fuse SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 73 of 1456

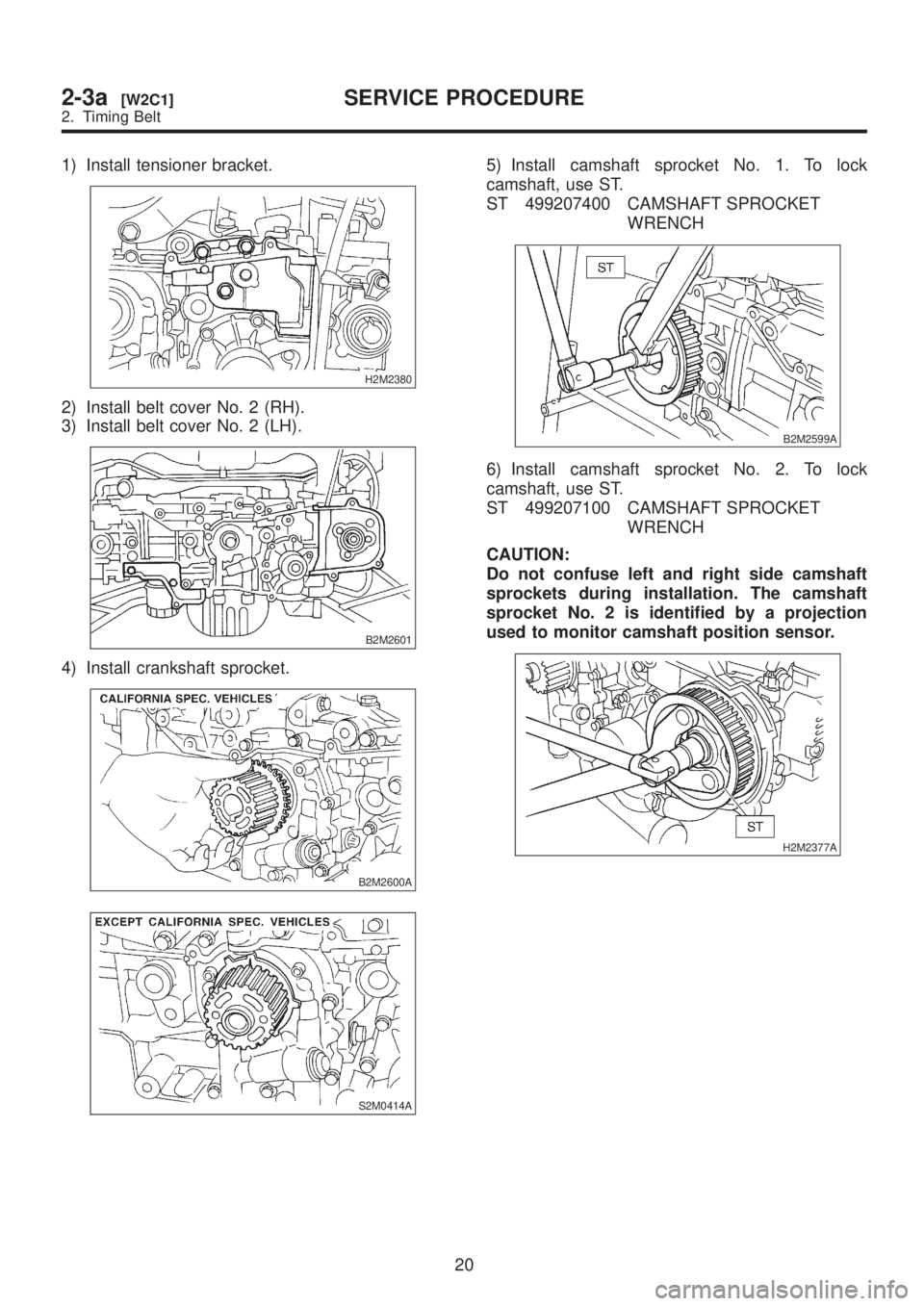

1) Install tensioner bracket.

H2M2380

2) Install belt cover No. 2 (RH).

3) Install belt cover No. 2 (LH).

B2M2601

4) Install crankshaft sprocket.

B2M2600A

S2M0414A

5) Install camshaft sprocket No. 1. To lock

camshaft, use ST.

ST 499207400 CAMSHAFT SPROCKET

WRENCH

B2M2599A

6) Install camshaft sprocket No. 2. To lock

camshaft, use ST.

ST 499207100 CAMSHAFT SPROCKET

WRENCH

CAUTION:

Do not confuse left and right side camshaft

sprockets during installation. The camshaft

sprocket No. 2 is identified by a projection

used to monitor camshaft position sensor.

H2M2377A

20

2-3a[W2C1]SERVICE PROCEDURE

2. Timing Belt

Page 109 of 1456

3) Draw out piston pin from #1 and #2 pistons

using ST.

ST 499097700 PISTON PIN REMOVER

CAUTION:

Be careful not to confuse original combination

of piston, piston pin and cylinder.

G2M0166

4) Similarly remove piston pins from #3 and #4

pistons.

5) Remove bolts which connect cylinder block on

the side of #2 and #4 cylinders.

6) Back off bolts which connect cylinder block on

the side of #1 and #3 cylinders two or three turns.

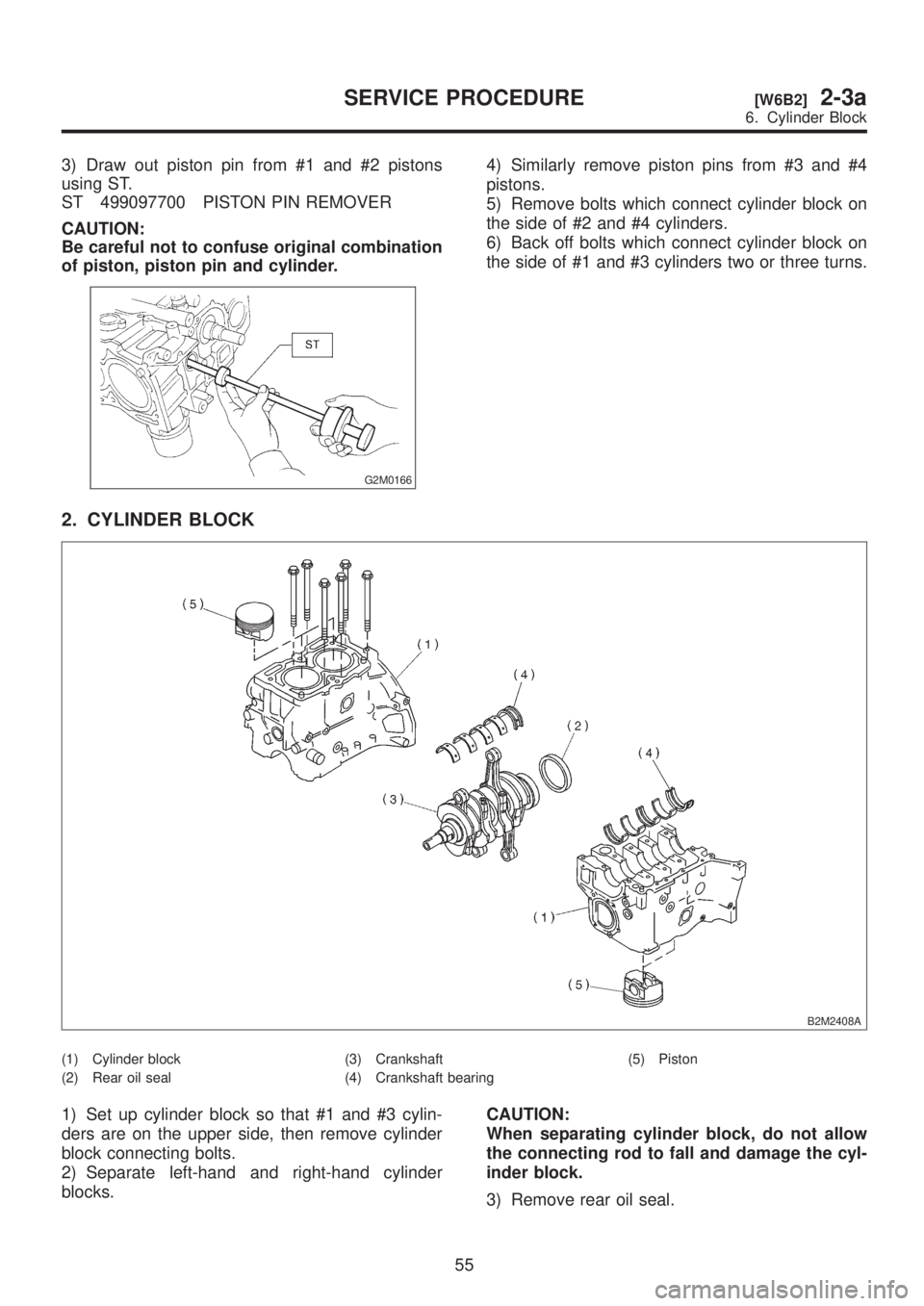

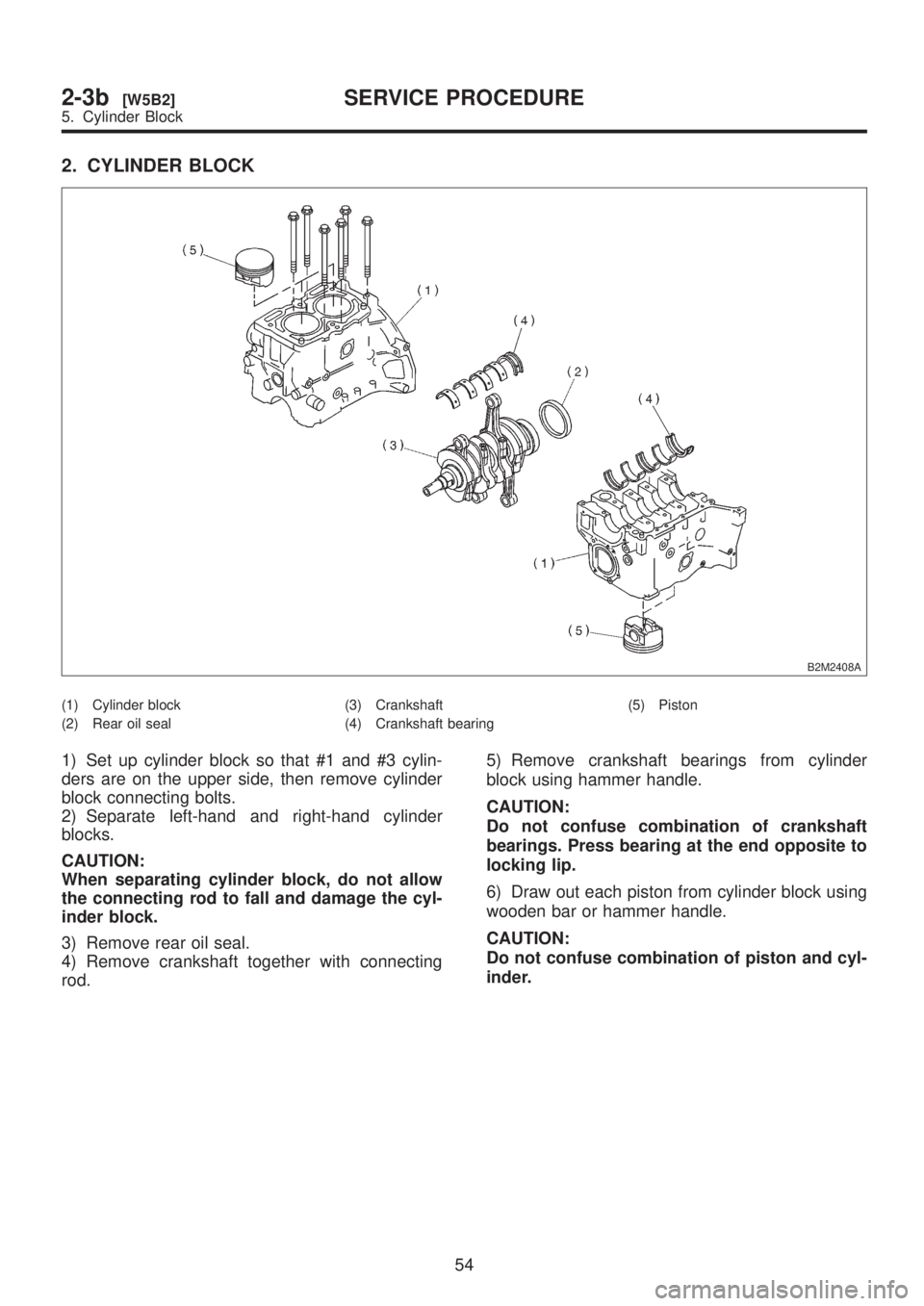

2. CYLINDER BLOCK

B2M2408A

(1) Cylinder block

(2) Rear oil seal(3) Crankshaft

(4) Crankshaft bearing(5) Piston

1) Set up cylinder block so that #1 and #3 cylin-

ders are on the upper side, then remove cylinder

block connecting bolts.

2) Separate left-hand and right-hand cylinder

blocks.CAUTION:

When separating cylinder block, do not allow

the connecting rod to fall and damage the cyl-

inder block.

3) Remove rear oil seal.

55

[W6B2]2-3aSERVICE PROCEDURE

6. Cylinder Block

Page 110 of 1456

4) Remove crankshaft together with connecting

rod.

5) Remove crankshaft bearings from cylinder

block using hammer handle.

CAUTION:

Do not confuse combination of crankshaft

bearings. Press bearing at the end opposite to

locking lip.6) Draw out each piston from cylinder block using

wooden bar or hammer handle.

CAUTION:

Do not confuse combination of piston and cyl-

inder.

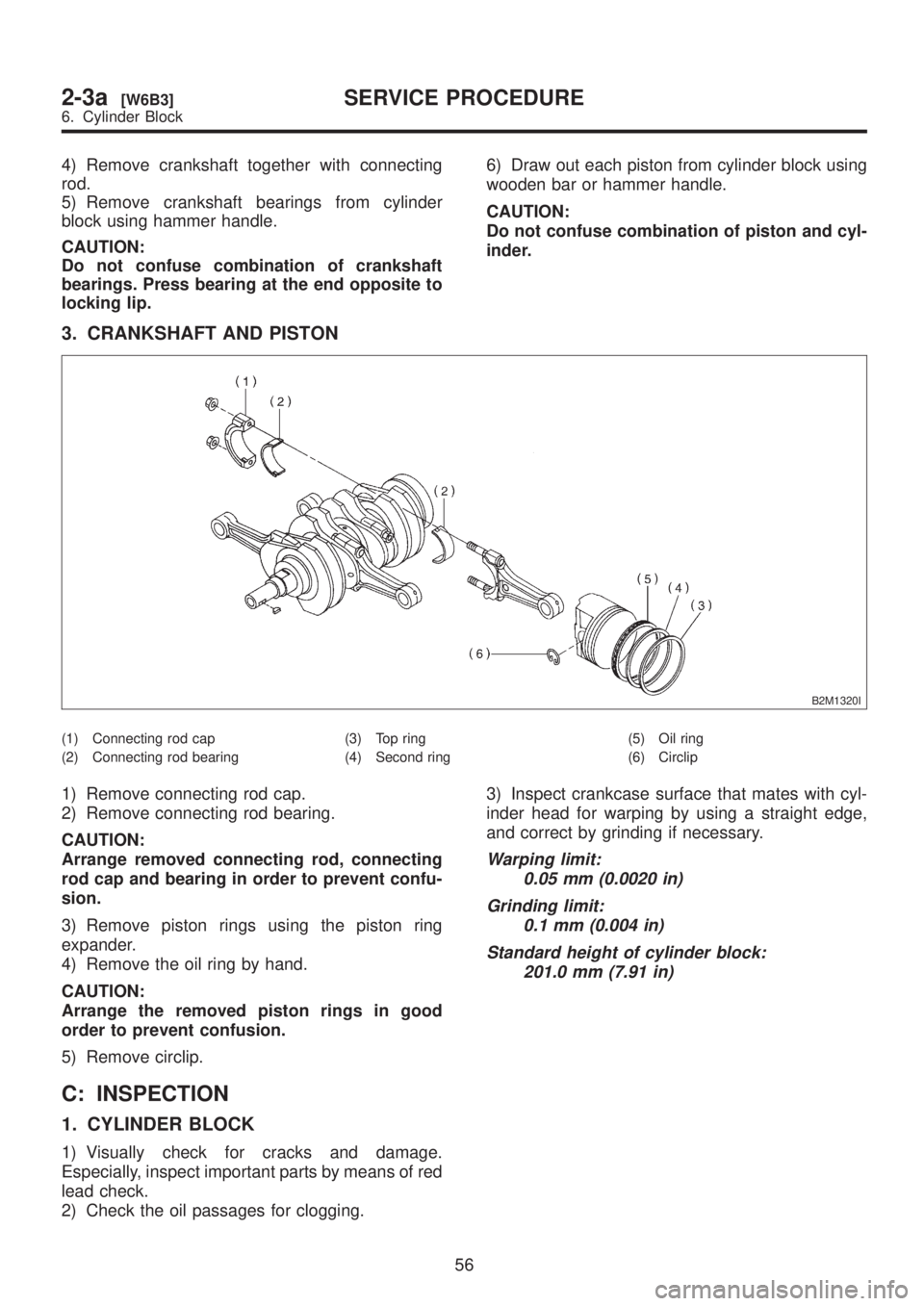

3. CRANKSHAFT AND PISTON

B2M1320I

(1) Connecting rod cap

(2) Connecting rod bearing(3) Top ring

(4) Second ring(5) Oil ring

(6) Circlip

1) Remove connecting rod cap.

2) Remove connecting rod bearing.

CAUTION:

Arrange removed connecting rod, connecting

rod cap and bearing in order to prevent confu-

sion.

3) Remove piston rings using the piston ring

expander.

4) Remove the oil ring by hand.

CAUTION:

Arrange the removed piston rings in good

order to prevent confusion.

5) Remove circlip.

C: INSPECTION

1. CYLINDER BLOCK

1) Visually check for cracks and damage.

Especially, inspect important parts by means of red

lead check.

2) Check the oil passages for clogging.3) Inspect crankcase surface that mates with cyl-

inder head for warping by using a straight edge,

and correct by grinding if necessary.

Warping limit:

0.05 mm (0.0020 in)

Grinding limit:

0.1 mm (0.004 in)

Standard height of cylinder block:

201.0 mm (7.91 in)

56

2-3a[W6B3]SERVICE PROCEDURE

6. Cylinder Block

Page 184 of 1456

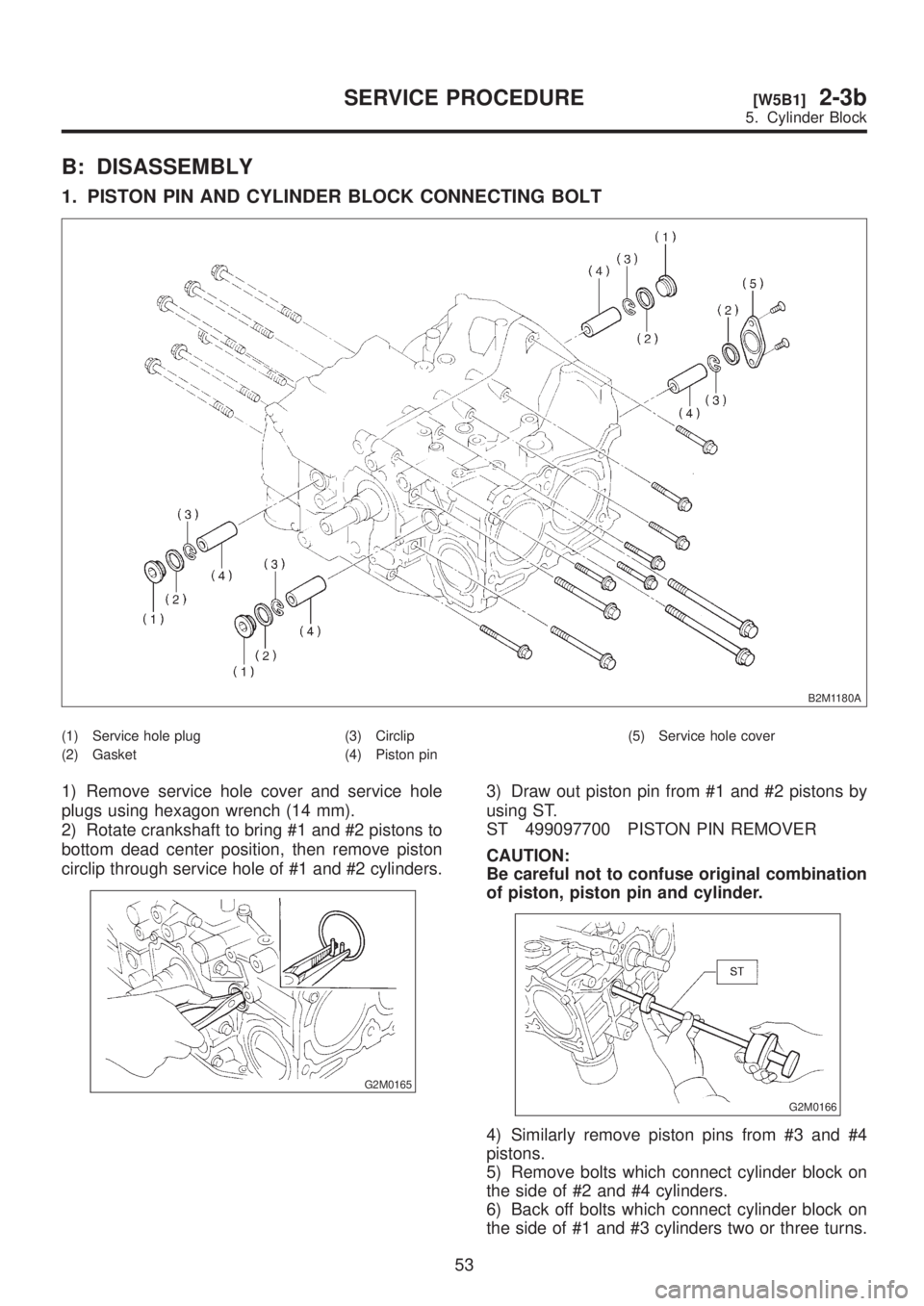

B: DISASSEMBLY

1. PISTON PIN AND CYLINDER BLOCK CONNECTING BOLT

B2M1180A

(1) Service hole plug

(2) Gasket(3) Circlip

(4) Piston pin(5) Service hole cover

1) Remove service hole cover and service hole

plugs using hexagon wrench (14 mm).

2) Rotate crankshaft to bring #1 and #2 pistons to

bottom dead center position, then remove piston

circlip through service hole of #1 and #2 cylinders.

G2M0165

3) Draw out piston pin from #1 and #2 pistons by

using ST.

ST 499097700 PISTON PIN REMOVER

CAUTION:

Be careful not to confuse original combination

of piston, piston pin and cylinder.

G2M0166

4) Similarly remove piston pins from #3 and #4

pistons.

5) Remove bolts which connect cylinder block on

the side of #2 and #4 cylinders.

6) Back off bolts which connect cylinder block on

the side of #1 and #3 cylinders two or three turns.

53

[W5B1]2-3bSERVICE PROCEDURE

5. Cylinder Block

Page 185 of 1456

2. CYLINDER BLOCK

B2M2408A

(1) Cylinder block

(2) Rear oil seal(3) Crankshaft

(4) Crankshaft bearing(5) Piston

1) Set up cylinder block so that #1 and #3 cylin-

ders are on the upper side, then remove cylinder

block connecting bolts.

2) Separate left-hand and right-hand cylinder

blocks.

CAUTION:

When separating cylinder block, do not allow

the connecting rod to fall and damage the cyl-

inder block.

3) Remove rear oil seal.

4) Remove crankshaft together with connecting

rod.5) Remove crankshaft bearings from cylinder

block using hammer handle.

CAUTION:

Do not confuse combination of crankshaft

bearings. Press bearing at the end opposite to

locking lip.

6) Draw out each piston from cylinder block using

wooden bar or hammer handle.

CAUTION:

Do not confuse combination of piston and cyl-

inder.

54

2-3b[W5B2]SERVICE PROCEDURE

5. Cylinder Block

Page 352 of 1456

9) Take out ECM.

B2M0679A

10) Installation is in the reverse order of removal.

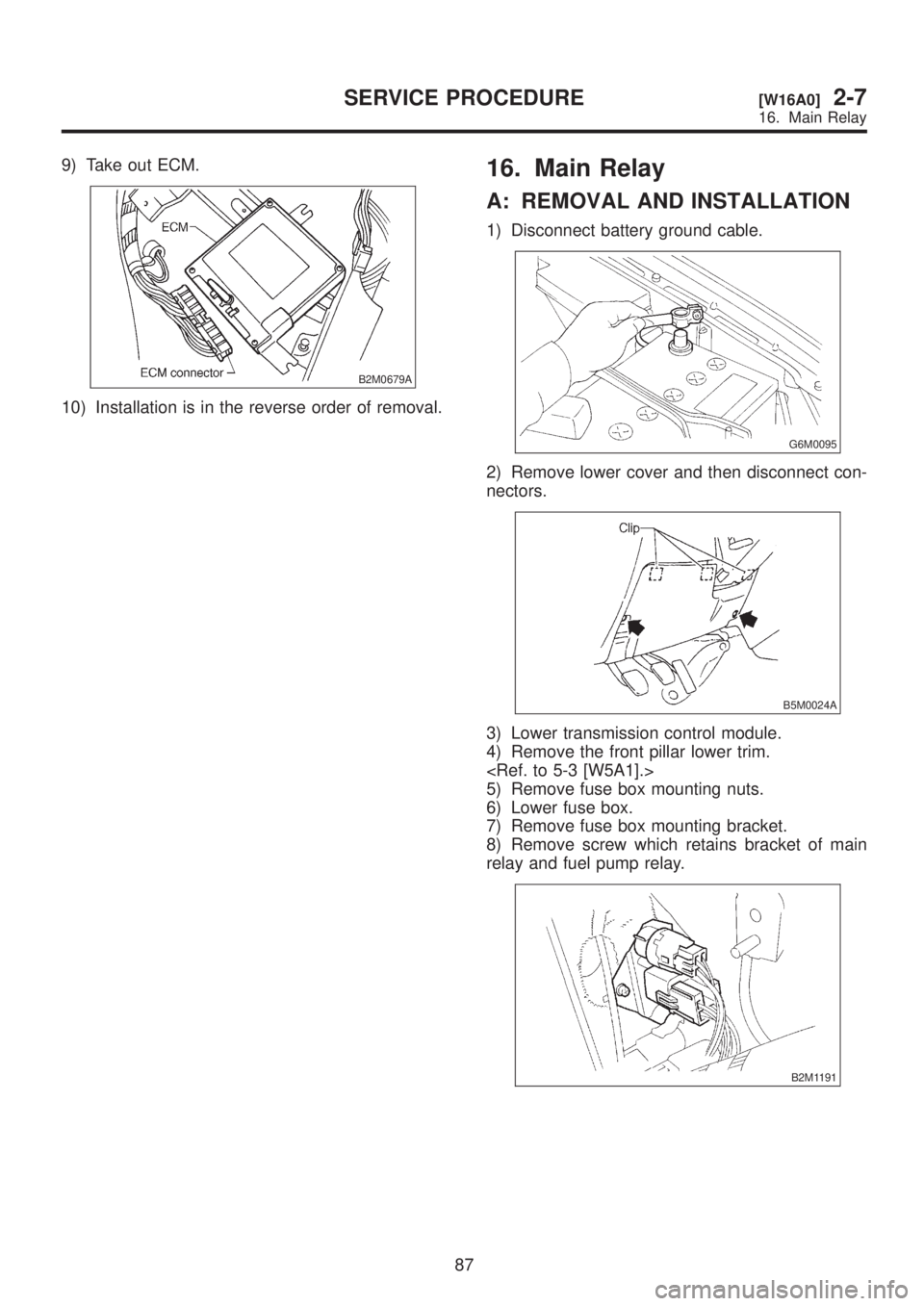

16. Main Relay

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove lower cover and then disconnect con-

nectors.

B5M0024A

3) Lower transmission control module.

4) Remove the front pillar lower trim.

5) Remove fuse box mounting nuts.

6) Lower fuse box.

7) Remove fuse box mounting bracket.

8) Remove screw which retains bracket of main

relay and fuel pump relay.

B2M1191

87

[W16A0]2-7SERVICE PROCEDURE

16. Main Relay

Page 353 of 1456

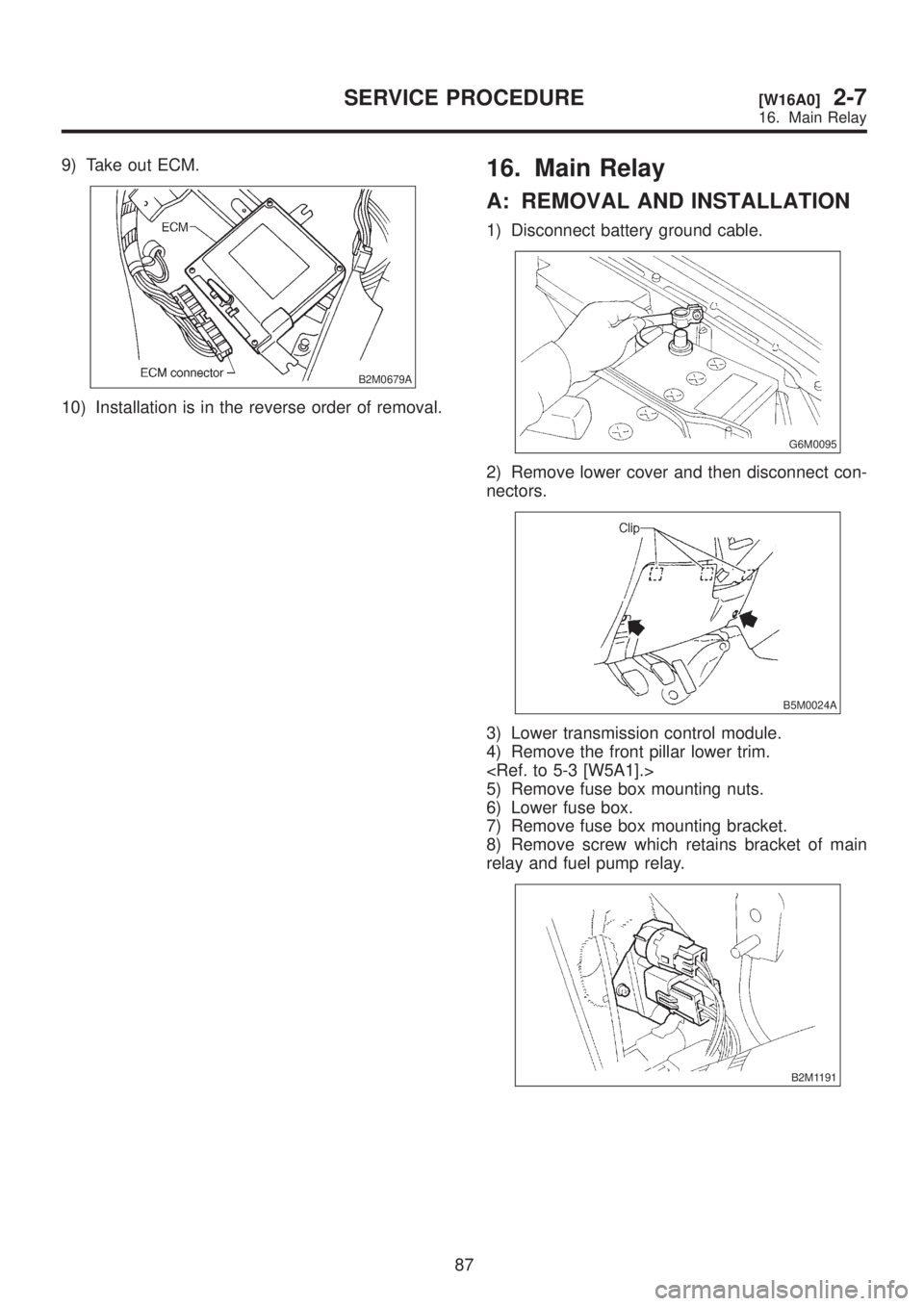

9) Take out ECM.

B2M0679A

10) Installation is in the reverse order of removal.

16. Main Relay

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove lower cover and then disconnect con-

nectors.

B5M0024A

3) Lower transmission control module.

4) Remove the front pillar lower trim.

5) Remove fuse box mounting nuts.

6) Lower fuse box.

7) Remove fuse box mounting bracket.

8) Remove screw which retains bracket of main

relay and fuel pump relay.

B2M1191

87

[W16A0]2-7SERVICE PROCEDURE

16. Main Relay

Page 354 of 1456

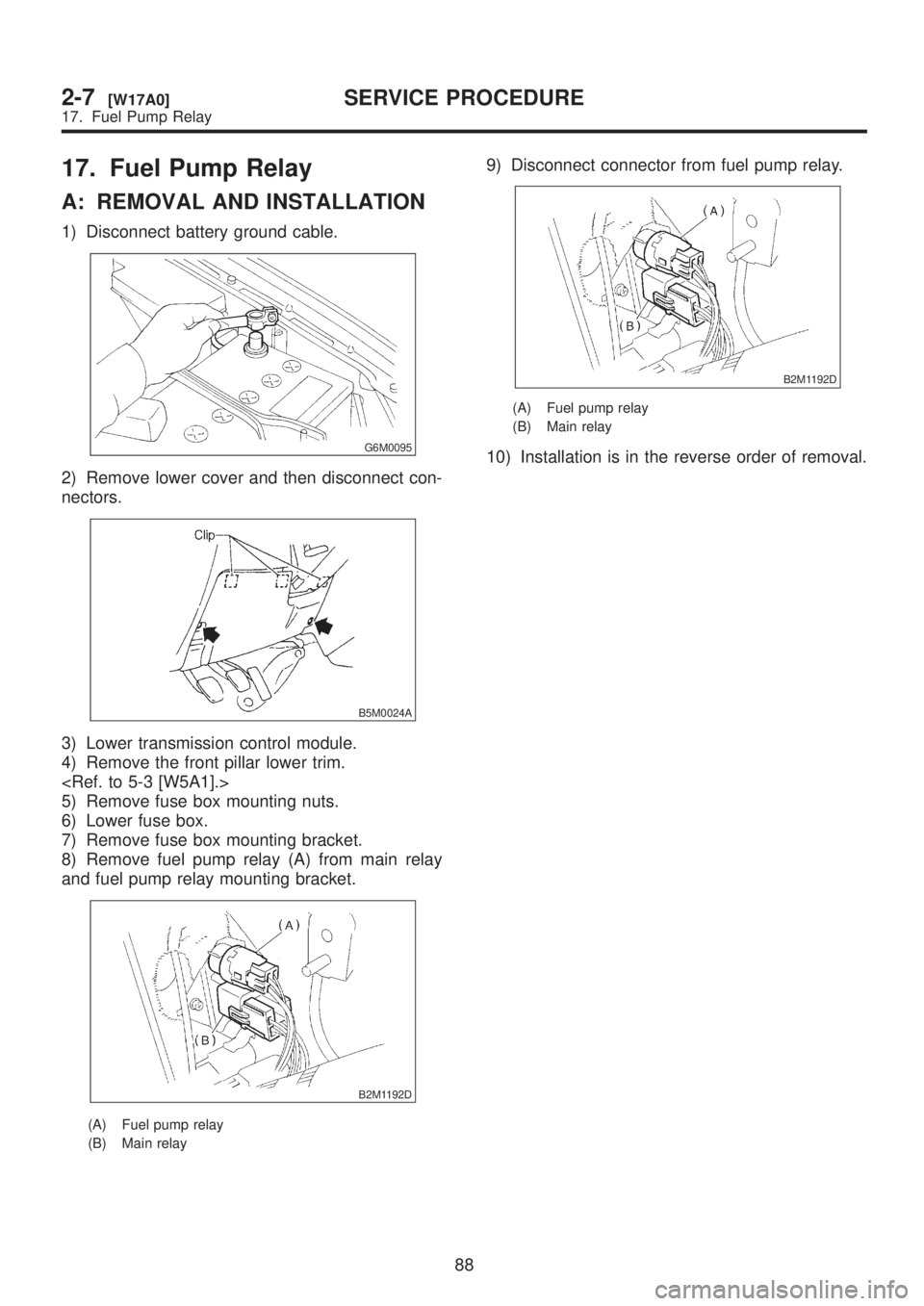

17. Fuel Pump Relay

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove lower cover and then disconnect con-

nectors.

B5M0024A

3) Lower transmission control module.

4) Remove the front pillar lower trim.

5) Remove fuse box mounting nuts.

6) Lower fuse box.

7) Remove fuse box mounting bracket.

8) Remove fuel pump relay (A) from main relay

and fuel pump relay mounting bracket.

B2M1192D

(A) Fuel pump relay

(B) Main relay

9) Disconnect connector from fuel pump relay.

B2M1192D

(A) Fuel pump relay

(B) Main relay

10) Installation is in the reverse order of removal.

88

2-7[W17A0]SERVICE PROCEDURE

17. Fuel Pump Relay

Page 484 of 1456

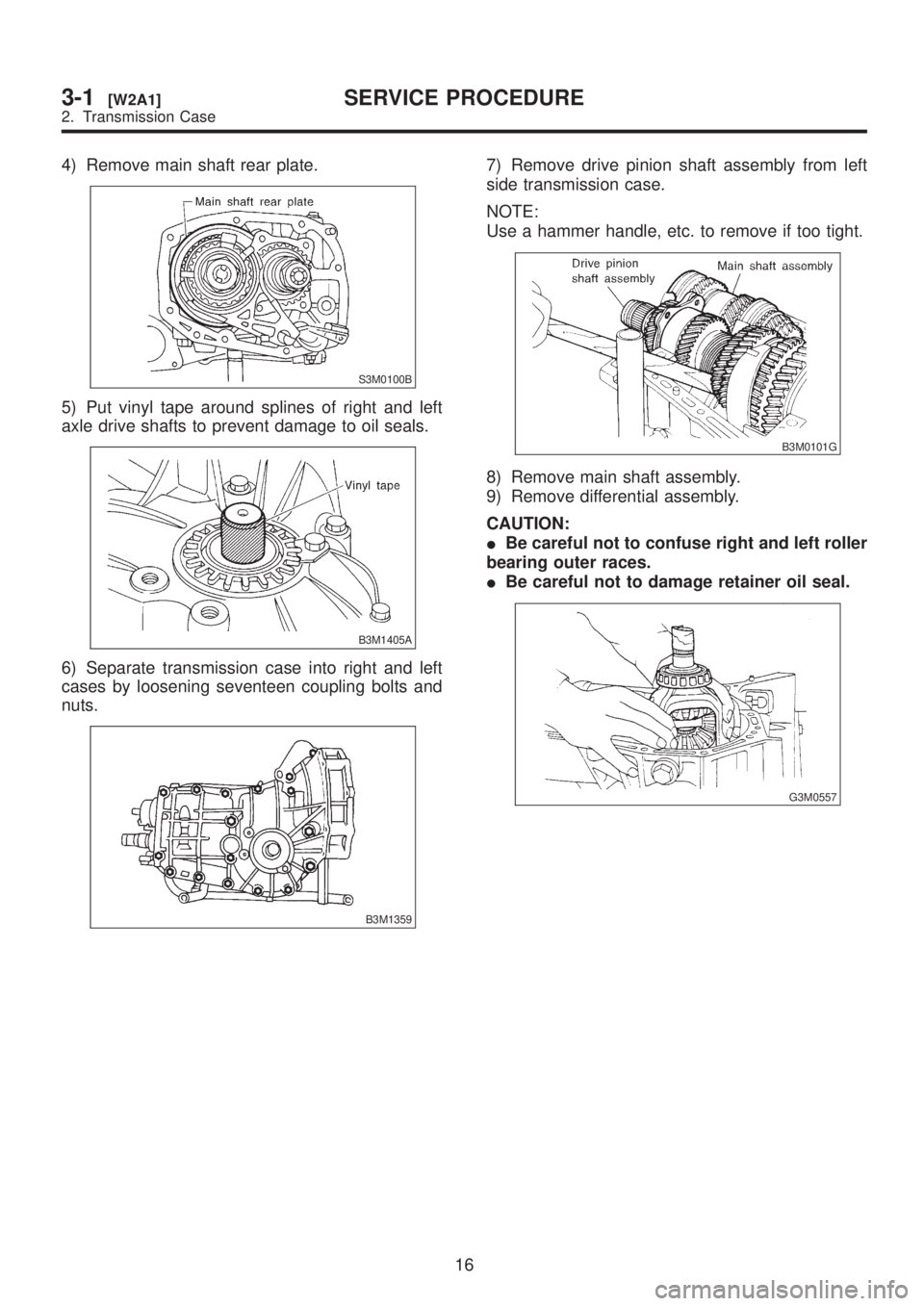

4) Remove main shaft rear plate.

S3M0100B

5) Put vinyl tape around splines of right and left

axle drive shafts to prevent damage to oil seals.

B3M1405A

6) Separate transmission case into right and left

cases by loosening seventeen coupling bolts and

nuts.

B3M1359

7) Remove drive pinion shaft assembly from left

side transmission case.

NOTE:

Use a hammer handle, etc. to remove if too tight.

B3M0101G

8) Remove main shaft assembly.

9) Remove differential assembly.

CAUTION:

IBe careful not to confuse right and left roller

bearing outer races.

IBe careful not to damage retainer oil seal.

G3M0557

16

3-1[W2A1]SERVICE PROCEDURE

2. Transmission Case

Page 525 of 1456

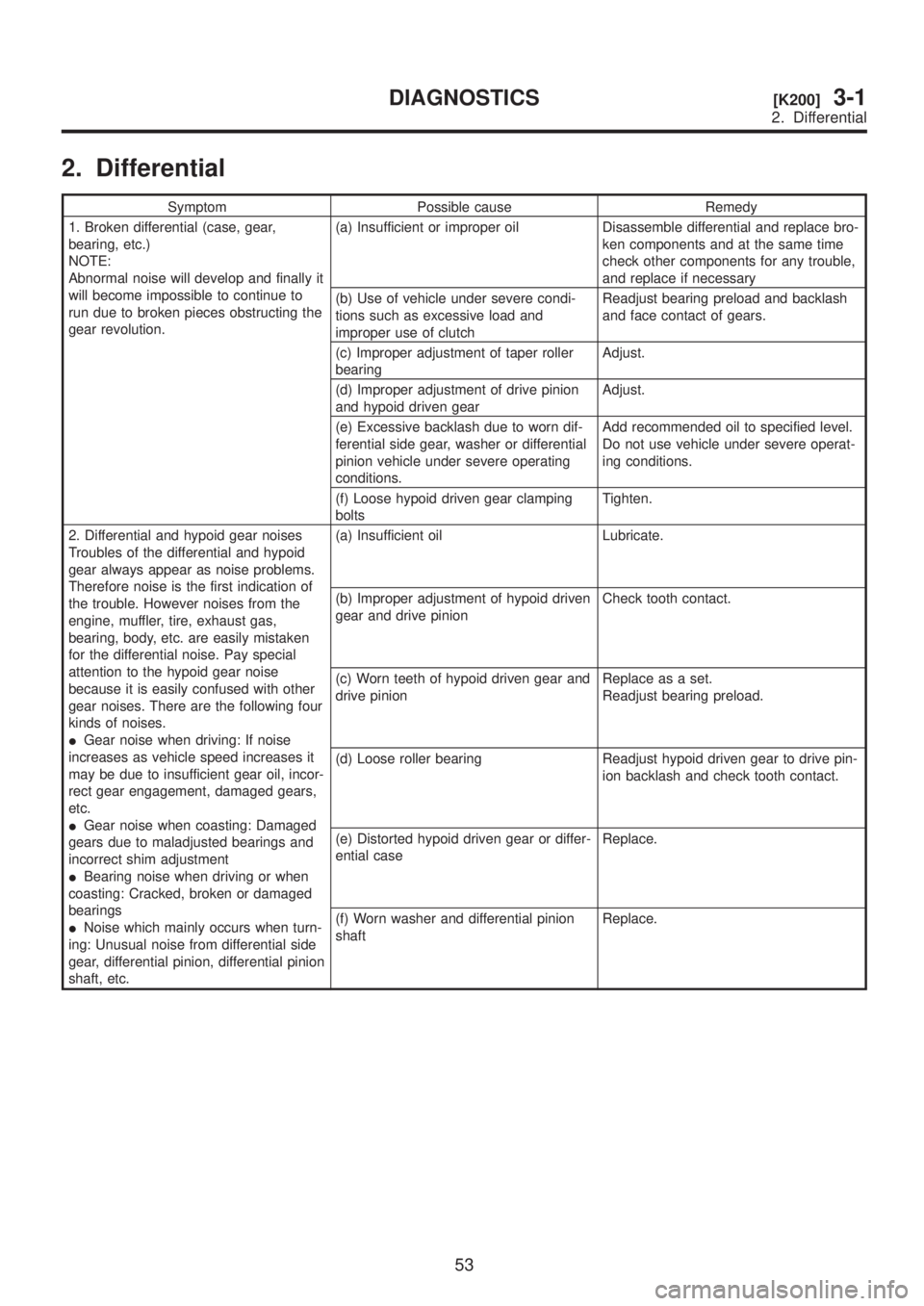

2. Differential

Symptom Possible cause Remedy

1. Broken differential (case, gear,

bearing, etc.)

NOTE:

Abnormal noise will develop and finally it

will become impossible to continue to

run due to broken pieces obstructing the

gear revolution.(a) Insufficient or improper oil Disassemble differential and replace bro-

ken components and at the same time

check other components for any trouble,

and replace if necessary

(b) Use of vehicle under severe condi-

tions such as excessive load and

improper use of clutchReadjust bearing preload and backlash

and face contact of gears.

(c) Improper adjustment of taper roller

bearingAdjust.

(d) Improper adjustment of drive pinion

and hypoid driven gearAdjust.

(e) Excessive backlash due to worn dif-

ferential side gear, washer or differential

pinion vehicle under severe operating

conditions.Add recommended oil to specified level.

Do not use vehicle under severe operat-

ing conditions.

(f) Loose hypoid driven gear clamping

boltsTighten.

2. Differential and hypoid gear noises

Troubles of the differential and hypoid

gear always appear as noise problems.

Therefore noise is the first indication of

the trouble. However noises from the

engine, muffler, tire, exhaust gas,

bearing, body, etc. are easily mistaken

for the differential noise. Pay special

attention to the hypoid gear noise

because it is easily confused with other

gear noises. There are the following four

kinds of noises.

IGear noise when driving: If noise

increases as vehicle speed increases it

may be due to insufficient gear oil, incor-

rect gear engagement, damaged gears,

etc.

IGear noise when coasting: Damaged

gears due to maladjusted bearings and

incorrect shim adjustment

IBearing noise when driving or when

coasting: Cracked, broken or damaged

bearings

INoise which mainly occurs when turn-

ing: Unusual noise from differential side

gear, differential pinion, differential pinion

shaft, etc.(a) Insufficient oil Lubricate.

(b) Improper adjustment of hypoid driven

gear and drive pinionCheck tooth contact.

(c) Worn teeth of hypoid driven gear and

drive pinionReplace as a set.

Readjust bearing preload.

(d) Loose roller bearing Readjust hypoid driven gear to drive pin-

ion backlash and check tooth contact.

(e) Distorted hypoid driven gear or differ-

ential caseReplace.

(f) Worn washer and differential pinion

shaftReplace.

53

[K200]3-1DIAGNOSTICS

2. Differential