load capacity SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 654 of 1456

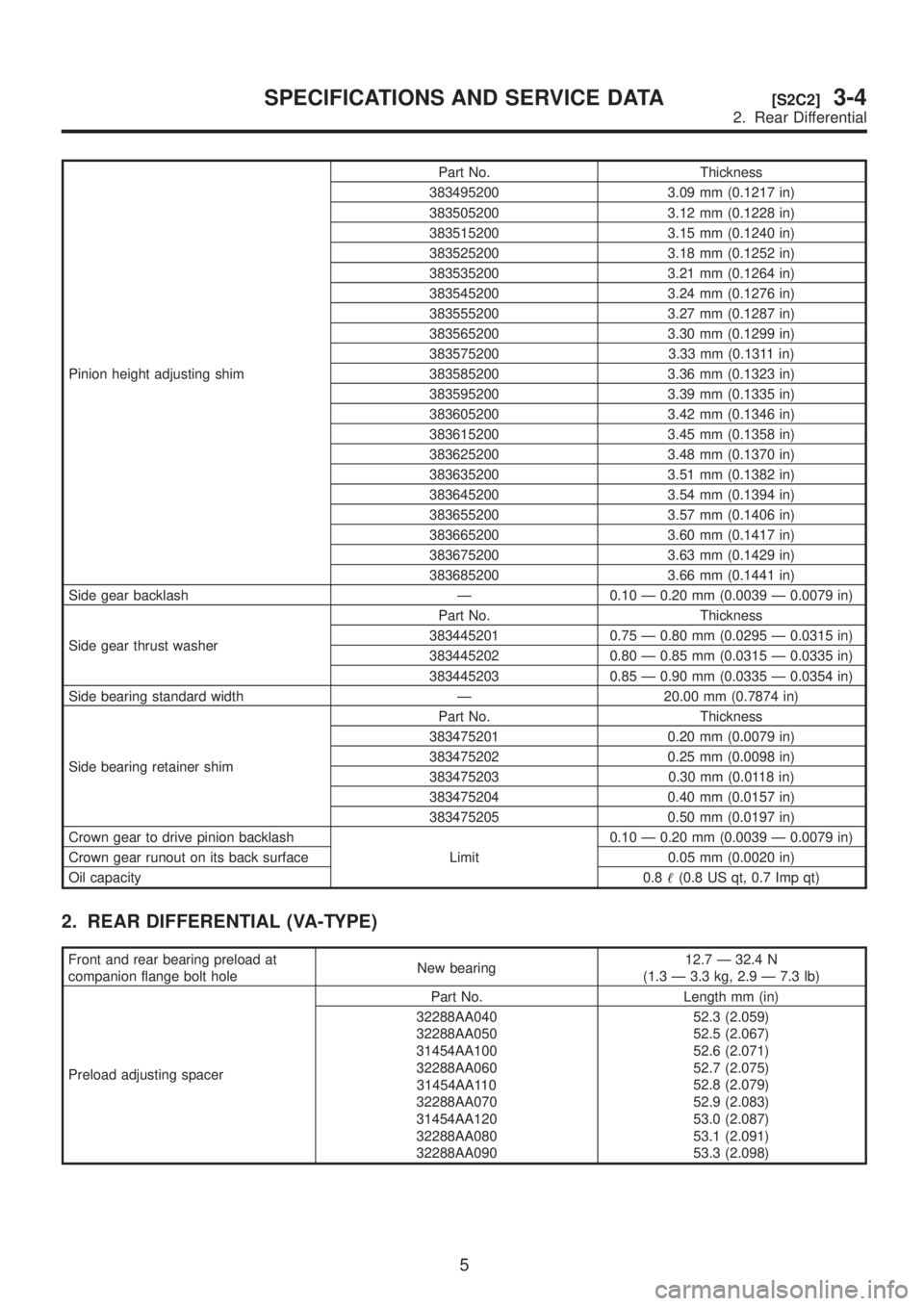

Pinion height adjusting shimPart No. Thickness

383495200 3.09 mm (0.1217 in)

383505200 3.12 mm (0.1228 in)

383515200 3.15 mm (0.1240 in)

383525200 3.18 mm (0.1252 in)

383535200 3.21 mm (0.1264 in)

383545200 3.24 mm (0.1276 in)

383555200 3.27 mm (0.1287 in)

383565200 3.30 mm (0.1299 in)

383575200 3.33 mm (0.1311 in)

383585200 3.36 mm (0.1323 in)

383595200 3.39 mm (0.1335 in)

383605200 3.42 mm (0.1346 in)

383615200 3.45 mm (0.1358 in)

383625200 3.48 mm (0.1370 in)

383635200 3.51 mm (0.1382 in)

383645200 3.54 mm (0.1394 in)

383655200 3.57 mm (0.1406 in)

383665200 3.60 mm (0.1417 in)

383675200 3.63 mm (0.1429 in)

383685200 3.66 mm (0.1441 in)

Side gear backlash Ð 0.10 Ð 0.20 mm (0.0039 Ð 0.0079 in)

Side gear thrust washerPart No. Thickness

383445201 0.75 Ð 0.80 mm (0.0295 Ð 0.0315 in)

383445202 0.80 Ð 0.85 mm (0.0315 Ð 0.0335 in)

383445203 0.85 Ð 0.90 mm (0.0335 Ð 0.0354 in)

Side bearing standard width Ð 20.00 mm (0.7874 in)

Side bearing retainer shimPart No. Thickness

383475201 0.20 mm (0.0079 in)

383475202 0.25 mm (0.0098 in)

383475203 0.30 mm (0.0118 in)

383475204 0.40 mm (0.0157 in)

383475205 0.50 mm (0.0197 in)

Crown gear to drive pinion backlash

Limit0.10 Ð 0.20 mm (0.0039 Ð 0.0079 in)

Crown gear runout on its back surface 0.05 mm (0.0020 in)

Oil capacity0.8(0.8 US qt, 0.7 Imp qt)

2. REAR DIFFERENTIAL (VA-TYPE)

Front and rear bearing preload at

companion flange bolt holeNew bearing12.7 Ð 32.4 N

(1.3 Ð 3.3 kg, 2.9 Ð 7.3 lb)

Preload adjusting spacerPart No. Length mm (in)

32288AA040

32288AA050

31454AA100

32288AA060

31454AA110

32288AA070

31454AA120

32288AA080

32288AA09052.3 (2.059)

52.5 (2.067)

52.6 (2.071)

52.7 (2.075)

52.8 (2.079)

52.9 (2.083)

53.0 (2.087)

53.1 (2.091)

53.3 (2.098)

5

[S2C2]3-4SPECIFICATIONS AND SERVICE DATA

2. Rear Differential

Page 655 of 1456

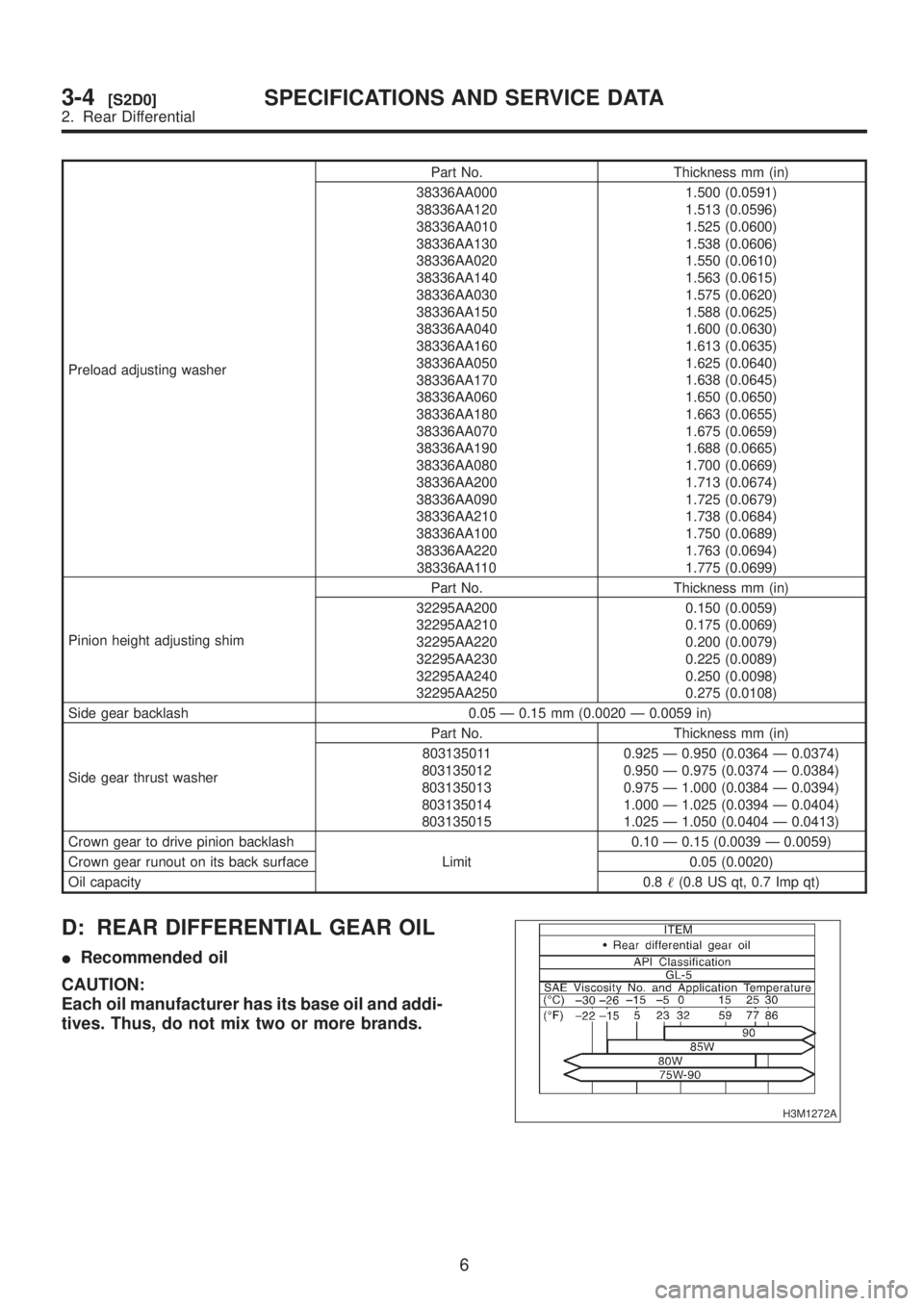

Preload adjusting washerPart No. Thickness mm (in)

38336AA000

38336AA120

38336AA010

38336AA130

38336AA020

38336AA140

38336AA030

38336AA150

38336AA040

38336AA160

38336AA050

38336AA170

38336AA060

38336AA180

38336AA070

38336AA190

38336AA080

38336AA200

38336AA090

38336AA210

38336AA100

38336AA220

38336AA1101.500 (0.0591)

1.513 (0.0596)

1.525 (0.0600)

1.538 (0.0606)

1.550 (0.0610)

1.563 (0.0615)

1.575 (0.0620)

1.588 (0.0625)

1.600 (0.0630)

1.613 (0.0635)

1.625 (0.0640)

1.638 (0.0645)

1.650 (0.0650)

1.663 (0.0655)

1.675 (0.0659)

1.688 (0.0665)

1.700 (0.0669)

1.713 (0.0674)

1.725 (0.0679)

1.738 (0.0684)

1.750 (0.0689)

1.763 (0.0694)

1.775 (0.0699)

Pinion height adjusting shimPart No. Thickness mm (in)

32295AA200

32295AA210

32295AA220

32295AA230

32295AA240

32295AA2500.150 (0.0059)

0.175 (0.0069)

0.200 (0.0079)

0.225 (0.0089)

0.250 (0.0098)

0.275 (0.0108)

Side gear backlash 0.05 Ð 0.15 mm (0.0020 Ð 0.0059 in)

Side gear thrust washerPart No. Thickness mm (in)

803135011

803135012

803135013

803135014

8031350150.925 Ð 0.950 (0.0364 Ð 0.0374)

0.950 Ð 0.975 (0.0374 Ð 0.0384)

0.975 Ð 1.000 (0.0384 Ð 0.0394)

1.000 Ð 1.025 (0.0394 Ð 0.0404)

1.025 Ð 1.050 (0.0404 Ð 0.0413)

Crown gear to drive pinion backlash

Limit0.10 Ð 0.15 (0.0039 Ð 0.0059)

Crown gear runout on its back surface 0.05 (0.0020)

Oil capacity0.8(0.8 US qt, 0.7 Imp qt)

D: REAR DIFFERENTIAL GEAR OIL

IRecommended oil

CAUTION:

Each oil manufacturer has its base oil and addi-

tives. Thus, do not mix two or more brands.

H3M1272A

6

3-4[S2D0]SPECIFICATIONS AND SERVICE DATA

2. Rear Differential

Page 994 of 1456

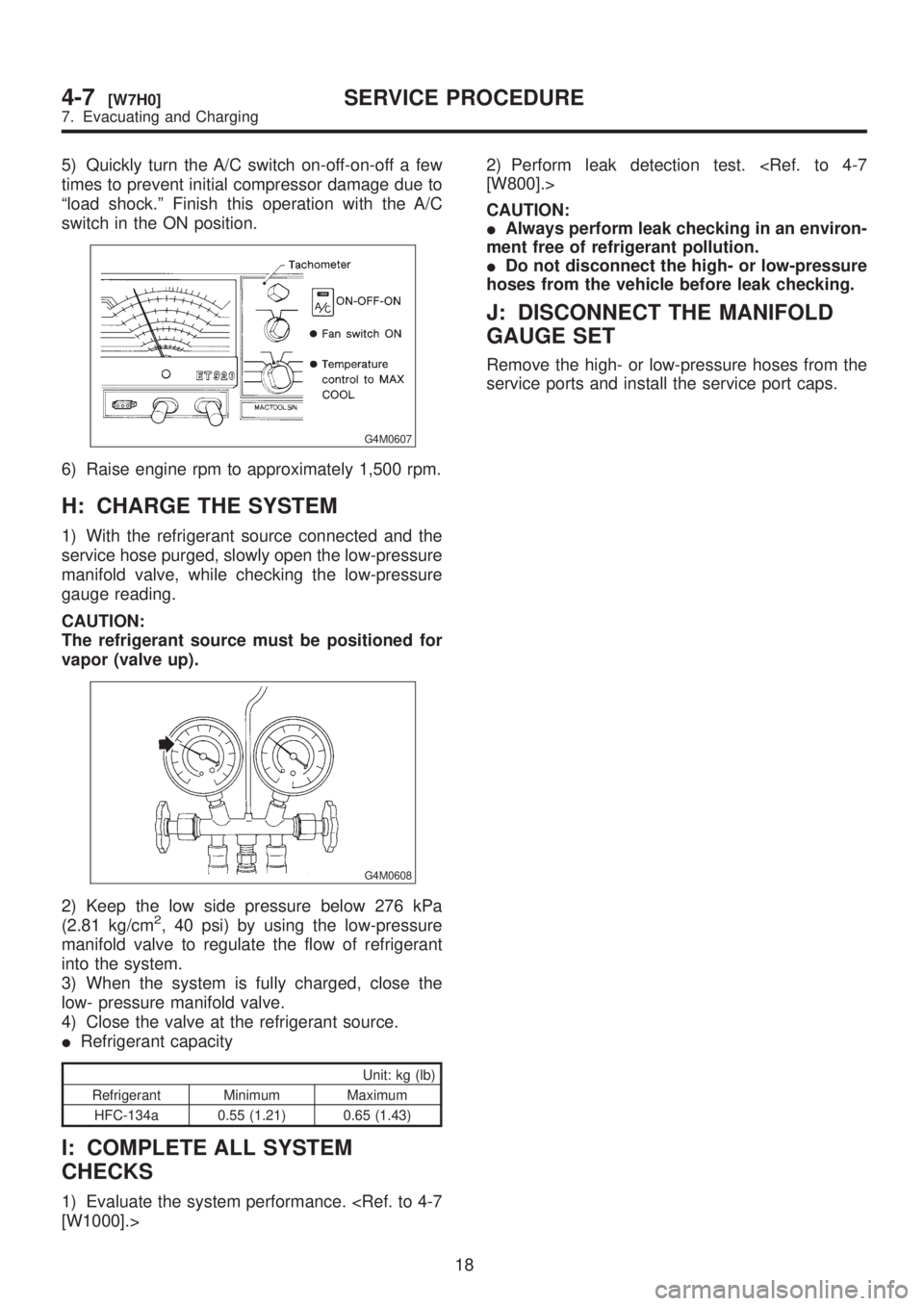

5) Quickly turn the A/C switch on-off-on-off a few

times to prevent initial compressor damage due to

ªload shock.º Finish this operation with the A/C

switch in the ON position.

G4M0607

6) Raise engine rpm to approximately 1,500 rpm.

H: CHARGE THE SYSTEM

1) With the refrigerant source connected and the

service hose purged, slowly open the low-pressure

manifold valve, while checking the low-pressure

gauge reading.

CAUTION:

The refrigerant source must be positioned for

vapor (valve up).

G4M0608

2) Keep the low side pressure below 276 kPa

(2.81 kg/cm2, 40 psi) by using the low-pressure

manifold valve to regulate the flow of refrigerant

into the system.

3) When the system is fully charged, close the

low- pressure manifold valve.

4) Close the valve at the refrigerant source.

IRefrigerant capacity

Unit: kg (lb)

Refrigerant Minimum Maximum

HFC-134a 0.55 (1.21) 0.65 (1.43)

I: COMPLETE ALL SYSTEM

CHECKS

1) Evaluate the system performance.

CAUTION:

IAlways perform leak checking in an environ-

ment free of refrigerant pollution.

IDo not disconnect the high- or low-pressure

hoses from the vehicle before leak checking.

J: DISCONNECT THE MANIFOLD

GAUGE SET

Remove the high- or low-pressure hoses from the

service ports and install the service port caps.

18

4-7[W7H0]SERVICE PROCEDURE

7. Evacuating and Charging

Page 1189 of 1456

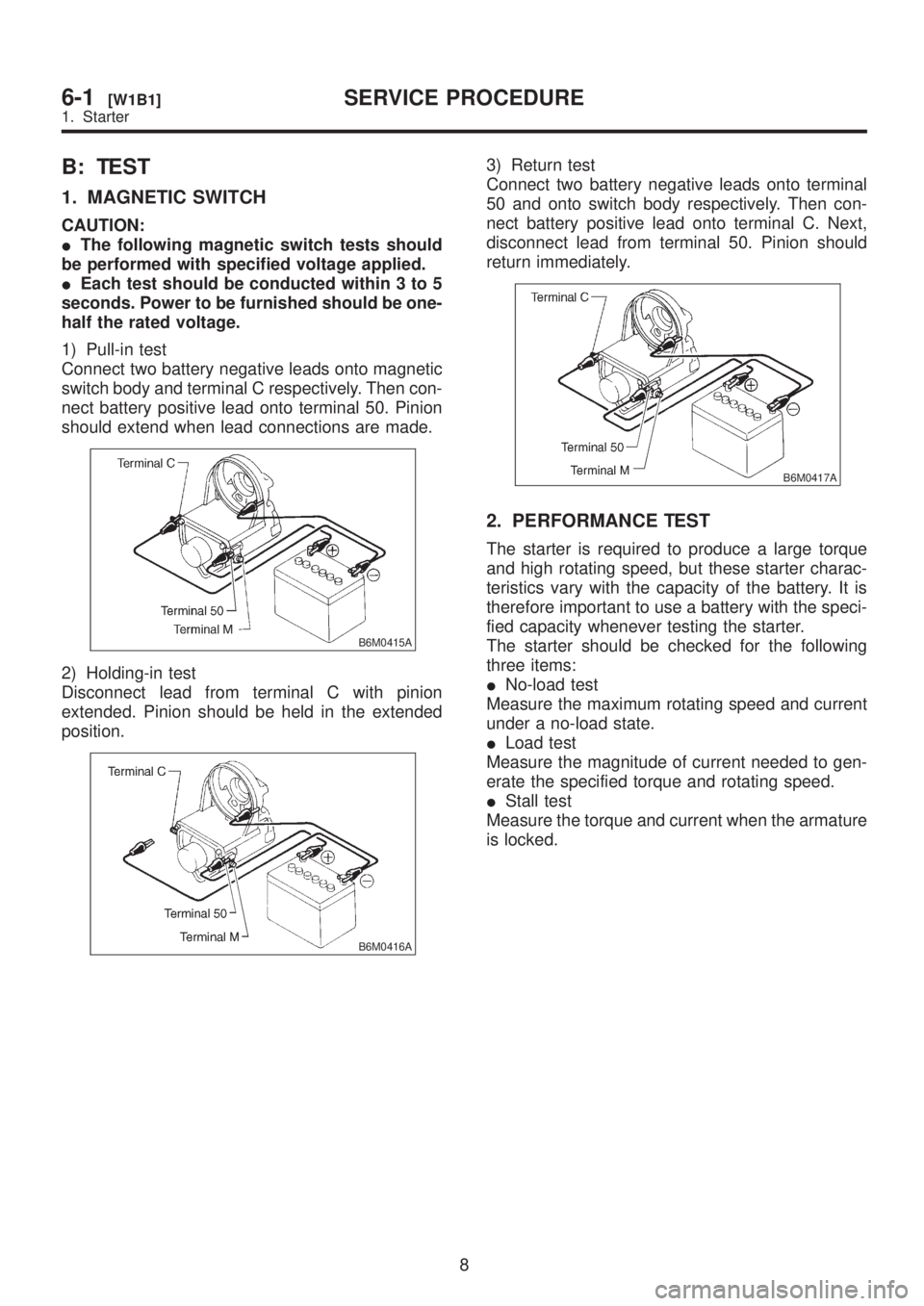

B: TEST

1. MAGNETIC SWITCH

CAUTION:

IThe following magnetic switch tests should

be performed with specified voltage applied.

IEach test should be conducted within 3 to 5

seconds. Power to be furnished should be one-

half the rated voltage.

1) Pull-in test

Connect two battery negative leads onto magnetic

switch body and terminal C respectively. Then con-

nect battery positive lead onto terminal 50. Pinion

should extend when lead connections are made.

B6M0415A

2) Holding-in test

Disconnect lead from terminal C with pinion

extended. Pinion should be held in the extended

position.

B6M0416A

3) Return test

Connect two battery negative leads onto terminal

50 and onto switch body respectively. Then con-

nect battery positive lead onto terminal C. Next,

disconnect lead from terminal 50. Pinion should

return immediately.

B6M0417A

2. PERFORMANCE TEST

The starter is required to produce a large torque

and high rotating speed, but these starter charac-

teristics vary with the capacity of the battery. It is

therefore important to use a battery with the speci-

fied capacity whenever testing the starter.

The starter should be checked for the following

three items:

INo-load test

Measure the maximum rotating speed and current

under a no-load state.

ILoad test

Measure the magnitude of current needed to gen-

erate the specified torque and rotating speed.

IStall test

Measure the torque and current when the armature

is locked.

8

6-1[W1B1]SERVICE PROCEDURE

1. Starter