engine coolant SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2046 of 2453

5AT-30

Stall Test

AUTOMATIC TRANSMISSION

5. Stall Test

A: INSPECTION

NOTE:

The stall test is extremely important in diagnosing

the condition of an automatic transmission and en-

gine. It should be conducted to measure the engine

stall speeds in “R” and “2nd of manual mode”.

Purposes of the stall test:

•Operational check of the automatic transmission

clutch

•Operational check of the torque converter clutch

•Engine performance check

1) Check that the throttle valve fully opens.

2) Check that the engine oil level is correct.

3) Check that the coolant level is correct.

4) Check that the ATF level is correct.

5) Check that the differential gear oil level is cor-

rect.

6) Raise the ATF temperature to 70 to 80°C (158 to

176°F) by driving a distance of 5 to 10 km (3 to 6

miles). Confirm the ATF temperature on Subaru

Select Monitor.

tor.>

7) Place the wheel chocks at the front and rear of

all wheels and apply the parking brake.

8) Move the select lever to ensure it operates prop-

erly, and then set to the “2nd gear of manual

mode”.

9) While stepping hard on the brake pedal, gradu-

ally step on the accelerator pedal.

10) When the engine speed is stabilized, quickly

record the engine speed and release accelerator

pedal.

11) Shift the select lever to “N” range, and cool

down the engine by idling it for more than one

minute.

12) Perform the procedure for “R” range in the

same way as “2nd on manual mode”.

NOTE:

•Do not continue the stall test for MORE THAN

FIVE SECONDS at a time (from fully closed throttle

to fully open throttle until stall speed reading). Do-

ing so will make the engine oil and ATF deteriorate

and the clutch and brake to be adversely affected.

•After performing the stall test, be sure to cool

down the engine for at least one minute with the se-

lect lever set in “P” or “N” range, and at an idle

speed of 1,200 rpm or less.

•If the stall speed is higher than the specified

range, attempt to finish the stall test in as short a

time as possible, in order to prevent the automatic

transmission from sustaining damage.

Stall speed (at sea level):

2,300 — 2,800 rpm

AT-03297

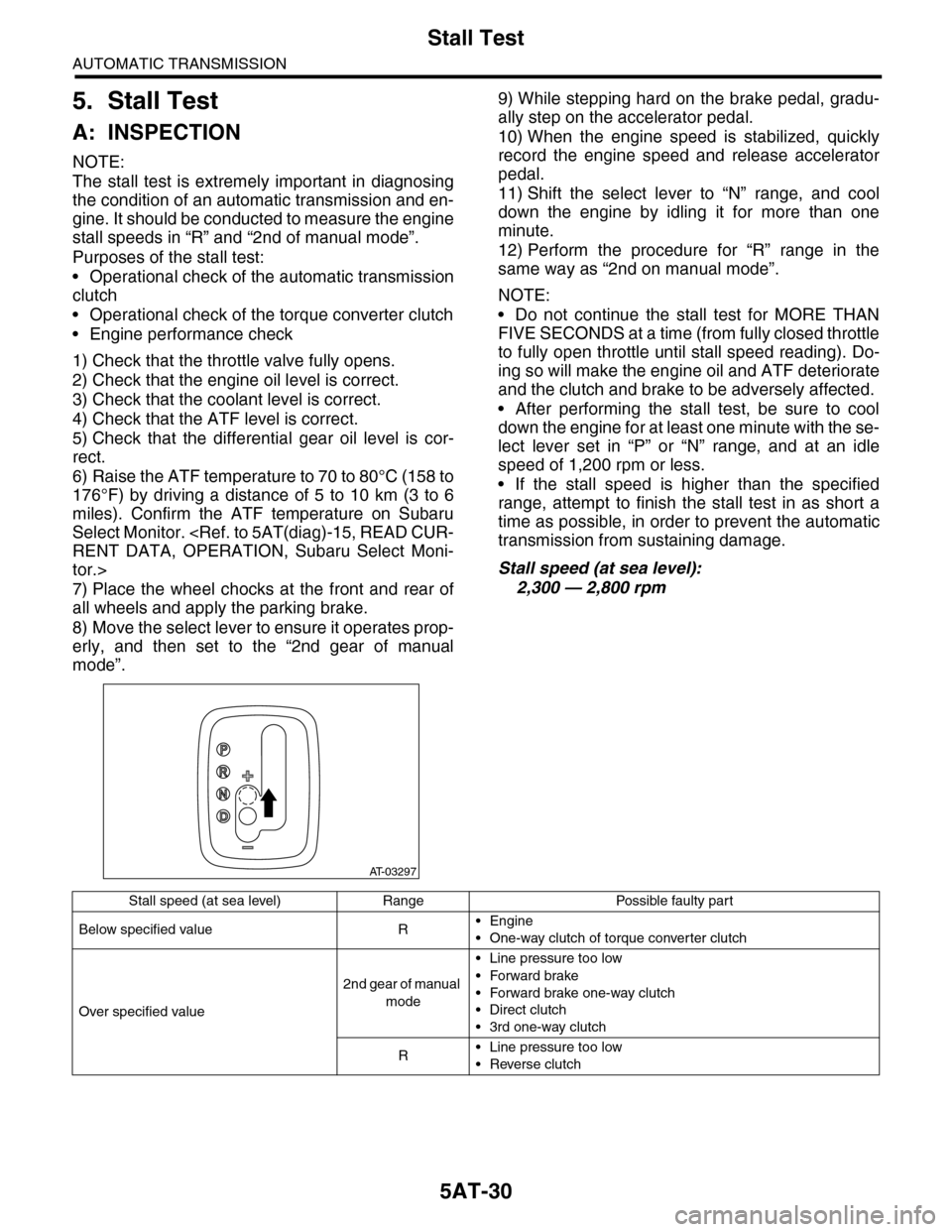

Stall speed (at sea level) Range Possible faulty part

Below specified value R•Engine

•One-way clutch of torque converter clutch

Over specified value

2nd gear of manual

mode

•Line pressure too low

•Forward brake

•Forward brake one-way clutch

•Direct clutch

•3rd one-way clutch

R•Line pressure too low

•Reverse clutch

Page 2317 of 2453

WI-33

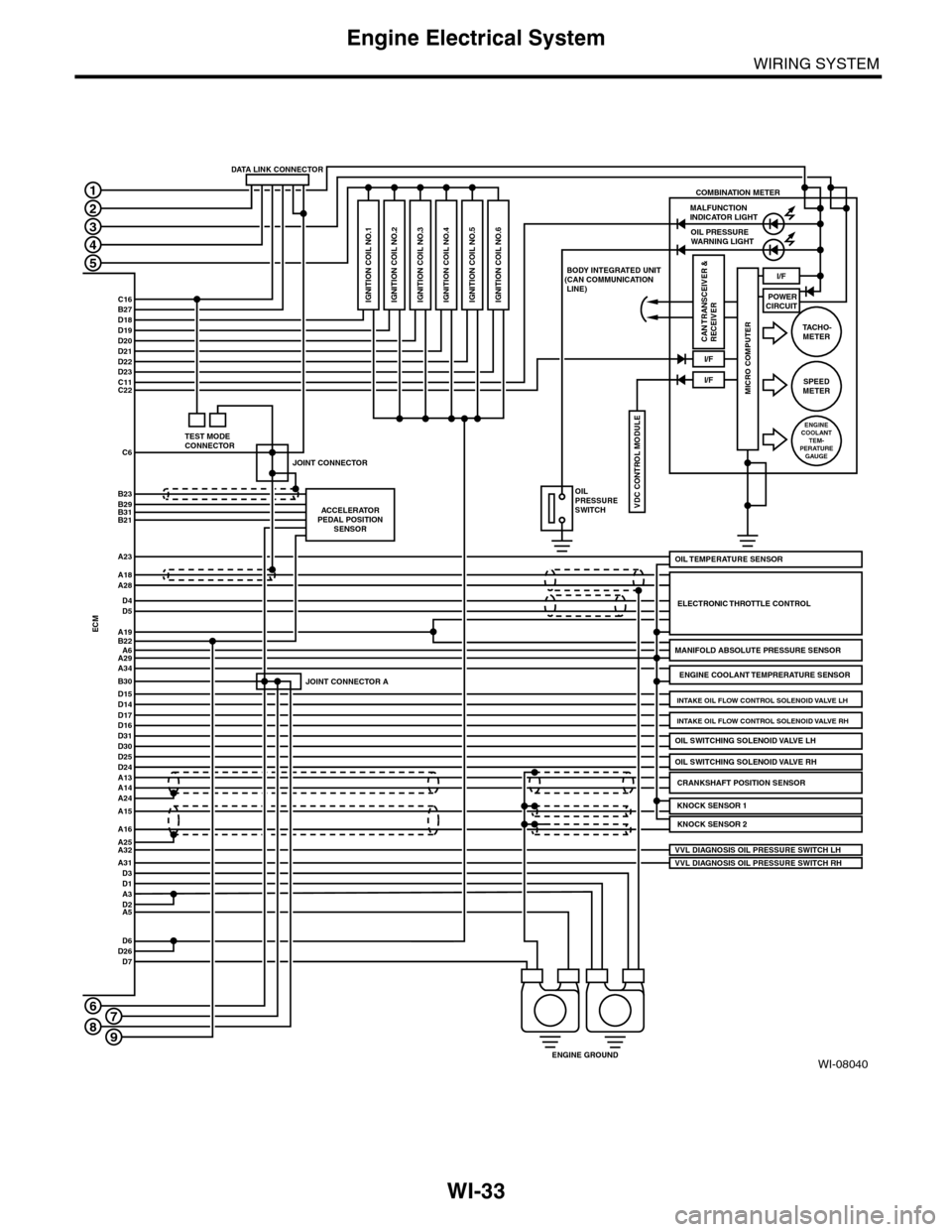

Engine Electrical System

WIRING SYSTEM

WI-08040

A3D2

D22D23

POWERCIRCUIT

COMBINATION METER

C16B27D18D19D20D21

C11C22

C6

B23B29B31B21

1

2

3

4

5

6

ACCELERATORPEDAL POSITIONSENSOR

JOINT CONNECTOR A

JOINT CONNECTOR

MALFUNCTION INDICATOR LIGHTOIL PRESSUREWARNING LIGHT

I/F

I/F

I/F

VDC CONTROL MODULE

IGNITION COIL NO.1

BODY INTEGRATED UNIT(CAN COMMUNICATION LINE)

OILPRESSURESWITCH

CRANKSHAFT POSITION SENSORA13A14

ENGINE GROUND

ECM

A18A28

D4D5

A19B22A6A29A34

D15B30

D14D17D16D31D30

ELECTRONIC THROTTLE CONTROL

A24

A25A16

A15

A32

D1

MANIFOLD ABSOLUTE PRESSURE SENSOR

ENGINE COOLANT TEMPRERATURE SENSOR

VVL DIAGNOSIS OIL PRESSURE SWITCH RH

D25D24

KNOCK SENSOR 2

D6D26D7

A5

MICRO COMPUTER

CAN TRANSCEIVER &RECEIVER

OIL SWITCHING SOLENOID VALVE RH

TA C H O -METER

SPEEDMETER

ENGINECOOLANTTEM-PERATUREGAUGE

DATA LINK CONNECTOR

TEST MODECONNECTOR

OIL TEMPERATURE SENSORA23

A31D3

VVL DIAGNOSIS OIL PRESSURE SWITCH LH

KNOCK SENSOR 1

OIL SWITCHING SOLENOID VALVE LH

INTAKE OIL FLOW CONTROL SOLENOID VALVE RH

INTAKE OIL FLOW CONTROL SOLENOID VALVE LH

IGNITION COIL NO.2 IGNITION COIL NO.3 IGNITION COIL NO.4 IGNITION COIL NO.5 IGNITION COIL NO.6

789

Page 2320 of 2453

WI-36

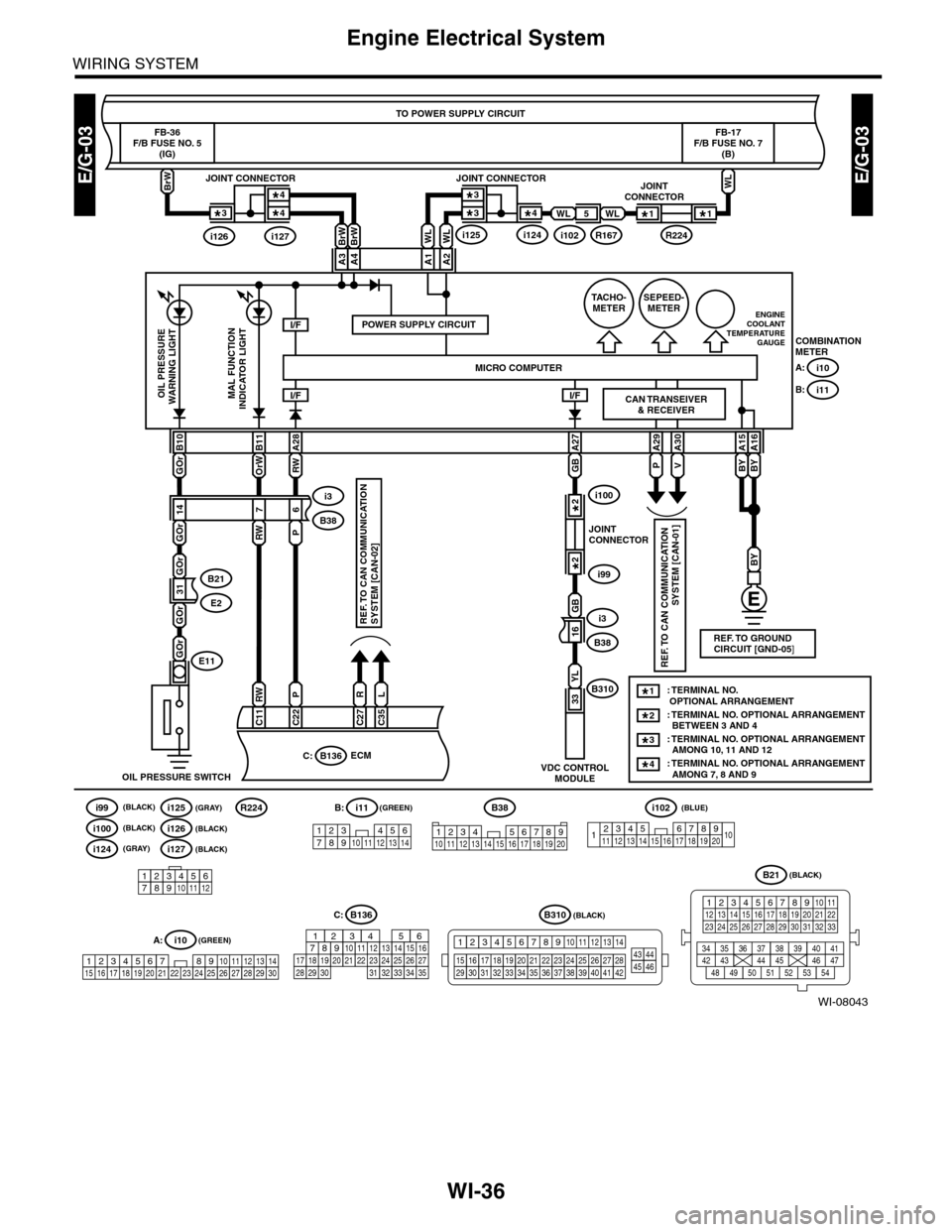

Engine Electrical System

WIRING SYSTEM

WI-08043

E/G-03E/G-03

TO POWER SUPPLY CIRCUIT

FB-36F/B FUSE NO. 5(IG)

BrW

COMBINATIONMETER

i10A:

i11B:

BrWBrW

GOr

B10

OrW B11RW

A28

GB

GB A27

P

A29

V

A30

BY

A15

BY

A16

I/F

GOr

GOr

GOr

14

RWP

76

16

FB-17F/B FUSE NO. 7(B)

A2A1

B38

i3

B38

i3

POWER SUPPLY CIRCUITI/F

B21

E231

A3A4

ECM

OIL PRESSURE SWITCH

RW

C11

P

C22

R

C27

L

C35

C:B136

OIL PRESSUREWARNING LIGHTMAL FUNCTIONINDICATOR LIGHTI/F

MICRO COMPUTER

SEPEED-METERENGINECOOLANTTEMPERATUREGAUGE

TACHO-METER

B310YL

33

VDC CONTROLMODULE

BY

CAN TRANSEIVER& RECEIVER

E11GOr

B38

12345678910 11 12 13 14 15 16 17 18 19 20

B21

12345678910 1112 13 14 15 16 17 18 19 20 21 2223 24 25 26 27 28 29 30 31 32 33

34 3542 4336 3738 39

48 4950 5152 5354

40 41444546 47

REF. TO CAN COMMUNICATION

SYSTEM [CAN-01]

REF. TO CAN COMMUNICATION SYSTEM [CAN-02]

REF. TO GROUND CIRCUIT [GND-05]

JOINTCONNECTOR

i99

i1002*

2*

: TERMINAL NO. OPTIONAL ARRANGEMENT: TERMINAL NO. OPTIONAL ARRANGEMENT BETWEEN 3 AND 4

1*

2*

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 10, 11 AND 123*

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 7, 8 AND 94*

WL

WLWL

WLWL5

i102R167

JOINTCONNECTOR

R224

1*1*

JOINT CONNECTOR

i125i124

3*3*4*

JOINT CONNECTOR

i127i126

4*4*3*

1234567891413121110151617181920

i102(BLUE)(GREEN)

(GREEN)

(BLACK)

(BLACK)

i11

123 45678910 11 12 13 14

B:

i10

19 20 2115 16 17 182223242526272829301234568910 11 12 13 147

A:

C: B136

16101112131415252430

9871718192028212223293231

123456

2726333435

B310

1234

1516171819202122232425262728293031323334353637383940414245464344568910 11 12 13 147

123456789101112

i126(BLACK)

i124(GRAY)

i100(BLACK)

R224

i127(BLACK)

i99(BLACK)i125(GRAY)

Page 2326 of 2453

WI-42

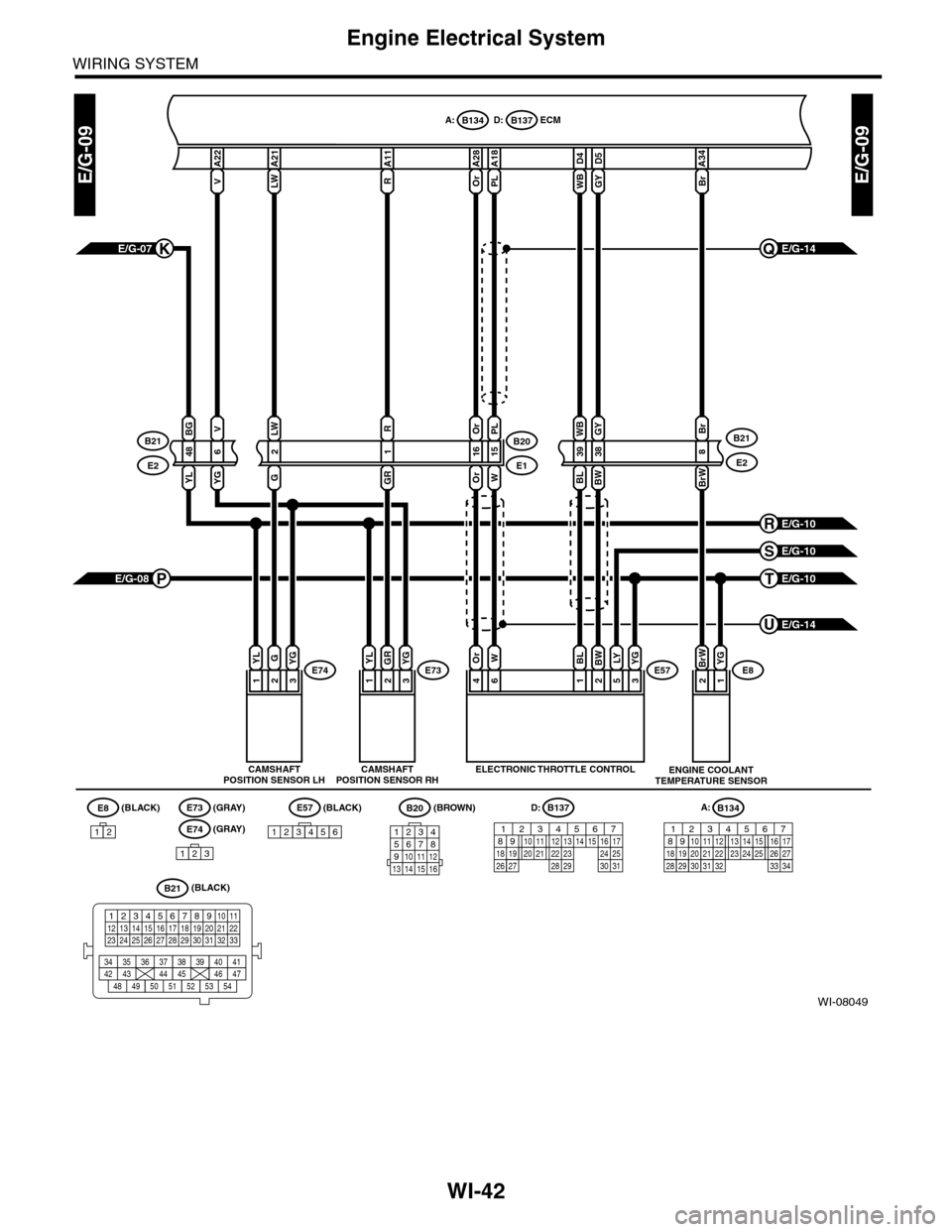

Engine Electrical System

WIRING SYSTEM

WI-08049

E/G-09E/G-09

D:B137

A21

LW

A22

V

A28

Or

D5

GY

A18

PL

LWPL

13E73

B20

E1

43E57

215

Or

16

A11

R

R

1

YLGROr

6

W

1

BL

2

BW

5

LYE74

A:B134ECM

CAMSHAFTPOSITION SENSOR LHELECTRONIC THROTTLE CONTROL

(GRAY)(BLACK) (BROWN)

E/G-14Q

38398

GYWBBr

E2

B21

D4

WB

13

YLG

(BLACK)

(BLACK)

E8

12

E73E57

123456

B20

1234567891011 121413 15 16

B21

12345678910 1112 13 14 15 16 17 18 19 20 21 2223 24 25 26 27 28 29 30 31 32 33

34 3542 4336 3738 39

48 4950 5152 5354

40 41444546 47

Br

A34

E/G-07K

D: B137

85610 11 12 13 14 157213416

3019 20 2228 29

91718 2521 23 243126 27

E/G-10R

E/G-10S

WOrGRBWBLBrW

YG

2

YG

2

YG

E/G-14U

21E8BrW

ENGINE COOLANTTEMPERATURE SENSOR

YG

G

E/G-10TE/G-08P

E2

B21BG

486

YLYG

V

CAMSHAFTPOSITION SENSOR RH

E74

123

(GRAY)

A:B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 2417 of 2453

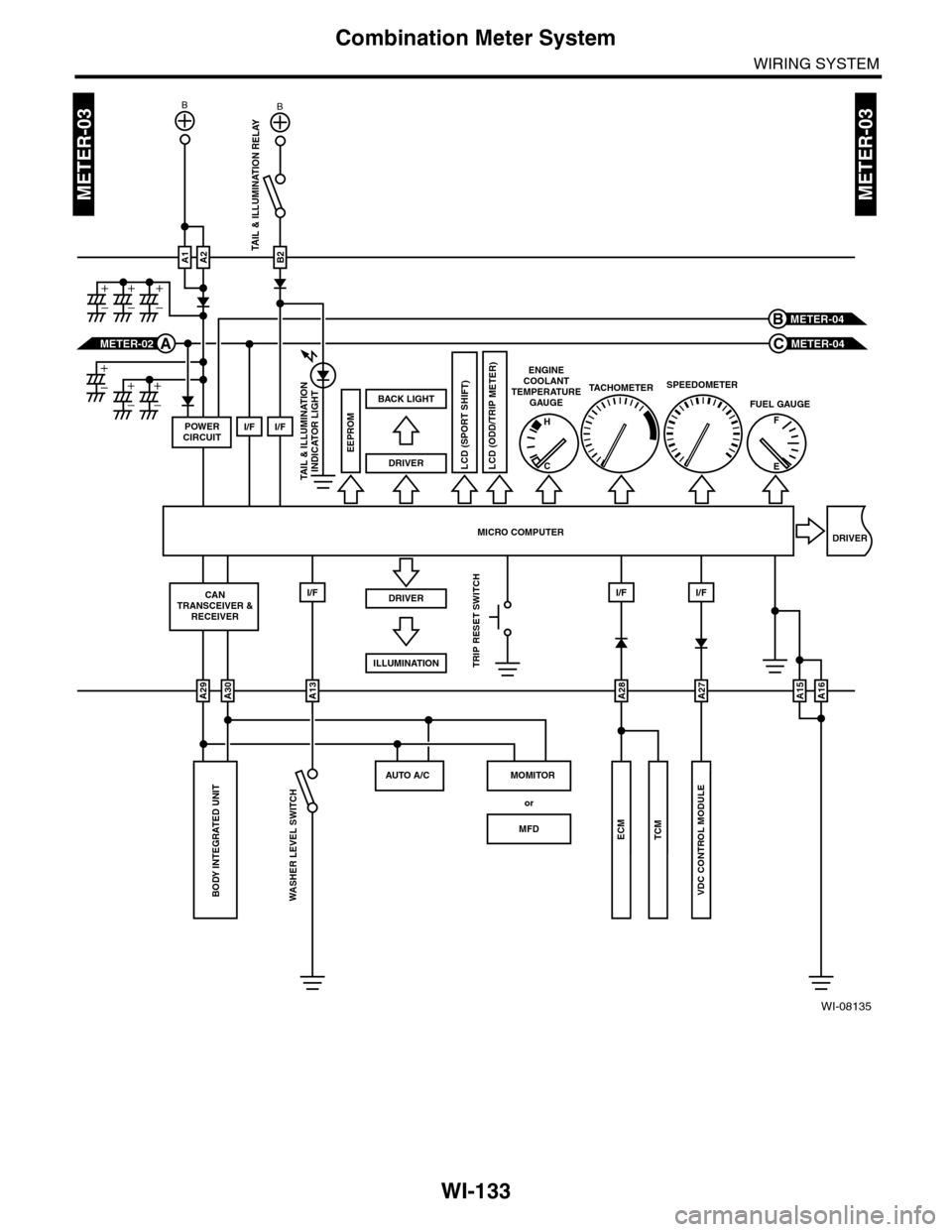

WI-133

Combination Meter System

WIRING SYSTEM

METER-03METER-03

WI-08135

I/F

MFD

or

I/FI/F

VDC CONTROL MODULE

ECMTCM

LCD (SPORT SHIFT)

EEPROM

SPEEDOMETERTAC H O M E T E R

FUEL GAUGE

F

E

B

A27A28

TAIL & ILLUMINATION RELAY

B

ENGINECOOLANTTEMPERATUREGAUGE

H

C

A1A2B2

POWERCIRCUIT

BACK LIGHT

ILLUMINATION

AUTO A/CMOMITOR

DRIVER

DRIVER

DRIVER

I/FI/F

TAIL & ILLUMINATIONINDICATOR LIGHT

METER-02A

MICRO COMPUTER

CANTRANSCEIVER &RECEIVER

A29A30A15A16

TRIP RESET SWITCH

METER-04B

METER-04C

BODY INTEGRATED UNIT

LCD (ODD/TRIP METER)

WASHER LEVEL SW

ITCH

A13

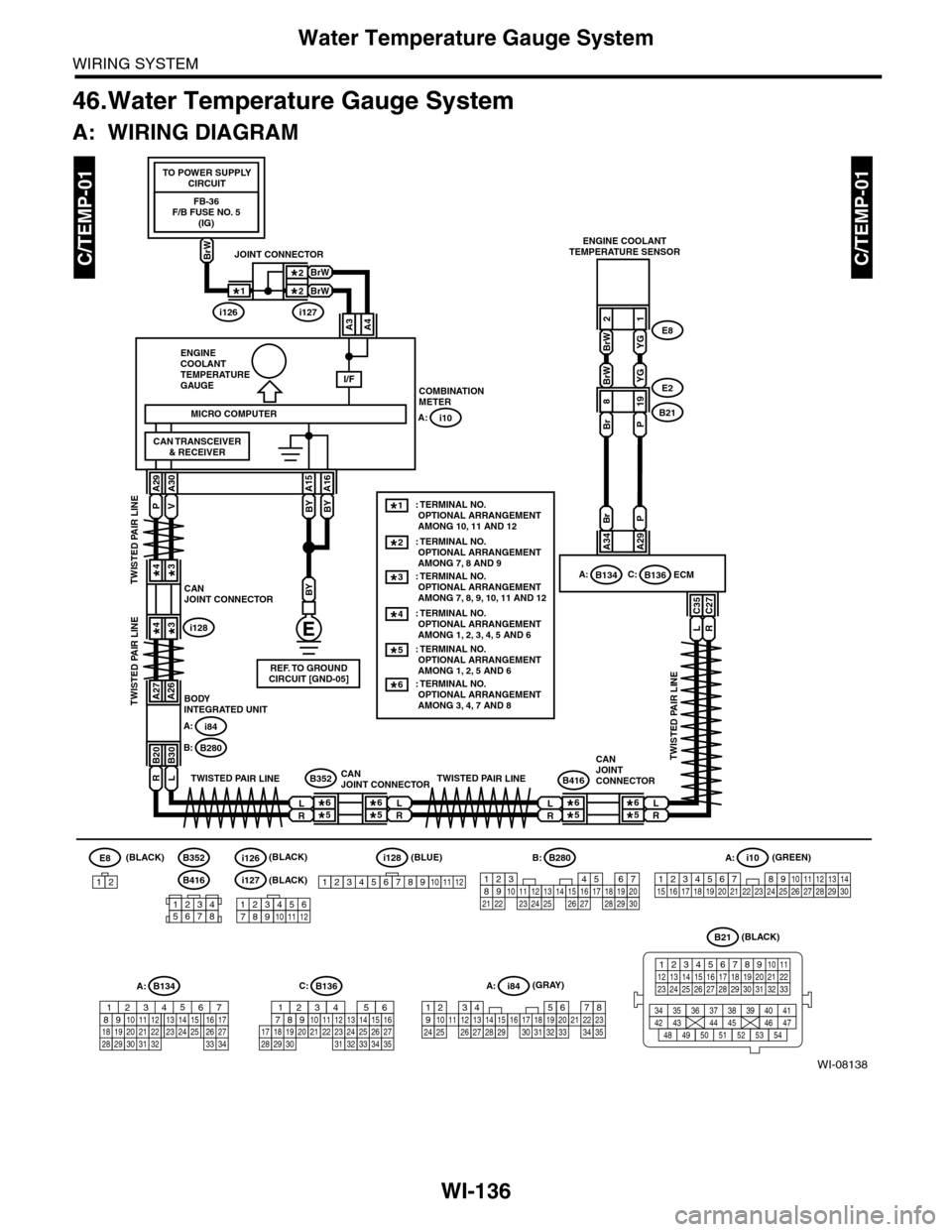

Page 2420 of 2453

WI-136

Water Temperature Gauge System

WIRING SYSTEM

46.Water Temperature Gauge System

A: WIRING DIAGRAM

C/TEMP-01C/TEMP-01

WI-08138

B136

16101112131415252430

9871718192028212223293231

123456

2726333435

C:B136A:B134ECM

TO POWER SUPPLYCIRCUIT

FB-36F/B FUSE NO. 5(IG)

BrPB21

E2819

Br

B:

(BLACK)

E8

12

123456789101112

5467821931022 23111213141524 25 26 2716171828 29192021 30

B280

COMBINATIONMETERA: i10

I/F

CAN TRANSCEIVER& RECEIVER

MICRO COMPUTER

PVBY

A15

BY

R

B20

L

B30

A27A26

BY

ENGINE COOLANTTEMPERATURE SENSOR

YGE81

BrW

YGBrW

2

P

RL

A34A29

C35C27

TWISTED PAIR LINE

TWISTED PAIR LINETWISTED PAIR LINE

TWISTED PAIR LINE

TWISTED PAIR LINE

C:

1234567891011121415161718192021222324252627282930313233343513

i84A:

B21

12345678910 1112 13 14 15 16 17 18 19 20 21 2223 24 25 26 27 28 29 30 31 32 33

34 3542 4336 3738 39

48 4950 5152 5354

40 41444546 47

(BLACK)

i127(BLACK)

i126(BLACK)(BLUE)(GREEN)

(GRAY)

A29A30A16

BODYINTEGRATED UNIT

i84

B280

A:

B:

REF. TO GROUNDCIRCUIT [GND-05]

CANJOINT CONNECTORB352

RLRL6*5*

6*5*

B416

B352

34561278

CANJOINT CONNECTOR

i128

4*

4*

3*

3*

CANJOINTCONNECTORB416

LL6*6*RR5*5*

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 10, 11 AND 12: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 7, 8 AND 9

1*

2*

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 7, 8, 9, 10, 11 AND 12

3*

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 1, 2, 3, 4, 5 AND 6

4*

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 1, 2, 5 AND 6

5*

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 3, 4, 7 AND 8

6*

i10

19 20 2115 16 17 182223242526272829301234568910 11 12 13 147

A:

A:B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

i128

123456789101112

BrW

A3A4

BrW

BrW

JOINT CONNECTOR

i126i127

1*

2*2*

ENGINECOOLANTTEMPERATUREGAUGE

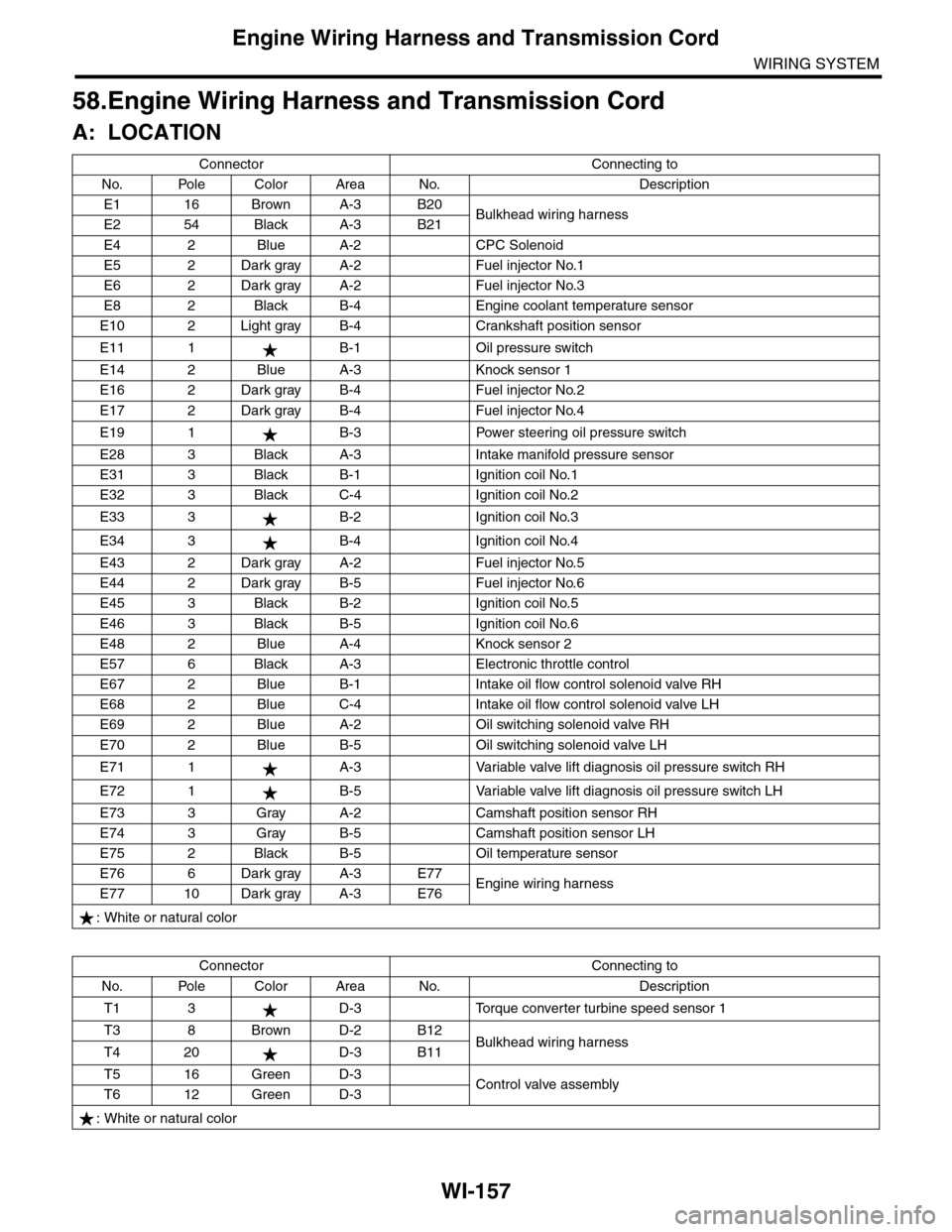

Page 2441 of 2453

WI-157

Engine Wiring Harness and Transmission Cord

WIRING SYSTEM

58.Engine Wiring Harness and Transmission Cord

A: LOCATION

Connector Connecting to

No. Pole Color Area No. Description

E1 16 Brown A-3 B20Bulkhead wiring harnessE2 54 Black A-3 B21

E4 2 Blue A-2 CPC Solenoid

E5 2 Dark gray A-2 Fuel injector No.1

E6 2 Dark gray A-2 Fuel injector No.3

E8 2 Black B-4 Engine coolant temperature sensor

E10 2 Light gray B-4 Crankshaft position sensor

E11 1 B-1 Oil pressure switch

E14 2 Blue A-3 Knock sensor 1

E16 2 Dark gray B-4 Fuel injector No.2

E17 2 Dark gray B-4 Fuel injector No.4

E19 1 B-3 Power steering oil pressure switch

E28 3 Black A-3 Intake manifold pressure sensor

E31 3 Black B-1 Ignition coil No.1

E32 3 Black C-4 Ignition coil No.2

E33 3 B-2 Ignition coil No.3

E34 3 B-4 Ignition coil No.4

E43 2 Dark gray A-2 Fuel injector No.5

E44 2 Dark gray B-5 Fuel injector No.6

E45 3 Black B-2 Ignition coil No.5

E46 3 Black B-5 Ignition coil No.6

E48 2 Blue A-4 Knock sensor 2

E57 6 Black A-3 Electronic throttle control

E67 2 Blue B-1 Intake oil flow control solenoid valve RH

E68 2 Blue C-4 Intake oil flow control solenoid valve LH

E69 2 Blue A-2 Oil switching solenoid valve RH

E70 2 Blue B-5 Oil switching solenoid valve LH

E71 1 A-3 Variable valve lift diagnosis oil pressure switch RH

E72 1 B-5 Variable valve lift diagnosis oil pressure switch LH

E73 3 Gray A-2 Camshaft position sensor RH

E74 3 Gray B-5 Camshaft position sensor LH

E75 2 Black B-5 Oil temperature sensor

E76 6 Dark gray A-3 E77Engine wiring harnessE77 10 Dark gray A-3 E76

: White or natural color

Connector Connecting to

No. Pole Color Area No. Description

T1 3 D-3 Torque converter turbine speed sensor 1

T3 8 Brown D-2 B12Bulkhead wiring harnessT4 20 D-3 B11

T5 16 Green D-3Control valve assemblyT6 12 Green D-3

: White or natural color