check engine SUBARU LEGACY 1999 Service Manual PDF

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 952 of 1456

2) If it is not in specified value, adjust it by turning

adjusting nut on engine side end of clutch cable.

Free play: L

3Ð4mm(0.12 Ð 0.16 in)

Full stroke: A

25.5 Ð 27 mm (1.004 Ð 1.063 in)

B4M1115A

(1) Lock nut

(2) Adjusting nut

(3) Release fork

3) Apply grease to connecting portion of clutch

pedal and clutch cable.

Lock nut tightening torque:

5.9

±1.5 N´m (0.60±0.15 kg-m, 4.3±1.1 ft-lb)

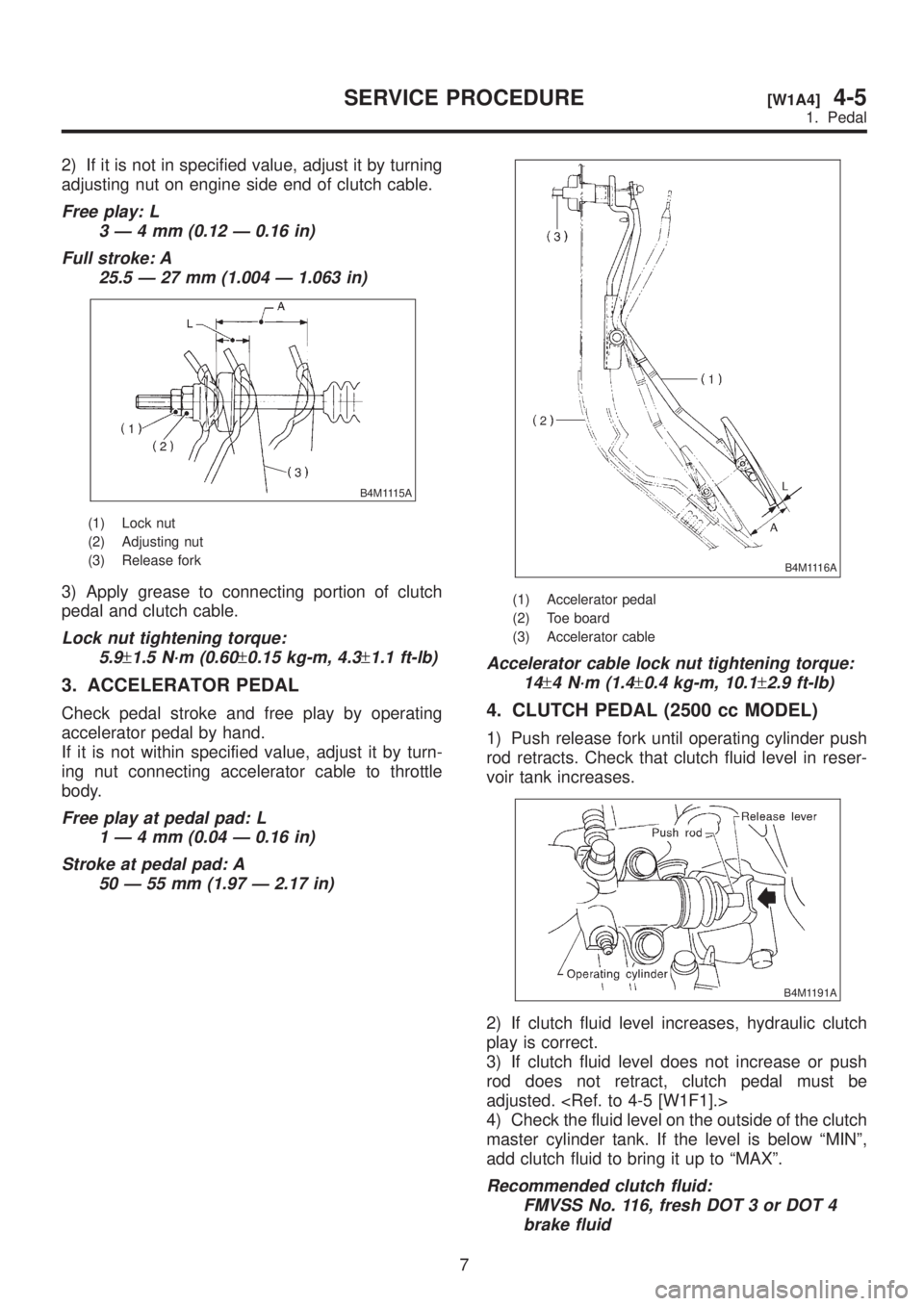

3. ACCELERATOR PEDAL

Check pedal stroke and free play by operating

accelerator pedal by hand.

If it is not within specified value, adjust it by turn-

ing nut connecting accelerator cable to throttle

body.

Free play at pedal pad: L

1Ð4mm(0.04 Ð 0.16 in)

Stroke at pedal pad: A

50 Ð 55 mm (1.97 Ð 2.17 in)

B4M1116A

(1) Accelerator pedal

(2) Toe board

(3) Accelerator cable

Accelerator cable lock nut tightening torque:

14

±4 N´m (1.4±0.4 kg-m, 10.1±2.9 ft-lb)

4. CLUTCH PEDAL (2500 cc MODEL)

1) Push release fork until operating cylinder push

rod retracts. Check that clutch fluid level in reser-

voir tank increases.

B4M1191A

2) If clutch fluid level increases, hydraulic clutch

play is correct.

3) If clutch fluid level does not increase or push

rod does not retract, clutch pedal must be

adjusted.

4) Check the fluid level on the outside of the clutch

master cylinder tank. If the level is below ªMINº,

add clutch fluid to bring it up to ªMAXº.

Recommended clutch fluid:

FMVSS No. 116, fresh DOT 3 or DOT 4

brake fluid

7

[W1A4]4-5SERVICE PROCEDURE

1. Pedal

Page 990 of 1456

6. Discharge the System

CAUTION:

The following points should be kept in mind

when discharging the system.

IBe certain that goggles and gloves are worn.

IConnect refrigerant recovery system to

manifold gauge set and remove recycle refrig-

erant from A/C system.

NOTE:

Refer to appropriate refrigerant recovery system

instruction manual for operation.

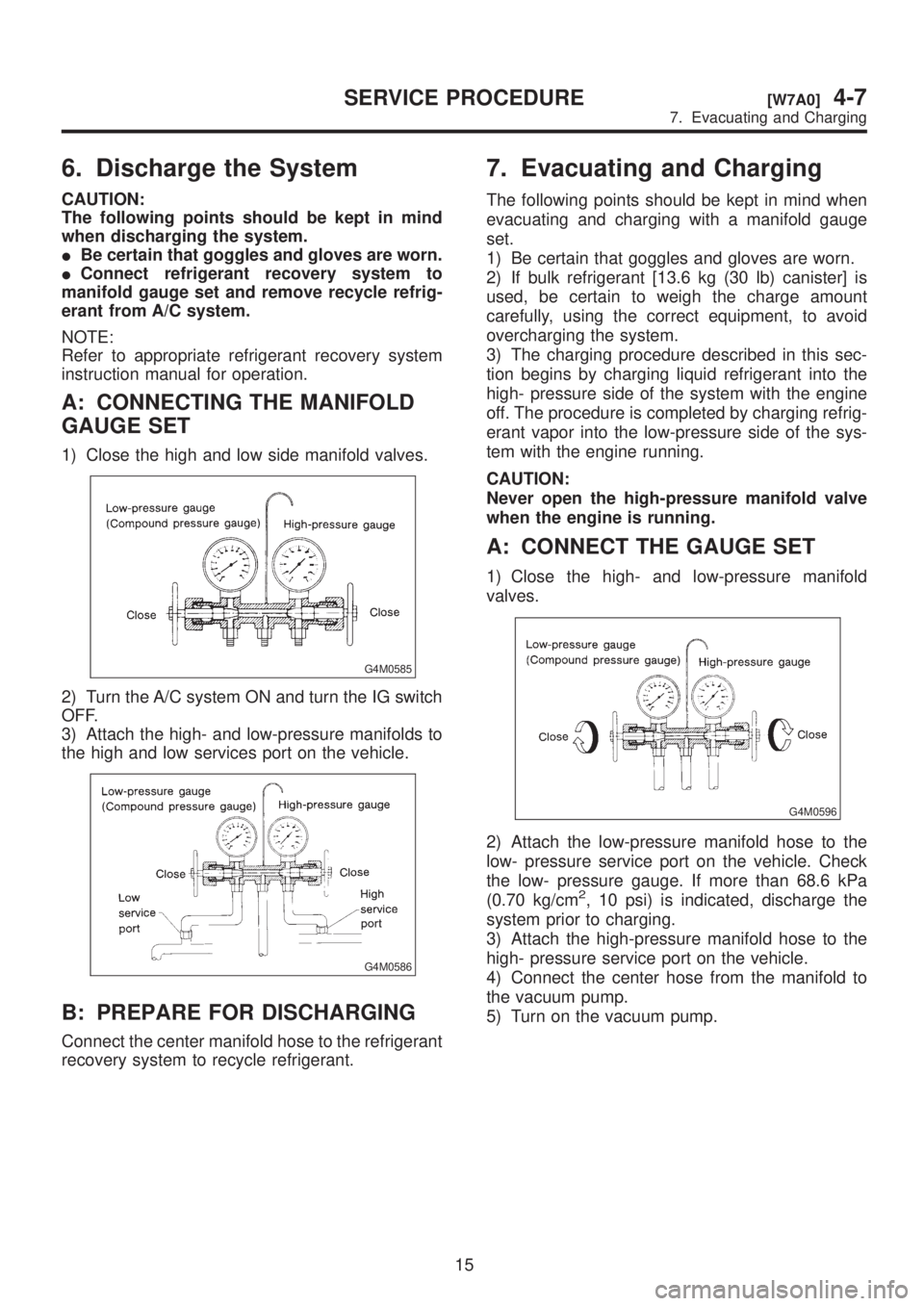

A: CONNECTING THE MANIFOLD

GAUGE SET

1) Close the high and low side manifold valves.

G4M0585

2) Turn the A/C system ON and turn the IG switch

OFF.

3) Attach the high- and low-pressure manifolds to

the high and low services port on the vehicle.

G4M0586

B: PREPARE FOR DISCHARGING

Connect the center manifold hose to the refrigerant

recovery system to recycle refrigerant.

7. Evacuating and Charging

The following points should be kept in mind when

evacuating and charging with a manifold gauge

set.

1) Be certain that goggles and gloves are worn.

2) If bulk refrigerant [13.6 kg (30 lb) canister] is

used, be certain to weigh the charge amount

carefully, using the correct equipment, to avoid

overcharging the system.

3) The charging procedure described in this sec-

tion begins by charging liquid refrigerant into the

high- pressure side of the system with the engine

off. The procedure is completed by charging refrig-

erant vapor into the low-pressure side of the sys-

tem with the engine running.

CAUTION:

Never open the high-pressure manifold valve

when the engine is running.

A: CONNECT THE GAUGE SET

1) Close the high- and low-pressure manifold

valves.

G4M0596

2) Attach the low-pressure manifold hose to the

low- pressure service port on the vehicle. Check

the low- pressure gauge. If more than 68.6 kPa

(0.70 kg/cm

2, 10 psi) is indicated, discharge the

system prior to charging.

3) Attach the high-pressure manifold hose to the

high- pressure service port on the vehicle.

4) Connect the center hose from the manifold to

the vacuum pump.

5) Turn on the vacuum pump.

15

[W7A0]4-7SERVICE PROCEDURE

7. Evacuating and Charging

Page 991 of 1456

6. Discharge the System

CAUTION:

The following points should be kept in mind

when discharging the system.

IBe certain that goggles and gloves are worn.

IConnect refrigerant recovery system to

manifold gauge set and remove recycle refrig-

erant from A/C system.

NOTE:

Refer to appropriate refrigerant recovery system

instruction manual for operation.

A: CONNECTING THE MANIFOLD

GAUGE SET

1) Close the high and low side manifold valves.

G4M0585

2) Turn the A/C system ON and turn the IG switch

OFF.

3) Attach the high- and low-pressure manifolds to

the high and low services port on the vehicle.

G4M0586

B: PREPARE FOR DISCHARGING

Connect the center manifold hose to the refrigerant

recovery system to recycle refrigerant.

7. Evacuating and Charging

The following points should be kept in mind when

evacuating and charging with a manifold gauge

set.

1) Be certain that goggles and gloves are worn.

2) If bulk refrigerant [13.6 kg (30 lb) canister] is

used, be certain to weigh the charge amount

carefully, using the correct equipment, to avoid

overcharging the system.

3) The charging procedure described in this sec-

tion begins by charging liquid refrigerant into the

high- pressure side of the system with the engine

off. The procedure is completed by charging refrig-

erant vapor into the low-pressure side of the sys-

tem with the engine running.

CAUTION:

Never open the high-pressure manifold valve

when the engine is running.

A: CONNECT THE GAUGE SET

1) Close the high- and low-pressure manifold

valves.

G4M0596

2) Attach the low-pressure manifold hose to the

low- pressure service port on the vehicle. Check

the low- pressure gauge. If more than 68.6 kPa

(0.70 kg/cm

2, 10 psi) is indicated, discharge the

system prior to charging.

3) Attach the high-pressure manifold hose to the

high- pressure service port on the vehicle.

4) Connect the center hose from the manifold to

the vacuum pump.

5) Turn on the vacuum pump.

15

[W7A0]4-7SERVICE PROCEDURE

7. Evacuating and Charging

Page 993 of 1456

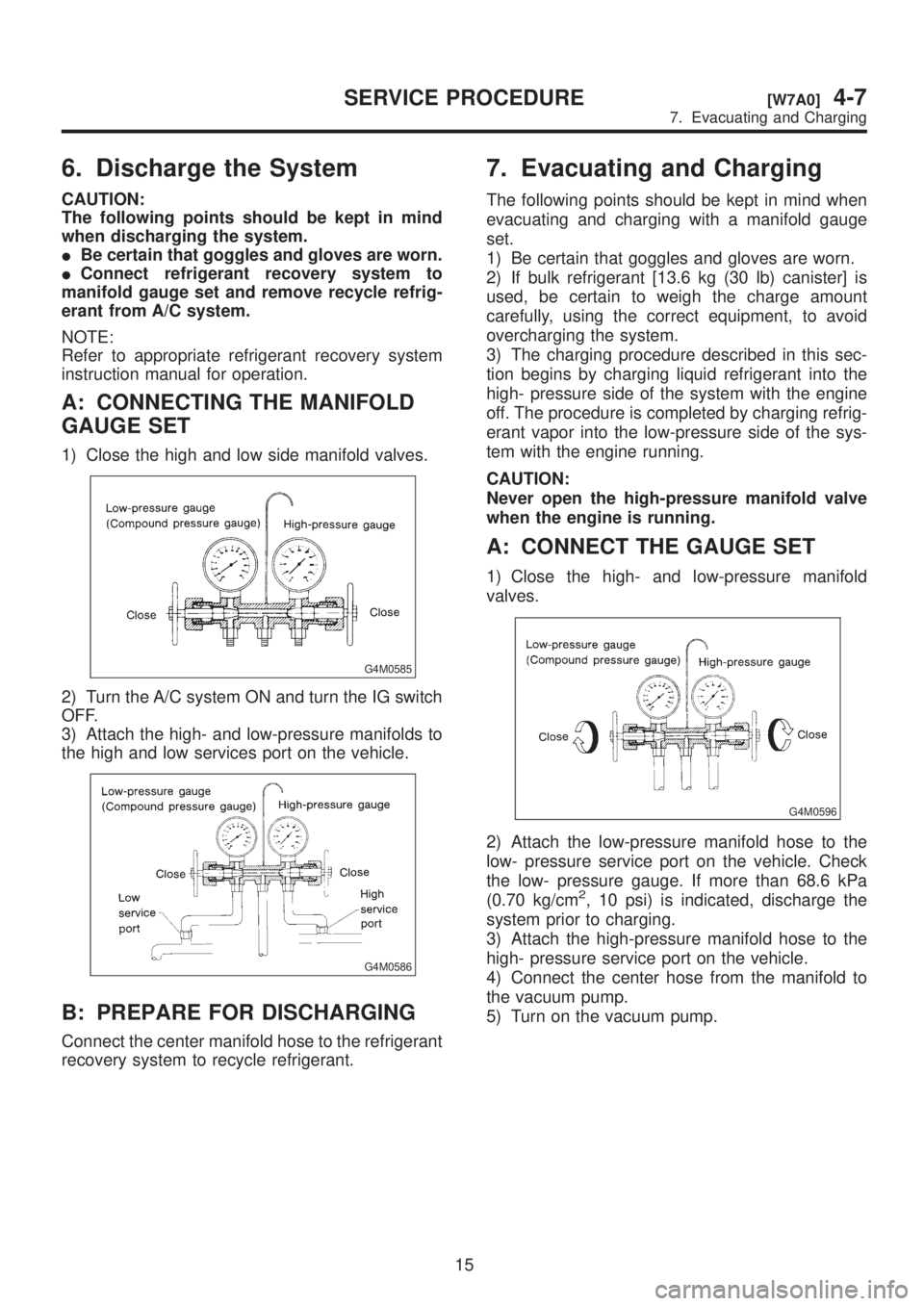

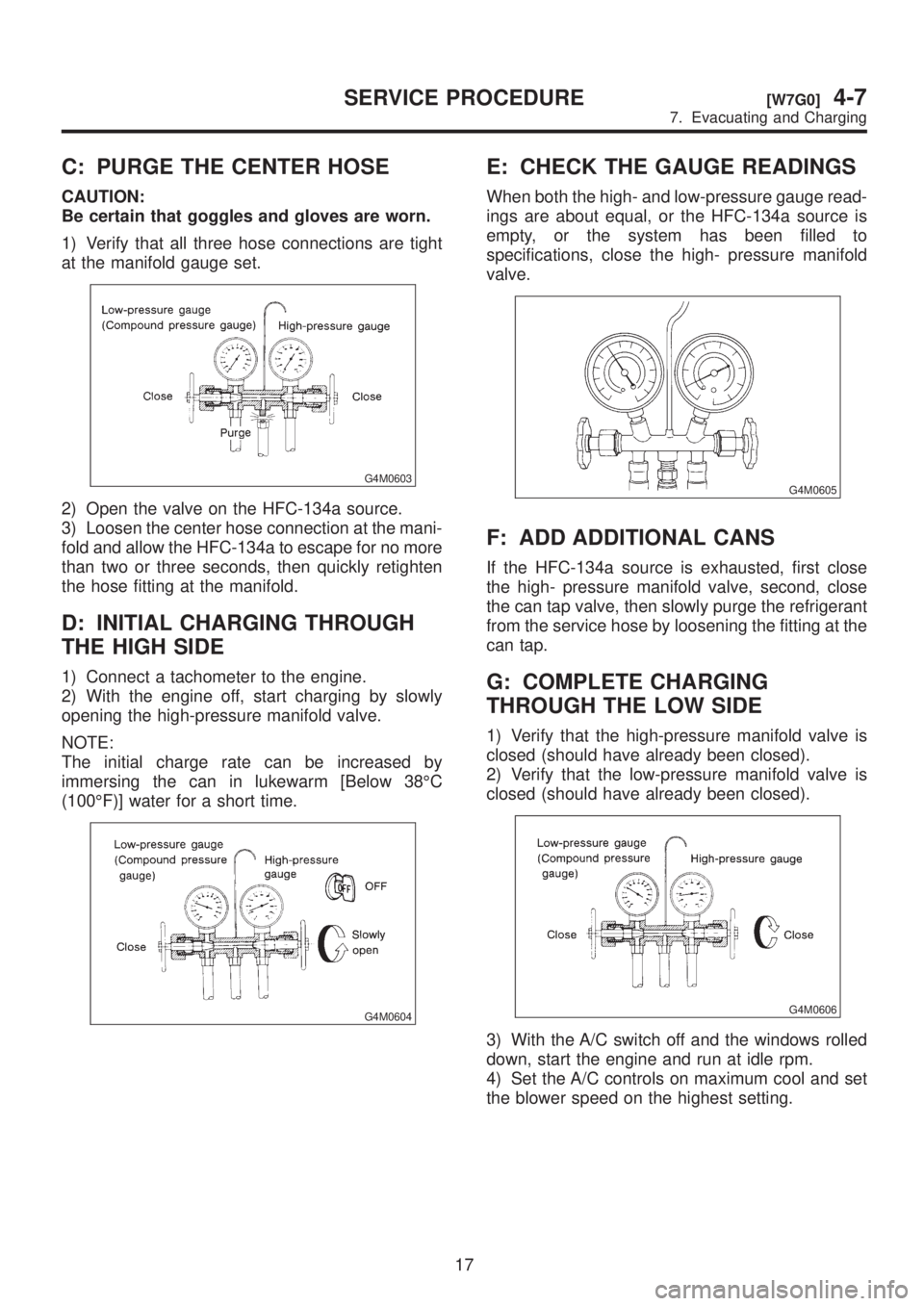

C: PURGE THE CENTER HOSE

CAUTION:

Be certain that goggles and gloves are worn.

1) Verify that all three hose connections are tight

at the manifold gauge set.

G4M0603

2) Open the valve on the HFC-134a source.

3) Loosen the center hose connection at the mani-

fold and allow the HFC-134a to escape for no more

than two or three seconds, then quickly retighten

the hose fitting at the manifold.

D: INITIAL CHARGING THROUGH

THE HIGH SIDE

1) Connect a tachometer to the engine.

2) With the engine off, start charging by slowly

opening the high-pressure manifold valve.

NOTE:

The initial charge rate can be increased by

immersing the can in lukewarm [Below 38ÉC

(100ÉF)] water for a short time.

G4M0604

E: CHECK THE GAUGE READINGS

When both the high- and low-pressure gauge read-

ings are about equal, or the HFC-134a source is

empty, or the system has been filled to

specifications, close the high- pressure manifold

valve.

G4M0605

F: ADD ADDITIONAL CANS

If the HFC-134a source is exhausted, first close

the high- pressure manifold valve, second, close

the can tap valve, then slowly purge the refrigerant

from the service hose by loosening the fitting at the

can tap.

G: COMPLETE CHARGING

THROUGH THE LOW SIDE

1) Verify that the high-pressure manifold valve is

closed (should have already been closed).

2) Verify that the low-pressure manifold valve is

closed (should have already been closed).

G4M0606

3) With the A/C switch off and the windows rolled

down, start the engine and run at idle rpm.

4) Set the A/C controls on maximum cool and set

the blower speed on the highest setting.

17

[W7G0]4-7SERVICE PROCEDURE

7. Evacuating and Charging

Page 994 of 1456

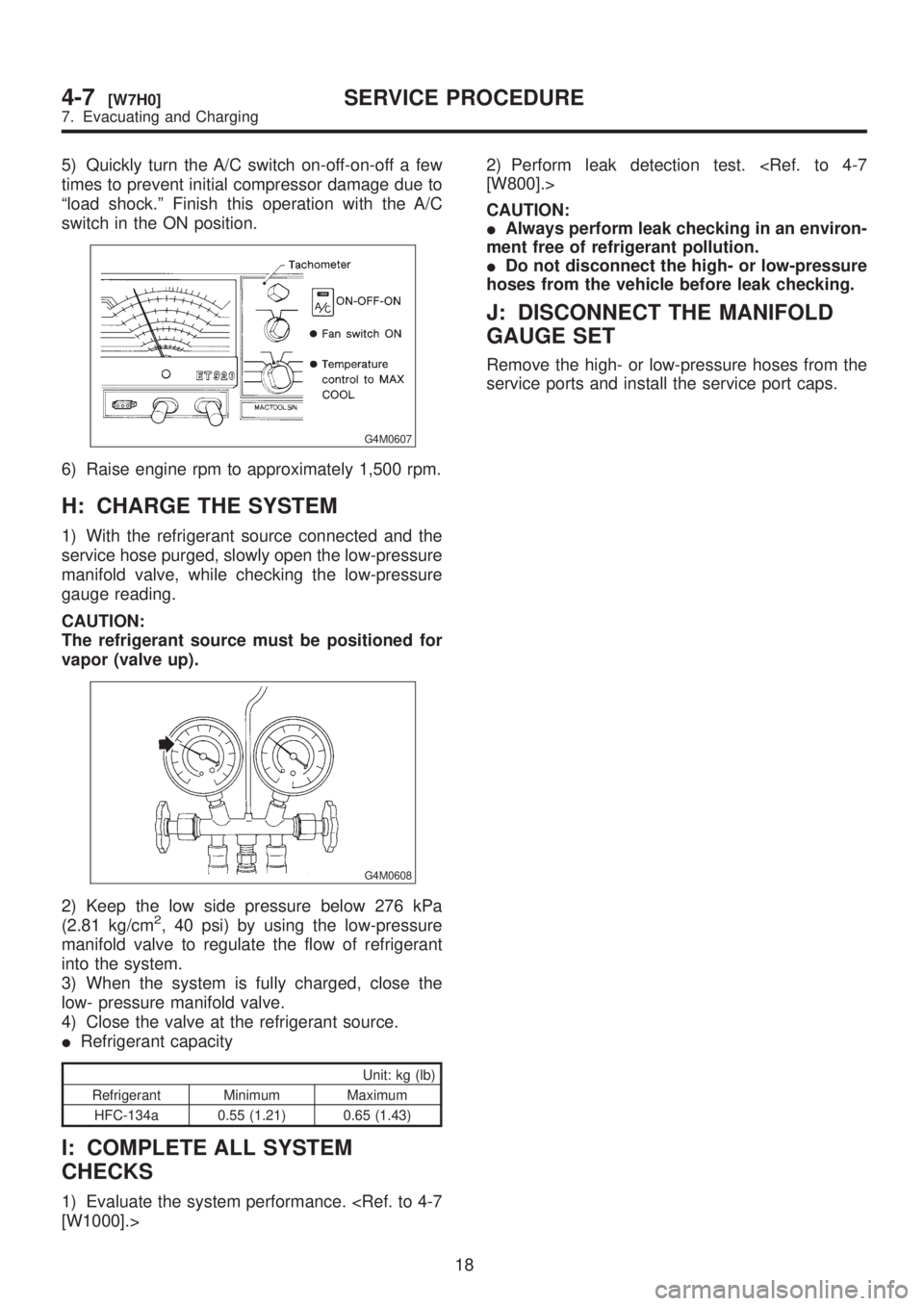

5) Quickly turn the A/C switch on-off-on-off a few

times to prevent initial compressor damage due to

ªload shock.º Finish this operation with the A/C

switch in the ON position.

G4M0607

6) Raise engine rpm to approximately 1,500 rpm.

H: CHARGE THE SYSTEM

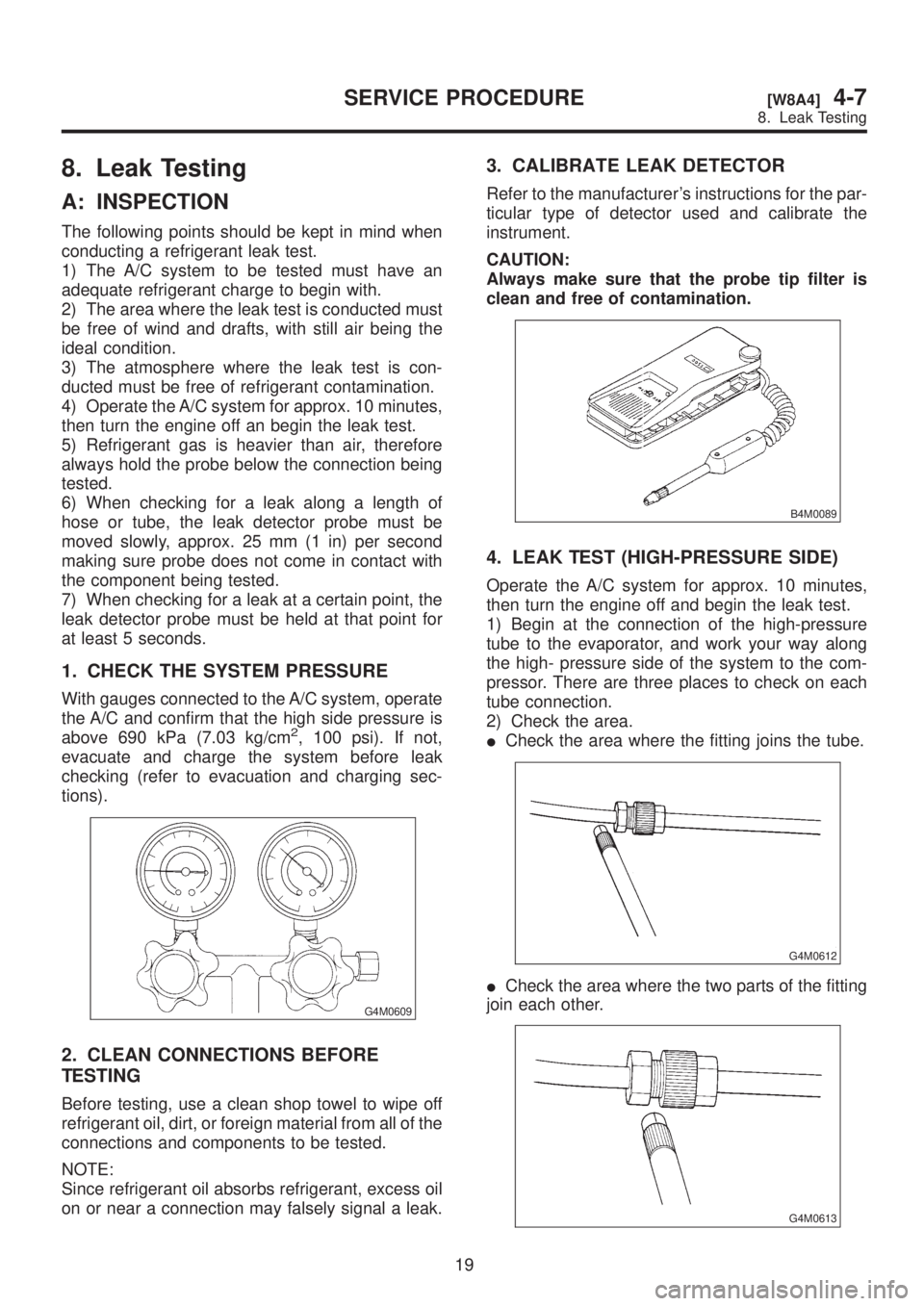

1) With the refrigerant source connected and the

service hose purged, slowly open the low-pressure

manifold valve, while checking the low-pressure

gauge reading.

CAUTION:

The refrigerant source must be positioned for

vapor (valve up).

G4M0608

2) Keep the low side pressure below 276 kPa

(2.81 kg/cm2, 40 psi) by using the low-pressure

manifold valve to regulate the flow of refrigerant

into the system.

3) When the system is fully charged, close the

low- pressure manifold valve.

4) Close the valve at the refrigerant source.

IRefrigerant capacity

Unit: kg (lb)

Refrigerant Minimum Maximum

HFC-134a 0.55 (1.21) 0.65 (1.43)

I: COMPLETE ALL SYSTEM

CHECKS

1) Evaluate the system performance.

CAUTION:

IAlways perform leak checking in an environ-

ment free of refrigerant pollution.

IDo not disconnect the high- or low-pressure

hoses from the vehicle before leak checking.

J: DISCONNECT THE MANIFOLD

GAUGE SET

Remove the high- or low-pressure hoses from the

service ports and install the service port caps.

18

4-7[W7H0]SERVICE PROCEDURE

7. Evacuating and Charging

Page 995 of 1456

8. Leak Testing

A: INSPECTION

The following points should be kept in mind when

conducting a refrigerant leak test.

1) The A/C system to be tested must have an

adequate refrigerant charge to begin with.

2) The area where the leak test is conducted must

be free of wind and drafts, with still air being the

ideal condition.

3) The atmosphere where the leak test is con-

ducted must be free of refrigerant contamination.

4) Operate the A/C system for approx. 10 minutes,

then turn the engine off an begin the leak test.

5) Refrigerant gas is heavier than air, therefore

always hold the probe below the connection being

tested.

6) When checking for a leak along a length of

hose or tube, the leak detector probe must be

moved slowly, approx. 25 mm (1 in) per second

making sure probe does not come in contact with

the component being tested.

7) When checking for a leak at a certain point, the

leak detector probe must be held at that point for

at least 5 seconds.

1. CHECK THE SYSTEM PRESSURE

With gauges connected to the A/C system, operate

the A/C and confirm that the high side pressure is

above 690 kPa (7.03 kg/cm

2, 100 psi). If not,

evacuate and charge the system before leak

checking (refer to evacuation and charging sec-

tions).

G4M0609

2. CLEAN CONNECTIONS BEFORE

TESTING

Before testing, use a clean shop towel to wipe off

refrigerant oil, dirt, or foreign material from all of the

connections and components to be tested.

NOTE:

Since refrigerant oil absorbs refrigerant, excess oil

on or near a connection may falsely signal a leak.

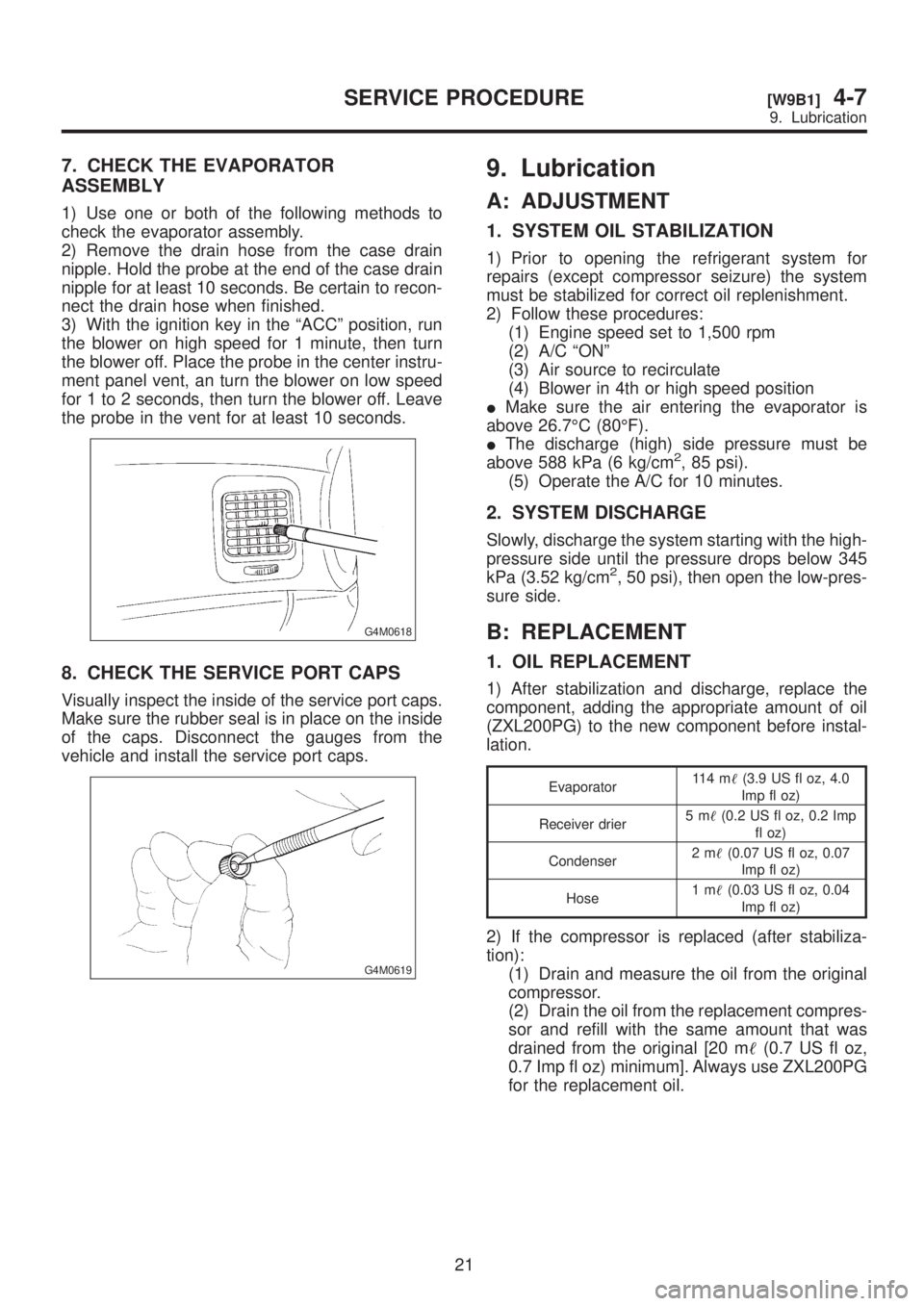

3. CALIBRATE LEAK DETECTOR

Refer to the manufacturer's instructions for the par-

ticular type of detector used and calibrate the

instrument.

CAUTION:

Always make sure that the probe tip filter is

clean and free of contamination.

B4M0089

4. LEAK TEST (HIGH-PRESSURE SIDE)

Operate the A/C system for approx. 10 minutes,

then turn the engine off and begin the leak test.

1) Begin at the connection of the high-pressure

tube to the evaporator, and work your way along

the high- pressure side of the system to the com-

pressor. There are three places to check on each

tube connection.

2) Check the area.

ICheck the area where the fitting joins the tube.

G4M0612

ICheck the area where the two parts of the fitting

join each other.

G4M0613

19

[W8A4]4-7SERVICE PROCEDURE

8. Leak Testing

Page 997 of 1456

7. CHECK THE EVAPORATOR

ASSEMBLY

1) Use one or both of the following methods to

check the evaporator assembly.

2) Remove the drain hose from the case drain

nipple. Hold the probe at the end of the case drain

nipple for at least 10 seconds. Be certain to recon-

nect the drain hose when finished.

3) With the ignition key in the ªACCº position, run

the blower on high speed for 1 minute, then turn

the blower off. Place the probe in the center instru-

ment panel vent, an turn the blower on low speed

for 1 to 2 seconds, then turn the blower off. Leave

the probe in the vent for at least 10 seconds.

G4M0618

8. CHECK THE SERVICE PORT CAPS

Visually inspect the inside of the service port caps.

Make sure the rubber seal is in place on the inside

of the caps. Disconnect the gauges from the

vehicle and install the service port caps.

G4M0619

9. Lubrication

A: ADJUSTMENT

1. SYSTEM OIL STABILIZATION

1) Prior to opening the refrigerant system for

repairs (except compressor seizure) the system

must be stabilized for correct oil replenishment.

2) Follow these procedures:

(1) Engine speed set to 1,500 rpm

(2) A/C ªONº

(3) Air source to recirculate

(4) Blower in 4th or high speed position

IMake sure the air entering the evaporator is

above 26.7ÉC (80ÉF).

IThe discharge (high) side pressure must be

above 588 kPa (6 kg/cm

2, 85 psi).

(5) Operate the A/C for 10 minutes.

2. SYSTEM DISCHARGE

Slowly, discharge the system starting with the high-

pressure side until the pressure drops below 345

kPa (3.52 kg/cm

2, 50 psi), then open the low-pres-

sure side.

B: REPLACEMENT

1. OIL REPLACEMENT

1) After stabilization and discharge, replace the

component, adding the appropriate amount of oil

(ZXL200PG) to the new component before instal-

lation.

Evaporator11 4 m(3.9 US fl oz, 4.0

Imp fl oz)

Receiver drier5m(0.2 US fl oz, 0.2 Imp

fl oz)

Condenser2m(0.07 US fl oz, 0.07

Imp fl oz)

Hose1m(0.03 US fl oz, 0.04

Imp fl oz)

2) If the compressor is replaced (after stabiliza-

tion):

(1) Drain and measure the oil from the original

compressor.

(2) Drain the oil from the replacement compres-

sor and refill with the same amount that was

drained from the original [20 m(0.7 US fl oz,

0.7 Imp fl oz) minimum]. Always use ZXL200PG

for the replacement oil.

21

[W9B1]4-7SERVICE PROCEDURE

9. Lubrication

Page 998 of 1456

7. CHECK THE EVAPORATOR

ASSEMBLY

1) Use one or both of the following methods to

check the evaporator assembly.

2) Remove the drain hose from the case drain

nipple. Hold the probe at the end of the case drain

nipple for at least 10 seconds. Be certain to recon-

nect the drain hose when finished.

3) With the ignition key in the ªACCº position, run

the blower on high speed for 1 minute, then turn

the blower off. Place the probe in the center instru-

ment panel vent, an turn the blower on low speed

for 1 to 2 seconds, then turn the blower off. Leave

the probe in the vent for at least 10 seconds.

G4M0618

8. CHECK THE SERVICE PORT CAPS

Visually inspect the inside of the service port caps.

Make sure the rubber seal is in place on the inside

of the caps. Disconnect the gauges from the

vehicle and install the service port caps.

G4M0619

9. Lubrication

A: ADJUSTMENT

1. SYSTEM OIL STABILIZATION

1) Prior to opening the refrigerant system for

repairs (except compressor seizure) the system

must be stabilized for correct oil replenishment.

2) Follow these procedures:

(1) Engine speed set to 1,500 rpm

(2) A/C ªONº

(3) Air source to recirculate

(4) Blower in 4th or high speed position

IMake sure the air entering the evaporator is

above 26.7ÉC (80ÉF).

IThe discharge (high) side pressure must be

above 588 kPa (6 kg/cm

2, 85 psi).

(5) Operate the A/C for 10 minutes.

2. SYSTEM DISCHARGE

Slowly, discharge the system starting with the high-

pressure side until the pressure drops below 345

kPa (3.52 kg/cm

2, 50 psi), then open the low-pres-

sure side.

B: REPLACEMENT

1. OIL REPLACEMENT

1) After stabilization and discharge, replace the

component, adding the appropriate amount of oil

(ZXL200PG) to the new component before instal-

lation.

Evaporator11 4 m(3.9 US fl oz, 4.0

Imp fl oz)

Receiver drier5m(0.2 US fl oz, 0.2 Imp

fl oz)

Condenser2m(0.07 US fl oz, 0.07

Imp fl oz)

Hose1m(0.03 US fl oz, 0.04

Imp fl oz)

2) If the compressor is replaced (after stabiliza-

tion):

(1) Drain and measure the oil from the original

compressor.

(2) Drain the oil from the replacement compres-

sor and refill with the same amount that was

drained from the original [20 m(0.7 US fl oz,

0.7 Imp fl oz) minimum]. Always use ZXL200PG

for the replacement oil.

21

[W9B1]4-7SERVICE PROCEDURE

9. Lubrication

Page 1017 of 1456

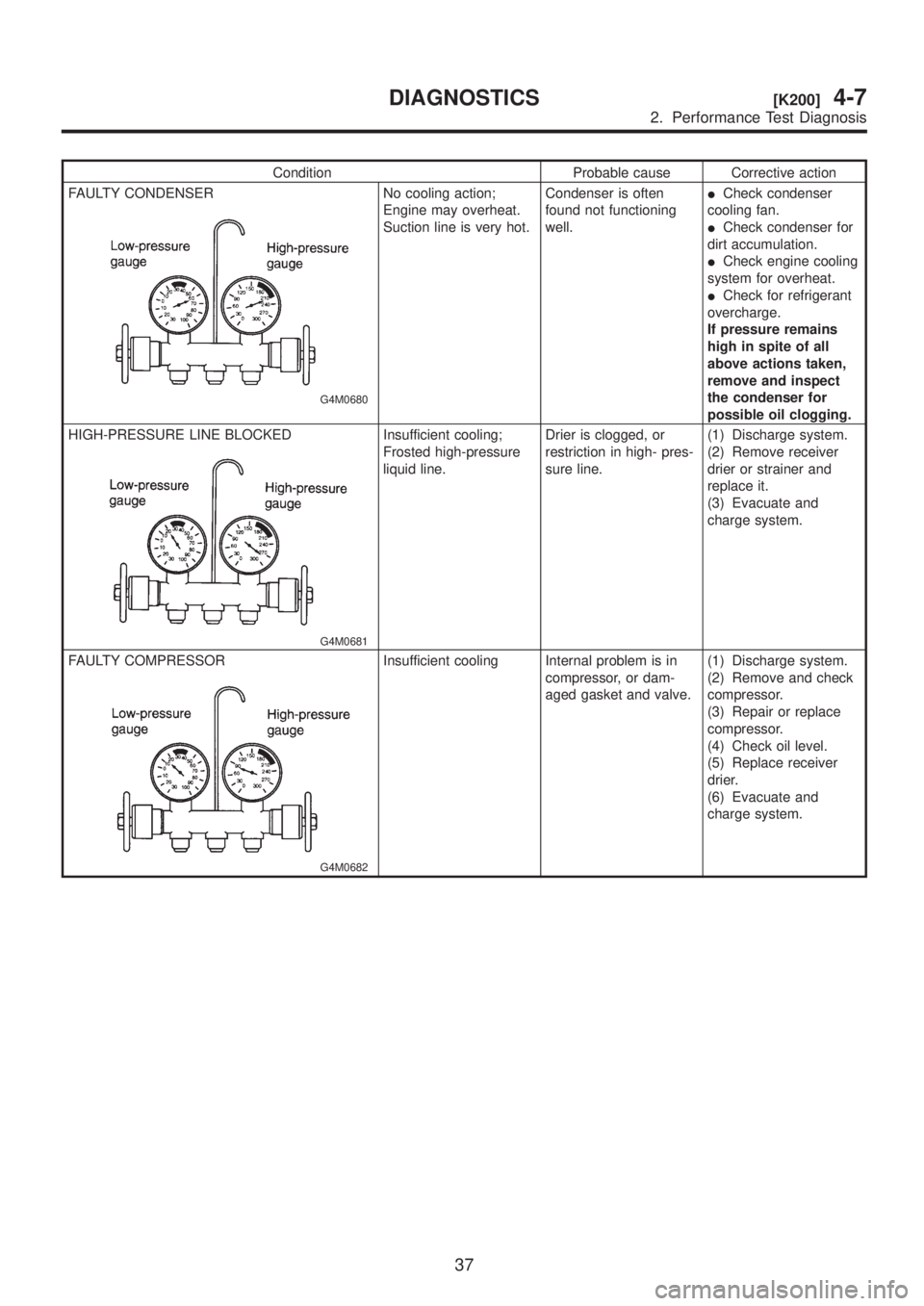

Condition Probable cause Corrective action

FAULTY CONDENSER

G4M0680

No cooling action;

Engine may overheat.

Suction line is very hot.Condenser is often

found not functioning

well.ICheck condenser

cooling fan.

ICheck condenser for

dirt accumulation.

ICheck engine cooling

system for overheat.

ICheck for refrigerant

overcharge.

If pressure remains

high in spite of all

above actions taken,

remove and inspect

the condenser for

possible oil clogging.

HIGH-PRESSURE LINE BLOCKED

G4M0681

Insufficient cooling;

Frosted high-pressure

liquid line.Drier is clogged, or

restriction in high- pres-

sure line.(1) Discharge system.

(2) Remove receiver

drier or strainer and

replace it.

(3) Evacuate and

charge system.

FAULTY COMPRESSOR

G4M0682

Insufficient cooling Internal problem is in

compressor, or dam-

aged gasket and valve.(1) Discharge system.

(2) Remove and check

compressor.

(3) Repair or replace

compressor.

(4) Check oil level.

(5) Replace receiver

drier.

(6) Evacuate and

charge system.

37

[K200]4-7DIAGNOSTICS

2. Performance Test Diagnosis

Page 1215 of 1456

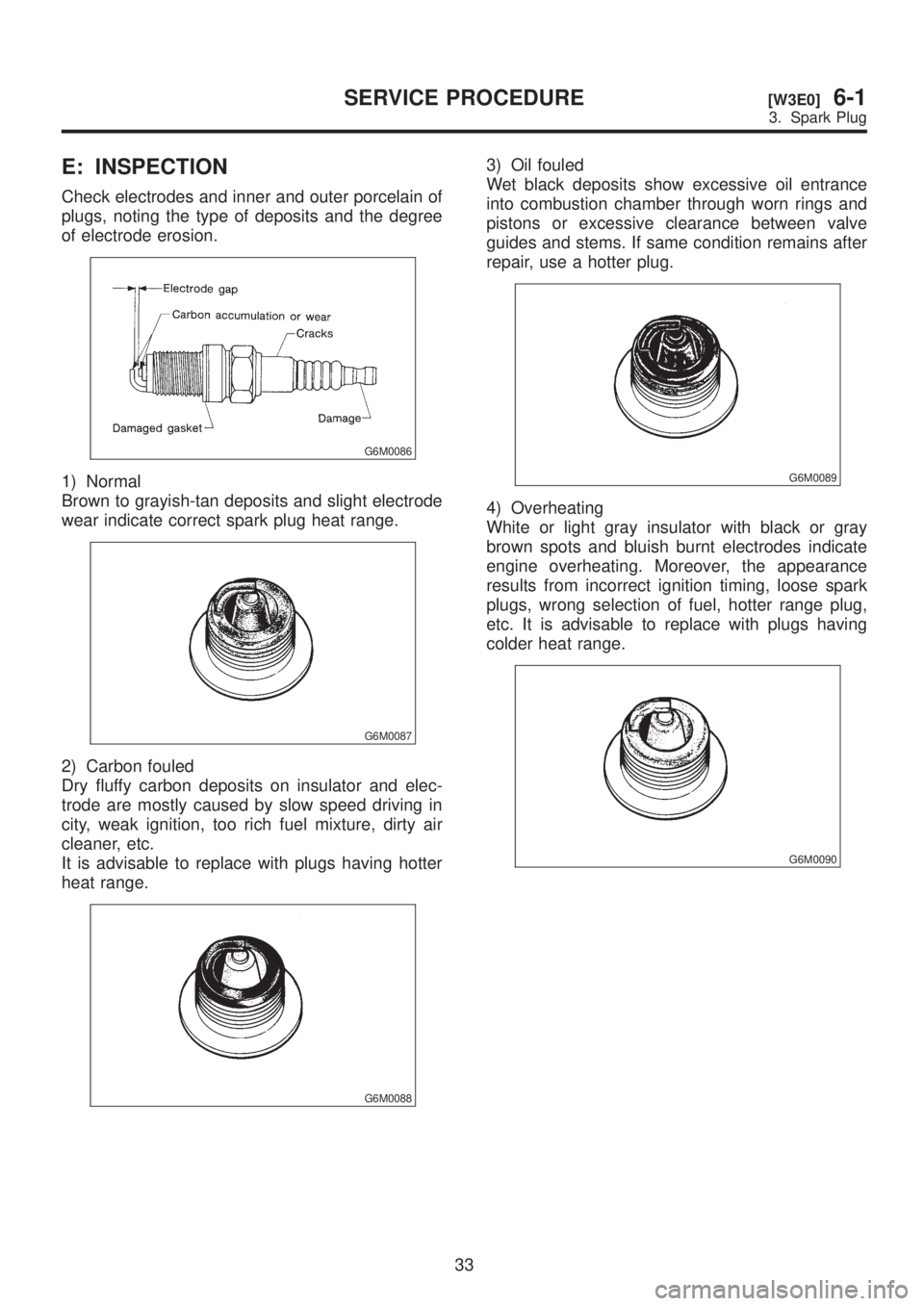

E: INSPECTION

Check electrodes and inner and outer porcelain of

plugs, noting the type of deposits and the degree

of electrode erosion.

G6M0086

1) Normal

Brown to grayish-tan deposits and slight electrode

wear indicate correct spark plug heat range.

G6M0087

2) Carbon fouled

Dry fluffy carbon deposits on insulator and elec-

trode are mostly caused by slow speed driving in

city, weak ignition, too rich fuel mixture, dirty air

cleaner, etc.

It is advisable to replace with plugs having hotter

heat range.

G6M0088

3) Oil fouled

Wet black deposits show excessive oil entrance

into combustion chamber through worn rings and

pistons or excessive clearance between valve

guides and stems. If same condition remains after

repair, use a hotter plug.

G6M0089

4) Overheating

White or light gray insulator with black or gray

brown spots and bluish burnt electrodes indicate

engine overheating. Moreover, the appearance

results from incorrect ignition timing, loose spark

plugs, wrong selection of fuel, hotter range plug,

etc. It is advisable to replace with plugs having

colder heat range.

G6M0090

33

[W3E0]6-1SERVICE PROCEDURE

3. Spark Plug