coolant temperature SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 229 of 1456

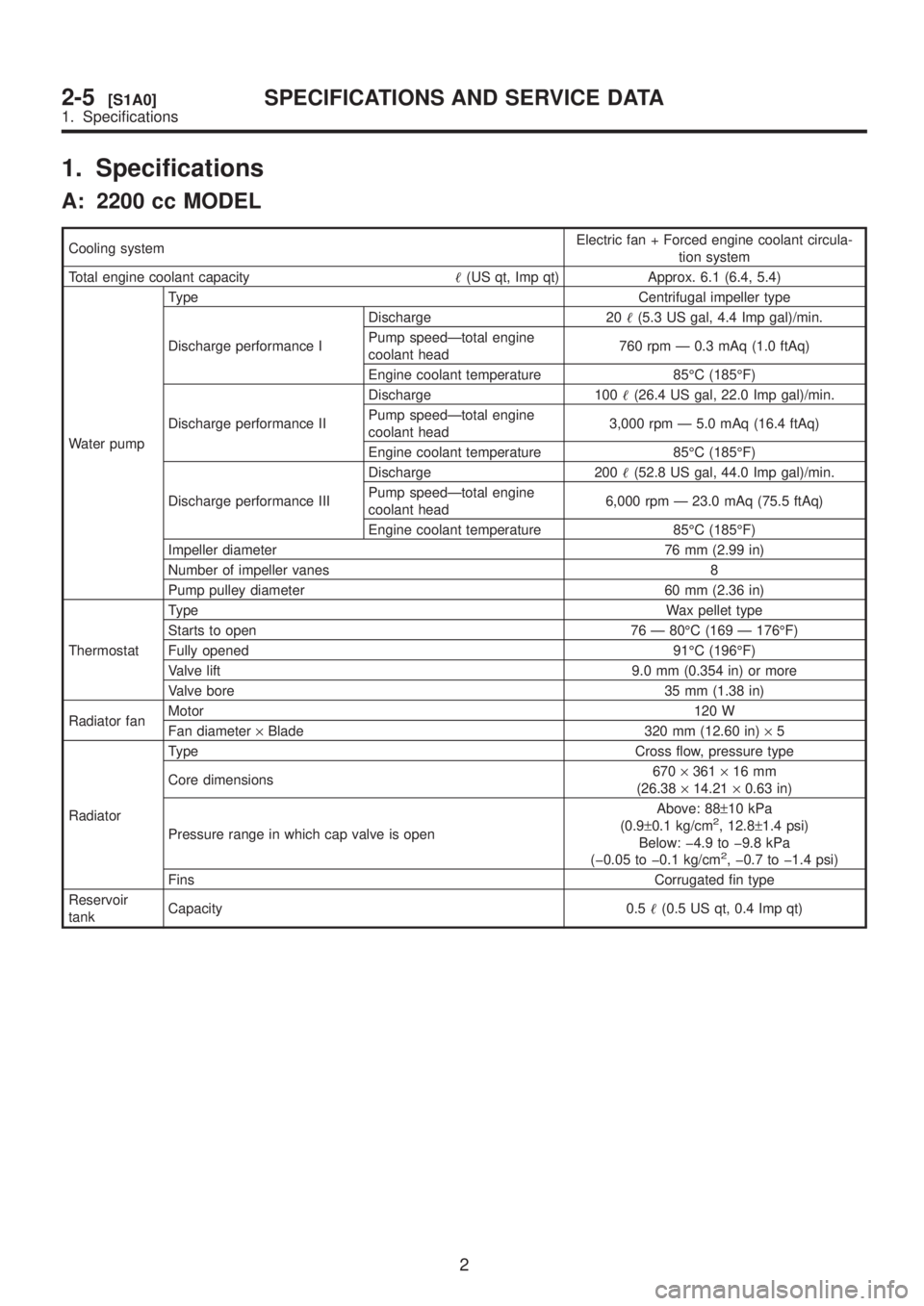

1. Specifications

A: 2200 cc MODEL

Cooling systemElectric fan + Forced engine coolant circula-

tion system

Total engine coolant capacity(US qt, Imp qt) Approx. 6.1 (6.4, 5.4)

Water pumpType Centrifugal impeller type

Discharge performance IDischarge 20(5.3 US gal, 4.4 Imp gal)/min.

Pump speedÐtotal engine

coolant head760 rpm Ð 0.3 mAq (1.0 ftAq)

Engine coolant temperature 85ÉC (185ÉF)

Discharge performance IIDischarge 100(26.4 US gal, 22.0 Imp gal)/min.

Pump speedÐtotal engine

coolant head3,000 rpm Ð 5.0 mAq (16.4 ftAq)

Engine coolant temperature 85ÉC (185ÉF)

Discharge performance IIIDischarge 200(52.8 US gal, 44.0 Imp gal)/min.

Pump speedÐtotal engine

coolant head6,000 rpm Ð 23.0 mAq (75.5 ftAq)

Engine coolant temperature 85ÉC (185ÉF)

Impeller diameter 76 mm (2.99 in)

Number of impeller vanes 8

Pump pulley diameter 60 mm (2.36 in)

ThermostatTypeWax pellet type

Starts to open 76 Ð 80ÉC (169 Ð 176ÉF)

Fully opened 91ÉC (196ÉF)

Valve lift 9.0 mm (0.354 in) or more

Valve bore 35 mm (1.38 in)

Radiator fanMotor120 W

Fan diameter´Blade 320 mm (12.60 in)´5

RadiatorType Cross flow, pressure type

Core dimensions670´361´16 mm

(26.38´14.21´0.63 in)

Pressure range in which cap valve is openAbove: 88±10 kPa

(0.9±0.1 kg/cm

2, 12.8±1.4 psi)

Below: þ4.9 to þ9.8 kPa

(þ0.05 to þ0.1 kg/cm

2, þ0.7 to þ1.4 psi)

FinsCorrugated fin type

Reservoir

tankCapacity 0.5(0.5 US qt, 0.4 Imp qt)

2

2-5[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Specifications

Page 230 of 1456

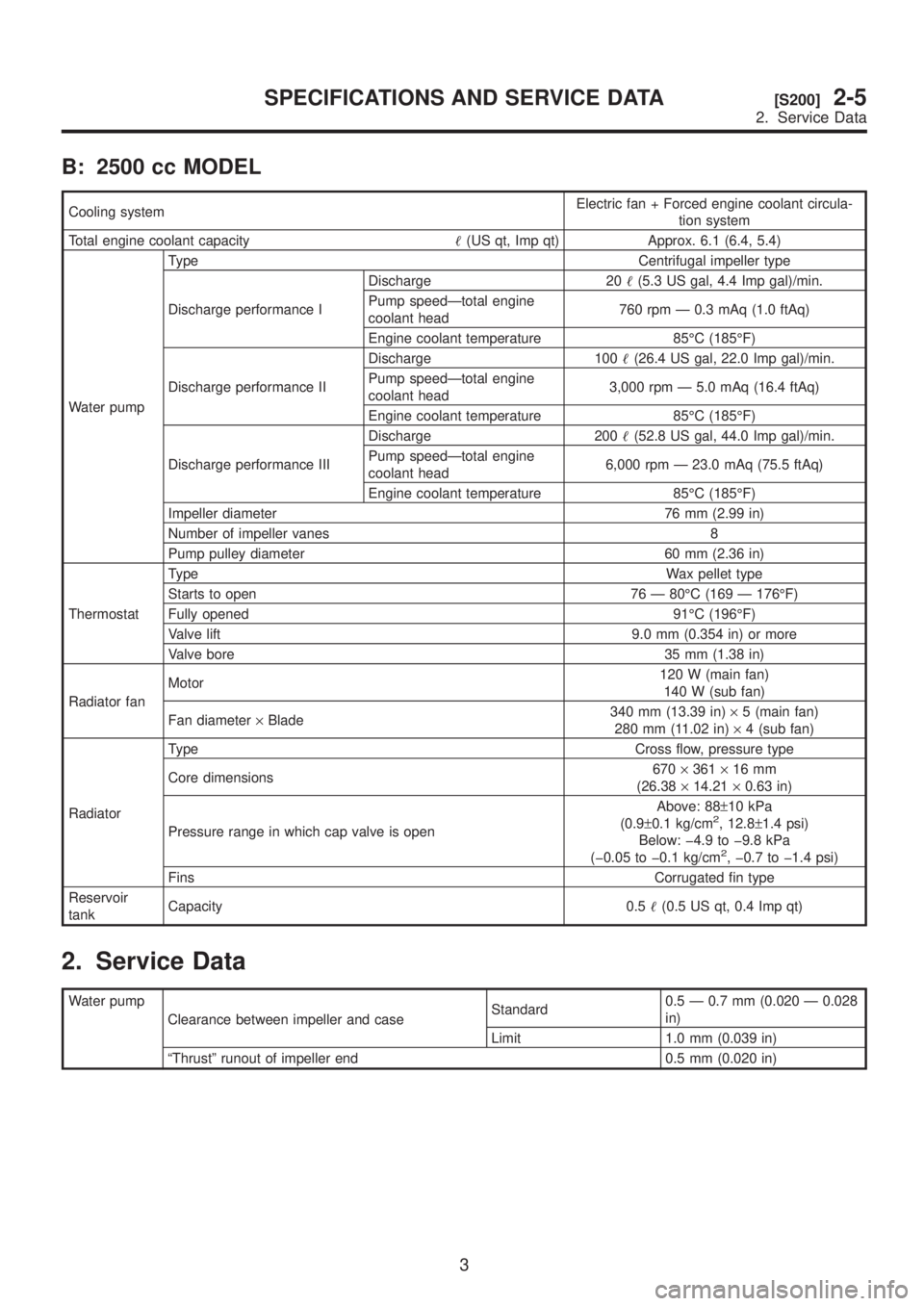

B: 2500 cc MODEL

Cooling systemElectric fan + Forced engine coolant circula-

tion system

Total engine coolant capacity(US qt, Imp qt) Approx. 6.1 (6.4, 5.4)

Water pumpType Centrifugal impeller type

Discharge performance IDischarge 20(5.3 US gal, 4.4 Imp gal)/min.

Pump speedÐtotal engine

coolant head760 rpm Ð 0.3 mAq (1.0 ftAq)

Engine coolant temperature 85ÉC (185ÉF)

Discharge performance IIDischarge 100(26.4 US gal, 22.0 Imp gal)/min.

Pump speedÐtotal engine

coolant head3,000 rpm Ð 5.0 mAq (16.4 ftAq)

Engine coolant temperature 85ÉC (185ÉF)

Discharge performance IIIDischarge 200(52.8 US gal, 44.0 Imp gal)/min.

Pump speedÐtotal engine

coolant head6,000 rpm Ð 23.0 mAq (75.5 ftAq)

Engine coolant temperature 85ÉC (185ÉF)

Impeller diameter 76 mm (2.99 in)

Number of impeller vanes 8

Pump pulley diameter 60 mm (2.36 in)

ThermostatTypeWax pellet type

Starts to open 76 Ð 80ÉC (169 Ð 176ÉF)

Fully opened 91ÉC (196ÉF)

Valve lift 9.0 mm (0.354 in) or more

Valve bore 35 mm (1.38 in)

Radiator fanMotor120 W (main fan)

140 W (sub fan)

Fan diameter´Blade340 mm (13.39 in)´5 (main fan)

280 mm (11.02 in)´4 (sub fan)

RadiatorType Cross flow, pressure type

Core dimensions670´361´16 mm

(26.38´14.21´0.63 in)

Pressure range in which cap valve is openAbove: 88±10 kPa

(0.9±0.1 kg/cm

2, 12.8±1.4 psi)

Below: þ4.9 to þ9.8 kPa

(þ0.05 to þ0.1 kg/cm

2, þ0.7 to þ1.4 psi)

FinsCorrugated fin type

Reservoir

tankCapacity 0.5(0.5 US qt, 0.4 Imp qt)

2. Service Data

Water pump

Clearance between impeller and caseStandard0.5 Ð 0.7 mm (0.020 Ð 0.028

in)

Limit 1.0 mm (0.039 in)

ªThrustº runout of impeller end 0.5 mm (0.020 in)

3

[S200]2-5SPECIFICATIONS AND SERVICE DATA

2. Service Data

Page 231 of 1456

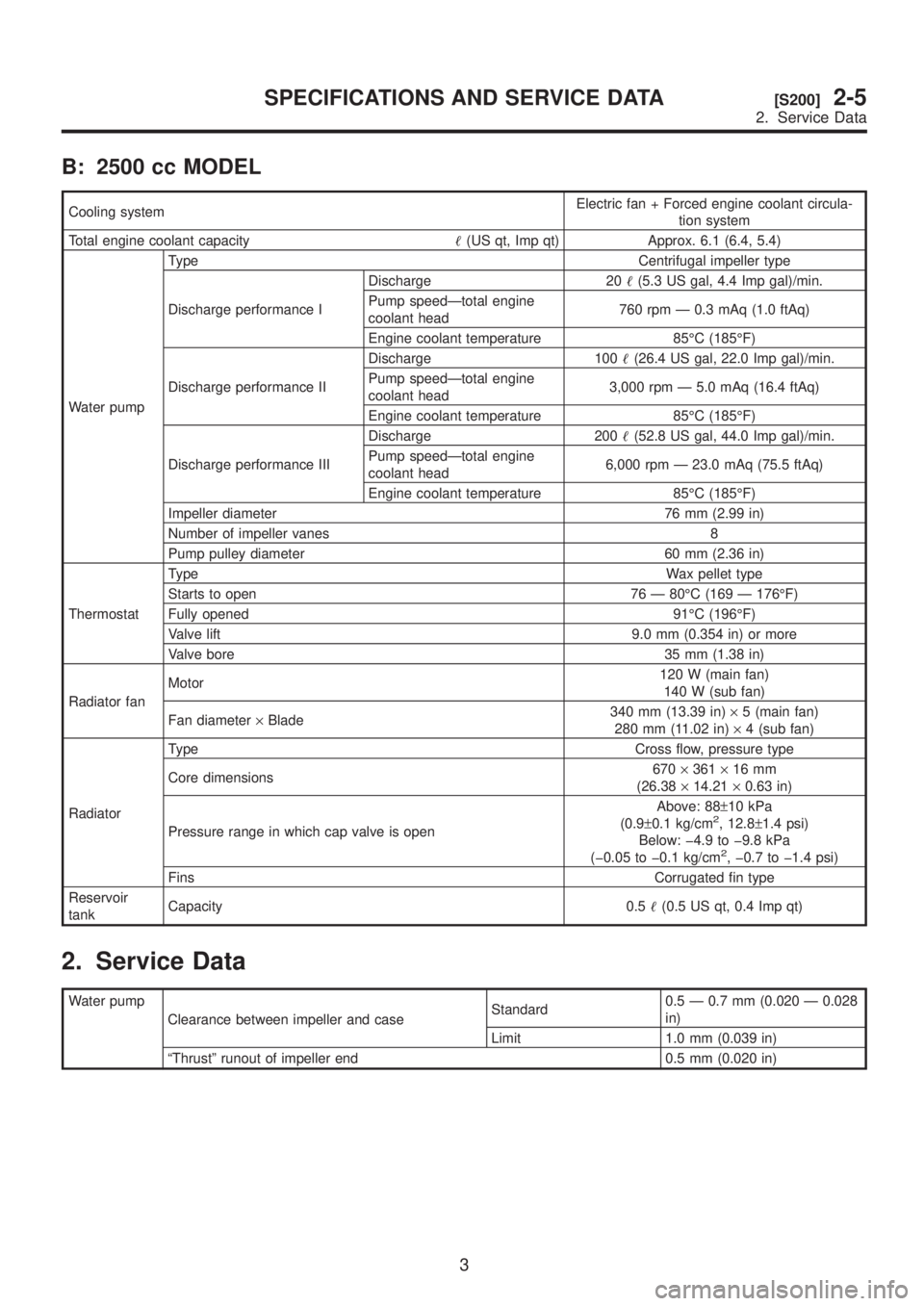

B: 2500 cc MODEL

Cooling systemElectric fan + Forced engine coolant circula-

tion system

Total engine coolant capacity(US qt, Imp qt) Approx. 6.1 (6.4, 5.4)

Water pumpType Centrifugal impeller type

Discharge performance IDischarge 20(5.3 US gal, 4.4 Imp gal)/min.

Pump speedÐtotal engine

coolant head760 rpm Ð 0.3 mAq (1.0 ftAq)

Engine coolant temperature 85ÉC (185ÉF)

Discharge performance IIDischarge 100(26.4 US gal, 22.0 Imp gal)/min.

Pump speedÐtotal engine

coolant head3,000 rpm Ð 5.0 mAq (16.4 ftAq)

Engine coolant temperature 85ÉC (185ÉF)

Discharge performance IIIDischarge 200(52.8 US gal, 44.0 Imp gal)/min.

Pump speedÐtotal engine

coolant head6,000 rpm Ð 23.0 mAq (75.5 ftAq)

Engine coolant temperature 85ÉC (185ÉF)

Impeller diameter 76 mm (2.99 in)

Number of impeller vanes 8

Pump pulley diameter 60 mm (2.36 in)

ThermostatTypeWax pellet type

Starts to open 76 Ð 80ÉC (169 Ð 176ÉF)

Fully opened 91ÉC (196ÉF)

Valve lift 9.0 mm (0.354 in) or more

Valve bore 35 mm (1.38 in)

Radiator fanMotor120 W (main fan)

140 W (sub fan)

Fan diameter´Blade340 mm (13.39 in)´5 (main fan)

280 mm (11.02 in)´4 (sub fan)

RadiatorType Cross flow, pressure type

Core dimensions670´361´16 mm

(26.38´14.21´0.63 in)

Pressure range in which cap valve is openAbove: 88±10 kPa

(0.9±0.1 kg/cm

2, 12.8±1.4 psi)

Below: þ4.9 to þ9.8 kPa

(þ0.05 to þ0.1 kg/cm

2, þ0.7 to þ1.4 psi)

FinsCorrugated fin type

Reservoir

tankCapacity 0.5(0.5 US qt, 0.4 Imp qt)

2. Service Data

Water pump

Clearance between impeller and caseStandard0.5 Ð 0.7 mm (0.020 Ð 0.028

in)

Limit 1.0 mm (0.039 in)

ªThrustº runout of impeller end 0.5 mm (0.020 in)

3

[S200]2-5SPECIFICATIONS AND SERVICE DATA

2. Service Data

Page 234 of 1456

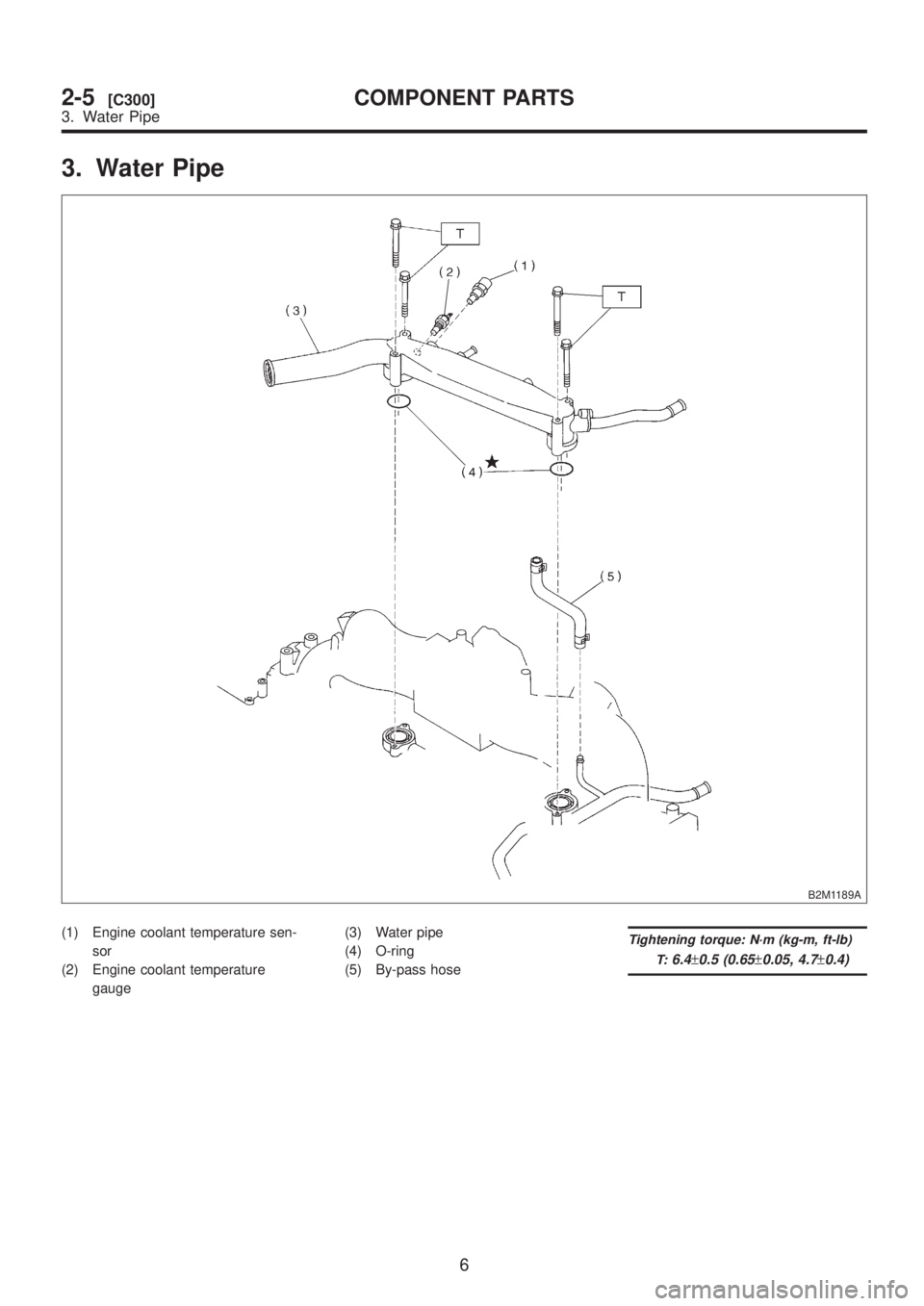

3. Water Pipe

B2M1189A

(1) Engine coolant temperature sen-

sor

(2) Engine coolant temperature

gauge(3) Water pipe

(4) O-ring

(5) By-pass hoseTightening torque: N´m (kg-m, ft-lb)

T:

6.4±0.5 (0.65±0.05, 4.7±0.4)

6

2-5[C300]COMPONENT PARTS

3. Water Pipe

Page 235 of 1456

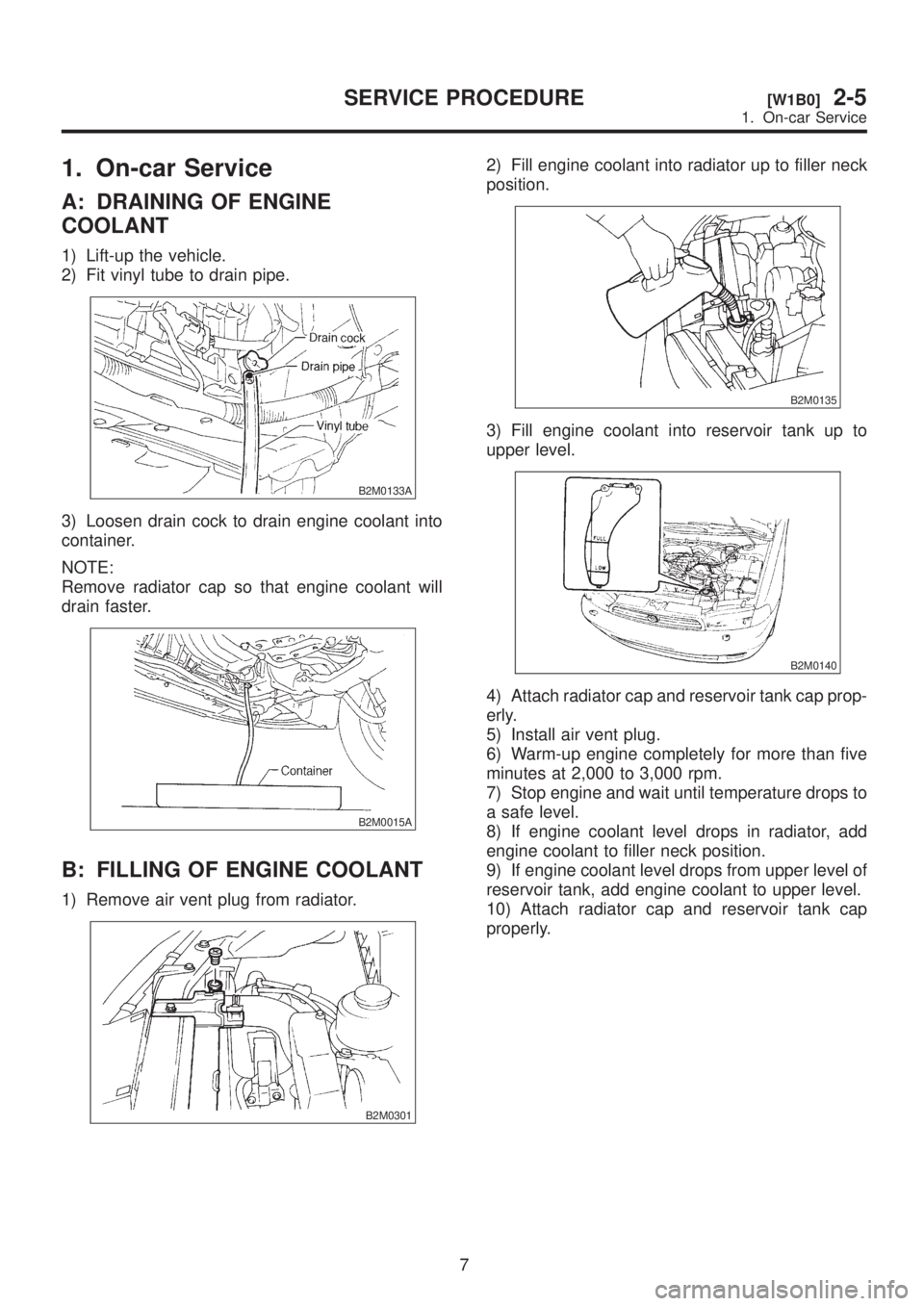

1. On-car Service

A: DRAINING OF ENGINE

COOLANT

1) Lift-up the vehicle.

2) Fit vinyl tube to drain pipe.

B2M0133A

3) Loosen drain cock to drain engine coolant into

container.

NOTE:

Remove radiator cap so that engine coolant will

drain faster.

B2M0015A

B: FILLING OF ENGINE COOLANT

1) Remove air vent plug from radiator.

B2M0301

2) Fill engine coolant into radiator up to filler neck

position.

B2M0135

3) Fill engine coolant into reservoir tank up to

upper level.

B2M0140

4) Attach radiator cap and reservoir tank cap prop-

erly.

5) Install air vent plug.

6) Warm-up engine completely for more than five

minutes at 2,000 to 3,000 rpm.

7) Stop engine and wait until temperature drops to

a safe level.

8) If engine coolant level drops in radiator, add

engine coolant to filler neck position.

9) If engine coolant level drops from upper level of

reservoir tank, add engine coolant to upper level.

10) Attach radiator cap and reservoir tank cap

properly.

7

[W1B0]2-5SERVICE PROCEDURE

1. On-car Service

Page 244 of 1456

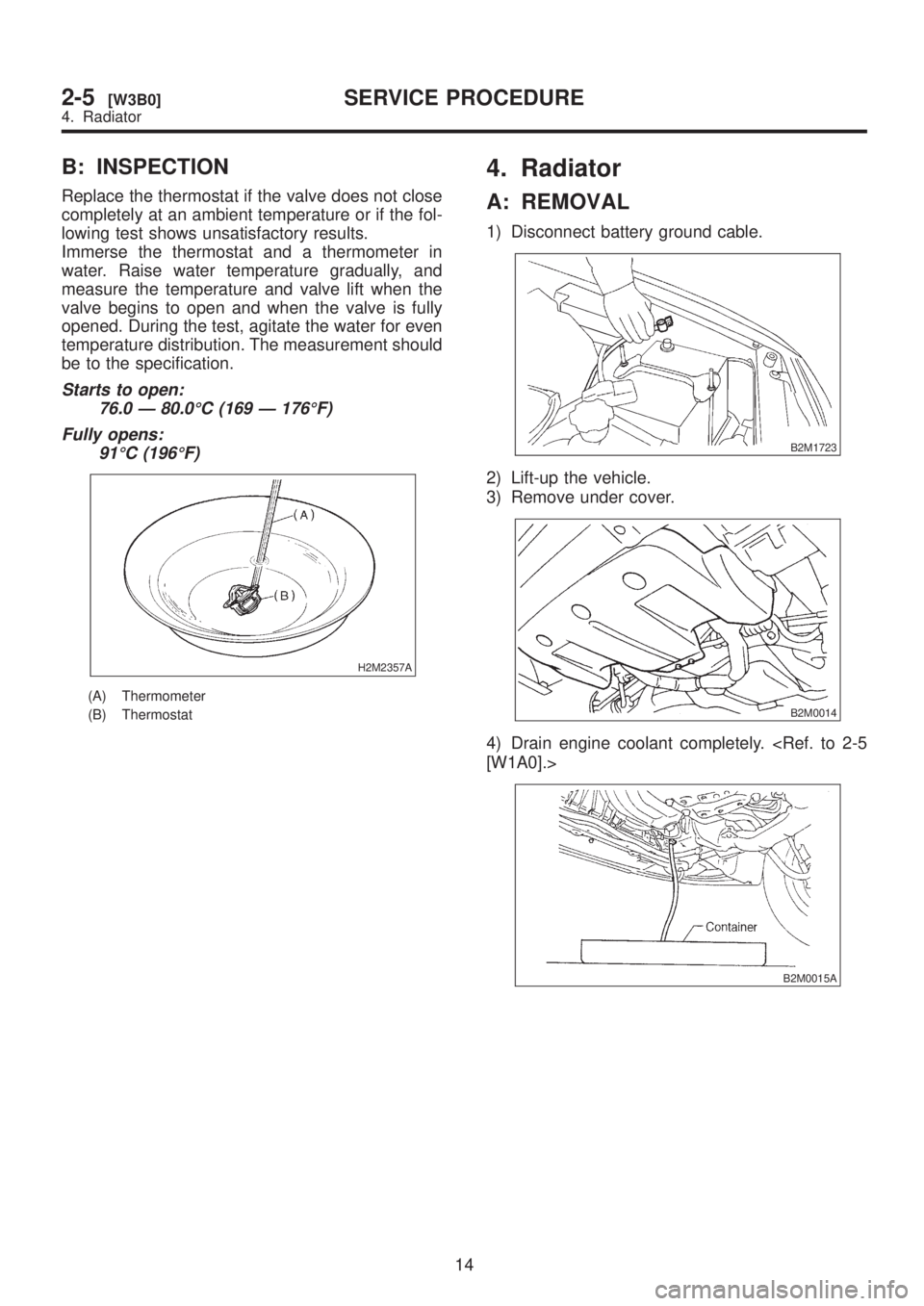

B: INSPECTION

Replace the thermostat if the valve does not close

completely at an ambient temperature or if the fol-

lowing test shows unsatisfactory results.

Immerse the thermostat and a thermometer in

water. Raise water temperature gradually, and

measure the temperature and valve lift when the

valve begins to open and when the valve is fully

opened. During the test, agitate the water for even

temperature distribution. The measurement should

be to the specification.

Starts to open:

76.0 Ð 80.0ÉC (169 Ð 176ÉF)

Fully opens:

91ÉC (196ÉF)

H2M2357A

(A) Thermometer

(B) Thermostat

4. Radiator

A: REMOVAL

1) Disconnect battery ground cable.

B2M1723

2) Lift-up the vehicle.

3) Remove under cover.

B2M0014

4) Drain engine coolant completely.

B2M0015A

14

2-5[W3B0]SERVICE PROCEDURE

4. Radiator

Page 245 of 1456

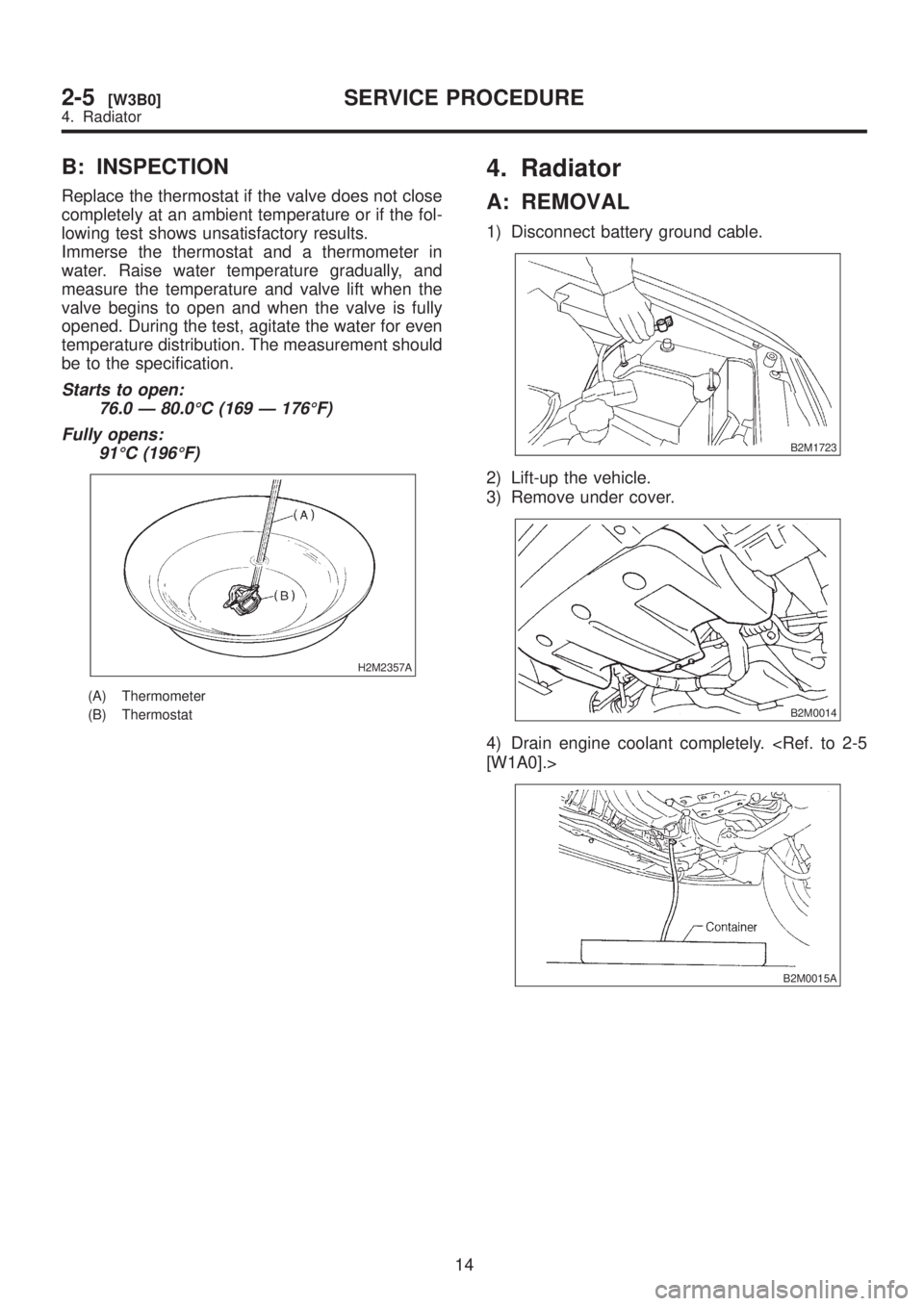

B: INSPECTION

Replace the thermostat if the valve does not close

completely at an ambient temperature or if the fol-

lowing test shows unsatisfactory results.

Immerse the thermostat and a thermometer in

water. Raise water temperature gradually, and

measure the temperature and valve lift when the

valve begins to open and when the valve is fully

opened. During the test, agitate the water for even

temperature distribution. The measurement should

be to the specification.

Starts to open:

76.0 Ð 80.0ÉC (169 Ð 176ÉF)

Fully opens:

91ÉC (196ÉF)

H2M2357A

(A) Thermometer

(B) Thermostat

4. Radiator

A: REMOVAL

1) Disconnect battery ground cable.

B2M1723

2) Lift-up the vehicle.

3) Remove under cover.

B2M0014

4) Drain engine coolant completely.

B2M0015A

14

2-5[W3B0]SERVICE PROCEDURE

4. Radiator

Page 260 of 1456

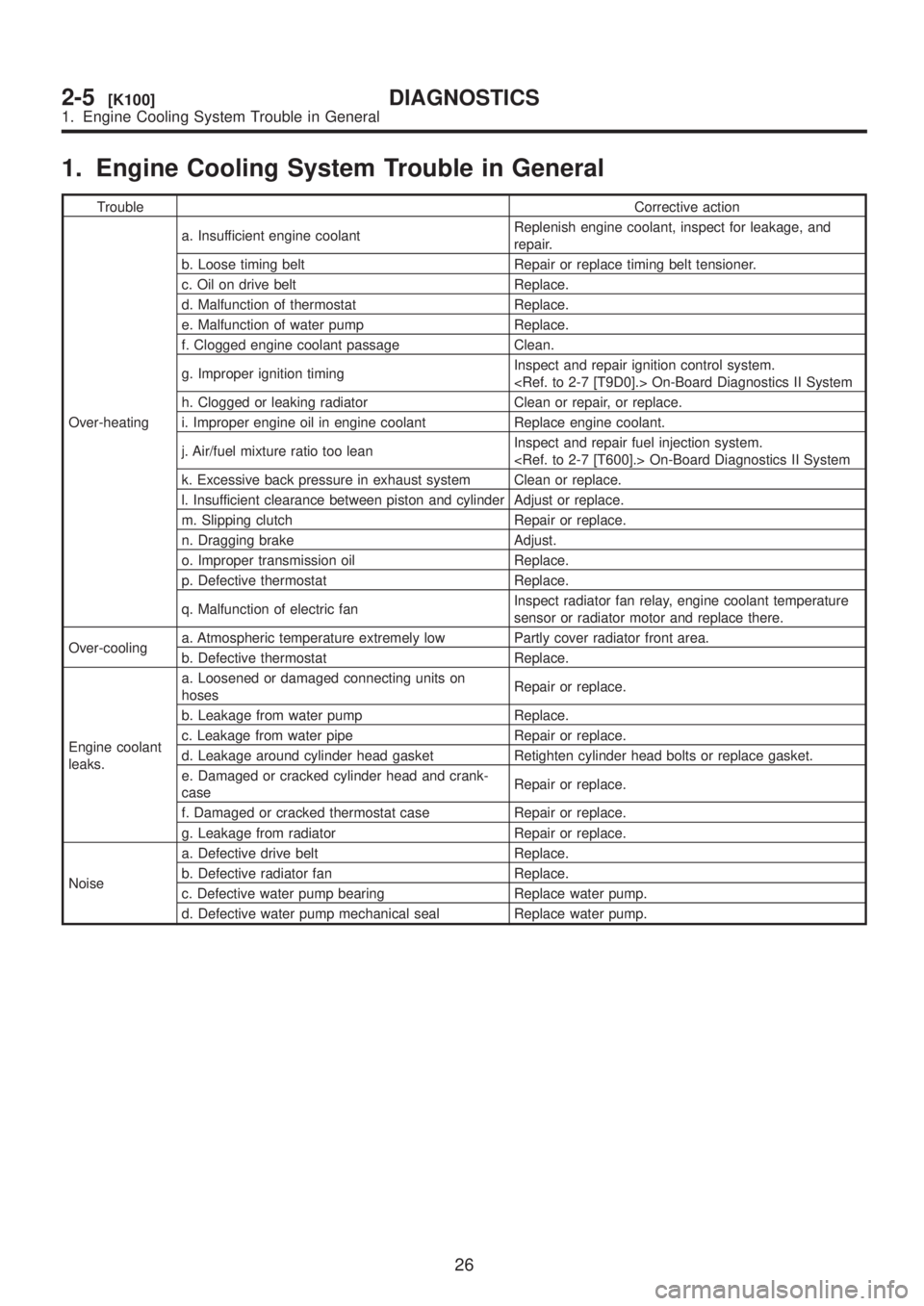

1. Engine Cooling System Trouble in General

TroubleCorrective action

Over-heatinga. Insufficient engine coolantReplenish engine coolant, inspect for leakage, and

repair.

b. Loose timing belt Repair or replace timing belt tensioner.

c. Oil on drive belt Replace.

d. Malfunction of thermostat Replace.

e. Malfunction of water pump Replace.

f. Clogged engine coolant passage Clean.

g. Improper ignition timingInspect and repair ignition control system.

h. Clogged or leaking radiator Clean or repair, or replace.

i. Improper engine oil in engine coolant Replace engine coolant.

j. Air/fuel mixture ratio too leanInspect and repair fuel injection system.

k. Excessive back pressure in exhaust system Clean or replace.

l. Insufficient clearance between piston and cylinder Adjust or replace.

m. Slipping clutch Repair or replace.

n. Dragging brake Adjust.

o. Improper transmission oil Replace.

p. Defective thermostat Replace.

q. Malfunction of electric fanInspect radiator fan relay, engine coolant temperature

sensor or radiator motor and replace there.

Over-coolinga. Atmospheric temperature extremely low Partly cover radiator front area.

b. Defective thermostat Replace.

Engine coolant

leaks.a. Loosened or damaged connecting units on

hosesRepair or replace.

b. Leakage from water pump Replace.

c. Leakage from water pipe Repair or replace.

d. Leakage around cylinder head gasket Retighten cylinder head bolts or replace gasket.

e. Damaged or cracked cylinder head and crank-

caseRepair or replace.

f. Damaged or cracked thermostat case Repair or replace.

g. Leakage from radiator Repair or replace.

Noisea. Defective drive belt Replace.

b. Defective radiator fan Replace.

c. Defective water pump bearing Replace water pump.

d. Defective water pump mechanical seal Replace water pump.

26

2-5[K100]DIAGNOSTICS

1. Engine Cooling System Trouble in General

Page 289 of 1456

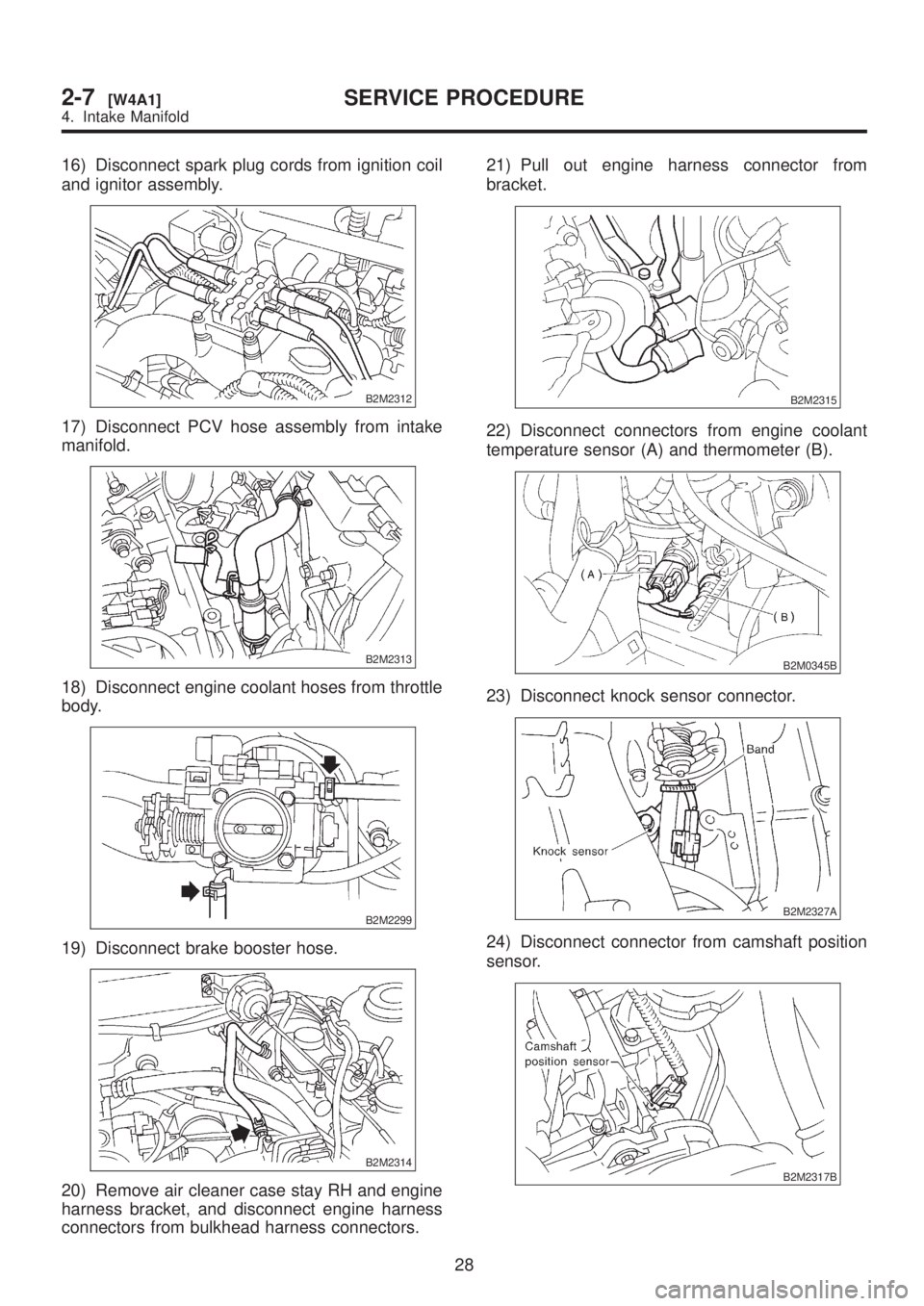

16) Disconnect spark plug cords from ignition coil

and ignitor assembly.

B2M2312

17) Disconnect PCV hose assembly from intake

manifold.

B2M2313

18) Disconnect engine coolant hoses from throttle

body.

B2M2299

19) Disconnect brake booster hose.

B2M2314

20) Remove air cleaner case stay RH and engine

harness bracket, and disconnect engine harness

connectors from bulkhead harness connectors.21) Pull out engine harness connector from

bracket.

B2M2315

22) Disconnect connectors from engine coolant

temperature sensor (A) and thermometer (B).

B2M0345B

23) Disconnect knock sensor connector.

B2M2327A

24) Disconnect connector from camshaft position

sensor.

B2M2317B

28

2-7[W4A1]SERVICE PROCEDURE

4. Intake Manifold

Page 293 of 1456

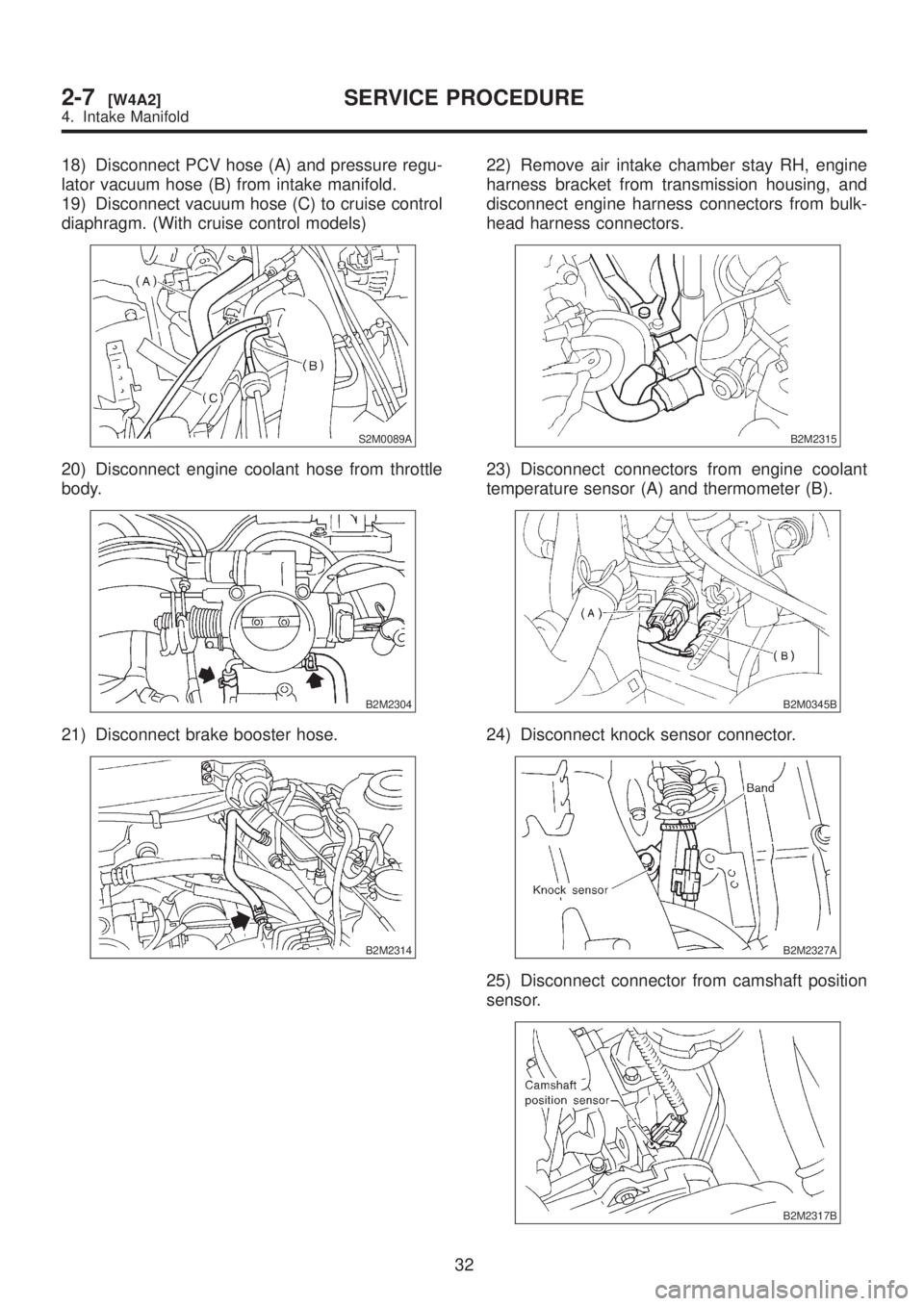

18) Disconnect PCV hose (A) and pressure regu-

lator vacuum hose (B) from intake manifold.

19) Disconnect vacuum hose (C) to cruise control

diaphragm. (With cruise control models)

S2M0089A

20) Disconnect engine coolant hose from throttle

body.

B2M2304

21) Disconnect brake booster hose.

B2M2314

22) Remove air intake chamber stay RH, engine

harness bracket from transmission housing, and

disconnect engine harness connectors from bulk-

head harness connectors.

B2M2315

23) Disconnect connectors from engine coolant

temperature sensor (A) and thermometer (B).

B2M0345B

24) Disconnect knock sensor connector.

B2M2327A

25) Disconnect connector from camshaft position

sensor.

B2M2317B

32

2-7[W4A2]SERVICE PROCEDURE

4. Intake Manifold