key SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 61 of 1456

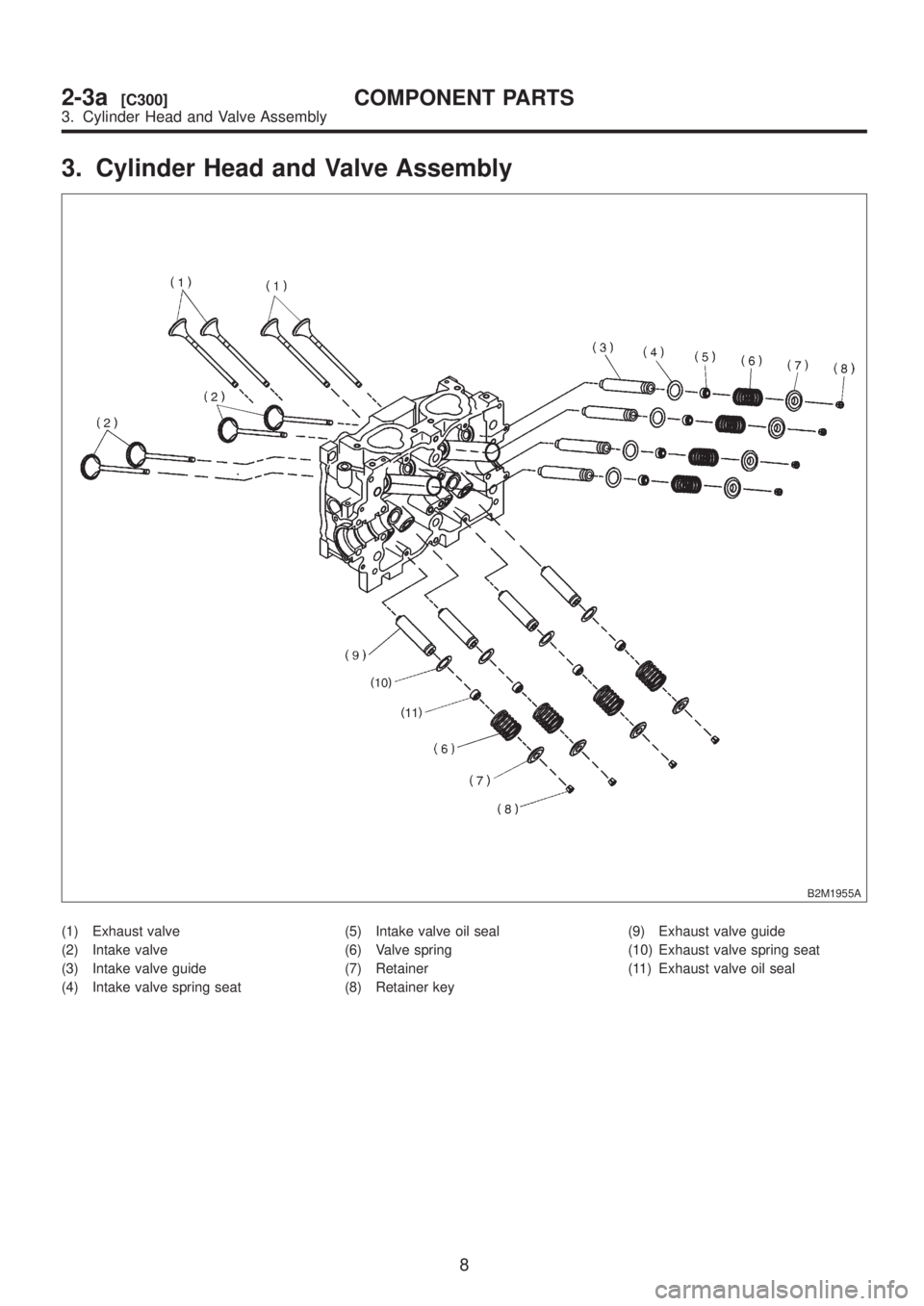

3. Cylinder Head and Valve Assembly

B2M1955A

(1) Exhaust valve

(2) Intake valve

(3) Intake valve guide

(4) Intake valve spring seat(5) Intake valve oil seal

(6) Valve spring

(7) Retainer

(8) Retainer key(9) Exhaust valve guide

(10) Exhaust valve spring seat

(11) Exhaust valve oil seal

8

2-3a[C300]COMPONENT PARTS

3. Cylinder Head and Valve Assembly

Page 63 of 1456

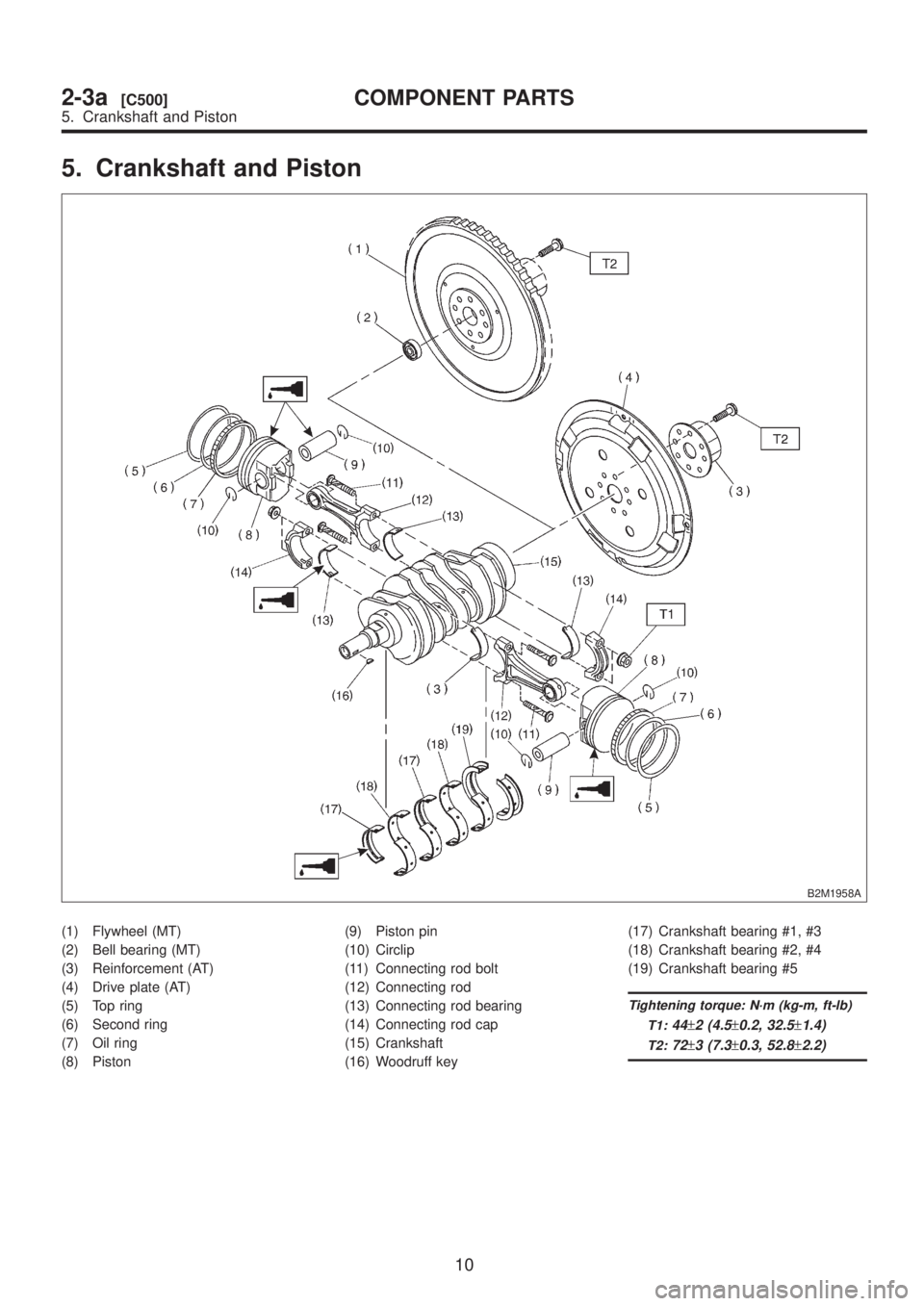

5. Crankshaft and Piston

B2M1958A

(1) Flywheel (MT)

(2) Bell bearing (MT)

(3) Reinforcement (AT)

(4) Drive plate (AT)

(5) Top ring

(6) Second ring

(7) Oil ring

(8) Piston(9) Piston pin

(10) Circlip

(11) Connecting rod bolt

(12) Connecting rod

(13) Connecting rod bearing

(14) Connecting rod cap

(15) Crankshaft

(16) Woodruff key(17) Crankshaft bearing #1, #3

(18) Crankshaft bearing #2, #4

(19) Crankshaft bearing #5

Tightening torque: N´m (kg-m, ft-lb)

T1:

44±2 (4.5±0.2, 32.5±1.4)

T2:72±3 (7.3±0.3, 52.8±2.2)

10

2-3a[C500]COMPONENT PARTS

5. Crankshaft and Piston

Page 72 of 1456

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

5.7

±0.5 mm (0.224±0.020 in)

H2M2381A

3. BELT TENSION PULLEY

1) Check mating surfaces of timing belt and con-

tact point of adjuster rod for abnormal wear or

scratches. Replace automatic belt tension adjuster

assembly if faulty.

2) Check tension pulley for smooth rotation.

Replace if noise or excessive play is noted.

3) Check tension pulley for grease leakage.

4. BELT IDLER

1) Check belt idler for smooth rotation. Replace if

noise or excessive play is noted.

2) Check belt outer contacting surfaces of idler

pulley for abnormal wear and scratches.

3) Check belt idler for grease leakage.

5. CAMSHAFT AND CRANKSHAFT

SPROCKET

1) Check sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between

sprocket and key.

3) Check crankshaft sprocket notch for sensor for

damage and contamination of foreign matter.

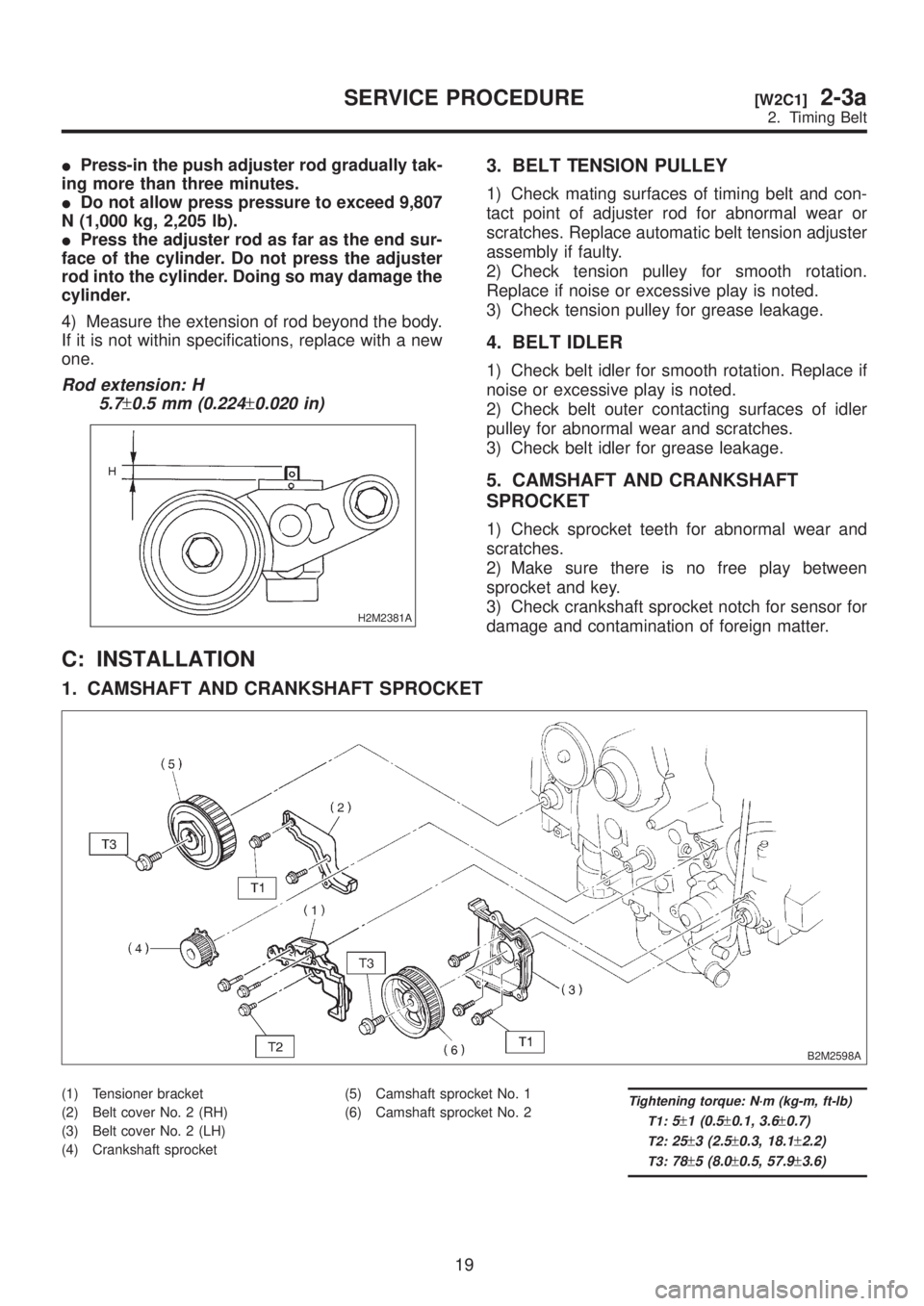

C: INSTALLATION

1. CAMSHAFT AND CRANKSHAFT SPROCKET

B2M2598A

(1) Tensioner bracket

(2) Belt cover No. 2 (RH)

(3) Belt cover No. 2 (LH)

(4) Crankshaft sprocket(5) Camshaft sprocket No. 1

(6) Camshaft sprocket No. 2Tightening torque: N´m (kg-m, ft-lb)

T1:

5±1 (0.5±0.1, 3.6±0.7)

T2:25±3 (2.5±0.3, 18.1±2.2)

T3:78±5 (8.0±0.5, 57.9±3.6)

19

[W2C1]2-3aSERVICE PROCEDURE

2. Timing Belt

Page 96 of 1456

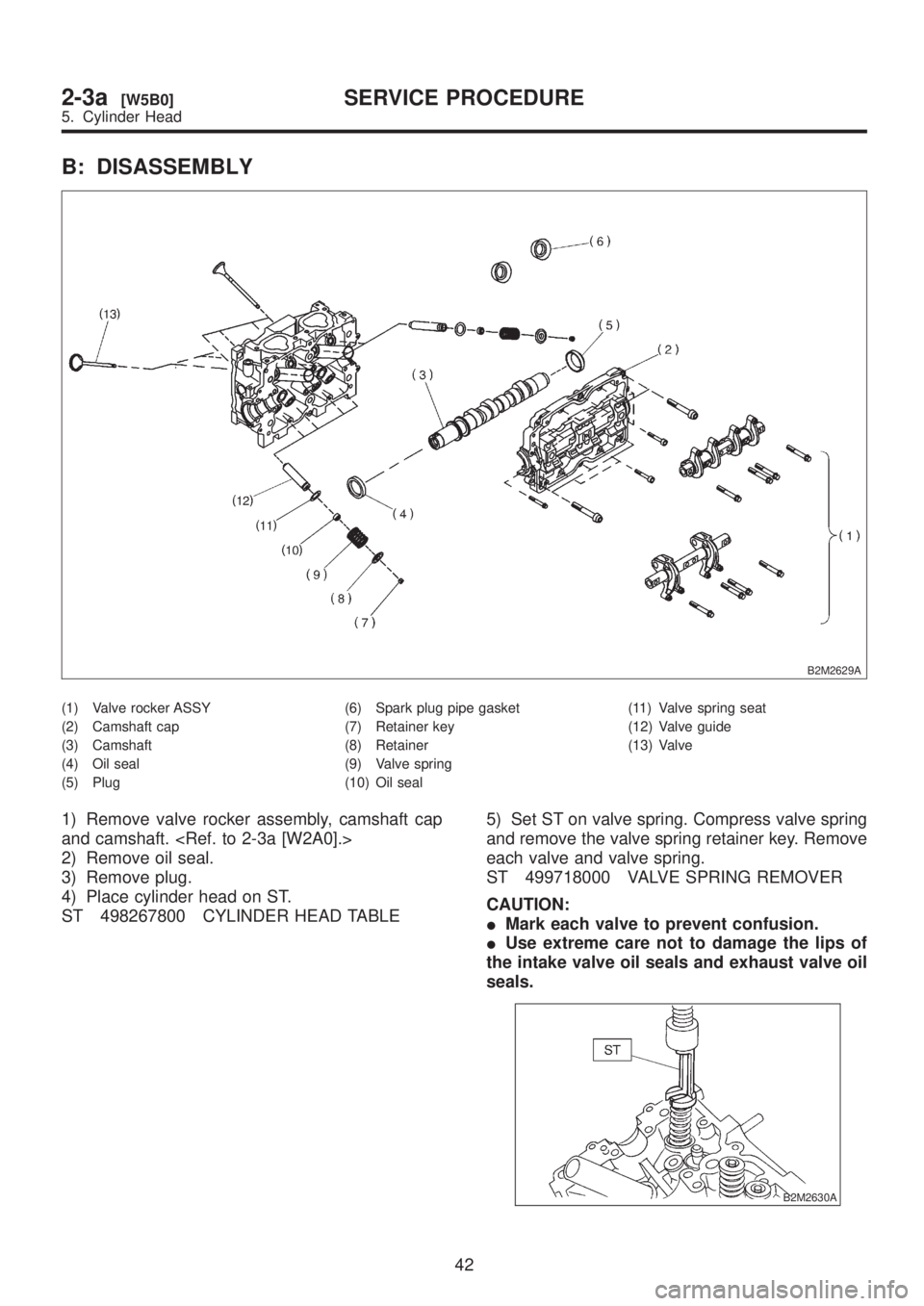

B: DISASSEMBLY

B2M2629A

(1) Valve rocker ASSY

(2) Camshaft cap

(3) Camshaft

(4) Oil seal

(5) Plug(6) Spark plug pipe gasket

(7) Retainer key

(8) Retainer

(9) Valve spring

(10) Oil seal(11) Valve spring seat

(12) Valve guide

(13) Valve

1) Remove valve rocker assembly, camshaft cap

and camshaft.

2) Remove oil seal.

3) Remove plug.

4) Place cylinder head on ST.

ST 498267800 CYLINDER HEAD TABLE5) Set ST on valve spring. Compress valve spring

and remove the valve spring retainer key. Remove

each valve and valve spring.

ST 499718000 VALVE SPRING REMOVER

CAUTION:

IMark each valve to prevent confusion.

IUse extreme care not to damage the lips of

the intake valve oil seals and exhaust valve oil

seals.

B2M2630A

42

2-3a[W5B0]SERVICE PROCEDURE

5. Cylinder Head

Page 102 of 1456

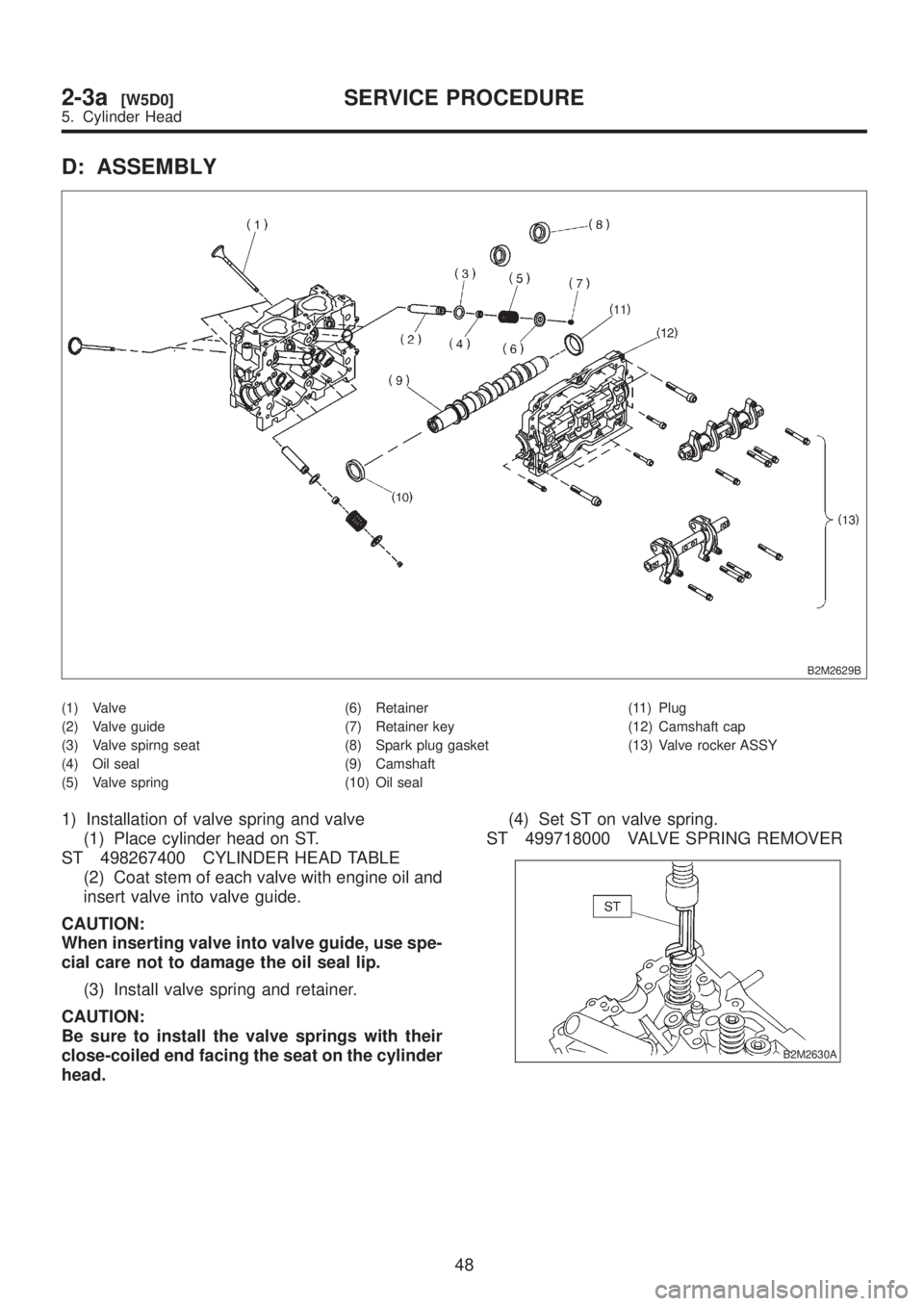

D: ASSEMBLY

B2M2629B

(1) Valve

(2) Valve guide

(3) Valve spirng seat

(4) Oil seal

(5) Valve spring(6) Retainer

(7) Retainer key

(8) Spark plug gasket

(9) Camshaft

(10) Oil seal(11) Plug

(12) Camshaft cap

(13) Valve rocker ASSY

1) Installation of valve spring and valve

(1) Place cylinder head on ST.

ST 498267400 CYLINDER HEAD TABLE

(2) Coat stem of each valve with engine oil and

insert valve into valve guide.

CAUTION:

When inserting valve into valve guide, use spe-

cial care not to damage the oil seal lip.

(3) Install valve spring and retainer.

CAUTION:

Be sure to install the valve springs with their

close-coiled end facing the seat on the cylinder

head.(4) Set ST on valve spring.

ST 499718000 VALVE SPRING REMOVER

B2M2630A

48

2-3a[W5D0]SERVICE PROCEDURE

5. Cylinder Head

Page 103 of 1456

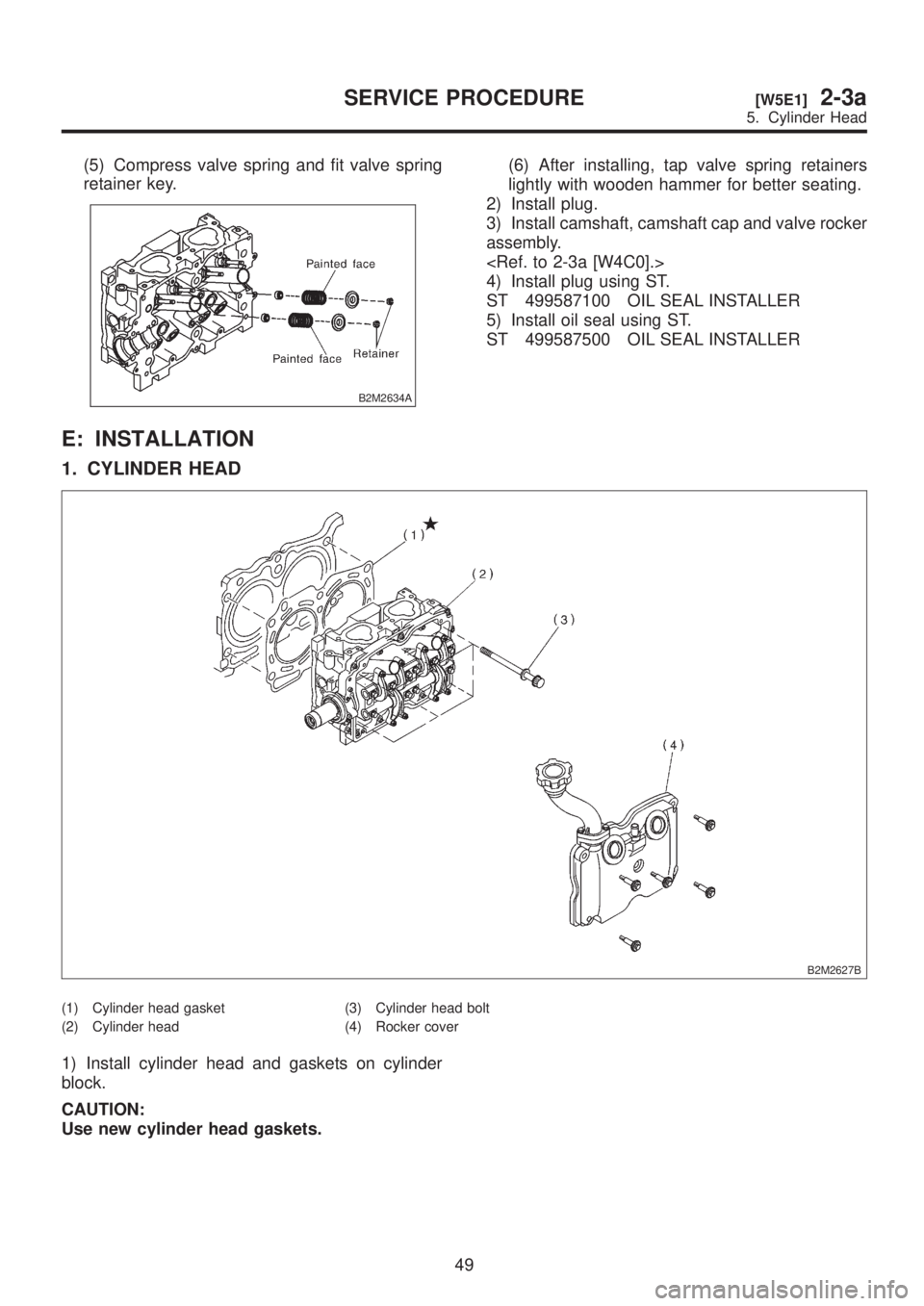

(5) Compress valve spring and fit valve spring

retainer key.

B2M2634A

(6) After installing, tap valve spring retainers

lightly with wooden hammer for better seating.

2) Install plug.

3) Install camshaft, camshaft cap and valve rocker

assembly.

4) Install plug using ST.

ST 499587100 OIL SEAL INSTALLER

5) Install oil seal using ST.

ST 499587500 OIL SEAL INSTALLER

E: INSTALLATION

1. CYLINDER HEAD

B2M2627B

(1) Cylinder head gasket

(2) Cylinder head(3) Cylinder head bolt

(4) Rocker cover

1) Install cylinder head and gaskets on cylinder

block.

CAUTION:

Use new cylinder head gaskets.

49

[W5E1]2-3aSERVICE PROCEDURE

5. Cylinder Head

Page 141 of 1456

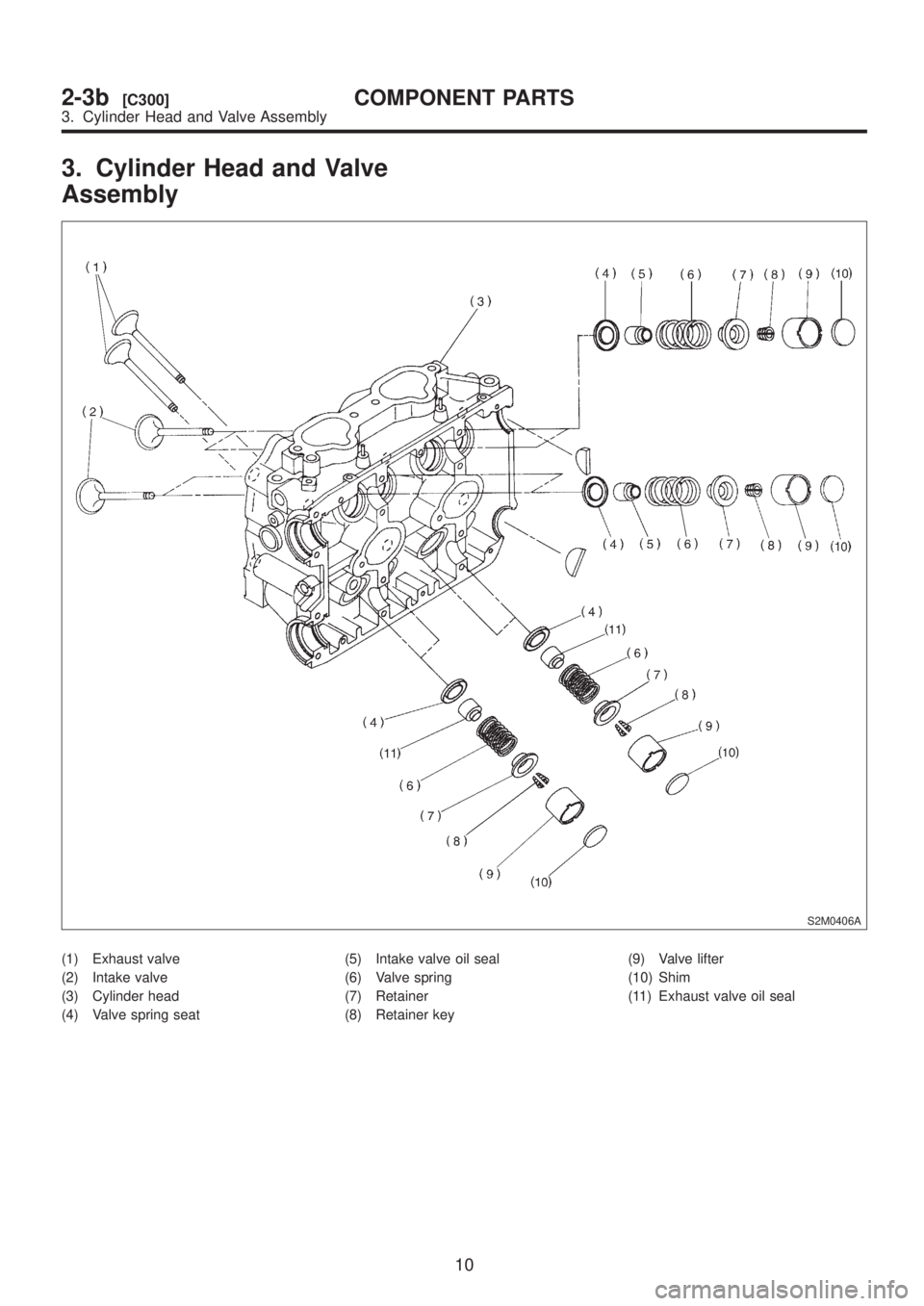

3. Cylinder Head and Valve

Assembly

S2M0406A

(1) Exhaust valve

(2) Intake valve

(3) Cylinder head

(4) Valve spring seat(5) Intake valve oil seal

(6) Valve spring

(7) Retainer

(8) Retainer key(9) Valve lifter

(10) Shim

(11) Exhaust valve oil seal

10

2-3b[C300]COMPONENT PARTS

3. Cylinder Head and Valve Assembly

Page 143 of 1456

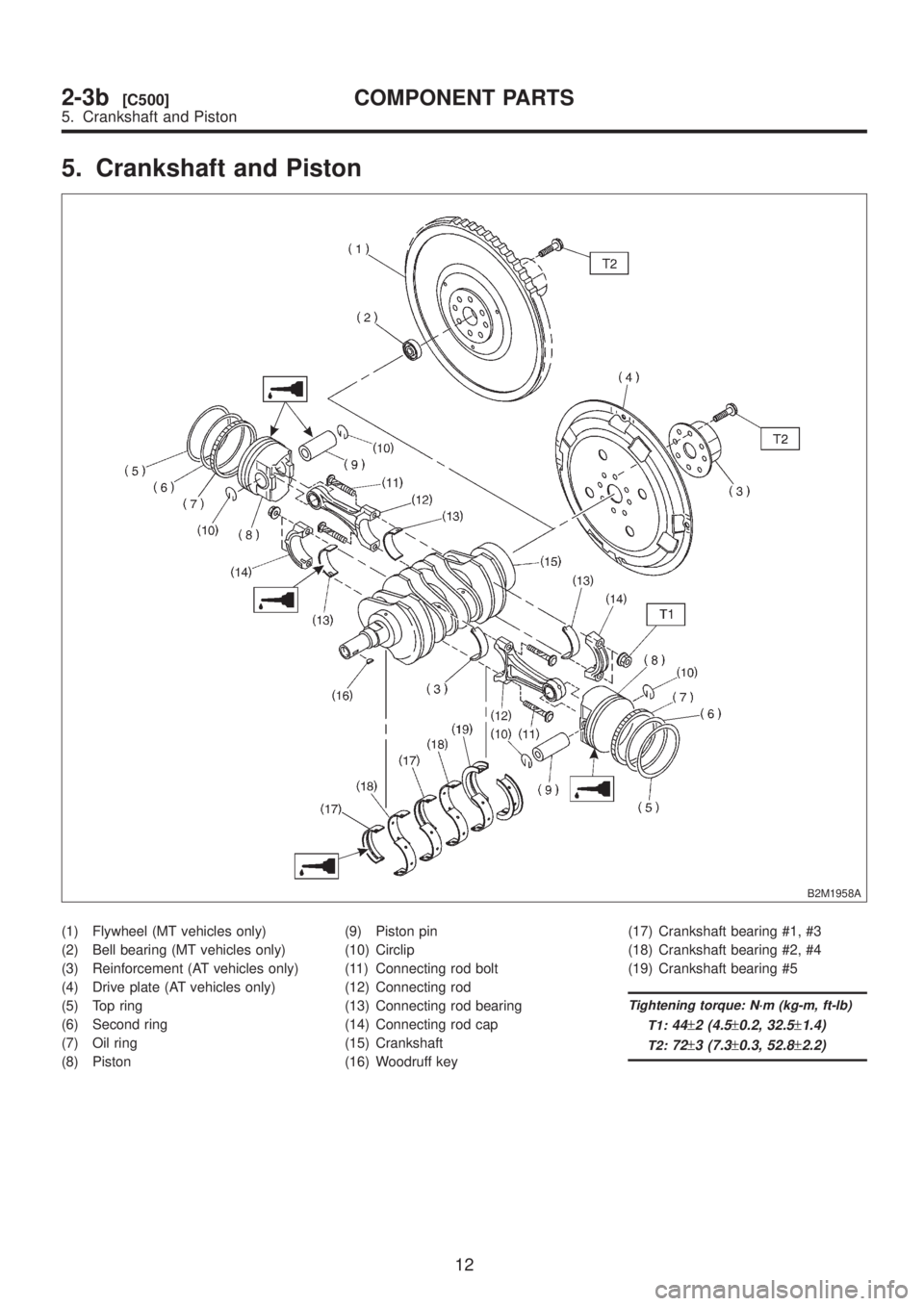

5. Crankshaft and Piston

B2M1958A

(1) Flywheel (MT vehicles only)

(2) Bell bearing (MT vehicles only)

(3) Reinforcement (AT vehicles only)

(4) Drive plate (AT vehicles only)

(5) Top ring

(6) Second ring

(7) Oil ring

(8) Piston(9) Piston pin

(10) Circlip

(11) Connecting rod bolt

(12) Connecting rod

(13) Connecting rod bearing

(14) Connecting rod cap

(15) Crankshaft

(16) Woodruff key(17) Crankshaft bearing #1, #3

(18) Crankshaft bearing #2, #4

(19) Crankshaft bearing #5

Tightening torque: N´m (kg-m, ft-lb)

T1:

44±2 (4.5±0.2, 32.5±1.4)

T2:72±3 (7.3±0.3, 52.8±2.2)

12

2-3b[C500]COMPONENT PARTS

5. Crankshaft and Piston

Page 151 of 1456

(1) Slowly press the adjuster rod down to the

end surface of the cylinder. Repeat this motion

2 or 3 times.

(2) With the adjuster rod moved all the way up,

apply a pressure of 294 N (30 kg, 66 lb) to it.

Check adjuster rod stiffness.

(3) If the adjuster rod is not stiff and moves

down, replace the automatic belt tension

adjuster assembly with a new one.

CAUTION:

IAlways use a vertical type pressing tool to

move the adjuster rod down.

IDo not use a lateral type vise.

IPush adjuster rod vertically.

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

5.7

±0.5 mm (0.224±0.020 in)

H2M2381A

3. BELT TENSION PULLEY

1) Check mating surfaces of timing belt and con-

tact point of adjuster rod for abnormal wear or

scratches. Replace belt tension pulley if faulty.

2) Check belt tension pulley for smooth rotation.

Replace if noise or excessive play is noted.

3) Check belt tension pulley for grease leakage.

4. BELT IDLER

1) Check idler for smooth rotation. Replace if

noise or excessive play is noted.

2) Check outer contacting surfaces of idler pulley

for abnormal wear and scratches.

3) Check idler for grease leakage.

5. SPROCKET

1) Check sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between

sprocket and key.

3) Check crankshaft sprocket notch for sensor for

damage and contamination of foreign matter.

20

2-3b[W2B3]SERVICE PROCEDURE

2. Timing Belt

Page 168 of 1456

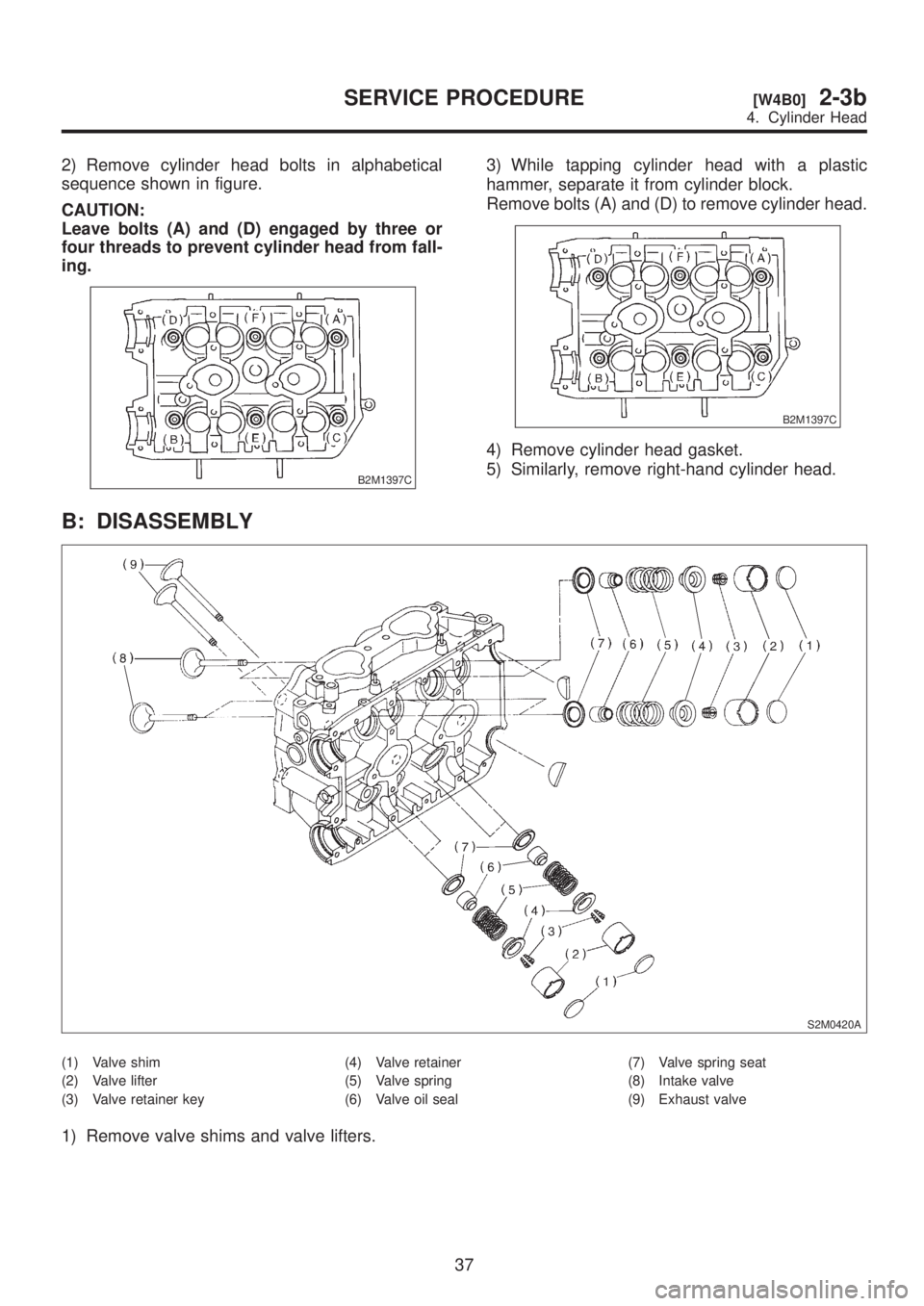

2) Remove cylinder head bolts in alphabetical

sequence shown in figure.

CAUTION:

Leave bolts (A) and (D) engaged by three or

four threads to prevent cylinder head from fall-

ing.

B2M1397C

3) While tapping cylinder head with a plastic

hammer, separate it from cylinder block.

Remove bolts (A) and (D) to remove cylinder head.

B2M1397C

4) Remove cylinder head gasket.

5) Similarly, remove right-hand cylinder head.

B: DISASSEMBLY

S2M0420A

(1) Valve shim

(2) Valve lifter

(3) Valve retainer key(4) Valve retainer

(5) Valve spring

(6) Valve oil seal(7) Valve spring seat

(8) Intake valve

(9) Exhaust valve

1) Remove valve shims and valve lifters.

37

[W4B0]2-3bSERVICE PROCEDURE

4. Cylinder Head