read SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 35 of 1456

3. Engine Idle Speed

A: MEASUREMENT

1) Before checking idle speed, check the follow-

ing:

(1) Ensure that air cleaner element is free from

clogging, ignition timing is correct, spark plugs

are in good condition, and that hoses are con-

nected properly.

(2) Ensure that malfunction indicator light

(CHECK ENGINE light) does not illuminate.

2) Warm-up the engine.

3) Stop the engine, and turn ignition switch to

OFF.

4) When using SUBARU SELECT MONITOR;

NOTE:

For detailed operation procedures, refer to the

SUBARU SELECT MONITOR OPERATION

MANUAL.

(1) Insert the cartridge to SUBARU SELECT

MONITOR.

ST 24082AA090 CARTRIDGE

S2M0286A

(2) Connect SUBARU SELECT MONITOR to

the data link connector.

(3) Turn ignition switch to ON, and SUBARU

SELECT MONITOR switch to ON.

(4) Select {2. Each System Check} in Main

Menu.

(5) Select {EGI/EMPI} in Selection Menu.

(6) Select {1. Current Data Display & Save} in

EGI/EMPI Diagnosis.

(7) Select {1.12 Data Display} in Data Display

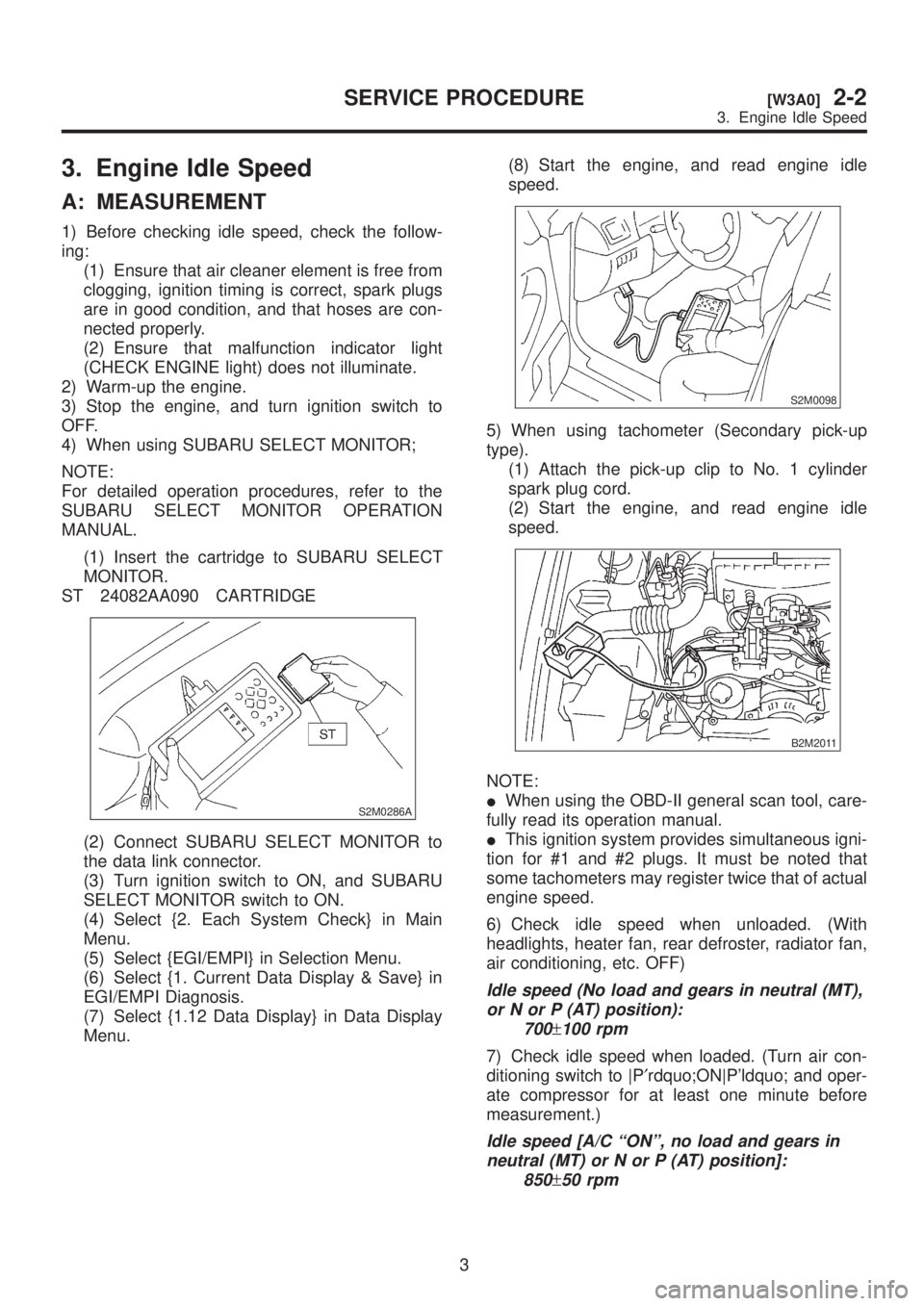

Menu.(8) Start the engine, and read engine idle

speed.

S2M0098

5) When using tachometer (Secondary pick-up

type).

(1) Attach the pick-up clip to No. 1 cylinder

spark plug cord.

(2) Start the engine, and read engine idle

speed.

B2M2011

NOTE:

IWhen using the OBD-II general scan tool, care-

fully read its operation manual.

IThis ignition system provides simultaneous igni-

tion for #1 and #2 plugs. It must be noted that

some tachometers may register twice that of actual

engine speed.

6) Check idle speed when unloaded. (With

headlights, heater fan, rear defroster, radiator fan,

air conditioning, etc. OFF)

Idle speed (No load and gears in neutral (MT),

or N or P (AT) position):

700

±100 rpm

7) Check idle speed when loaded. (Turn air con-

ditioning switch to |P¢rdquo;ON|P'ldquo; and oper-

ate compressor for at least one minute before

measurement.)

Idle speed [A/C ªONº, no load and gears in

neutral (MT) or N or P (AT) position]:

850

±50 rpm

3

[W3A0]2-2SERVICE PROCEDURE

3. Engine Idle Speed

Page 36 of 1456

![SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng](/img/17/57435/w960_57435-35.png)

CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

A: MEASUREMENT

1. 2200 cc MODEL

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

G2M0098

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (200 Ð 300 rpm and fully open

throttle):

Standard;

1,079 Ð 1,275 kPa (11.0 Ð 13.0 kg/cm

2,

156 Ð 185 psi)

Limit;

883 kPa (9.0 kg/cm

2, 128 psi)

Difference between cylinders;

196 kPa (2.0 kg/cm

2, 28 psi)

4

2-2[W4A1]SERVICE PROCEDURE

4. Engine Compression

Page 37 of 1456

![SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng](/img/17/57435/w960_57435-36.png)

CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

A: MEASUREMENT

1. 2200 cc MODEL

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

G2M0098

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (200 Ð 300 rpm and fully open

throttle):

Standard;

1,079 Ð 1,275 kPa (11.0 Ð 13.0 kg/cm

2,

156 Ð 185 psi)

Limit;

883 kPa (9.0 kg/cm

2, 128 psi)

Difference between cylinders;

196 kPa (2.0 kg/cm

2, 28 psi)

4

2-2[W4A1]SERVICE PROCEDURE

4. Engine Compression

Page 38 of 1456

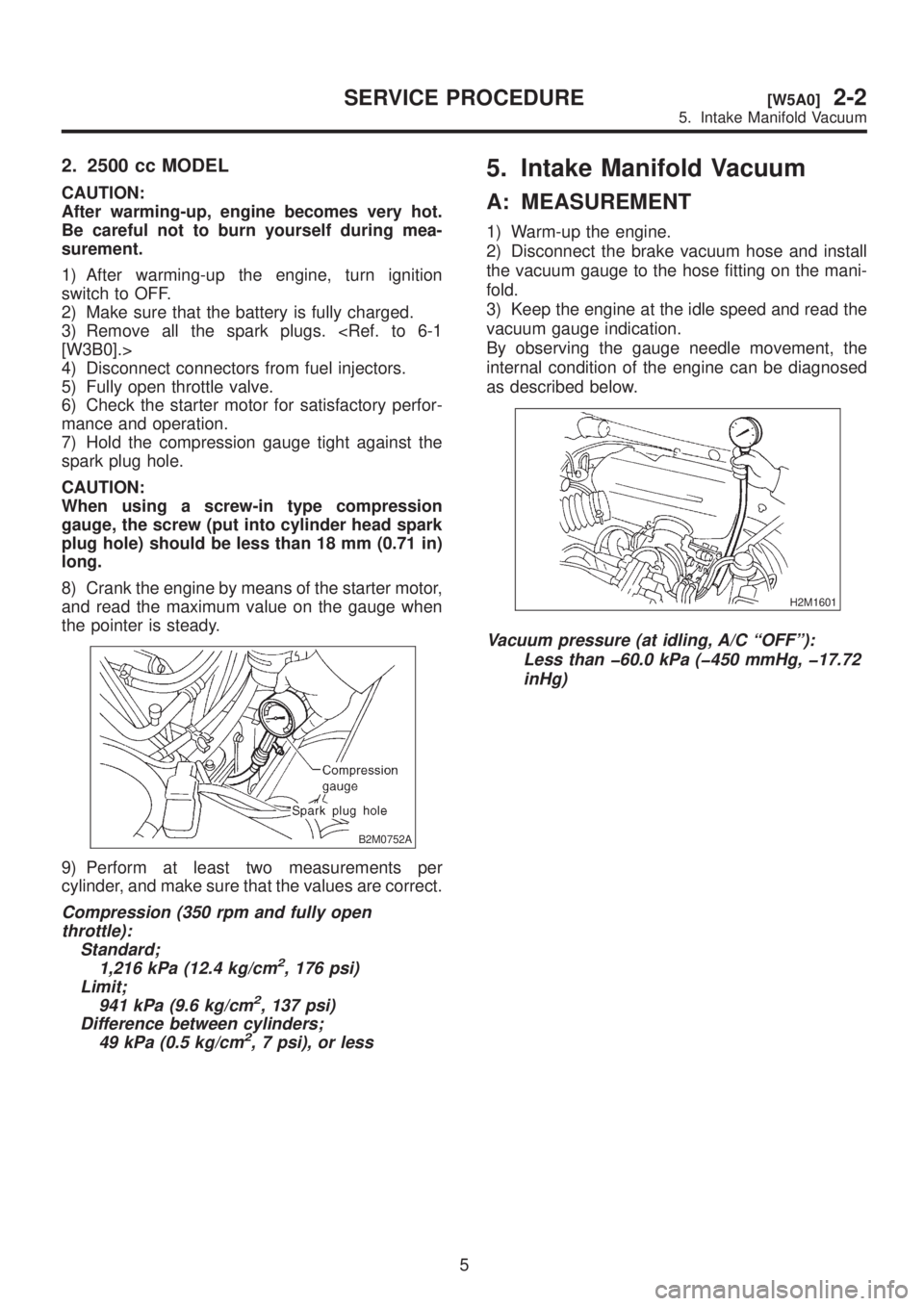

2. 2500 cc MODEL

CAUTION:

After warming-up, engine becomes very hot.

Be careful not to burn yourself during mea-

surement.

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

B2M0752A

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (350 rpm and fully open

throttle):

Standard;

1,216 kPa (12.4 kg/cm

2, 176 psi)

Limit;

941 kPa (9.6 kg/cm

2, 137 psi)

Difference between cylinders;

49 kPa (0.5 kg/cm

2, 7 psi), or less

5. Intake Manifold Vacuum

A: MEASUREMENT

1) Warm-up the engine.

2) Disconnect the brake vacuum hose and install

the vacuum gauge to the hose fitting on the mani-

fold.

3) Keep the engine at the idle speed and read the

vacuum gauge indication.

By observing the gauge needle movement, the

internal condition of the engine can be diagnosed

as described below.

H2M1601

Vacuum pressure (at idling, A/C ªOFFº):

Less than þ60.0 kPa (þ450 mmHg, þ17.72

inHg)

5

[W5A0]2-2SERVICE PROCEDURE

5. Intake Manifold Vacuum

Page 39 of 1456

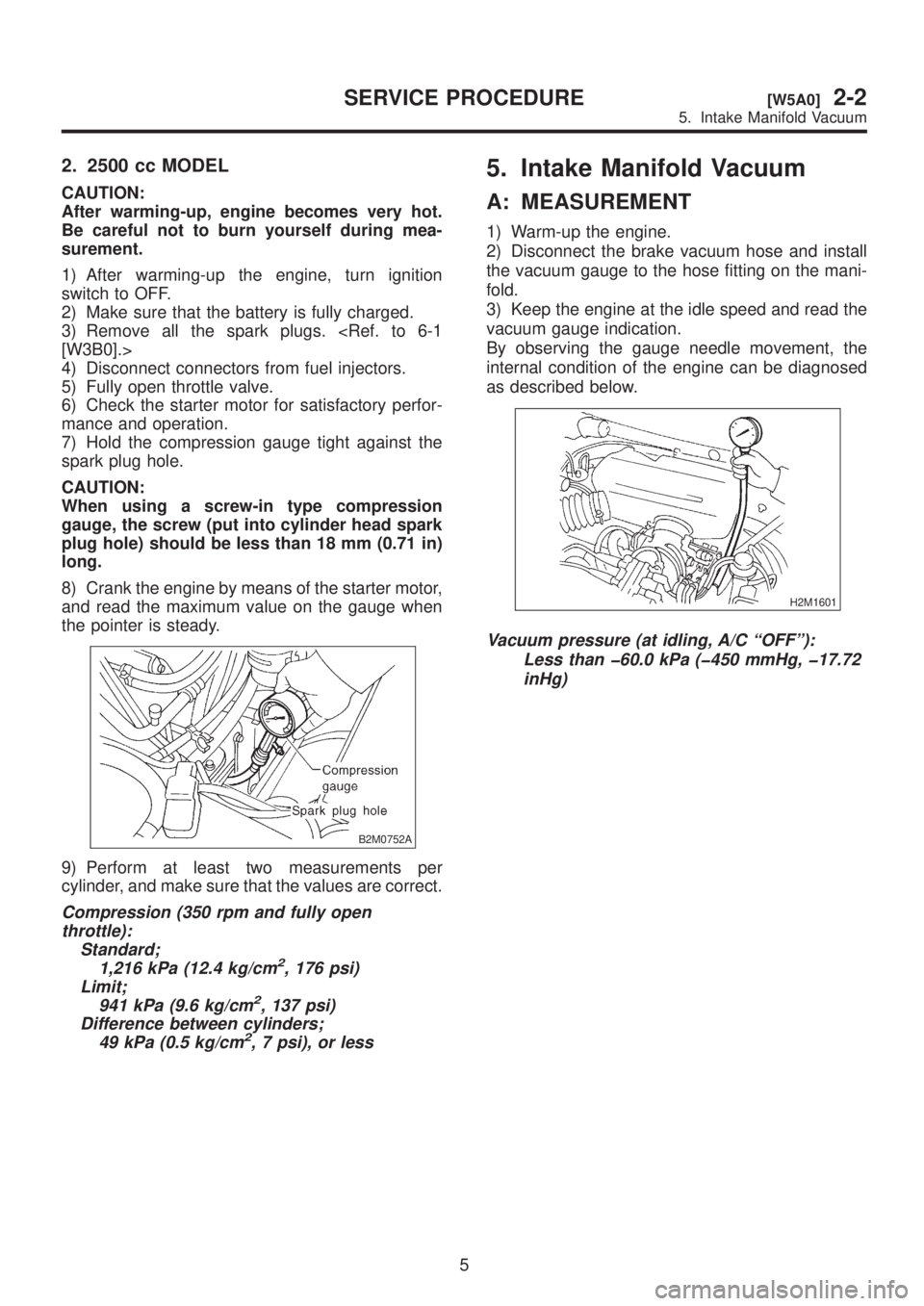

2. 2500 cc MODEL

CAUTION:

After warming-up, engine becomes very hot.

Be careful not to burn yourself during mea-

surement.

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

B2M0752A

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (350 rpm and fully open

throttle):

Standard;

1,216 kPa (12.4 kg/cm

2, 176 psi)

Limit;

941 kPa (9.6 kg/cm

2, 137 psi)

Difference between cylinders;

49 kPa (0.5 kg/cm

2, 7 psi), or less

5. Intake Manifold Vacuum

A: MEASUREMENT

1) Warm-up the engine.

2) Disconnect the brake vacuum hose and install

the vacuum gauge to the hose fitting on the mani-

fold.

3) Keep the engine at the idle speed and read the

vacuum gauge indication.

By observing the gauge needle movement, the

internal condition of the engine can be diagnosed

as described below.

H2M1601

Vacuum pressure (at idling, A/C ªOFFº):

Less than þ60.0 kPa (þ450 mmHg, þ17.72

inHg)

5

[W5A0]2-2SERVICE PROCEDURE

5. Intake Manifold Vacuum

Page 78 of 1456

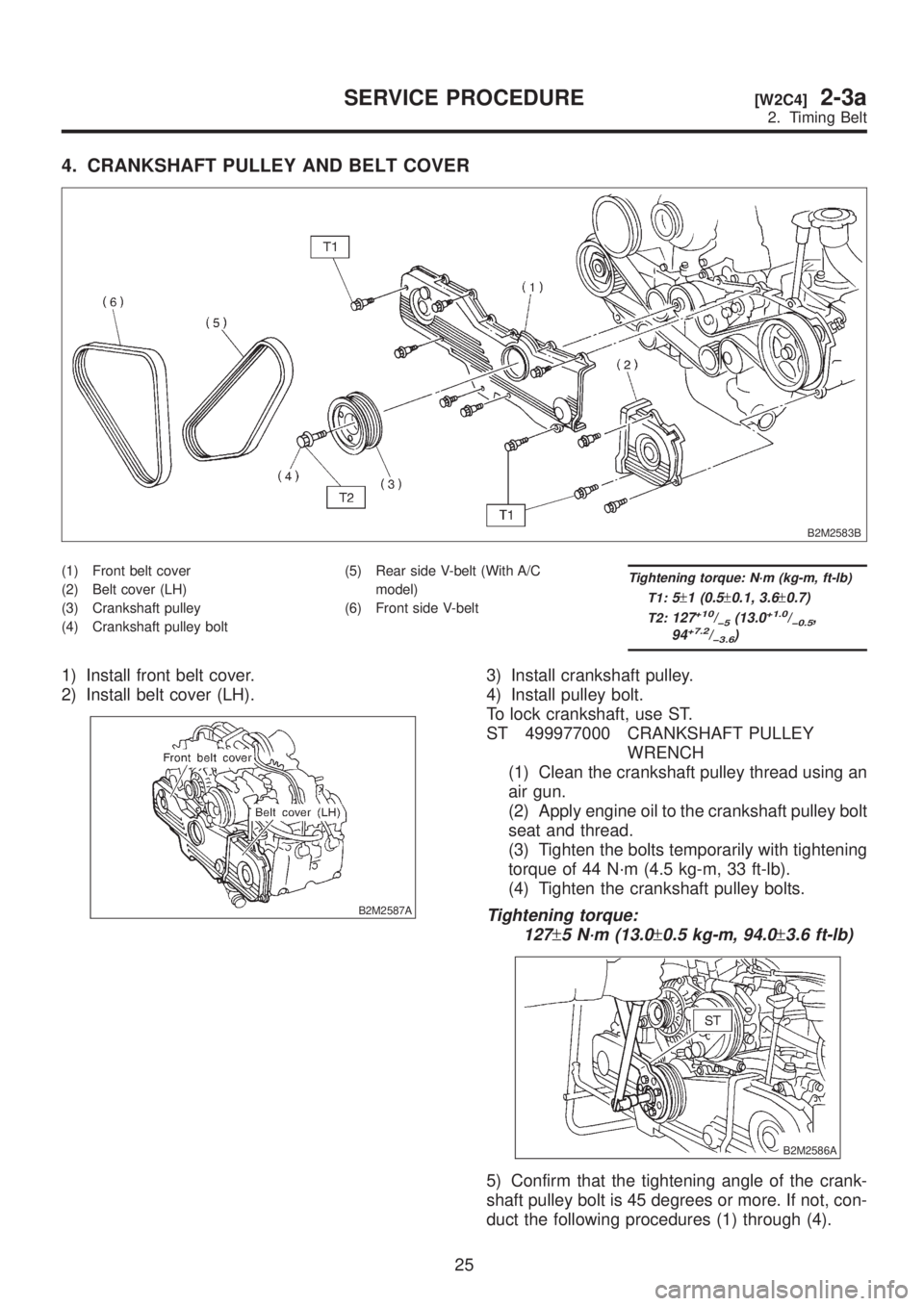

4. CRANKSHAFT PULLEY AND BELT COVER

B2M2583B

(1) Front belt cover

(2) Belt cover (LH)

(3) Crankshaft pulley

(4) Crankshaft pulley bolt(5) Rear side V-belt (With A/C

model)

(6) Front side V-beltTightening torque: N´m (kg-m, ft-lb)

T1:

5±1 (0.5±0.1, 3.6±0.7)

T2:127+10/þ5(13.0+1.0/þ0.5,

94+7.2/þ3.6)

1) Install front belt cover.

2) Install belt cover (LH).

B2M2587A

3) Install crankshaft pulley.

4) Install pulley bolt.

To lock crankshaft, use ST.

ST 499977000 CRANKSHAFT PULLEY

WRENCH

(1) Clean the crankshaft pulley thread using an

air gun.

(2) Apply engine oil to the crankshaft pulley bolt

seat and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N´m (4.5 kg-m, 33 ft-lb).

(4) Tighten the crankshaft pulley bolts.

Tightening torque:

127

±5 N´m (13.0±0.5 kg-m, 94.0±3.6 ft-lb)

B2M2586A

5) Confirm that the tightening angle of the crank-

shaft pulley bolt is 45 degrees or more. If not, con-

duct the following procedures (1) through (4).

25

[W2C4]2-3aSERVICE PROCEDURE

2. Timing Belt

Page 79 of 1456

(1) Replace the crankshaft pulley bolts and

clean them.

Crankshaft pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Tighten the bolts temporarily with tightening

torque of 44 N´m (4.5 kg-m, 33 ft-lb).

(4) Tighten the crankshaft pulley bolts keeping

them in an angle between 45 degrees and 60

degrees.

CAUTION:

Conduct the tightening procedures by confirm-

ing the turning angle of the crankshaft pulley

bolt referring to the gauge indicated on the belt

cover.

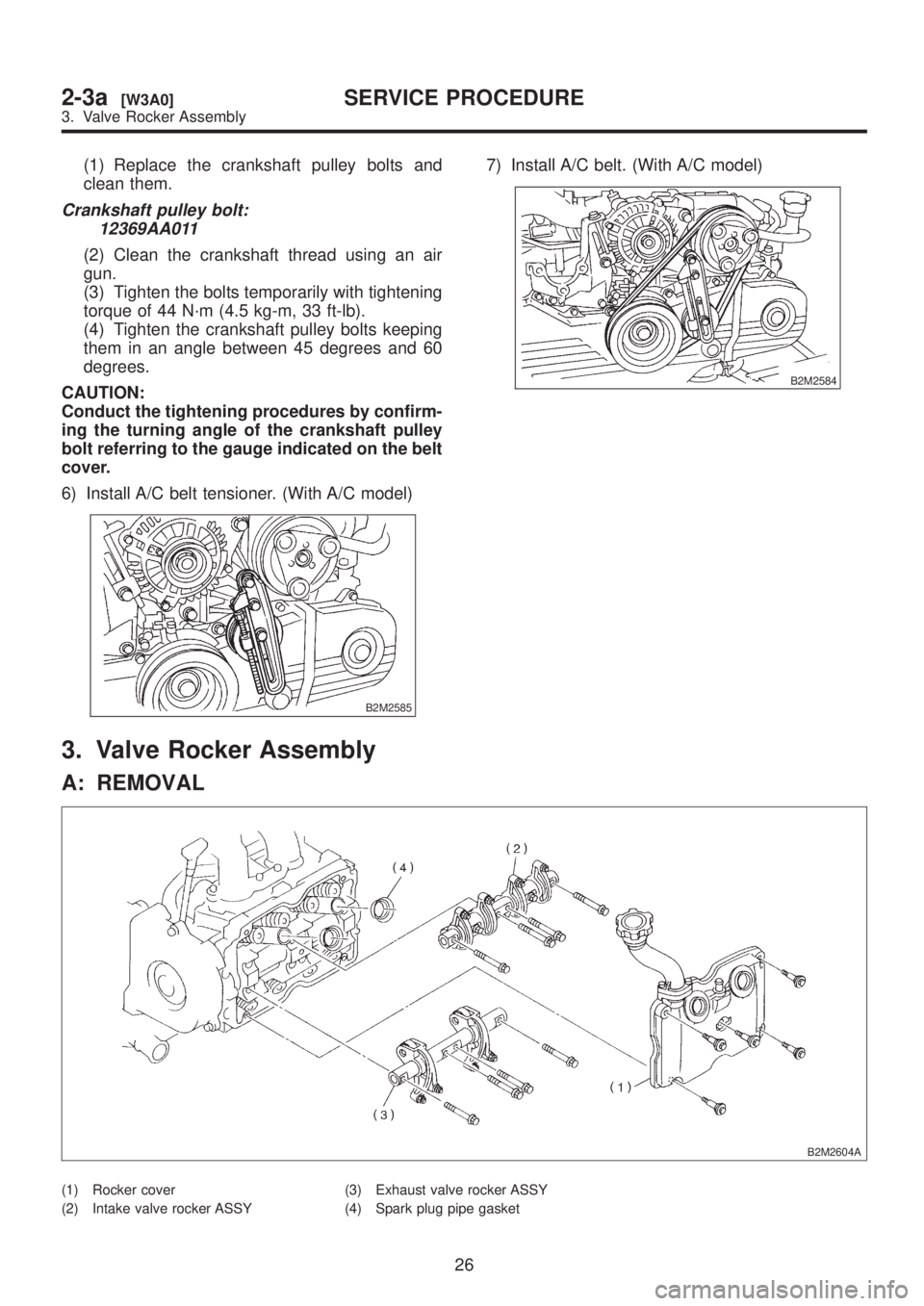

6) Install A/C belt tensioner. (With A/C model)

B2M2585

7) Install A/C belt. (With A/C model)

B2M2584

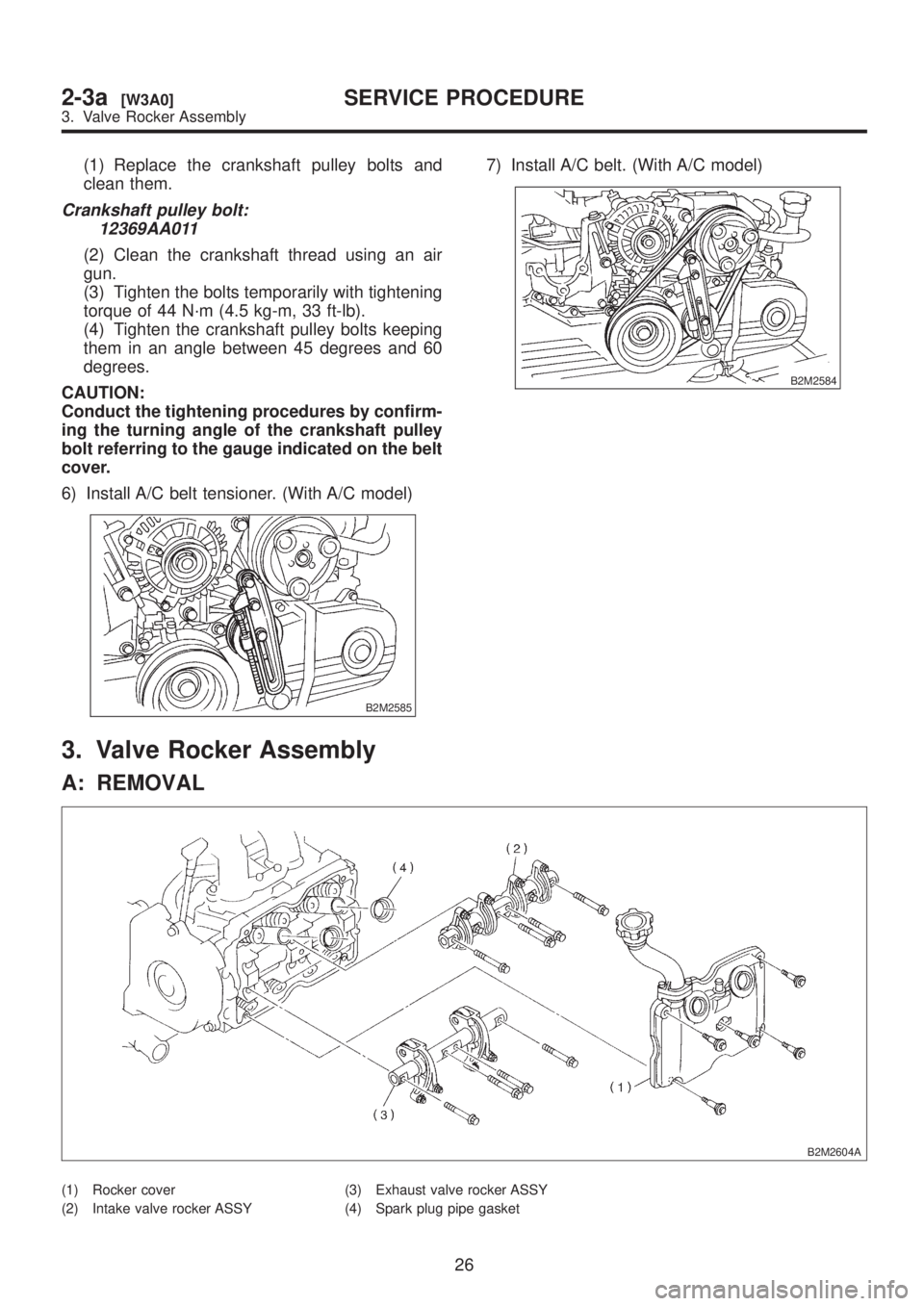

3. Valve Rocker Assembly

A: REMOVAL

B2M2604A

(1) Rocker cover

(2) Intake valve rocker ASSY(3) Exhaust valve rocker ASSY

(4) Spark plug pipe gasket

26

2-3a[W3A0]SERVICE PROCEDURE

3. Valve Rocker Assembly

Page 80 of 1456

(1) Replace the crankshaft pulley bolts and

clean them.

Crankshaft pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Tighten the bolts temporarily with tightening

torque of 44 N´m (4.5 kg-m, 33 ft-lb).

(4) Tighten the crankshaft pulley bolts keeping

them in an angle between 45 degrees and 60

degrees.

CAUTION:

Conduct the tightening procedures by confirm-

ing the turning angle of the crankshaft pulley

bolt referring to the gauge indicated on the belt

cover.

6) Install A/C belt tensioner. (With A/C model)

B2M2585

7) Install A/C belt. (With A/C model)

B2M2584

3. Valve Rocker Assembly

A: REMOVAL

B2M2604A

(1) Rocker cover

(2) Intake valve rocker ASSY(3) Exhaust valve rocker ASSY

(4) Spark plug pipe gasket

26

2-3a[W3A0]SERVICE PROCEDURE

3. Valve Rocker Assembly

Page 81 of 1456

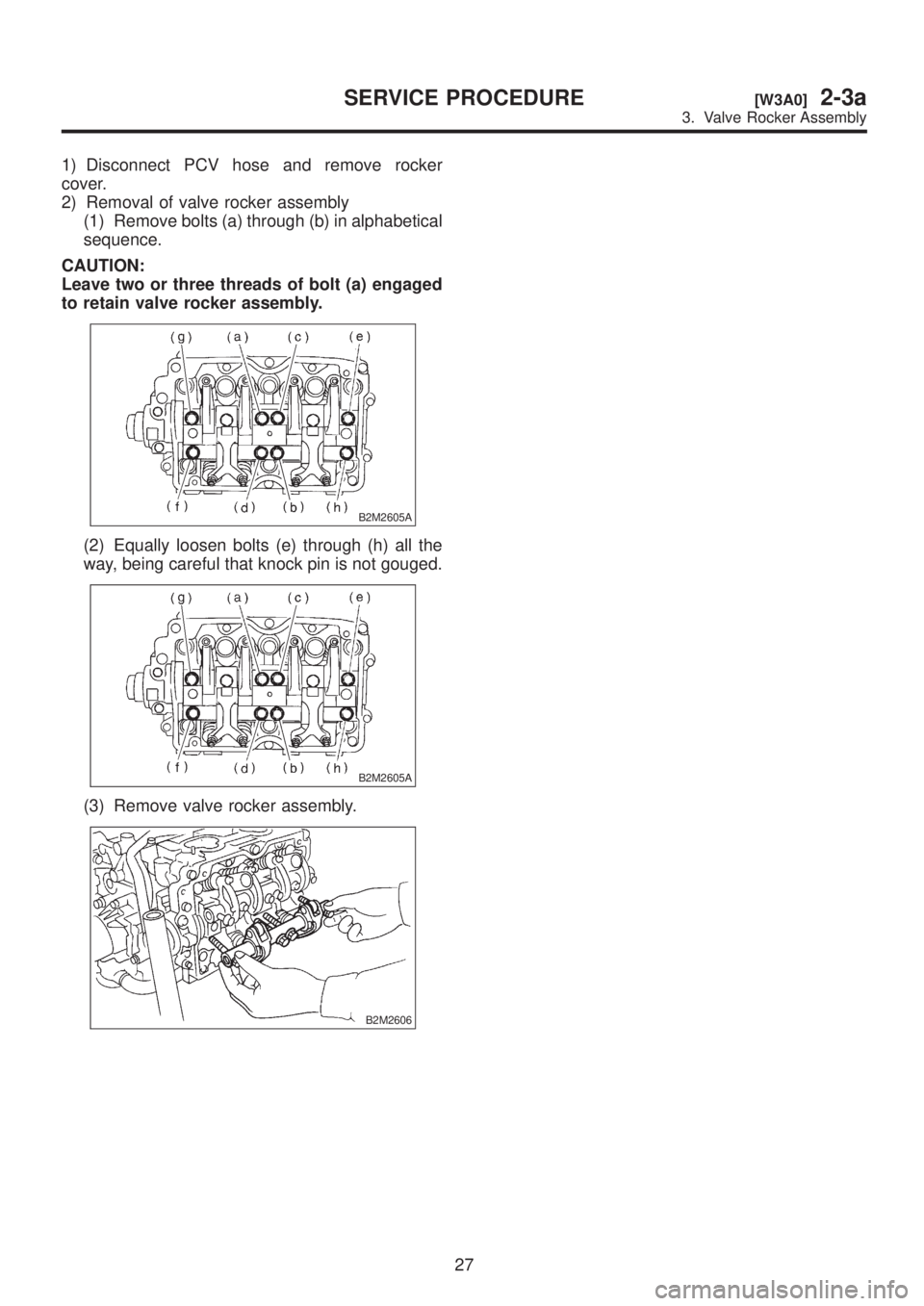

1) Disconnect PCV hose and remove rocker

cover.

2) Removal of valve rocker assembly

(1) Remove bolts (a) through (b) in alphabetical

sequence.

CAUTION:

Leave two or three threads of bolt (a) engaged

to retain valve rocker assembly.

B2M2605A

(2) Equally loosen bolts (e) through (h) all the

way, being careful that knock pin is not gouged.

B2M2605A

(3) Remove valve rocker assembly.

B2M2606

27

[W3A0]2-3aSERVICE PROCEDURE

3. Valve Rocker Assembly

Page 95 of 1456

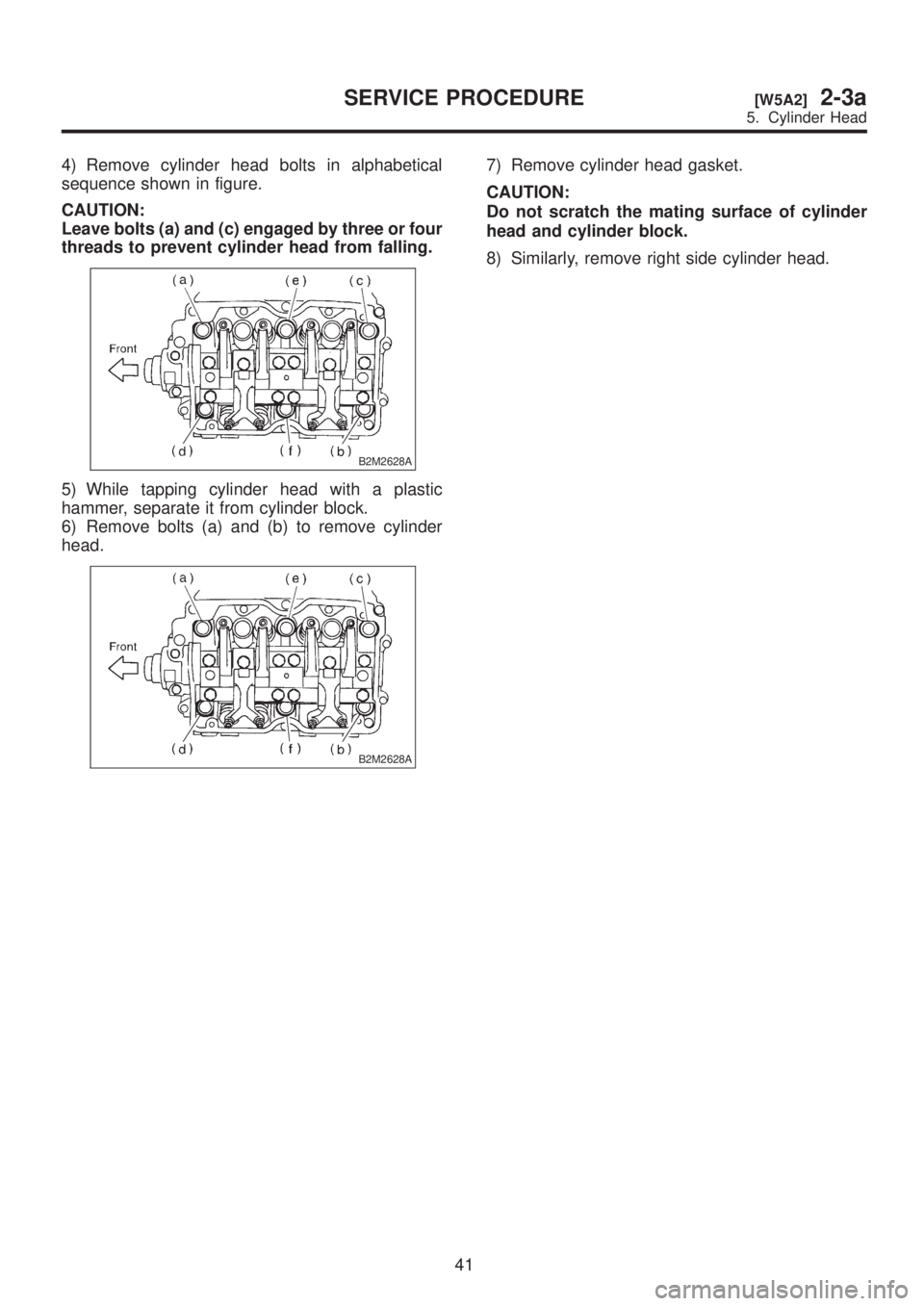

4) Remove cylinder head bolts in alphabetical

sequence shown in figure.

CAUTION:

Leave bolts (a) and (c) engaged by three or four

threads to prevent cylinder head from falling.

B2M2628A

5) While tapping cylinder head with a plastic

hammer, separate it from cylinder block.

6) Remove bolts (a) and (b) to remove cylinder

head.

B2M2628A

7) Remove cylinder head gasket.

CAUTION:

Do not scratch the mating surface of cylinder

head and cylinder block.

8) Similarly, remove right side cylinder head.

41

[W5A2]2-3aSERVICE PROCEDURE

5. Cylinder Head