (AT model) 12 V Ð 1.7 W

Front wiper motor Input 12VÐ54Worless

Rear wiper motor Input 12VÐ42Worless

Front washer motor Pump type Centrifugal

Input 12VÐ36Worless

Rear washer motor Pump type Centrifugal

Input 12VÐ36Worless

Horn12 V Ð 350 Hz

Accessory socket Input 12 V Ð 120 W

Rear window defogger Input 12 V Ð 160 W

Indicator light 12VÐ50mA

Wiper deicer Input 12VÐ88W

Indicator light 12VÐ50mA

2

6-2[S100]SPECIFICATIONS AND SERVICE DATA

1. Body Electrical

Page 1231 of 1456

4. Headlight

A: ADJUSTMENT

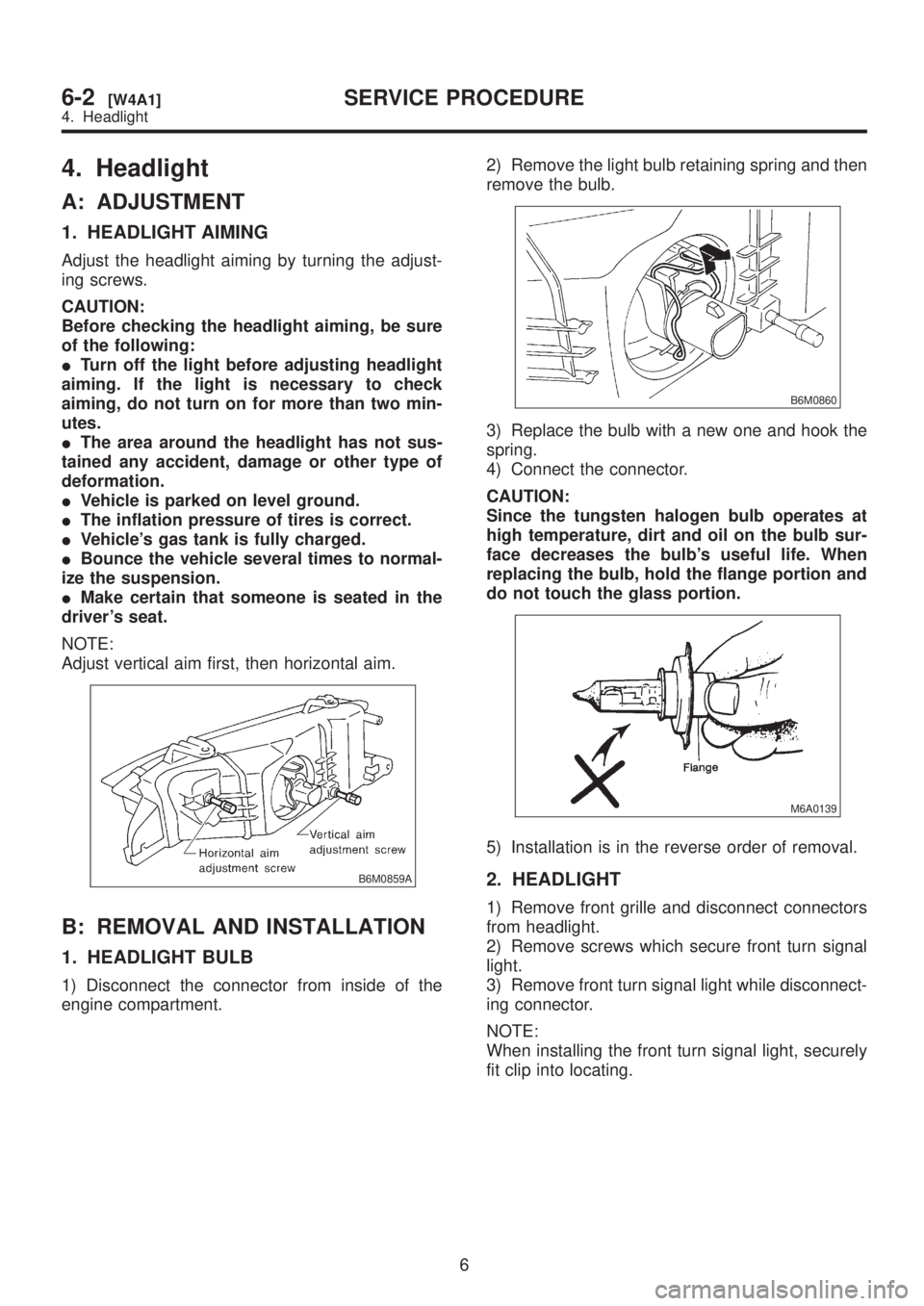

1. HEADLIGHT AIMING

Adjust the headlight aiming by turning the adjust-

ing screws.

CAUTION:

Before checking the headlight aiming, be sure

of the following:

ITurn off the light before adjusting headlight

aiming. If the light is necessary to check

aiming, do not turn on for more than two min-

utes.

IThe area around the headlight has not sus-

tained any accident, damage or other type of

deformation.

IVehicle is parked on level ground.

IThe inflation pressure of tires is correct.

IVehicle's gas tank is fully charged.

IBounce the vehicle several times to normal-

ize the suspension.

IMake certain that someone is seated in the

driver's seat.

NOTE:

Adjust vertical aim first, then horizontal aim.

B6M0859A

B: REMOVAL AND INSTALLATION

1. HEADLIGHT BULB

1) Disconnect the connector from inside of the

engine compartment.2) Remove the light bulb retaining spring and then

remove the bulb.

B6M0860

3) Replace the bulb with a new one and hook the

spring.

4) Connect the connector.

CAUTION:

Since the tungsten halogen bulb operates at

high temperature, dirt and oil on the bulb sur-

face decreases the bulb's useful life. When

replacing the bulb, hold the flange portion and

do not touch the glass portion.

M6A0139

5) Installation is in the reverse order of removal.

2. HEADLIGHT

1) Remove front grille and disconnect connectors

from headlight.

2) Remove screws which secure front turn signal

light.

3) Remove front turn signal light while disconnect-

ing connector.

NOTE:

When installing the front turn signal light, securely

fit clip into locating.

6

6-2[W4A1]SERVICE PROCEDURE

4. Headlight

Page 1240 of 1456

![SUBARU LEGACY 1999 Service Manual PDF 7. Turn Signal and Hazard

Warning Light

A: REMOVAL AND INSTALLATION

1. FRONT TURN SIGNAL LIGHT

Remove and install front turn signal light. <Ref. to

6-2 [W4B2].>

NOTE:

The front turn signal light is un SUBARU LEGACY 1999 Service Manual PDF 7. Turn Signal and Hazard

Warning Light

A: REMOVAL AND INSTALLATION

1. FRONT TURN SIGNAL LIGHT

Remove and install front turn signal light. <Ref. to

6-2 [W4B2].>

NOTE:

The front turn signal light is un](/img/17/57435/w960_57435-1239.png)

7. Turn Signal and Hazard

Warning Light

A: REMOVAL AND INSTALLATION

1. FRONT TURN SIGNAL LIGHT

Remove and install front turn signal light.

NOTE:

The front turn signal light is united with headlight

assembly.

2. REAR COMBINATION LIGHT

Remove and install rear combination light.

3. COMBINATION SWITCH

Remove and install combination switch.

4. HAZARD SWITCH

1) Remove center panel from instrument panel.

2) Disconnect connector of hazard switch from

body harness.

3) Remove hazard switch from center panel.

B6M0063

4) Installation is in the reverse order of removal.

5. TURN SIGNAL AND HAZARD UNIT

1) Remove instrument panel lower cover.

2) Remove engine hood opener lever bracket.

3) Disconnect connector of turn signal and hazard

unit.4) Remove screw, and then remove turn signal

and hazard unit from bracket.

B6M0343A

5) Installation is in the reverse order of removal.

B: DISASSEMBLY AND ASSEMBLY

1. COMBINATION SWITCH

Disassemble and assemble combination switch.

C: INSPECTION

1. COMBINATION SWITCH (ON-CAR)

1) Remove instrument panel lower cover.

2) Remove lower column cover.

3) Unfasten holddown clip which secures harness,

and disconnect connectors from body harness.

4) Move combination switch to respective posi-

tions and check continuity between terminals.

B6M0702

14

6-2[W7A1]SERVICE PROCEDURE

7. Turn Signal and Hazard Warning Light

Page 1253 of 1456

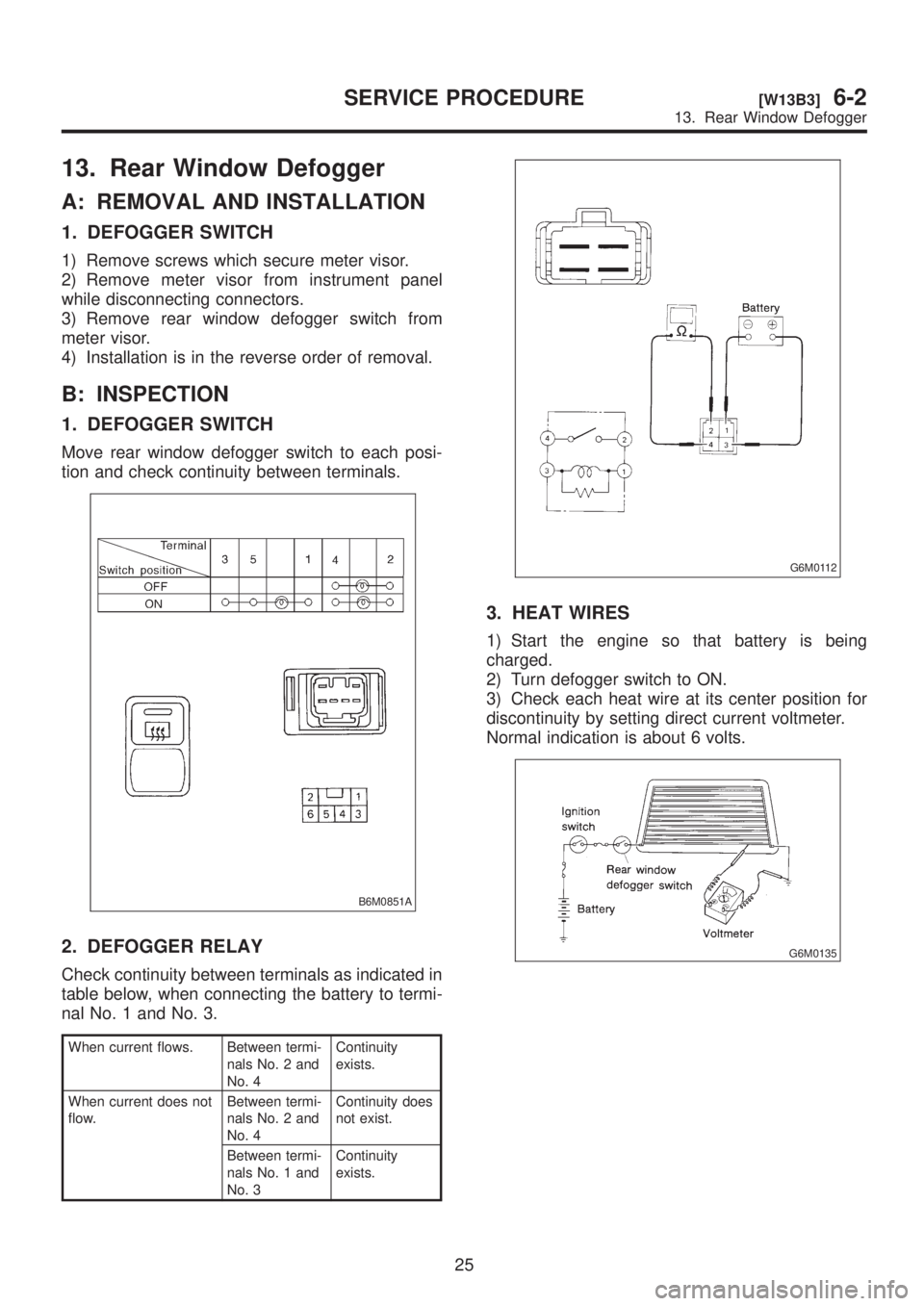

13. Rear Window Defogger

A: REMOVAL AND INSTALLATION

1. DEFOGGER SWITCH

1) Remove screws which secure meter visor.

2) Remove meter visor from instrument panel

while disconnecting connectors.

3) Remove rear window defogger switch from

meter visor.

4) Installation is in the reverse order of removal.

B: INSPECTION

1. DEFOGGER SWITCH

Move rear window defogger switch to each posi-

tion and check continuity between terminals.

B6M0851A

2. DEFOGGER RELAY

Check continuity between terminals as indicated in

table below, when connecting the battery to termi-

nal No. 1 and No. 3.

When current flows. Between termi-

nals No. 2 and

No. 4Continuity

exists.

When current does not

flow.Between termi-

nals No. 2 and

No. 4Continuity does

not exist.

Between termi-

nals No. 1 and

No. 3Continuity

exists.

G6M0112

3. HEAT WIRES

1) Start the engine so that battery is being

charged.

2) Turn defogger switch to ON.

3) Check each heat wire at its center position for

discontinuity by setting direct current voltmeter.

Normal indication is about 6 volts.

G6M0135

25

[W13B3]6-2SERVICE PROCEDURE

13. Rear Window Defogger

Page 1256 of 1456

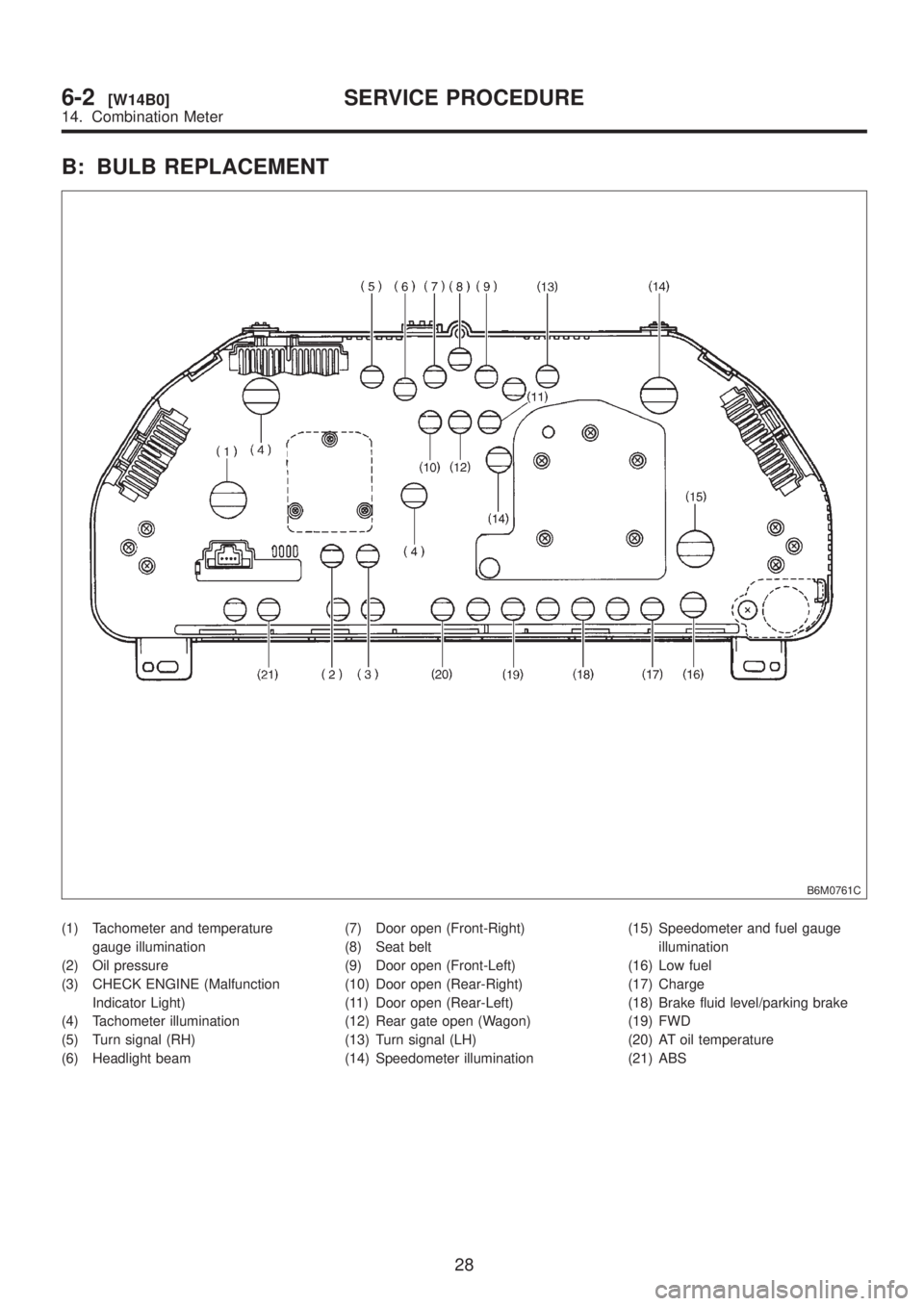

B: BULB REPLACEMENT

B6M0761C

(1) Tachometer and temperature

gauge illumination

(2) Oil pressure

(3) CHECK ENGINE (Malfunction

Indicator Light)

(4) Tachometer illumination

(5) Turn signal (RH)

(6) Headlight beam(7) Door open (Front-Right)

(8) Seat belt

(9) Door open (Front-Left)

(10) Door open (Rear-Right)

(11) Door open (Rear-Left)

(12) Rear gate open (Wagon)

(13) Turn signal (LH)

(14) Speedometer illumination(15) Speedometer and fuel gauge

illumination

(16) Low fuel

(17) Charge

(18) Brake fluid level/parking brake

(19) FWD

(20) AT oil temperature

(21) ABS

28

6-2[W14B0]SERVICE PROCEDURE

14. Combination Meter

Page 1258 of 1456

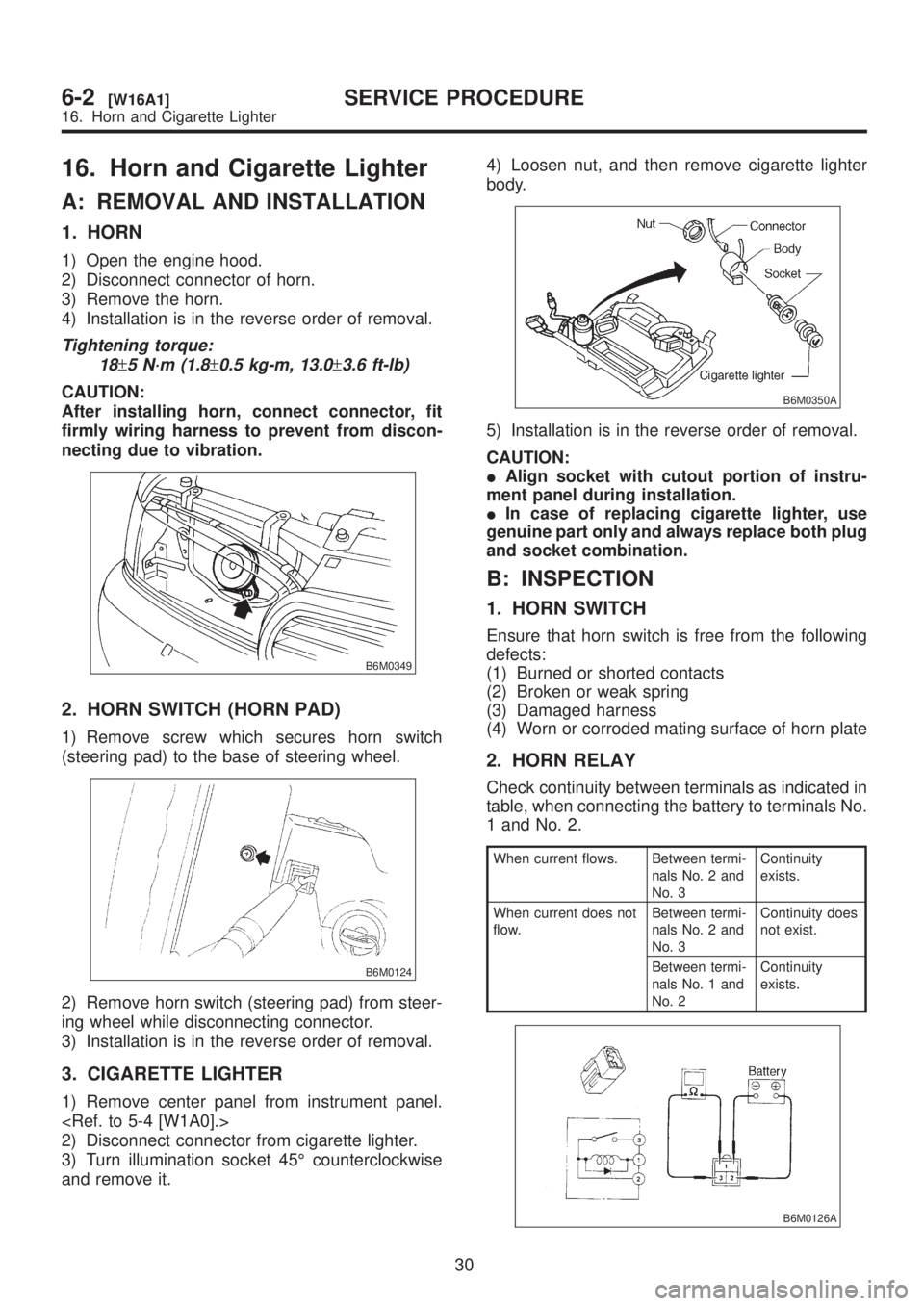

16. Horn and Cigarette Lighter

A: REMOVAL AND INSTALLATION

1. HORN

1) Open the engine hood.

2) Disconnect connector of horn.

3) Remove the horn.

4) Installation is in the reverse order of removal.

Tightening torque:

18

±5 N´m (1.8±0.5 kg-m, 13.0±3.6 ft-lb)

CAUTION:

After installing horn, connect connector, fit

firmly wiring harness to prevent from discon-

necting due to vibration.

B6M0349

2. HORN SWITCH (HORN PAD)

1) Remove screw which secures horn switch

(steering pad) to the base of steering wheel.

B6M0124

2) Remove horn switch (steering pad) from steer-

ing wheel while disconnecting connector.

3) Installation is in the reverse order of removal.

3. CIGARETTE LIGHTER

1) Remove center panel from instrument panel.

2) Disconnect connector from cigarette lighter.

3) Turn illumination socket 45É counterclockwise

and remove it.4) Loosen nut, and then remove cigarette lighter

body.

B6M0350A

5) Installation is in the reverse order of removal.

CAUTION:

IAlign socket with cutout portion of instru-

ment panel during installation.

IIn case of replacing cigarette lighter, use

genuine part only and always replace both plug

and socket combination.

B: INSPECTION

1. HORN SWITCH

Ensure that horn switch is free from the following

defects:

(1) Burned or shorted contacts

(2) Broken or weak spring

(3) Damaged harness

(4) Worn or corroded mating surface of horn plate

2. HORN RELAY

Check continuity between terminals as indicated in

table, when connecting the battery to terminals No.

1 and No. 2.

When current flows. Between termi-

nals No. 2 and

No. 3Continuity

exists.

When current does not

flow.Between termi-

nals No. 2 and

No. 3Continuity does

not exist.

Between termi-

nals No. 1 and

No. 2Continuity

exists.

B6M0126A

30

6-2[W16A1]SERVICE PROCEDURE

16. Horn and Cigarette Lighter

Page 1284 of 1456

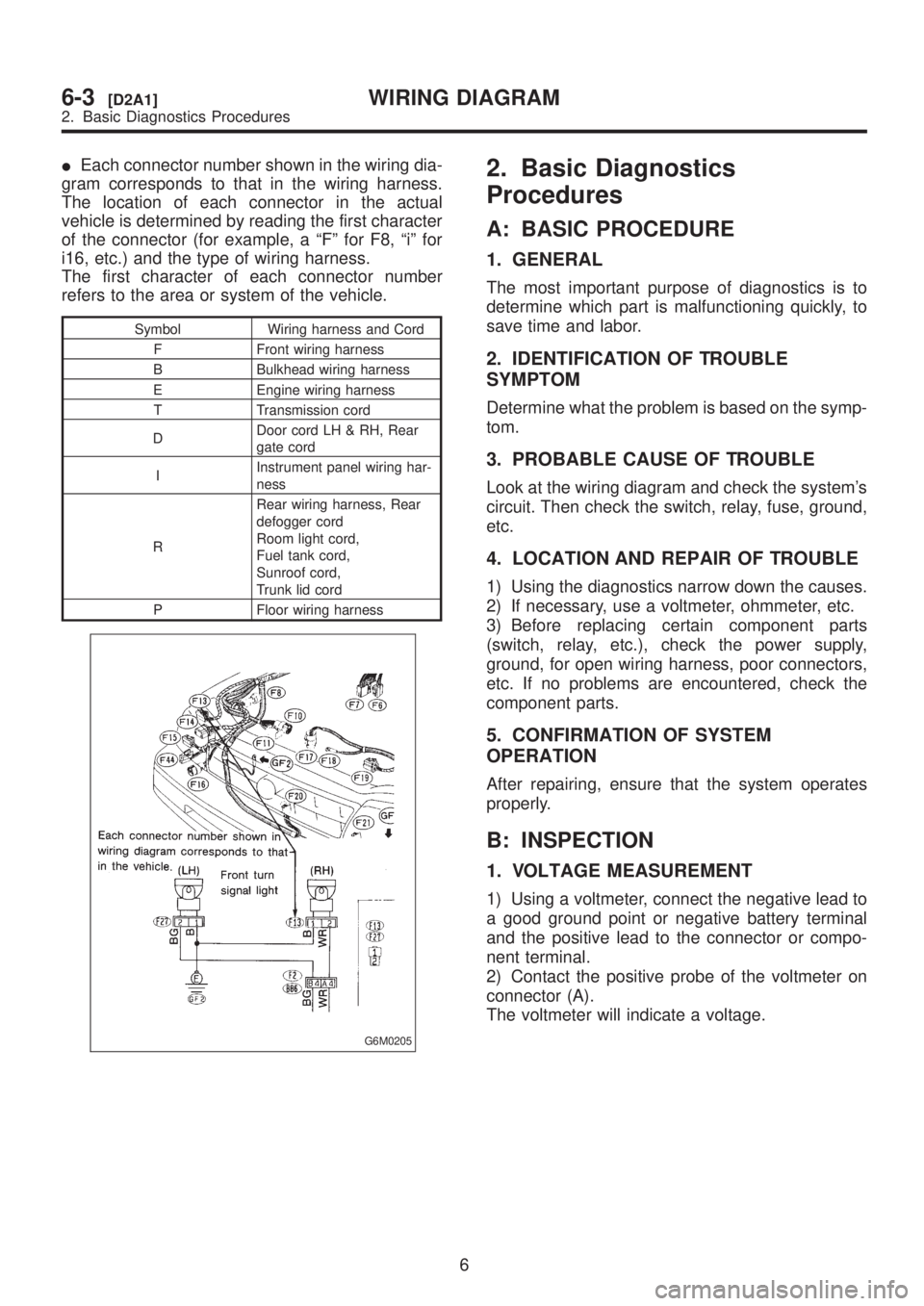

IEach connector number shown in the wiring dia-

gram corresponds to that in the wiring harness.

The location of each connector in the actual

vehicle is determined by reading the first character

of the connector (for example, a ªFº for F8, ªiº for

i16, etc.) and the type of wiring harness.

The first character of each connector number

refers to the area or system of the vehicle.

Symbol Wiring harness and Cord

F Front wiring harness

B Bulkhead wiring harness

E Engine wiring harness

T Transmission cord

DDoor cord LH & RH, Rear

gate cord

IInstrument panel wiring har-

ness

RRear wiring harness, Rear

defogger cord

Room light cord,

Fuel tank cord,

Sunroof cord,

Trunk lid cord

P Floor wiring harness

G6M0205

2. Basic Diagnostics

Procedures

A: BASIC PROCEDURE

1. GENERAL

The most important purpose of diagnostics is to

determine which part is malfunctioning quickly, to

save time and labor.

2. IDENTIFICATION OF TROUBLE

SYMPTOM

Determine what the problem is based on the symp-

tom.

3. PROBABLE CAUSE OF TROUBLE

Look at the wiring diagram and check the system's

circuit. Then check the switch, relay, fuse, ground,

etc.

4. LOCATION AND REPAIR OF TROUBLE

1) Using the diagnostics narrow down the causes.

2) If necessary, use a voltmeter, ohmmeter, etc.

3) Before replacing certain component parts

(switch, relay, etc.), check the power supply,

ground, for open wiring harness, poor connectors,

etc. If no problems are encountered, check the

component parts.

5. CONFIRMATION OF SYSTEM

OPERATION

After repairing, ensure that the system operates

properly.

B: INSPECTION

1. VOLTAGE MEASUREMENT

1) Using a voltmeter, connect the negative lead to

a good ground point or negative battery terminal

and the positive lead to the connector or compo-

nent terminal.

2) Contact the positive probe of the voltmeter on

connector (A).

The voltmeter will indicate a voltage.

6

6-3[D2A1]WIRING DIAGRAM

2. Basic Diagnostics Procedures

Page 1285 of 1456

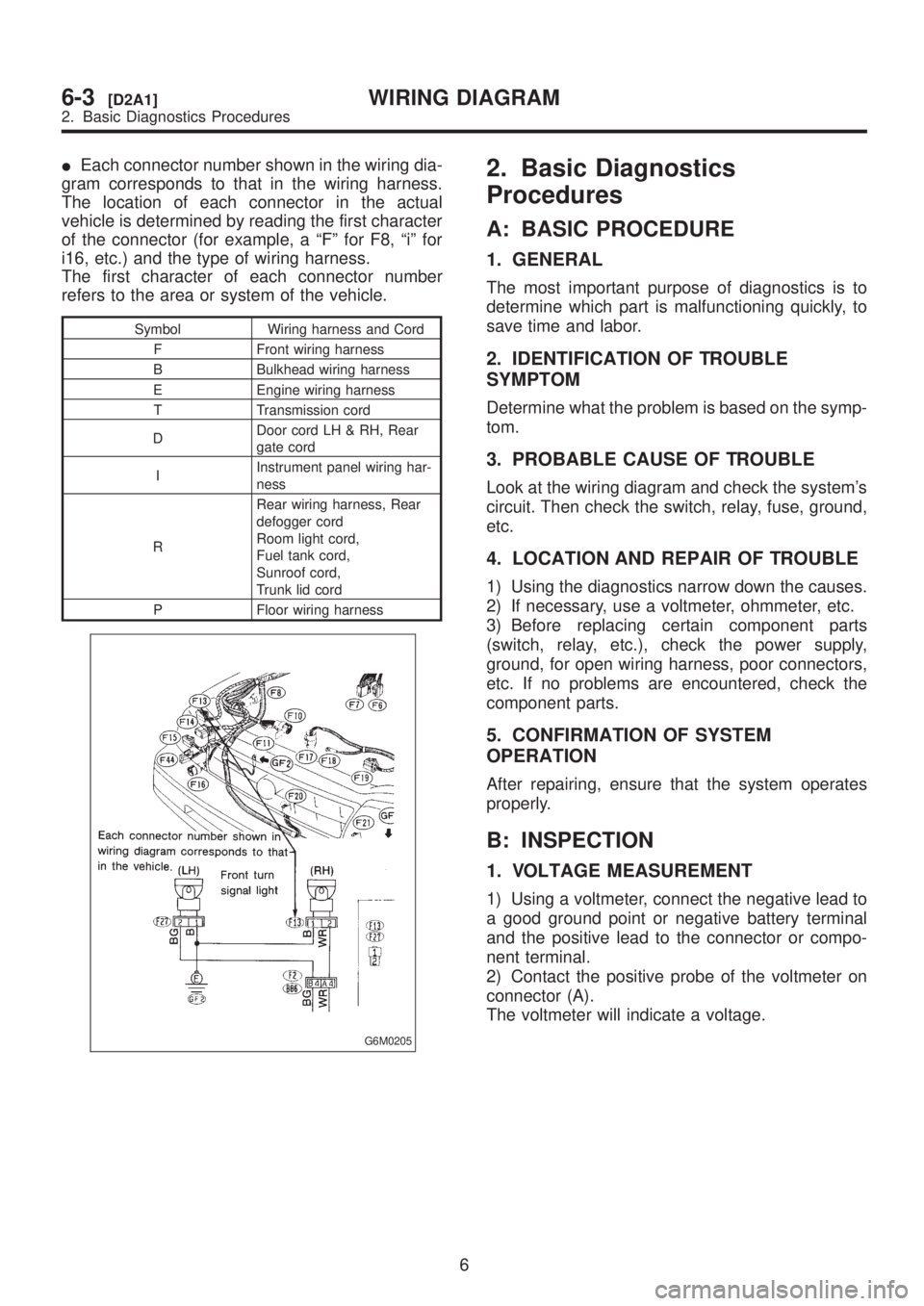

IEach connector number shown in the wiring dia-

gram corresponds to that in the wiring harness.

The location of each connector in the actual

vehicle is determined by reading the first character

of the connector (for example, a ªFº for F8, ªiº for

i16, etc.) and the type of wiring harness.

The first character of each connector number

refers to the area or system of the vehicle.

Symbol Wiring harness and Cord

F Front wiring harness

B Bulkhead wiring harness

E Engine wiring harness

T Transmission cord

DDoor cord LH & RH, Rear

gate cord

IInstrument panel wiring har-

ness

RRear wiring harness, Rear

defogger cord

Room light cord,

Fuel tank cord,

Sunroof cord,

Trunk lid cord

P Floor wiring harness

G6M0205

2. Basic Diagnostics

Procedures

A: BASIC PROCEDURE

1. GENERAL

The most important purpose of diagnostics is to

determine which part is malfunctioning quickly, to

save time and labor.

2. IDENTIFICATION OF TROUBLE

SYMPTOM

Determine what the problem is based on the symp-

tom.

3. PROBABLE CAUSE OF TROUBLE

Look at the wiring diagram and check the system's

circuit. Then check the switch, relay, fuse, ground,

etc.

4. LOCATION AND REPAIR OF TROUBLE

1) Using the diagnostics narrow down the causes.

2) If necessary, use a voltmeter, ohmmeter, etc.

3) Before replacing certain component parts

(switch, relay, etc.), check the power supply,

ground, for open wiring harness, poor connectors,

etc. If no problems are encountered, check the

component parts.

5. CONFIRMATION OF SYSTEM

OPERATION

After repairing, ensure that the system operates

properly.

B: INSPECTION

1. VOLTAGE MEASUREMENT

1) Using a voltmeter, connect the negative lead to

a good ground point or negative battery terminal

and the positive lead to the connector or compo-

nent terminal.

2) Contact the positive probe of the voltmeter on

connector (A).

The voltmeter will indicate a voltage.

6

6-3[D2A1]WIRING DIAGRAM

2. Basic Diagnostics Procedures

Page 1287 of 1456

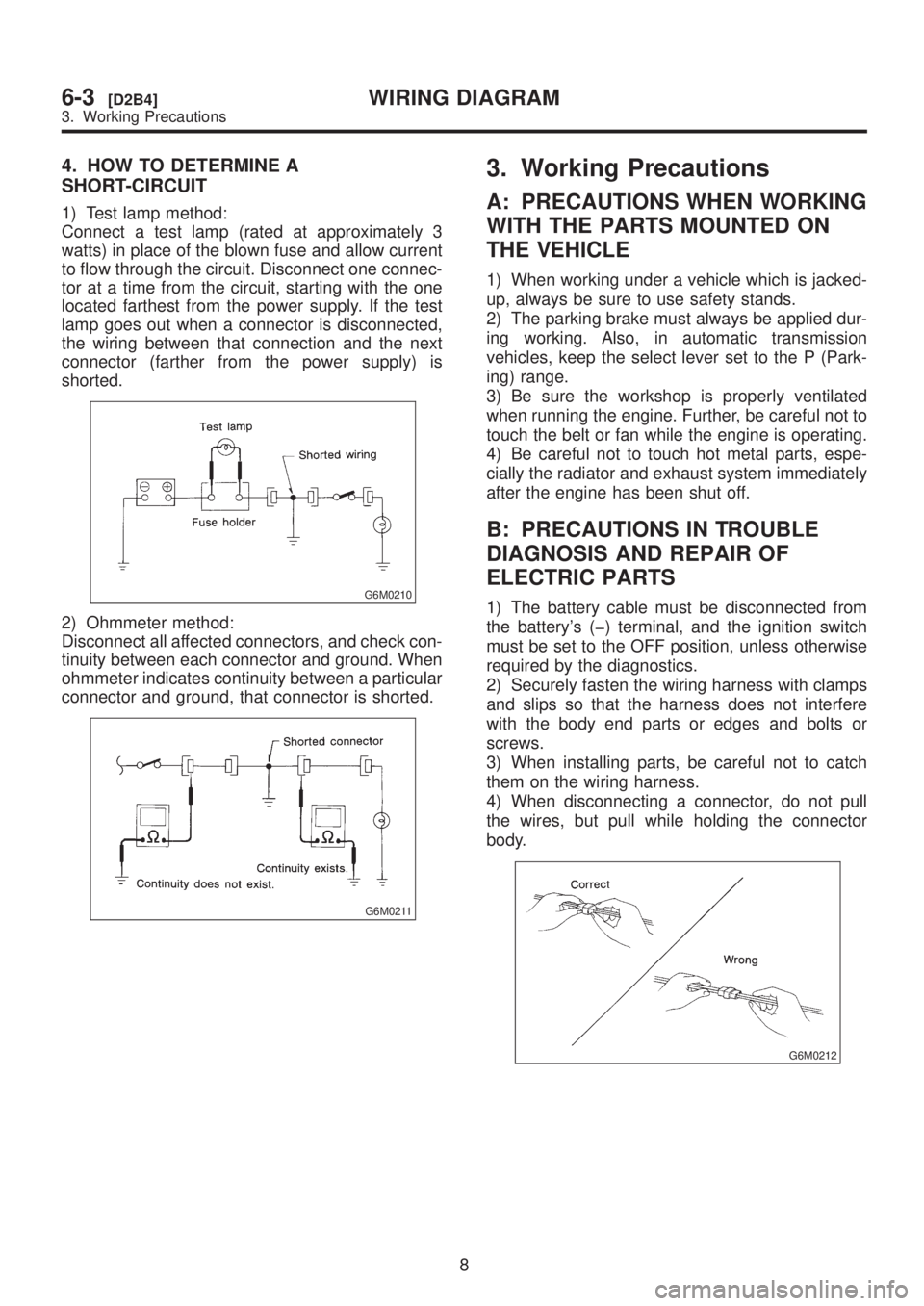

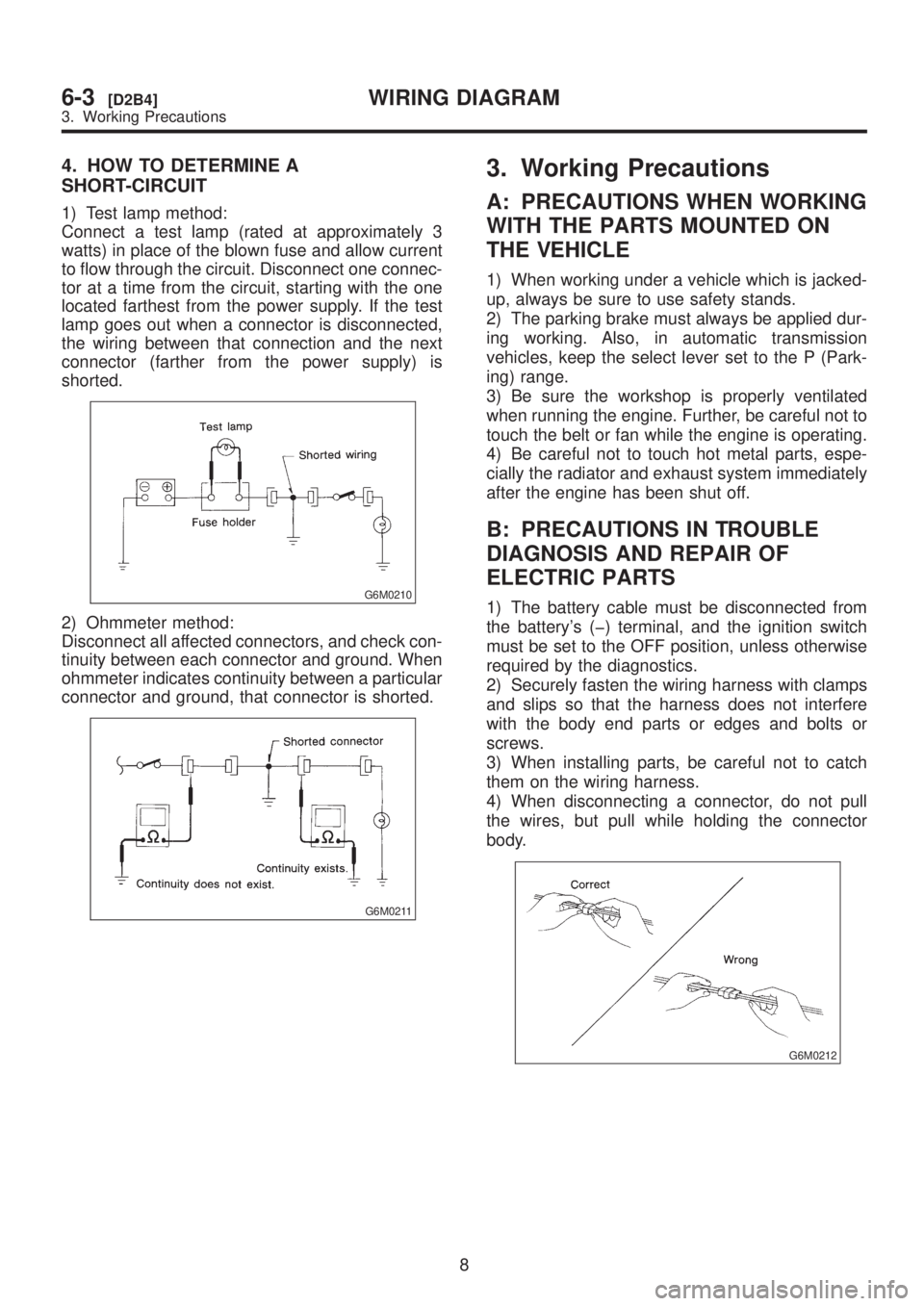

4. HOW TO DETERMINE A

SHORT-CIRCUIT

1) Test lamp method:

Connect a test lamp (rated at approximately 3

watts) in place of the blown fuse and allow current

to flow through the circuit. Disconnect one connec-

tor at a time from the circuit, starting with the one

located farthest from the power supply. If the test

lamp goes out when a connector is disconnected,

the wiring between that connection and the next

connector (farther from the power supply) is

shorted.

G6M0210

2) Ohmmeter method:

Disconnect all affected connectors, and check con-

tinuity between each connector and ground. When

ohmmeter indicates continuity between a particular

connector and ground, that connector is shorted.

G6M0211

3. Working Precautions

A: PRECAUTIONS WHEN WORKING

WITH THE PARTS MOUNTED ON

THE VEHICLE

1) When working under a vehicle which is jacked-

up, always be sure to use safety stands.

2) The parking brake must always be applied dur-

ing working. Also, in automatic transmission

vehicles, keep the select lever set to the P (Park-

ing) range.

3) Be sure the workshop is properly ventilated

when running the engine. Further, be careful not to

touch the belt or fan while the engine is operating.

4) Be careful not to touch hot metal parts, espe-

cially the radiator and exhaust system immediately

after the engine has been shut off.

B: PRECAUTIONS IN TROUBLE

DIAGNOSIS AND REPAIR OF

ELECTRIC PARTS

1) The battery cable must be disconnected from

the battery's (þ) terminal, and the ignition switch

must be set to the OFF position, unless otherwise

required by the diagnostics.

2) Securely fasten the wiring harness with clamps

and slips so that the harness does not interfere

with the body end parts or edges and bolts or

screws.

3) When installing parts, be careful not to catch

them on the wiring harness.

4) When disconnecting a connector, do not pull

the wires, but pull while holding the connector

body.

G6M0212

8

6-3[D2B4]WIRING DIAGRAM

3. Working Precautions

Page 1288 of 1456

4. HOW TO DETERMINE A

SHORT-CIRCUIT

1) Test lamp method:

Connect a test lamp (rated at approximately 3

watts) in place of the blown fuse and allow current

to flow through the circuit. Disconnect one connec-

tor at a time from the circuit, starting with the one

located farthest from the power supply. If the test

lamp goes out when a connector is disconnected,

the wiring between that connection and the next

connector (farther from the power supply) is

shorted.

G6M0210

2) Ohmmeter method:

Disconnect all affected connectors, and check con-

tinuity between each connector and ground. When

ohmmeter indicates continuity between a particular

connector and ground, that connector is shorted.

G6M0211

3. Working Precautions

A: PRECAUTIONS WHEN WORKING

WITH THE PARTS MOUNTED ON

THE VEHICLE

1) When working under a vehicle which is jacked-

up, always be sure to use safety stands.

2) The parking brake must always be applied dur-

ing working. Also, in automatic transmission

vehicles, keep the select lever set to the P (Park-

ing) range.

3) Be sure the workshop is properly ventilated

when running the engine. Further, be careful not to

touch the belt or fan while the engine is operating.

4) Be careful not to touch hot metal parts, espe-

cially the radiator and exhaust system immediately

after the engine has been shut off.

B: PRECAUTIONS IN TROUBLE

DIAGNOSIS AND REPAIR OF

ELECTRIC PARTS

1) The battery cable must be disconnected from

the battery's (þ) terminal, and the ignition switch

must be set to the OFF position, unless otherwise

required by the diagnostics.

2) Securely fasten the wiring harness with clamps

and slips so that the harness does not interfere

with the body end parts or edges and bolts or

screws.

3) When installing parts, be careful not to catch

them on the wiring harness.

4) When disconnecting a connector, do not pull

the wires, but pull while holding the connector

body.

G6M0212

8

6-3[D2B4]WIRING DIAGRAM

3. Working Precautions