ESP SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 47 of 1456

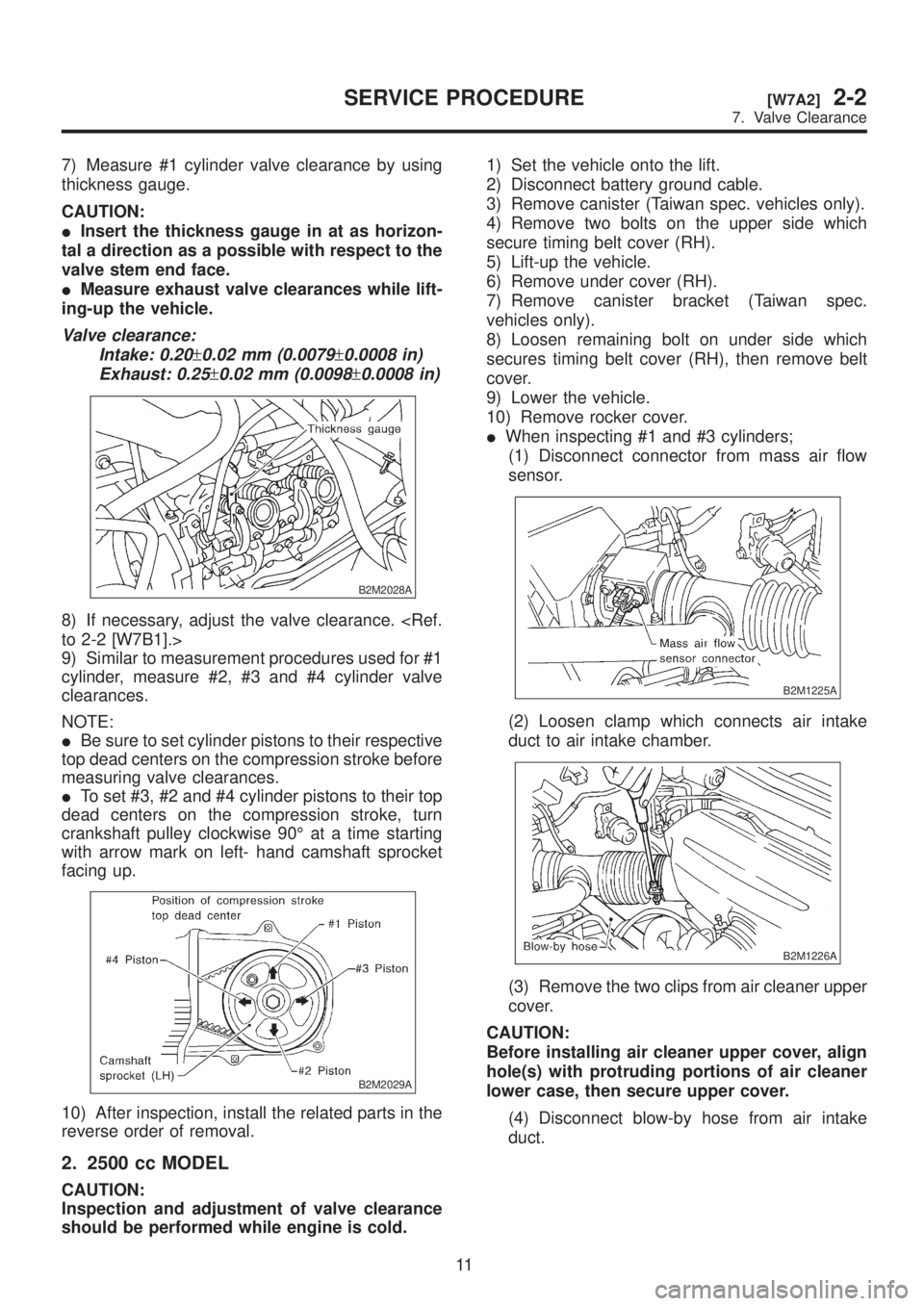

7) Measure #1 cylinder valve clearance by using

thickness gauge.

CAUTION:

IInsert the thickness gauge in at as horizon-

tal a direction as a possible with respect to the

valve stem end face.

IMeasure exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M2028A

8) If necessary, adjust the valve clearance.

9) Similar to measurement procedures used for #1

cylinder, measure #2, #3 and #4 cylinder valve

clearances.

NOTE:

IBe sure to set cylinder pistons to their respective

top dead centers on the compression stroke before

measuring valve clearances.

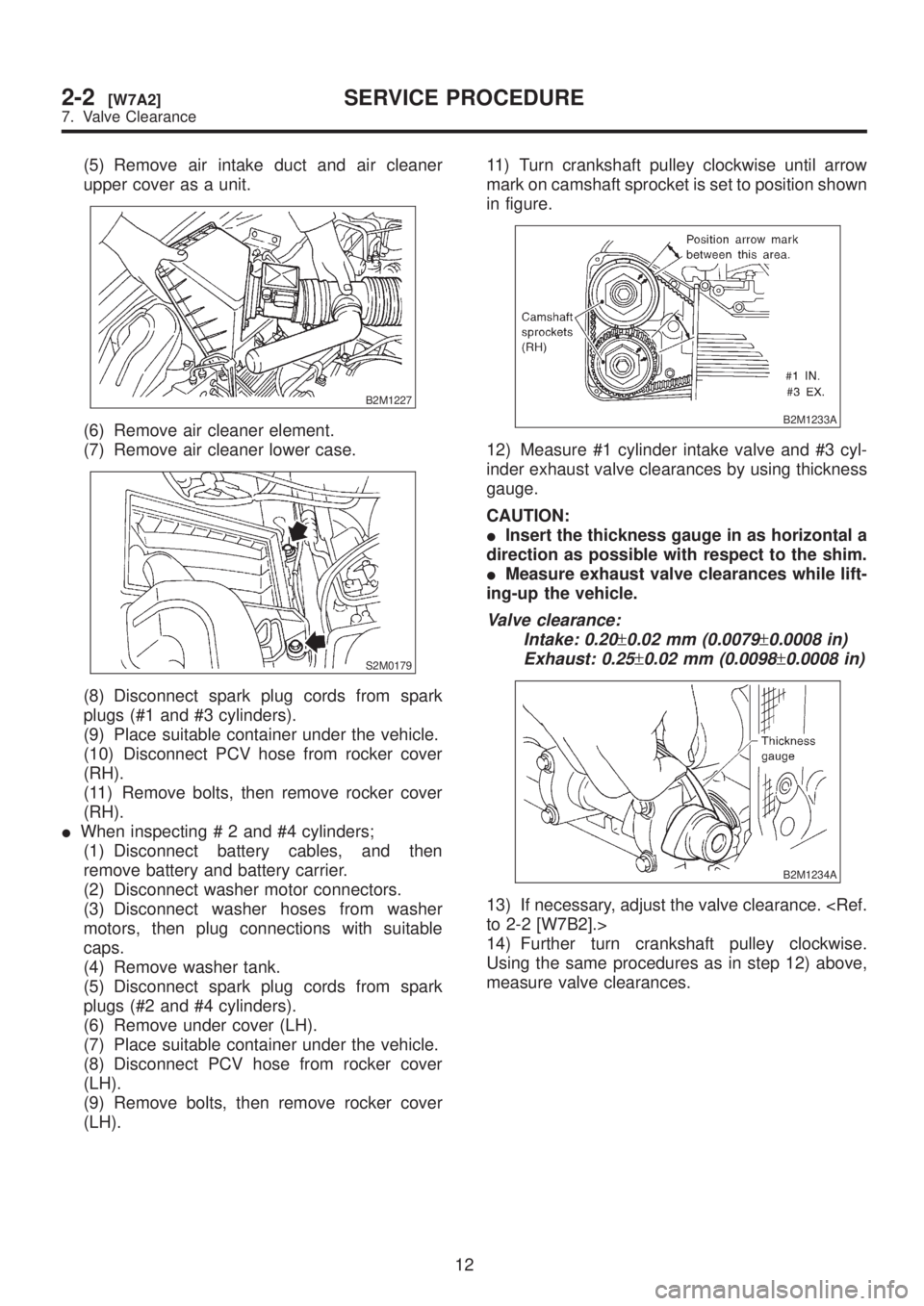

ITo set #3, #2 and #4 cylinder pistons to their top

dead centers on the compression stroke, turn

crankshaft pulley clockwise 90É at a time starting

with arrow mark on left- hand camshaft sprocket

facing up.

B2M2029A

10) After inspection, install the related parts in the

reverse order of removal.

2. 2500 cc MODEL

CAUTION:

Inspection and adjustment of valve clearance

should be performed while engine is cold.1) Set the vehicle onto the lift.

2) Disconnect battery ground cable.

3) Remove canister (Taiwan spec. vehicles only).

4) Remove two bolts on the upper side which

secure timing belt cover (RH).

5) Lift-up the vehicle.

6) Remove under cover (RH).

7) Remove canister bracket (Taiwan spec.

vehicles only).

8) Loosen remaining bolt on under side which

secures timing belt cover (RH), then remove belt

cover.

9) Lower the vehicle.

10) Remove rocker cover.

IWhen inspecting #1 and #3 cylinders;

(1) Disconnect connector from mass air flow

sensor.

B2M1225A

(2) Loosen clamp which connects air intake

duct to air intake chamber.

B2M1226A

(3) Remove the two clips from air cleaner upper

cover.

CAUTION:

Before installing air cleaner upper cover, align

hole(s) with protruding portions of air cleaner

lower case, then secure upper cover.

(4) Disconnect blow-by hose from air intake

duct.

11

[W7A2]2-2SERVICE PROCEDURE

7. Valve Clearance

Page 48 of 1456

(5) Remove air intake duct and air cleaner

upper cover as a unit.

B2M1227

(6) Remove air cleaner element.

(7) Remove air cleaner lower case.

S2M0179

(8) Disconnect spark plug cords from spark

plugs (#1 and #3 cylinders).

(9) Place suitable container under the vehicle.

(10) Disconnect PCV hose from rocker cover

(RH).

(11) Remove bolts, then remove rocker cover

(RH).

IWhen inspecting # 2 and #4 cylinders;

(1) Disconnect battery cables, and then

remove battery and battery carrier.

(2) Disconnect washer motor connectors.

(3) Disconnect washer hoses from washer

motors, then plug connections with suitable

caps.

(4) Remove washer tank.

(5) Disconnect spark plug cords from spark

plugs (#2 and #4 cylinders).

(6) Remove under cover (LH).

(7) Place suitable container under the vehicle.

(8) Disconnect PCV hose from rocker cover

(LH).

(9) Remove bolts, then remove rocker cover

(LH).11) Turn crankshaft pulley clockwise until arrow

mark on camshaft sprocket is set to position shown

in figure.

B2M1233A

12) Measure #1 cylinder intake valve and #3 cyl-

inder exhaust valve clearances by using thickness

gauge.

CAUTION:

IInsert the thickness gauge in as horizontal a

direction as possible with respect to the shim.

IMeasure exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M1234A

13) If necessary, adjust the valve clearance.

14) Further turn crankshaft pulley clockwise.

Using the same procedures as in step 12) above,

measure valve clearances.

12

2-2[W7A2]SERVICE PROCEDURE

7. Valve Clearance

Page 50 of 1456

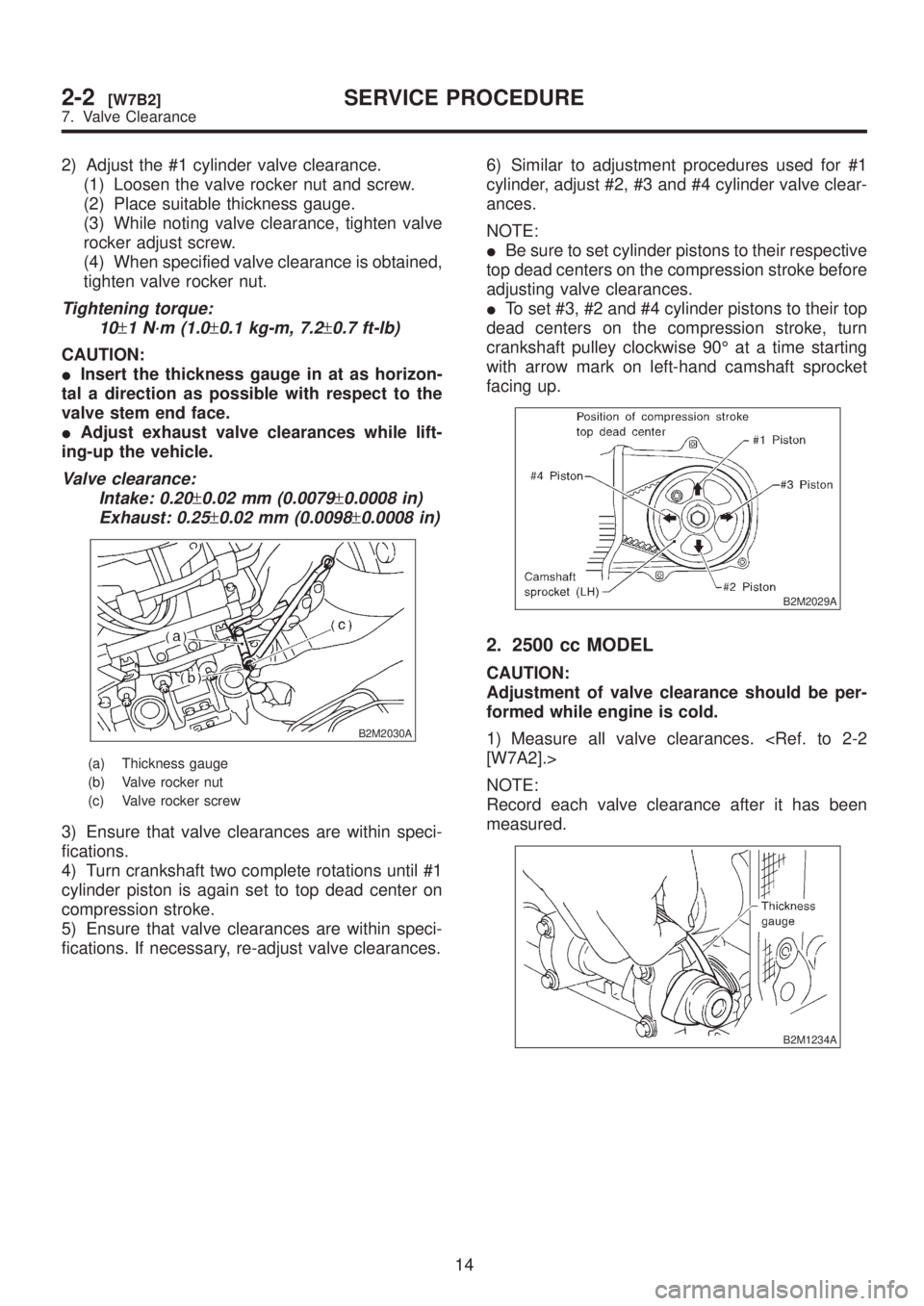

2) Adjust the #1 cylinder valve clearance.

(1) Loosen the valve rocker nut and screw.

(2) Place suitable thickness gauge.

(3) While noting valve clearance, tighten valve

rocker adjust screw.

(4) When specified valve clearance is obtained,

tighten valve rocker nut.

Tightening torque:

10

±1 N´m (1.0±0.1 kg-m, 7.2±0.7 ft-lb)

CAUTION:

IInsert the thickness gauge in at as horizon-

tal a direction as possible with respect to the

valve stem end face.

IAdjust exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M2030A

(a) Thickness gauge

(b) Valve rocker nut

(c) Valve rocker screw

3) Ensure that valve clearances are within speci-

fications.

4) Turn crankshaft two complete rotations until #1

cylinder piston is again set to top dead center on

compression stroke.

5) Ensure that valve clearances are within speci-

fications. If necessary, re-adjust valve clearances.6) Similar to adjustment procedures used for #1

cylinder, adjust #2, #3 and #4 cylinder valve clear-

ances.

NOTE:

IBe sure to set cylinder pistons to their respective

top dead centers on the compression stroke before

adjusting valve clearances.

ITo set #3, #2 and #4 cylinder pistons to their top

dead centers on the compression stroke, turn

crankshaft pulley clockwise 90É at a time starting

with arrow mark on left-hand camshaft sprocket

facing up.

B2M2029A

2. 2500 cc MODEL

CAUTION:

Adjustment of valve clearance should be per-

formed while engine is cold.

1) Measure all valve clearances.

NOTE:

Record each valve clearance after it has been

measured.

B2M1234A

14

2-2[W7B2]SERVICE PROCEDURE

7. Valve Clearance

Page 54 of 1456

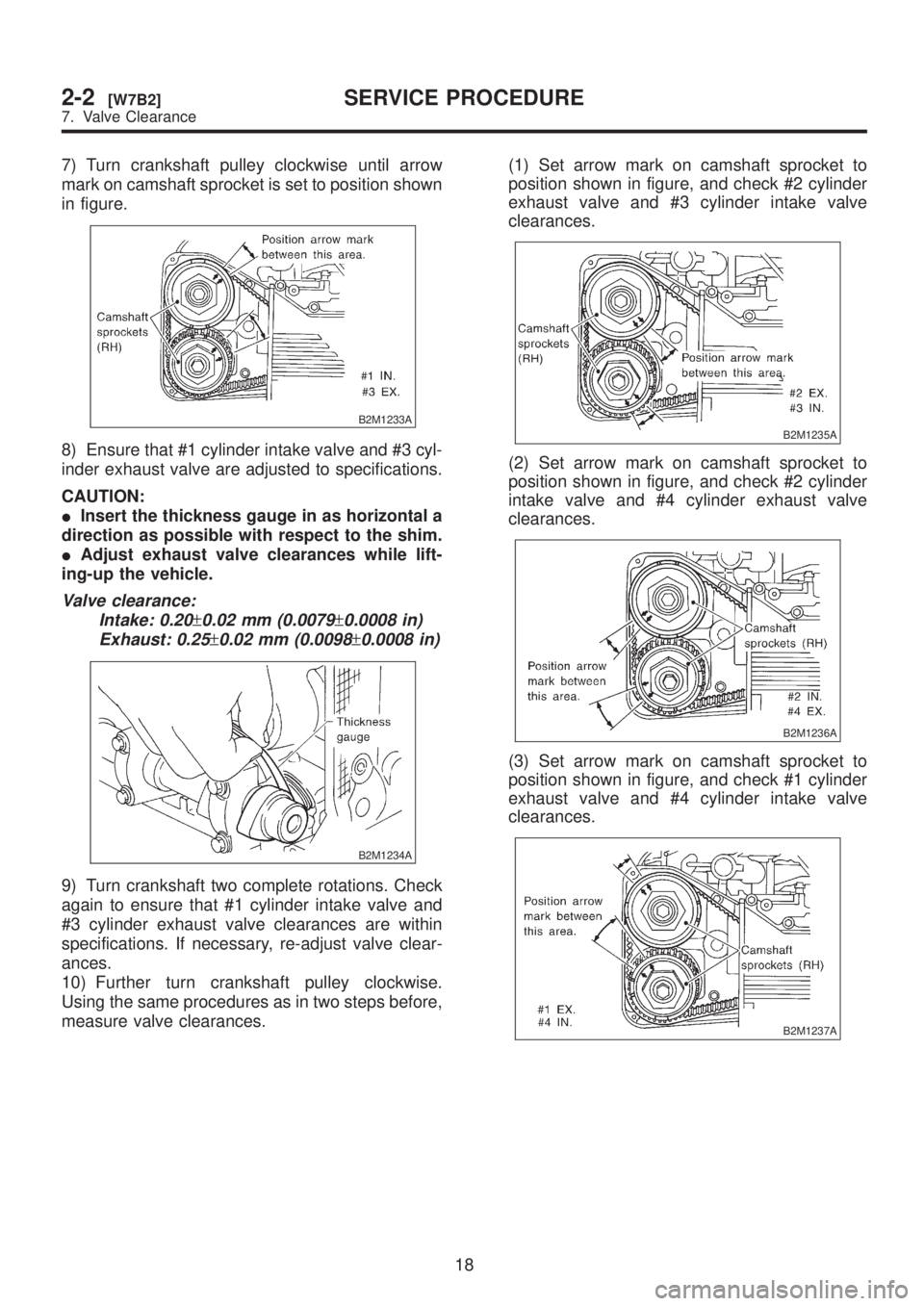

7) Turn crankshaft pulley clockwise until arrow

mark on camshaft sprocket is set to position shown

in figure.

B2M1233A

8) Ensure that #1 cylinder intake valve and #3 cyl-

inder exhaust valve are adjusted to specifications.

CAUTION:

IInsert the thickness gauge in as horizontal a

direction as possible with respect to the shim.

IAdjust exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M1234A

9) Turn crankshaft two complete rotations. Check

again to ensure that #1 cylinder intake valve and

#3 cylinder exhaust valve clearances are within

specifications. If necessary, re-adjust valve clear-

ances.

10) Further turn crankshaft pulley clockwise.

Using the same procedures as in two steps before,

measure valve clearances.(1) Set arrow mark on camshaft sprocket to

position shown in figure, and check #2 cylinder

exhaust valve and #3 cylinder intake valve

clearances.

B2M1235A

(2) Set arrow mark on camshaft sprocket to

position shown in figure, and check #2 cylinder

intake valve and #4 cylinder exhaust valve

clearances.

B2M1236A

(3) Set arrow mark on camshaft sprocket to

position shown in figure, and check #1 cylinder

exhaust valve and #4 cylinder intake valve

clearances.

B2M1237A

18

2-2[W7B2]SERVICE PROCEDURE

7. Valve Clearance

Page 98 of 1456

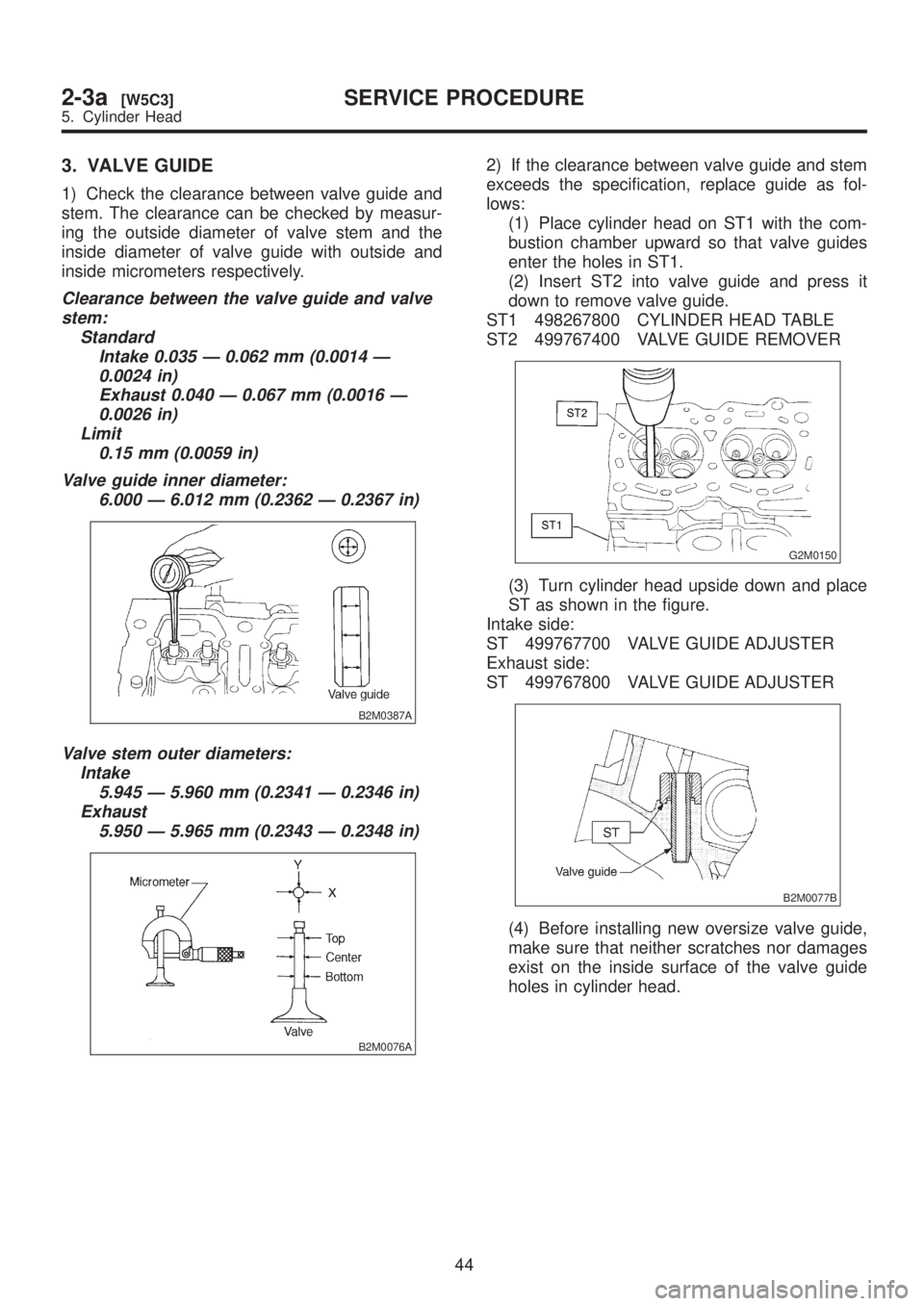

3. VALVE GUIDE

1) Check the clearance between valve guide and

stem. The clearance can be checked by measur-

ing the outside diameter of valve stem and the

inside diameter of valve guide with outside and

inside micrometers respectively.

Clearance between the valve guide and valve

stem:

Standard

Intake 0.035 Ð 0.062 mm (0.0014 Ð

0.0024 in)

Exhaust 0.040 Ð 0.067 mm (0.0016 Ð

0.0026 in)

Limit

0.15 mm (0.0059 in)

Valve guide inner diameter:

6.000 Ð 6.012 mm (0.2362 Ð 0.2367 in)

B2M0387A

Valve stem outer diameters:

Intake

5.945 Ð 5.960 mm (0.2341 Ð 0.2346 in)

Exhaust

5.950 Ð 5.965 mm (0.2343 Ð 0.2348 in)

B2M0076A

2) If the clearance between valve guide and stem

exceeds the specification, replace guide as fol-

lows:

(1) Place cylinder head on ST1 with the com-

bustion chamber upward so that valve guides

enter the holes in ST1.

(2) Insert ST2 into valve guide and press it

down to remove valve guide.

ST1 498267800 CYLINDER HEAD TABLE

ST2 499767400 VALVE GUIDE REMOVER

G2M0150

(3) Turn cylinder head upside down and place

ST as shown in the figure.

Intake side:

ST 499767700 VALVE GUIDE ADJUSTER

Exhaust side:

ST 499767800 VALVE GUIDE ADJUSTER

B2M0077B

(4) Before installing new oversize valve guide,

make sure that neither scratches nor damages

exist on the inside surface of the valve guide

holes in cylinder head.

44

2-3a[W5C3]SERVICE PROCEDURE

5. Cylinder Head

Page 110 of 1456

4) Remove crankshaft together with connecting

rod.

5) Remove crankshaft bearings from cylinder

block using hammer handle.

CAUTION:

Do not confuse combination of crankshaft

bearings. Press bearing at the end opposite to

locking lip.6) Draw out each piston from cylinder block using

wooden bar or hammer handle.

CAUTION:

Do not confuse combination of piston and cyl-

inder.

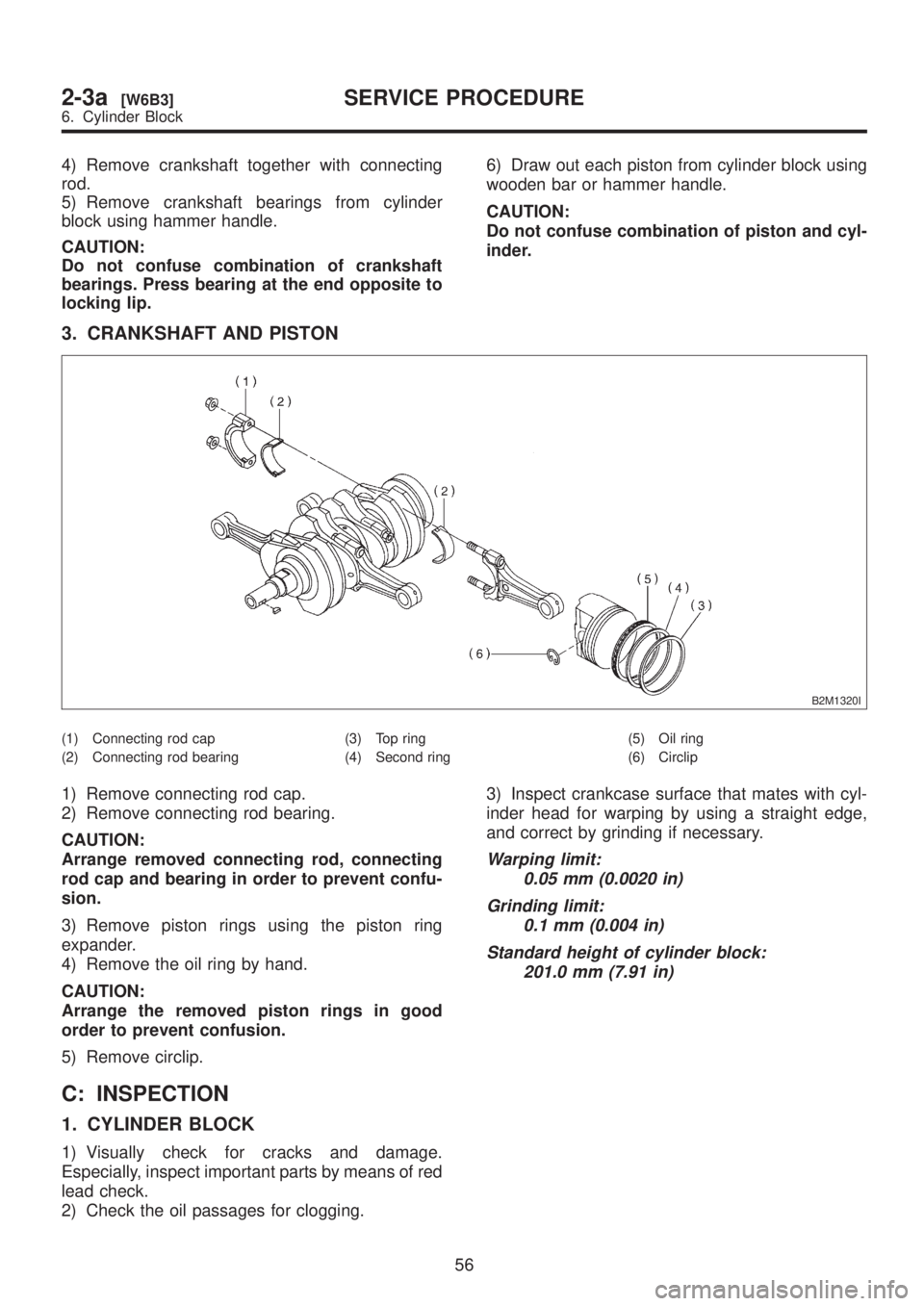

3. CRANKSHAFT AND PISTON

B2M1320I

(1) Connecting rod cap

(2) Connecting rod bearing(3) Top ring

(4) Second ring(5) Oil ring

(6) Circlip

1) Remove connecting rod cap.

2) Remove connecting rod bearing.

CAUTION:

Arrange removed connecting rod, connecting

rod cap and bearing in order to prevent confu-

sion.

3) Remove piston rings using the piston ring

expander.

4) Remove the oil ring by hand.

CAUTION:

Arrange the removed piston rings in good

order to prevent confusion.

5) Remove circlip.

C: INSPECTION

1. CYLINDER BLOCK

1) Visually check for cracks and damage.

Especially, inspect important parts by means of red

lead check.

2) Check the oil passages for clogging.3) Inspect crankcase surface that mates with cyl-

inder head for warping by using a straight edge,

and correct by grinding if necessary.

Warping limit:

0.05 mm (0.0020 in)

Grinding limit:

0.1 mm (0.004 in)

Standard height of cylinder block:

201.0 mm (7.91 in)

56

2-3a[W6B3]SERVICE PROCEDURE

6. Cylinder Block

Page 118 of 1456

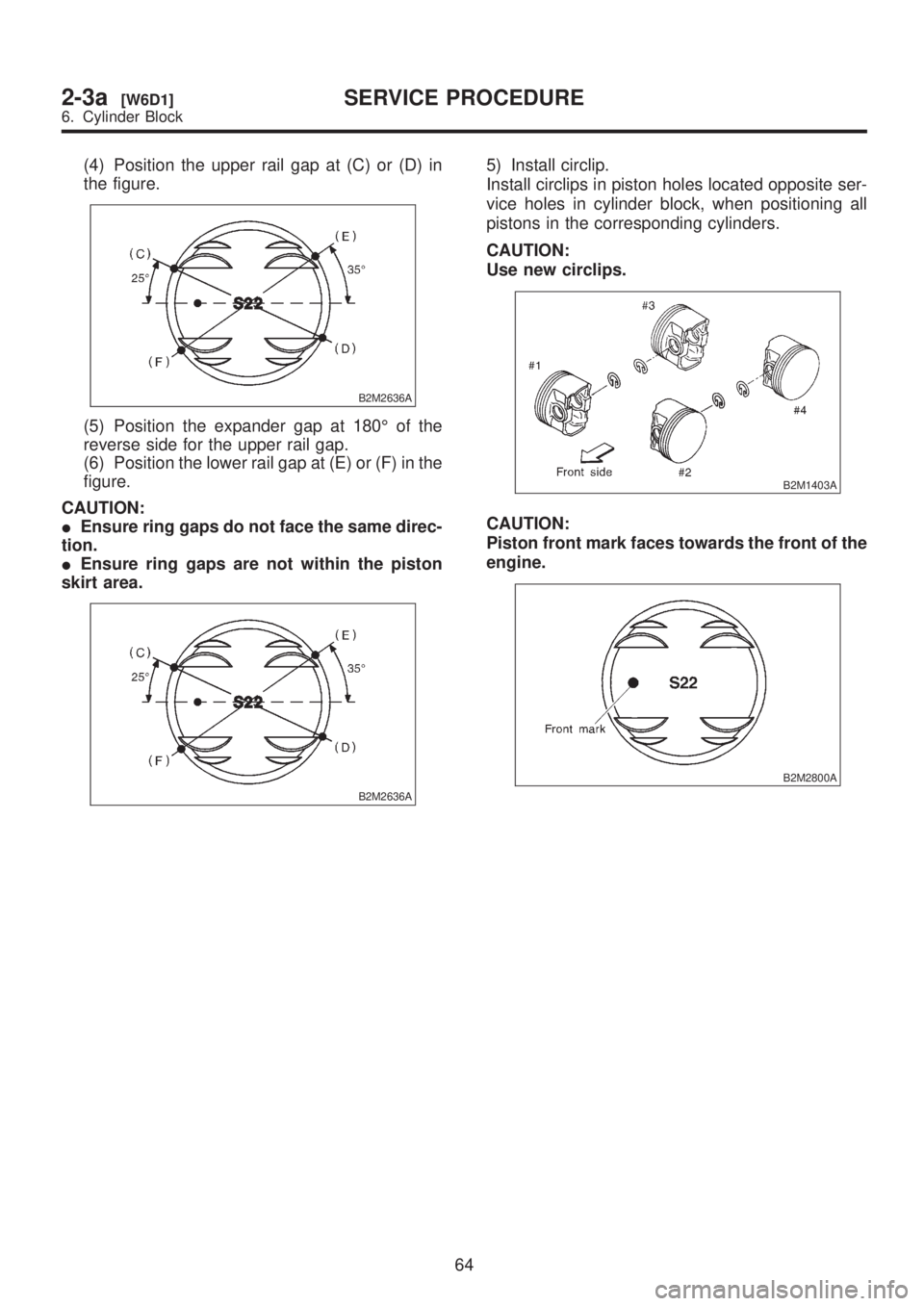

(4) Position the upper rail gap at (C) or (D) in

the figure.

B2M2636A

(5) Position the expander gap at 180É of the

reverse side for the upper rail gap.

(6) Position the lower rail gap at (E) or (F) in the

figure.

CAUTION:

IEnsure ring gaps do not face the same direc-

tion.

IEnsure ring gaps are not within the piston

skirt area.

B2M2636A

5) Install circlip.

Install circlips in piston holes located opposite ser-

vice holes in cylinder block, when positioning all

pistons in the corresponding cylinders.

CAUTION:

Use new circlips.

B2M1403A

CAUTION:

Piston front mark faces towards the front of the

engine.

B2M2800A

64

2-3a[W6D1]SERVICE PROCEDURE

6. Cylinder Block

Page 157 of 1456

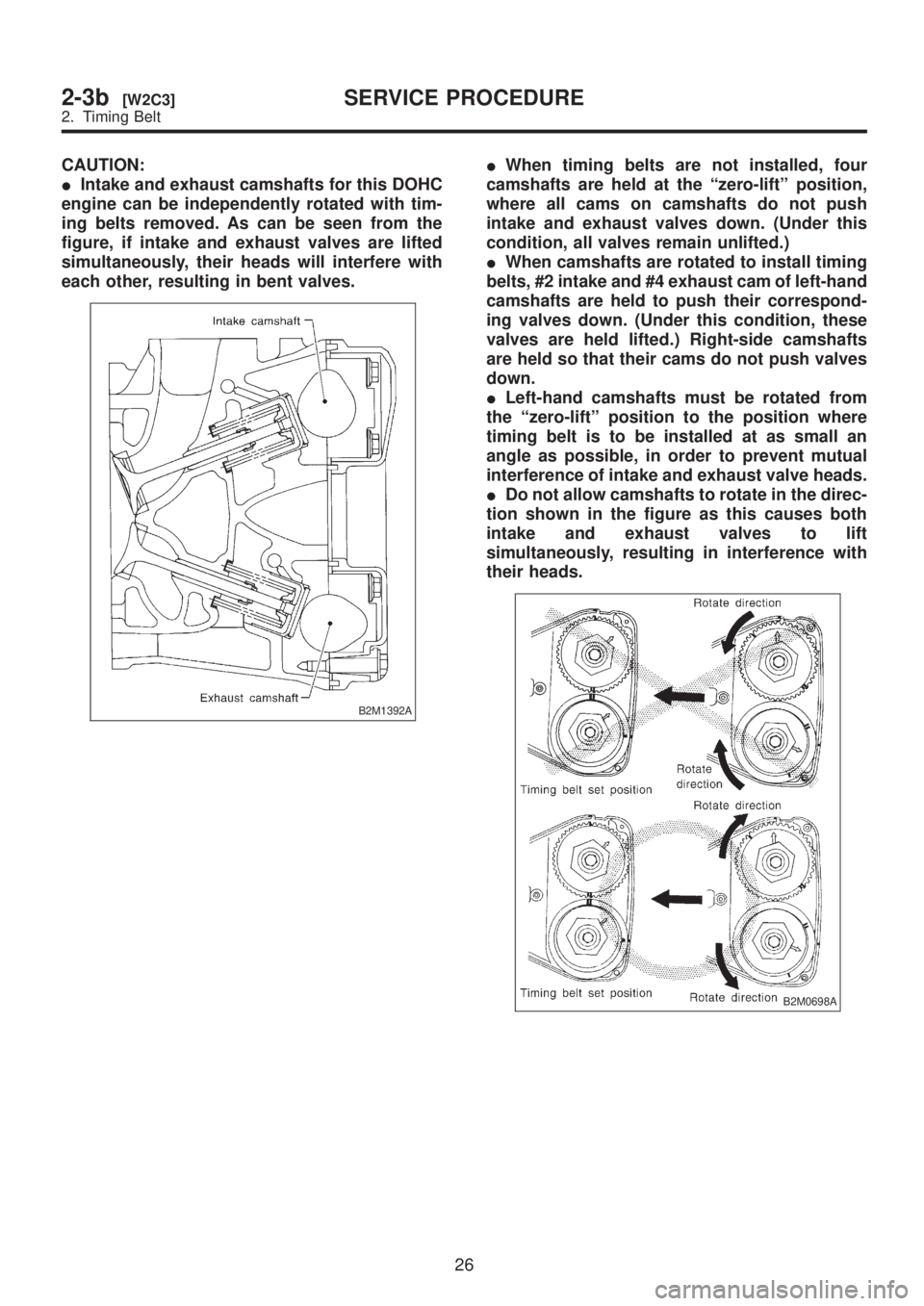

CAUTION:

IIntake and exhaust camshafts for this DOHC

engine can be independently rotated with tim-

ing belts removed. As can be seen from the

figure, if intake and exhaust valves are lifted

simultaneously, their heads will interfere with

each other, resulting in bent valves.

B2M1392A

IWhen timing belts are not installed, four

camshafts are held at the ªzero-liftº position,

where all cams on camshafts do not push

intake and exhaust valves down. (Under this

condition, all valves remain unlifted.)

IWhen camshafts are rotated to install timing

belts, #2 intake and #4 exhaust cam of left-hand

camshafts are held to push their correspond-

ing valves down. (Under this condition, these

valves are held lifted.) Right-side camshafts

are held so that their cams do not push valves

down.

ILeft-hand camshafts must be rotated from

the ªzero-liftº position to the position where

timing belt is to be installed at as small an

angle as possible, in order to prevent mutual

interference of intake and exhaust valve heads.

IDo not allow camshafts to rotate in the direc-

tion shown in the figure as this causes both

intake and exhaust valves to lift

simultaneously, resulting in interference with

their heads.

B2M0698A

26

2-3b[W2C3]SERVICE PROCEDURE

2. Timing Belt

Page 170 of 1456

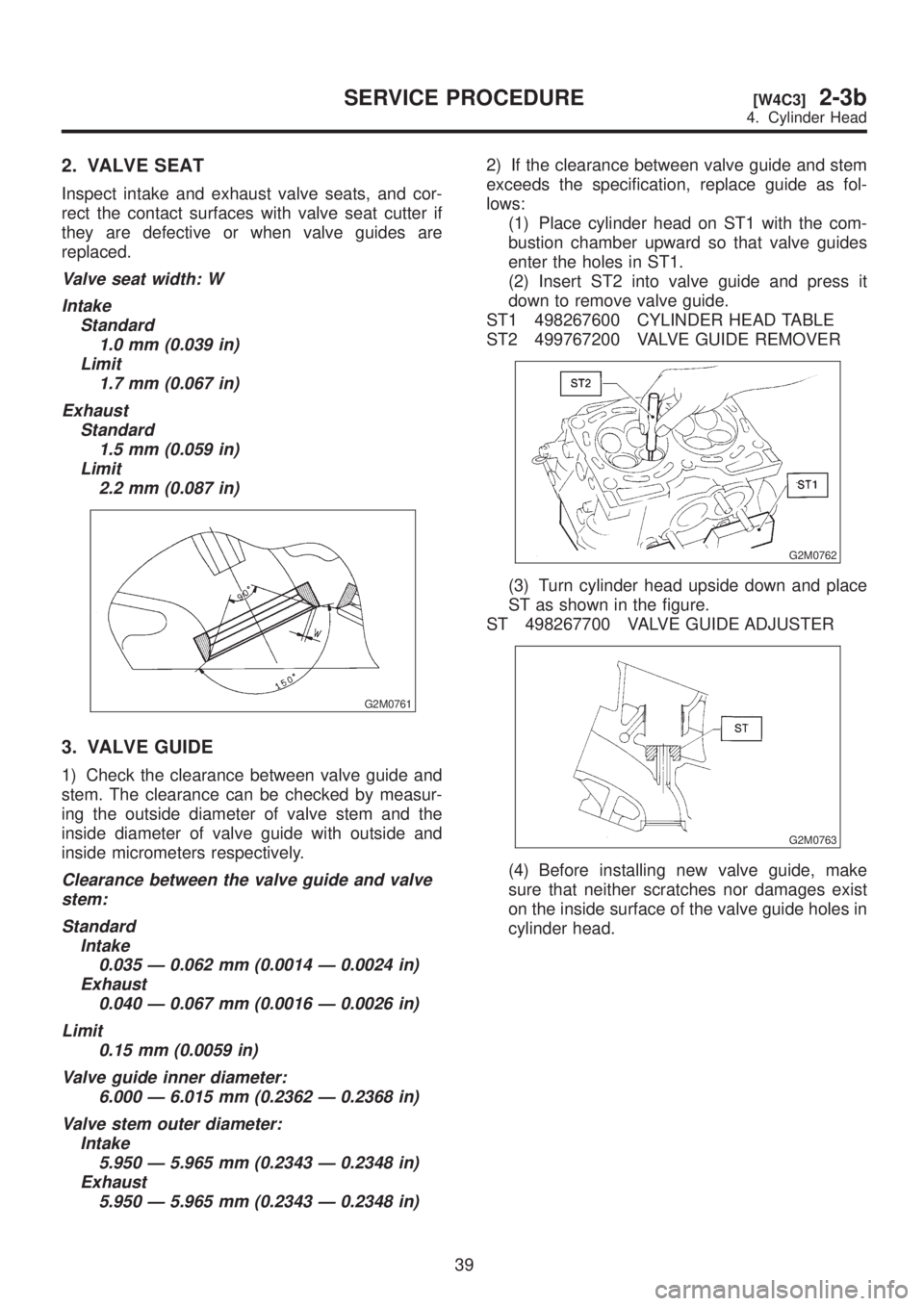

2. VALVE SEAT

Inspect intake and exhaust valve seats, and cor-

rect the contact surfaces with valve seat cutter if

they are defective or when valve guides are

replaced.

Valve seat width: W

Intake

Standard

1.0 mm (0.039 in)

Limit

1.7 mm (0.067 in)

Exhaust

Standard

1.5 mm (0.059 in)

Limit

2.2 mm (0.087 in)

G2M0761

3. VALVE GUIDE

1) Check the clearance between valve guide and

stem. The clearance can be checked by measur-

ing the outside diameter of valve stem and the

inside diameter of valve guide with outside and

inside micrometers respectively.

Clearance between the valve guide and valve

stem:

Standard

Intake

0.035 Ð 0.062 mm (0.0014 Ð 0.0024 in)

Exhaust

0.040 Ð 0.067 mm (0.0016 Ð 0.0026 in)

Limit

0.15 mm (0.0059 in)

Valve guide inner diameter:

6.000 Ð 6.015 mm (0.2362 Ð 0.2368 in)

Valve stem outer diameter:

Intake

5.950 Ð 5.965 mm (0.2343 Ð 0.2348 in)

Exhaust

5.950 Ð 5.965 mm (0.2343 Ð 0.2348 in)

2) If the clearance between valve guide and stem

exceeds the specification, replace guide as fol-

lows:

(1) Place cylinder head on ST1 with the com-

bustion chamber upward so that valve guides

enter the holes in ST1.

(2) Insert ST2 into valve guide and press it

down to remove valve guide.

ST1 498267600 CYLINDER HEAD TABLE

ST2 499767200 VALVE GUIDE REMOVER

G2M0762

(3) Turn cylinder head upside down and place

ST as shown in the figure.

ST 498267700 VALVE GUIDE ADJUSTER

G2M0763

(4) Before installing new valve guide, make

sure that neither scratches nor damages exist

on the inside surface of the valve guide holes in

cylinder head.

39

[W4C3]2-3bSERVICE PROCEDURE

4. Cylinder Head

Page 186 of 1456

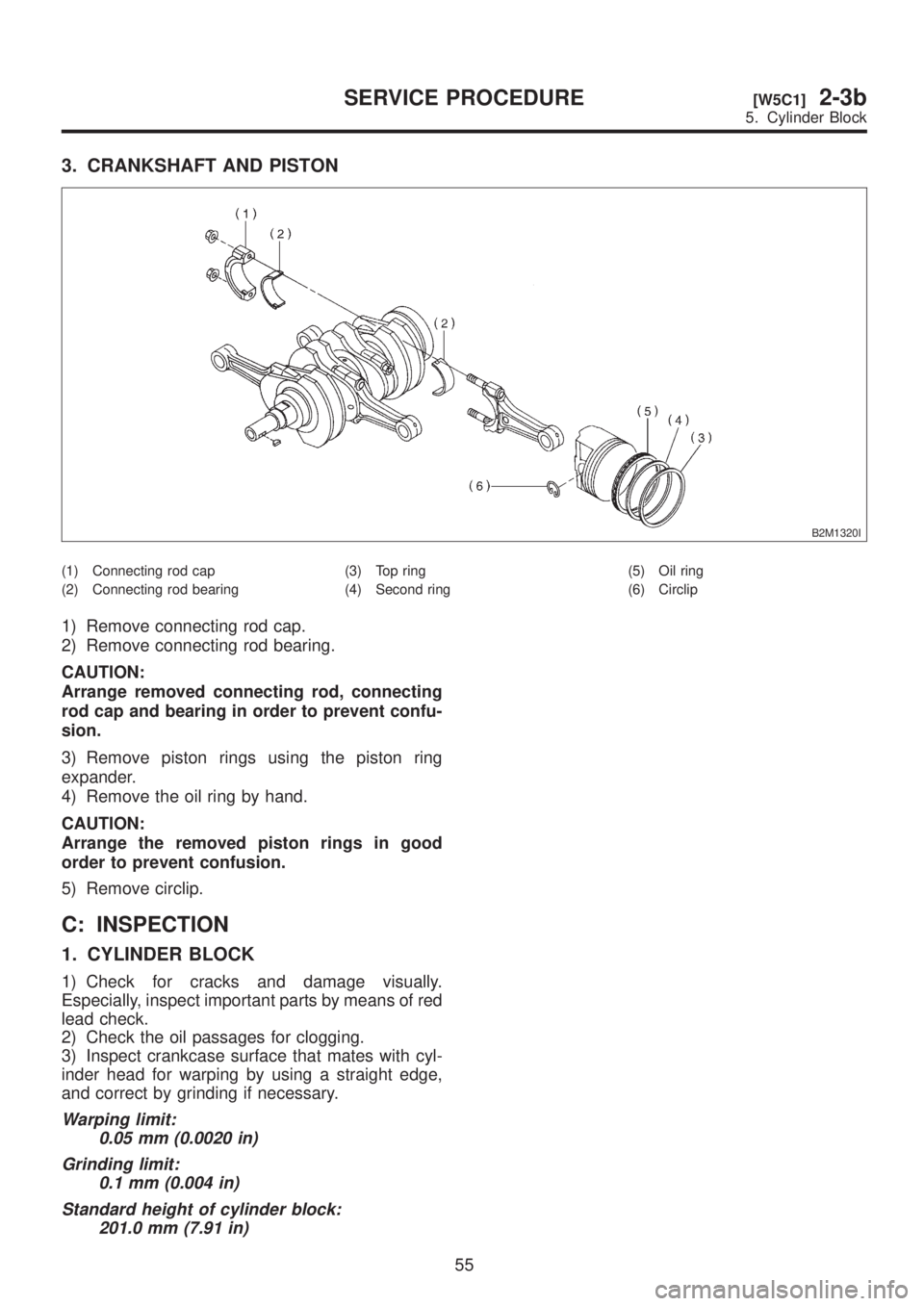

3. CRANKSHAFT AND PISTON

B2M1320I

(1) Connecting rod cap

(2) Connecting rod bearing(3) Top ring

(4) Second ring(5) Oil ring

(6) Circlip

1) Remove connecting rod cap.

2) Remove connecting rod bearing.

CAUTION:

Arrange removed connecting rod, connecting

rod cap and bearing in order to prevent confu-

sion.

3) Remove piston rings using the piston ring

expander.

4) Remove the oil ring by hand.

CAUTION:

Arrange the removed piston rings in good

order to prevent confusion.

5) Remove circlip.

C: INSPECTION

1. CYLINDER BLOCK

1) Check for cracks and damage visually.

Especially, inspect important parts by means of red

lead check.

2) Check the oil passages for clogging.

3) Inspect crankcase surface that mates with cyl-

inder head for warping by using a straight edge,

and correct by grinding if necessary.

Warping limit:

0.05 mm (0.0020 in)

Grinding limit:

0.1 mm (0.004 in)

Standard height of cylinder block:

201.0 mm (7.91 in)

55

[W5C1]2-3bSERVICE PROCEDURE

5. Cylinder Block