harness SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 429 of 2453

IM (diag)-13

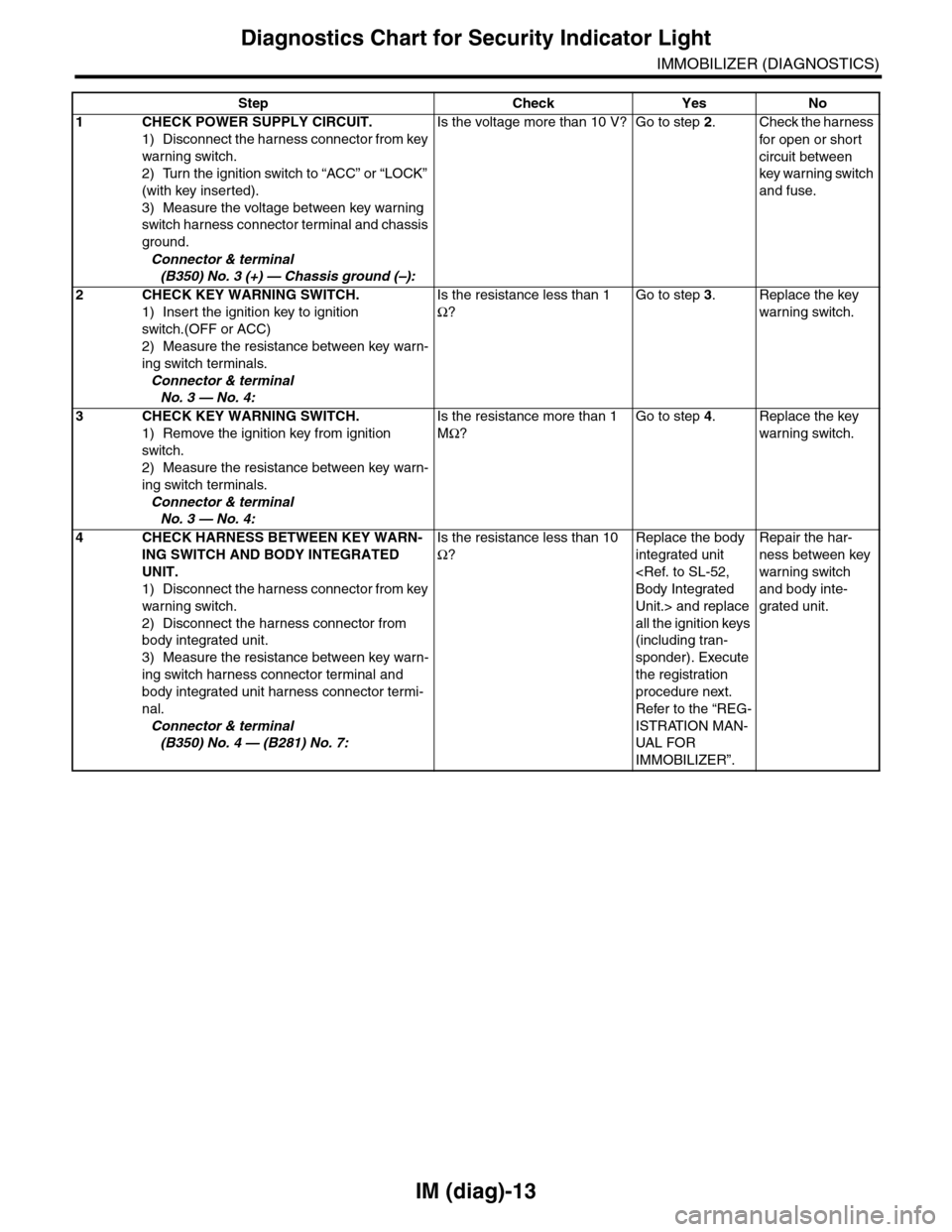

Diagnostics Chart for Security Indicator Light

IMMOBILIZER (DIAGNOSTICS)

Step Check Yes No

1CHECK POWER SUPPLY CIRCUIT.

1) Disconnect the harness connector from key

warning switch.

2) Turn the ignition switch to “ACC” or “LOCK”

(with key inserted).

3) Measure the voltage between key warning

switch harness connector terminal and chassis

ground.

Connector & terminal

(B350) No. 3 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Check the harness

for open or shor t

circuit between

key warning switch

and fuse.

2 CHECK KEY WARNING SWITCH.

1) Insert the ignition key to ignition

switch.(OFF or ACC)

2) Measure the resistance between key warn-

ing switch terminals.

Connector & terminal

No. 3 — No. 4:

Is the resistance less than 1

Ω?

Go to step 3.Replace the key

warning switch.

3 CHECK KEY WARNING SWITCH.

1) Remove the ignition key from ignition

switch.

2) Measure the resistance between key warn-

ing switch terminals.

Connector & terminal

No. 3 — No. 4:

Is the resistance more than 1

MΩ?

Go to step 4.Replace the key

warning switch.

4CHECK HARNESS BETWEEN KEY WARN-

ING SWITCH AND BODY INTEGRATED

UNIT.

1) Disconnect the harness connector from key

warning switch.

2) Disconnect the harness connector from

body integrated unit.

3) Measure the resistance between key warn-

ing switch harness connector terminal and

body integrated unit harness connector termi-

nal.

Connector & terminal

(B350) No. 4 — (B281) No. 7:

Is the resistance less than 10

Ω?

Replace the body

integrated unit

Unit.> and replace

all the ignition keys

(including tran-

sponder). Execute

the registration

procedure next.

Refer to the “REG-

ISTRATION MAN-

UAL FO R

IMMOBILIZER”.

Repair the har-

ness between key

warning switch

and body inte-

grated unit.

Page 434 of 2453

IM (diag)-18

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

IMMOBILIZER (DIAGNOSTICS)

Step Check Yes No

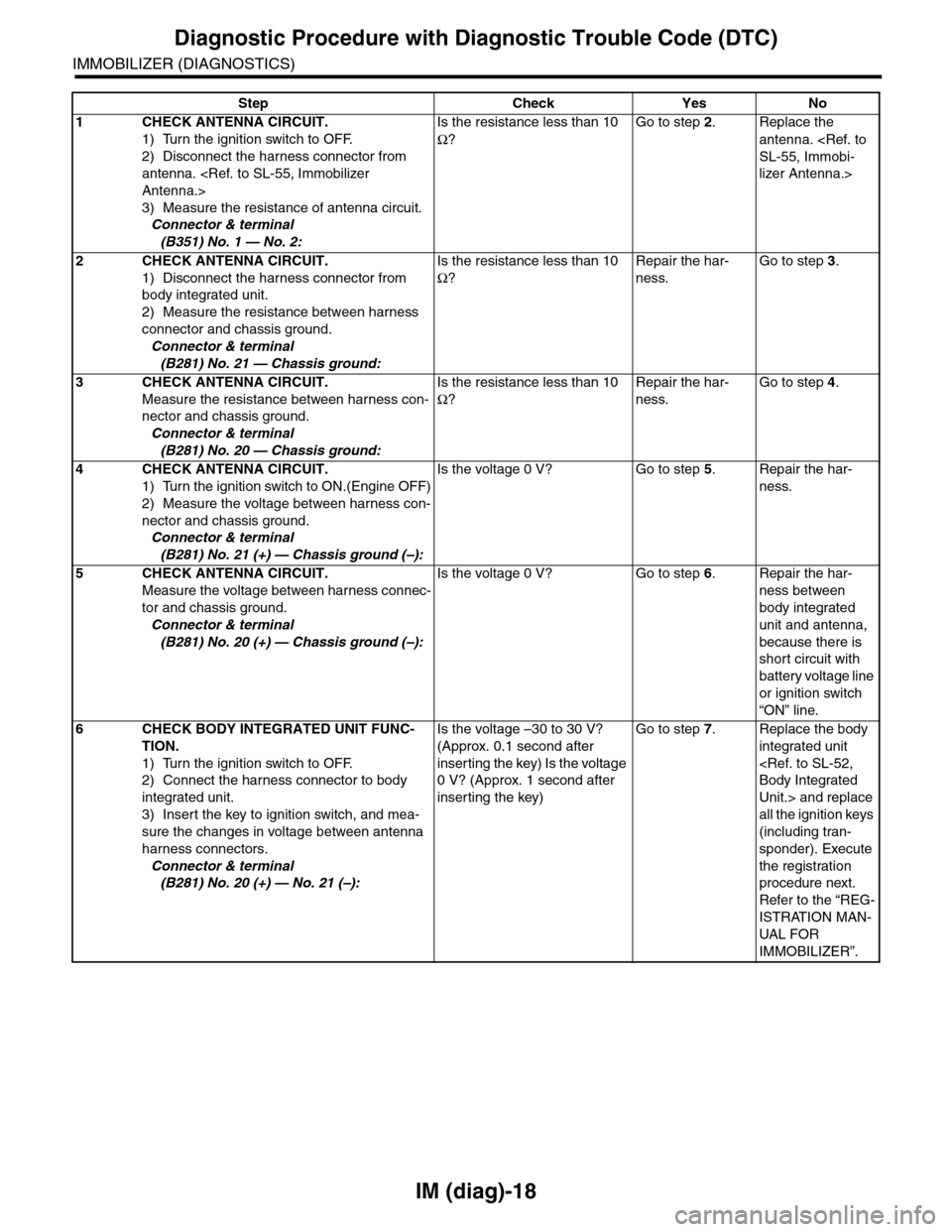

1CHECK ANTENNA CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector from

antenna.

3) Measure the resistance of antenna circuit.

Connector & terminal

(B351) No. 1 — No. 2:

Is the resistance less than 10

Ω?

Go to step 2.Replace the

antenna.

lizer Antenna.>

2CHECK ANTENNA CIRCUIT.

1) Disconnect the harness connector from

body integrated unit.

2) Measure the resistance between harness

connector and chassis ground.

Connector & terminal

(B281) No. 21 — Chassis ground:

Is the resistance less than 10

Ω?

Repair the har-

ness.

Go to step 3.

3CHECK ANTENNA CIRCUIT.

Measure the resistance between harness con-

nector and chassis ground.

Connector & terminal

(B281) No. 20 — Chassis ground:

Is the resistance less than 10

Ω?

Repair the har-

ness.

Go to step 4.

4CHECK ANTENNA CIRCUIT.

1) Turn the ignition switch to ON.(Engine OFF)

2) Measure the voltage between harness con-

nector and chassis ground.

Connector & terminal

(B281) No. 21 (+) — Chassis ground (–):

Is the voltage 0 V? Go to step 5.Repair the har-

ness.

5CHECK ANTENNA CIRCUIT.

Measure the voltage between harness connec-

tor and chassis ground.

Connector & terminal

(B281) No. 20 (+) — Chassis ground (–):

Is the voltage 0 V? Go to step 6.Repair the har-

ness between

body integrated

unit and antenna,

because there is

short circuit with

battery voltage line

or ignition switch

“ON” line.

6CHECK BODY INTEGRATED UNIT FUNC-

TION.

1) Turn the ignition switch to OFF.

2) Connect the harness connector to body

integrated unit.

3) Insert the key to ignition switch, and mea-

sure the changes in voltage between antenna

harness connectors.

Connector & terminal

(B281) No. 20 (+) — No. 21 (–):

Is the voltage –30 to 30 V?

(Approx. 0.1 second after

inserting the key) Is the voltage

0 V? (Approx. 1 second after

inserting the key)

Go to step 7.Replace the body

integrated unit

Unit.> and replace

all the ignition keys

(including tran-

sponder). Execute

the registration

procedure next.

Refer to the “REG-

ISTRATION MAN-

UAL FOR

IMMOBILIZER”.

Page 436 of 2453

IM (diag)-20

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

IMMOBILIZER (DIAGNOSTICS)

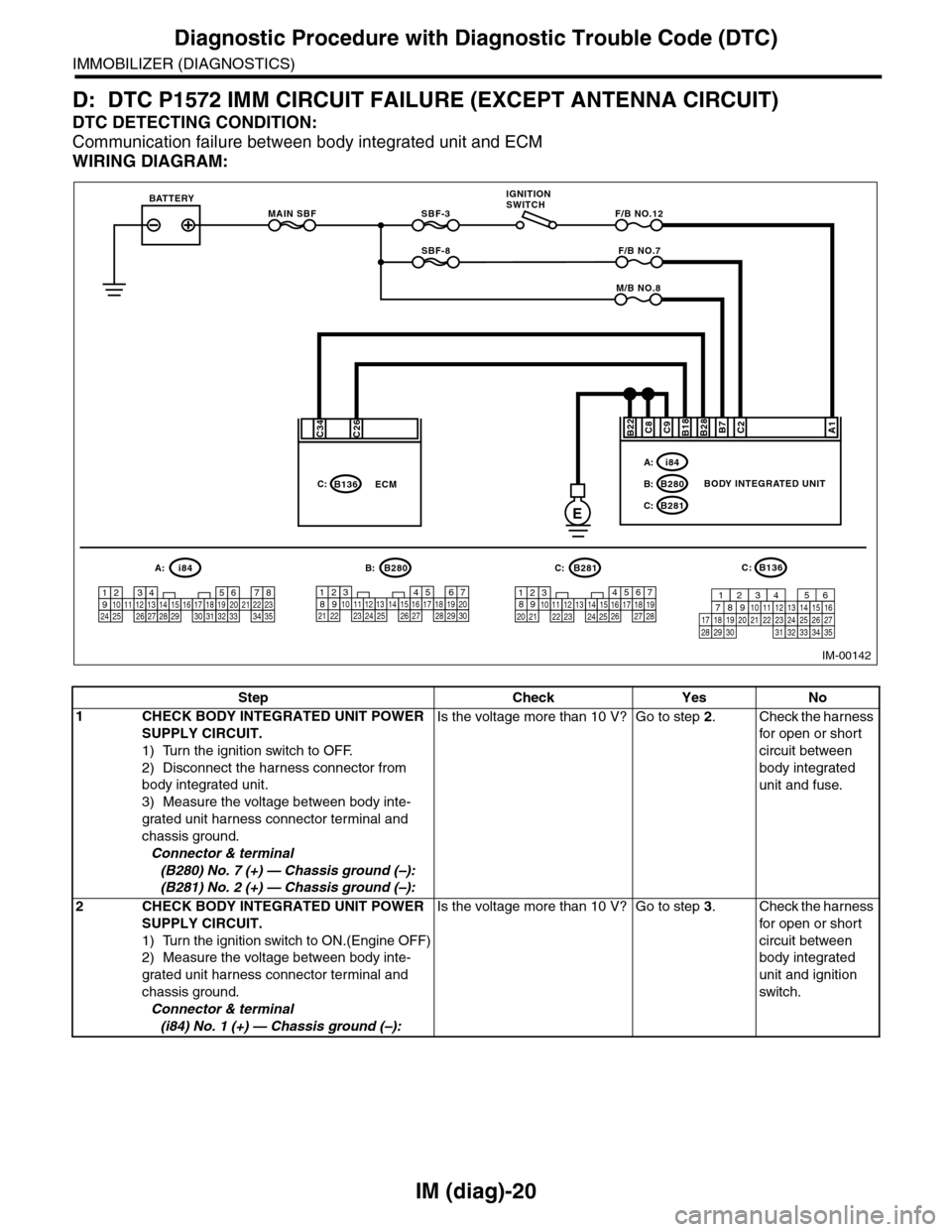

D: DTC P1572 IMM CIRCUIT FAILURE (EXCEPT ANTENNA CIRCUIT)

DTC DETECTING CONDITION:

Communication failure between body integrated unit and ECM

WIRING DIAGRAM:

MAIN SBF

SBF-8

SBF-3BATTERYF/B NO.12

IGNITIONSWITCH

A1B28B18C9C2B7C8

E

F/B NO.7

M/B NO.8

BODY INTEGRATED UNIT

i84A:

B280B:

B281C:

B22

567821943102422 23 25111213141526 27281617181920 21

B281i84

1234567891011121314151617181920212223242526272829303132333435

5467821931022 231112131415242526 2716171828 29192021 30

B280A:C:B:B136C:

C26C34

B136C:ECM

IM-00142

16101112131415252430

9871718192028212223293231

123456

2726333435

Step Check Yes No

1CHECK BODY INTEGRATED UNIT POWER

SUPPLY CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector from

body integrated unit.

3) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 7 (+) — Chassis ground (–):

(B281) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Check the harness

for open or shor t

circuit between

body integrated

unit and fuse.

2CHECK BODY INTEGRATED UNIT POWER

SUPPLY CIRCUIT.

1) Turn the ignition switch to ON.(Engine OFF)

2) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(i84) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Check the harness

for open or shor t

circuit between

body integrated

unit and ignition

switch.

Page 437 of 2453

IM (diag)-21

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

IMMOBILIZER (DIAGNOSTICS)

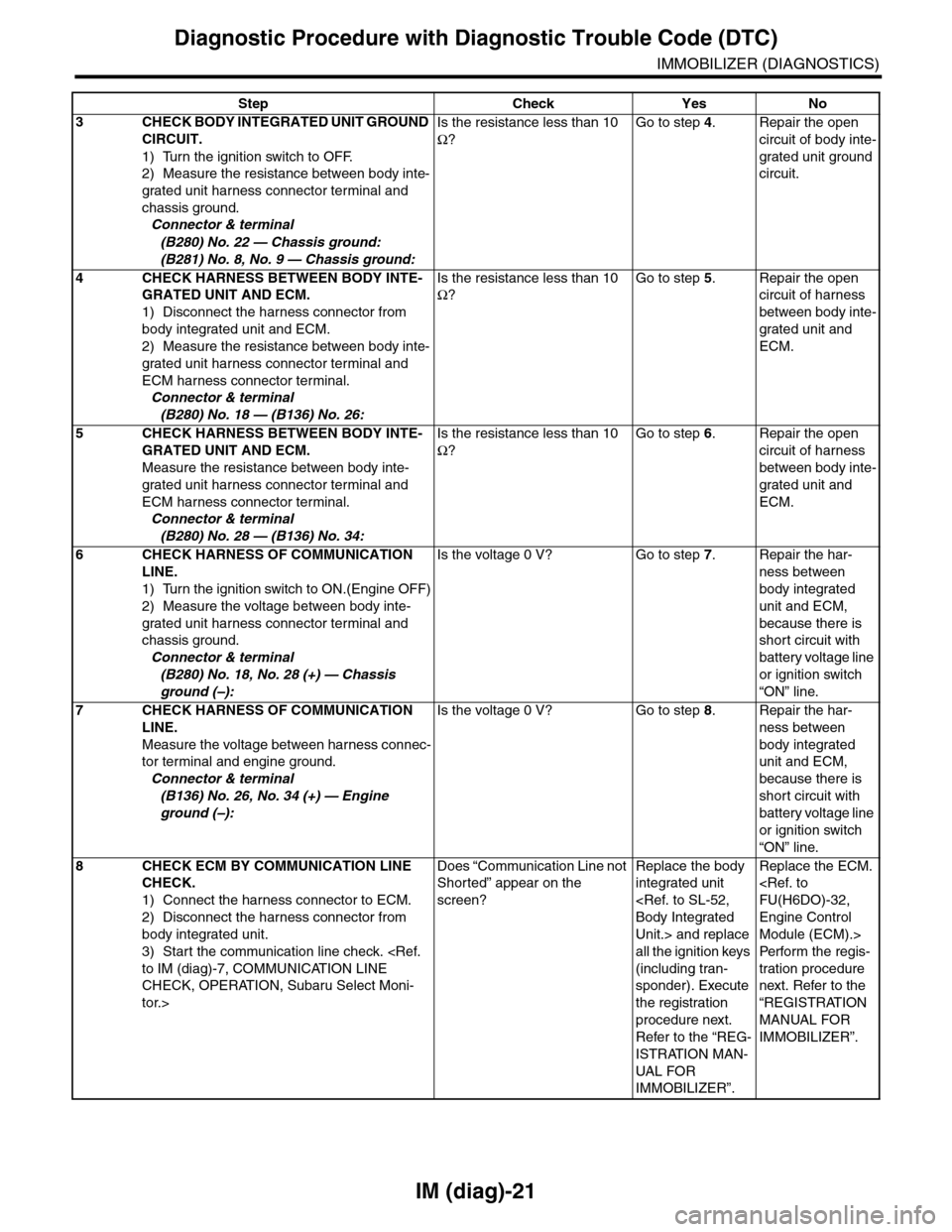

3CHECK BODY INTEGRATED UNIT GROUND

CIRCUIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 22 — Chassis ground:

(B281) No. 8, No. 9 — Chassis ground:

Is the resistance less than 10

Ω?

Go to step 4.Repair the open

circuit of body inte-

grated unit ground

circuit.

4CHECK HARNESS BETWEEN BODY INTE-

GRATED UNIT AND ECM.

1) Disconnect the harness connector from

body integrated unit and ECM.

2) Measure the resistance between body inte-

grated unit harness connector terminal and

ECM harness connector terminal.

Connector & terminal

(B280) No. 18 — (B136) No. 26:

Is the resistance less than 10

Ω?

Go to step 5.Repair the open

circuit of harness

between body inte-

grated unit and

ECM.

5CHECK HARNESS BETWEEN BODY INTE-

GRATED UNIT AND ECM.

Measure the resistance between body inte-

grated unit harness connector terminal and

ECM harness connector terminal.

Connector & terminal

(B280) No. 28 — (B136) No. 34:

Is the resistance less than 10

Ω?

Go to step 6.Repair the open

circuit of harness

between body inte-

grated unit and

ECM.

6CHECK HARNESS OF COMMUNICATION

LINE.

1) Turn the ignition switch to ON.(Engine OFF)

2) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 18, No. 28 (+) — Chassis

ground (–):

Is the voltage 0 V? Go to step 7.Repair the har-

ness between

body integrated

unit and ECM,

because there is

short circuit with

battery voltage line

or ignition switch

“ON” line.

7CHECK HARNESS OF COMMUNICATION

LINE.

Measure the voltage between harness connec-

tor terminal and engine ground.

Connector & terminal

(B136) No. 26, No. 34 (+) — Engine

ground (–):

Is the voltage 0 V? Go to step 8.Repair the har-

ness between

body integrated

unit and ECM,

because there is

short circuit with

battery voltage line

or ignition switch

“ON” line.

8CHECK ECM BY COMMUNICATION LINE

CHECK.

1) Connect the harness connector to ECM.

2) Disconnect the harness connector from

body integrated unit.

3) Start the communication line check.

CHECK, OPERATION, Subaru Select Moni-

tor.>

Does “Communication Line not

Shorted” appear on the

screen?

Replace the body

integrated unit

Unit.> and replace

all the ignition keys

(including tran-

sponder). Execute

the registration

procedure next.

Refer to the “REG-

ISTRATION MAN-

UAL FO R

IMMOBILIZER”.

Replace the ECM.

Engine Control

Module (ECM).>

Per fo r m th e re g is -

tration procedure

next. Refer to the

“REGISTRATION

MANUAL FOR

IMMOBILIZER”.

Step Check Yes No

Page 446 of 2453

IDI-7

Combination Meter System

INSTRUMENTATION/DRIVER INFO

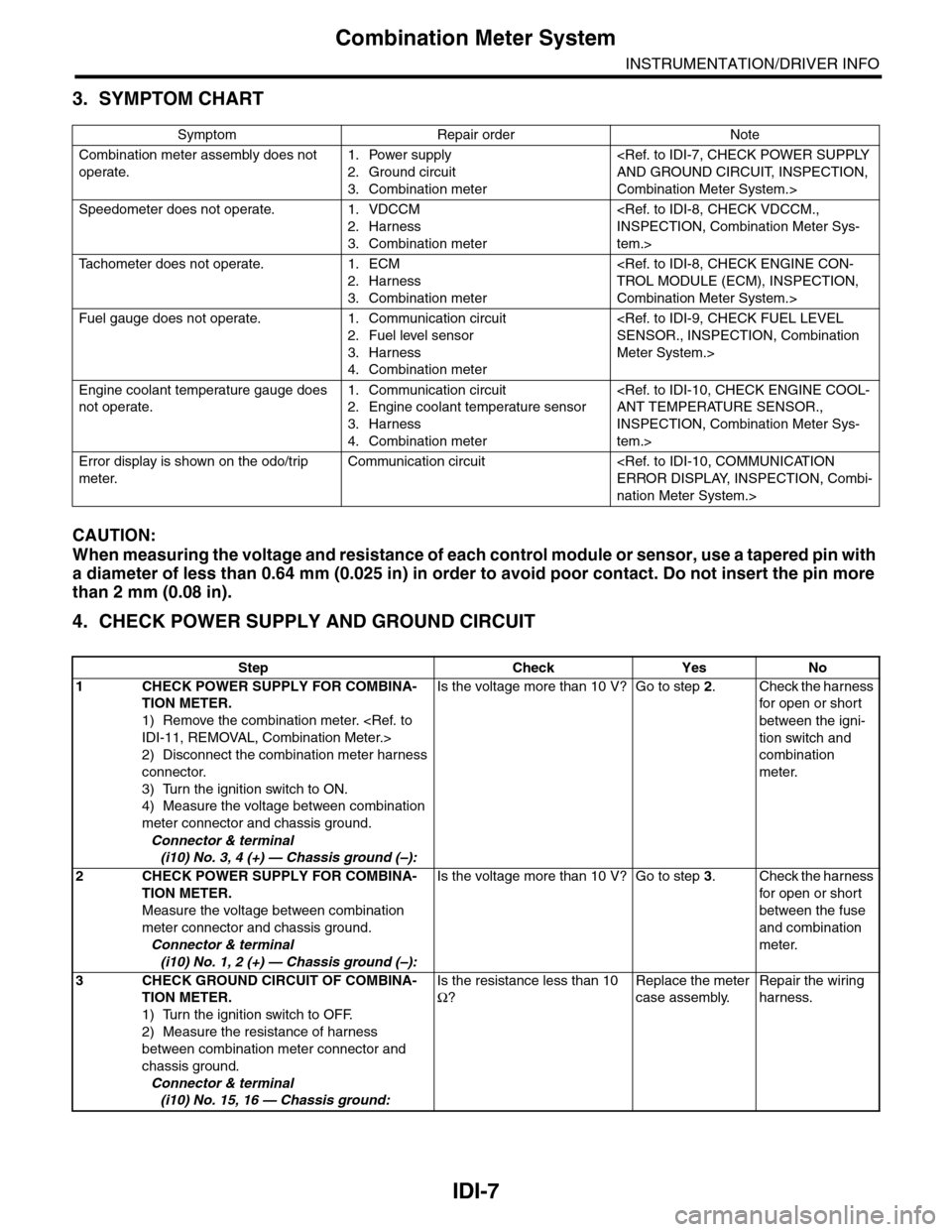

3. SYMPTOM CHART

CAUTION:

When measuring the voltage and resistance of each control module or sensor, use a tapered pin with

a diameter of less than 0.64 mm (0.025 in) in order to avoid poor contact. Do not insert the pin more

than 2 mm (0.08 in).

4. CHECK POWER SUPPLY AND GROUND CIRCUIT

Symptom Repair order Note

Combination meter assembly does not

operate.

1. Power supply

2. Ground circuit

3. Combination meter

Combination Meter System.>

Speedometer does not operate. 1. VDCCM

2. Harness

3. Combination meter

tem.>

Ta c h o m e t e r d o e s n o t o p e r a t e . 1 . E C M

2. Harness

3. Combination meter

Combination Meter System.>

Fuel gauge does not operate. 1. Communication circuit

2. Fuel level sensor

3. Harness

4. Combination meter

Meter System.>

Engine coolant temperature gauge does

not operate.

1. Communication circuit

2. Engine coolant temperature sensor

3. Harness

4. Combination meter

INSPECTION, Combination Meter Sys-

tem.>

Error display is shown on the odo/trip

meter.

Communication circuit

nation Meter System.>

Step Check Yes No

1CHECK POWER SUPPLY FOR COMBINA-

TION METER.

1) Remove the combination meter.

2) Disconnect the combination meter harness

connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 3, 4 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Check the harness

for open or shor t

between the igni-

tion switch and

combination

meter.

2CHECK POWER SUPPLY FOR COMBINA-

TION METER.

Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 1, 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Check the harness

for open or shor t

between the fuse

and combination

meter.

3CHECK GROUND CIRCUIT OF COMBINA-

TION METER.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between combination meter connector and

chassis ground.

Connector & terminal

(i10) No. 15, 16 — Chassis ground:

Is the resistance less than 10

Ω?

Replace the meter

case assembly.

Repair the wiring

harness.

Page 447 of 2453

IDI-8

Combination Meter System

INSTRUMENTATION/DRIVER INFO

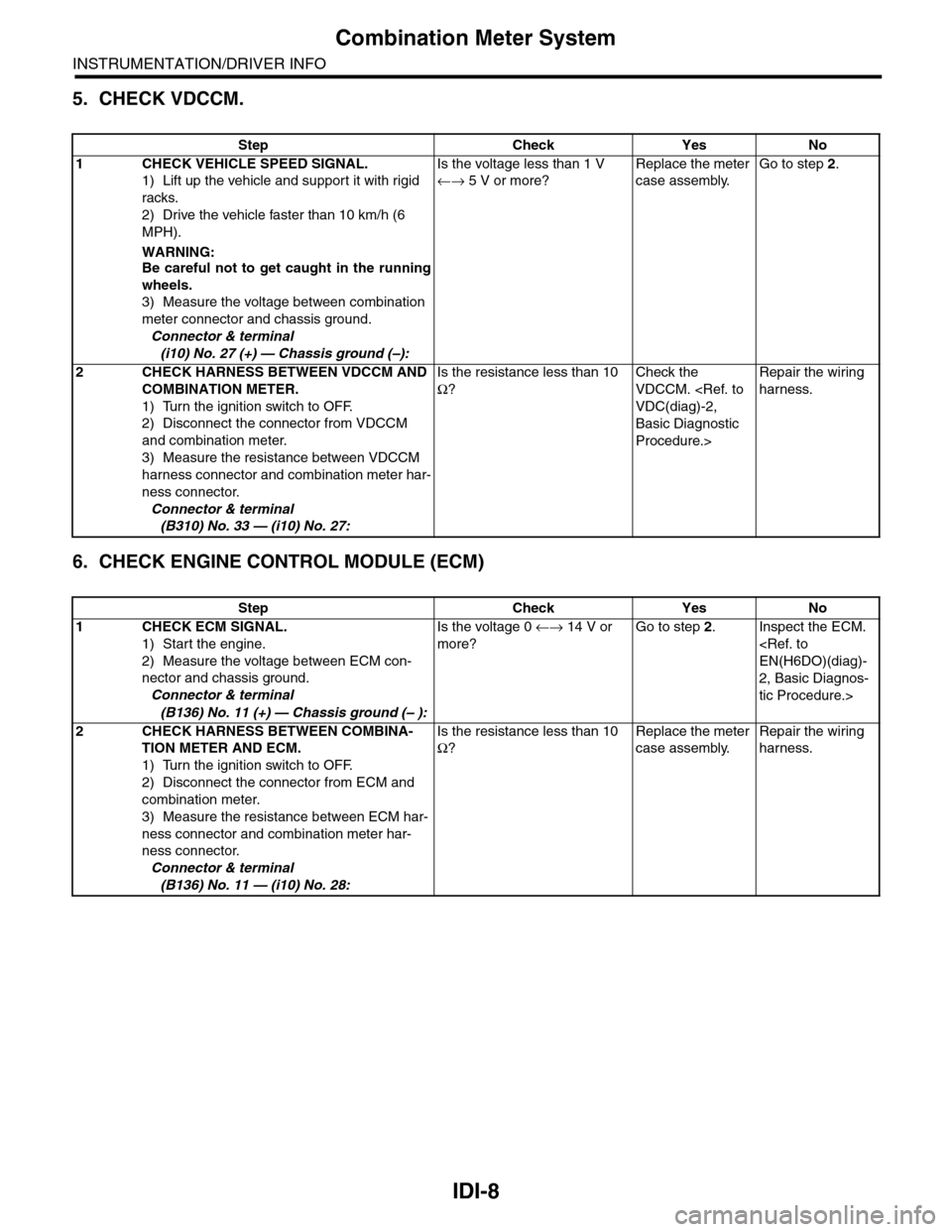

5. CHECK VDCCM.

6. CHECK ENGINE CONTROL MODULE (ECM)

Step Check Yes No

1CHECK VEHICLE SPEED SIGNAL.

1) Lift up the vehicle and support it with rigid

racks.

2) Drive the vehicle faster than 10 km/h (6

MPH).

WARNING:Be careful not to get caught in the running

wheels.

3) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 27 (+) — Chassis ground (–):

Is the voltage less than 1 V

←→ 5 V or more?

Replace the meter

case assembly.

Go to step 2.

2CHECK HARNESS BETWEEN VDCCM AND

COMBINATION METER.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from VDCCM

and combination meter.

3) Measure the resistance between VDCCM

harness connector and combination meter har-

ness connector.

Connector & terminal

(B310) No. 33 — (i10) No. 27:

Is the resistance less than 10

Ω?

Check the

VDCCM.

Basic Diagnostic

Procedure.>

Repair the wiring

harness.

Step Check Yes No

1CHECK ECM SIGNAL.

1) Start the engine.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 11 (+) — Chassis ground (– ):

Is the voltage 0 ←→ 14 V or

more?

Go to step 2.Inspect the ECM.

2, Basic Diagnos-

tic Procedure.>

2CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

combination meter.

3) Measure the resistance between ECM har-

ness connector and combination meter har-

ness connector.

Connector & terminal

(B136) No. 11 — (i10) No. 28:

Is the resistance less than 10

Ω?

Replace the meter

case assembly.

Repair the wiring

harness.

Page 448 of 2453

IDI-9

Combination Meter System

INSTRUMENTATION/DRIVER INFO

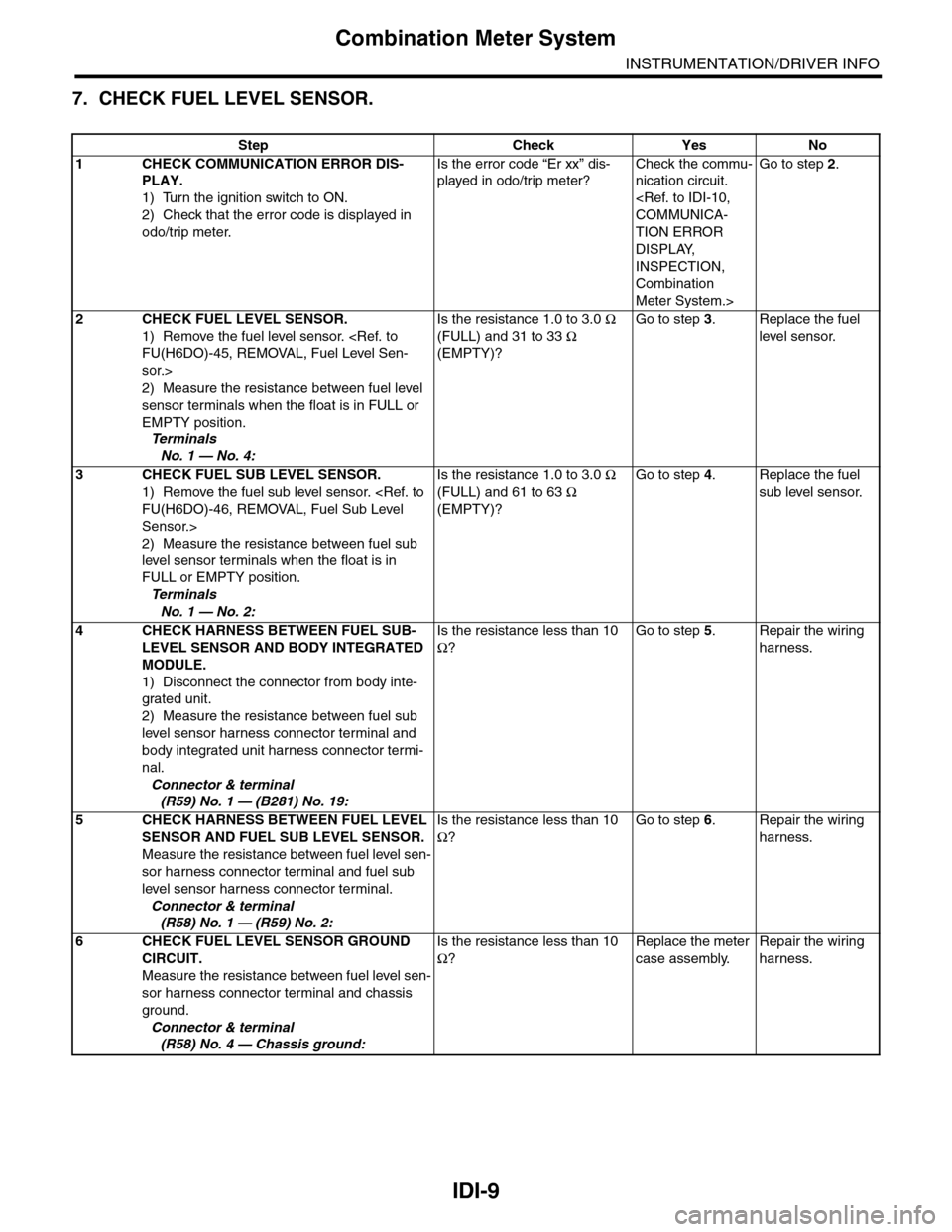

7. CHECK FUEL LEVEL SENSOR.

Step Check Yes No

1CHECK COMMUNICATION ERROR DIS-

PLAY.

1) Turn the ignition switch to ON.

2) Check that the error code is displayed in

odo/trip meter.

Is the error code “Er xx” dis-

played in odo/trip meter?

Check the commu-

nication circuit.

TION ERROR

DISPLAY,

INSPECTION,

Combination

Meter System.>

Go to step 2.

2CHECK FUEL LEVEL SENSOR.

1) Remove the fuel level sensor.

sor.>

2) Measure the resistance between fuel level

sensor terminals when the float is in FULL or

EMPTY position.

Te r m i n a l s

No. 1 — No. 4:

Is the resistance 1.0 to 3.0 Ω

(FULL) and 31 to 33 Ω

(EMPTY)?

Go to step 3.Replace the fuel

level sensor.

3CHECK FUEL SUB LEVEL SENSOR.

1) Remove the fuel sub level sensor.

Sensor.>

2) Measure the resistance between fuel sub

level sensor terminals when the float is in

FULL or EMPTY position.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance 1.0 to 3.0 Ω

(FULL) and 61 to 63 Ω

(EMPTY)?

Go to step 4.Replace the fuel

sub level sensor.

4CHECK HARNESS BETWEEN FUEL SUB-

LEVEL SENSOR AND BODY INTEGRATED

MODULE.

1) Disconnect the connector from body inte-

grated unit.

2) Measure the resistance between fuel sub

level sensor harness connector terminal and

body integrated unit harness connector termi-

nal.

Connector & terminal

(R59) No. 1 — (B281) No. 19:

Is the resistance less than 10

Ω?

Go to step 5.Repair the wiring

harness.

5CHECK HARNESS BETWEEN FUEL LEVEL

SENSOR AND FUEL SUB LEVEL SENSOR.

Measure the resistance between fuel level sen-

sor harness connector terminal and fuel sub

level sensor harness connector terminal.

Connector & terminal

(R58) No. 1 — (R59) No. 2:

Is the resistance less than 10

Ω?

Go to step 6.Repair the wiring

harness.

6CHECK FUEL LEVEL SENSOR GROUND

CIRCUIT.

Measure the resistance between fuel level sen-

sor harness connector terminal and chassis

ground.

Connector & terminal

(R58) No. 4 — Chassis ground:

Is the resistance less than 10

Ω?

Replace the meter

case assembly.

Repair the wiring

harness.

Page 458 of 2453

LAN(diag)-2

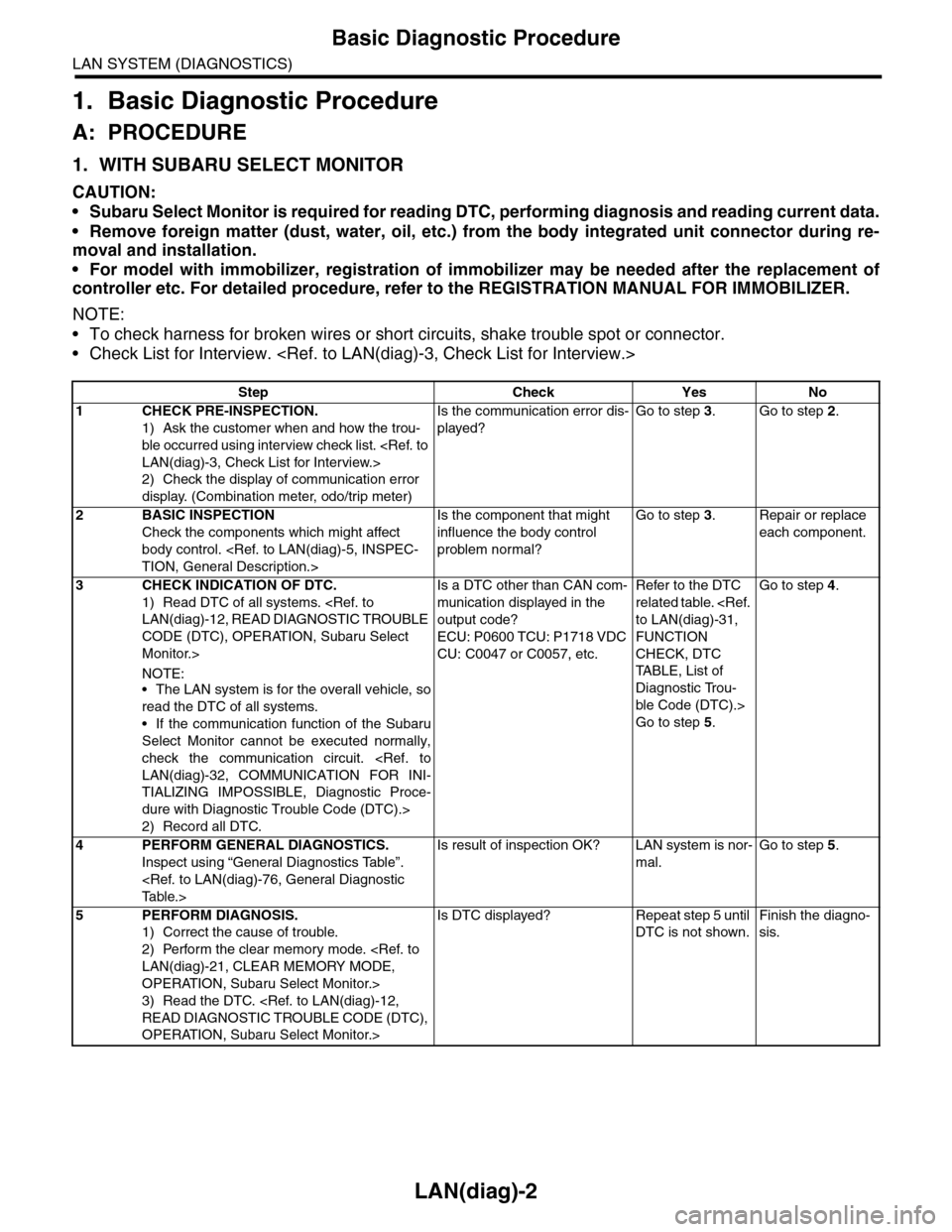

Basic Diagnostic Procedure

LAN SYSTEM (DIAGNOSTICS)

1. Basic Diagnostic Procedure

A: PROCEDURE

1. WITH SUBARU SELECT MONITOR

CAUTION:

•Subaru Select Monitor is required for reading DTC, performing diagnosis and reading current data.

•Remove foreign matter (dust, water, oil, etc.) from the body integrated unit connector during re-

moval and installation.

•For model with immobilizer, registration of immobilizer may be needed after the replacement of

controller etc. For detailed procedure, refer to the REGISTRATION MANUAL FOR IMMOBILIZER.

NOTE:

•To check harness for broken wires or short circuits, shake trouble spot or connector.

•Check List for Interview.

Step Check Yes No

1CHECK PRE-INSPECTION.

1) Ask the customer when and how the trou-

ble occurred using interview check list.

2) Check the display of communication error

display. (Combination meter, odo/trip meter)

Is the communication error dis-

played?

Go to step 3.Go to step 2.

2BASIC INSPECTION

Check the components which might affect

body control.

Is the component that might

influence the body control

problem normal?

Go to step 3.Repair or replace

each component.

3CHECK INDICATION OF DTC.

1) Read DTC of all systems.

CODE (DTC), OPERATION, Subaru Select

Monitor.>

NOTE:•The LAN system is for the overall vehicle, so

read the DTC of all systems.

•If the communication function of the Subaru

Select Monitor cannot be executed normally,

check the communication circuit.

TIALIZING IMPOSSIBLE, Diagnostic Proce-

dure with Diagnostic Trouble Code (DTC).>

2) Record all DTC.

Is a DTC other than CAN com-

munication displayed in the

output code?

ECU: P0600 TCU: P1718 VDC

CU: C0047 or C0057, etc.

Refer to the DTC

related table.

FUNCTION

CHECK, DTC

TA B L E , L i s t o f

Diagnostic Trou-

ble Code (DTC).>

Go to step 5.

Go to step 4.

4PERFORM GENERAL DIAGNOSTICS.

Inspect using “General Diagnostics Table”.

Is result of inspection OK? LAN system is nor-

mal.

Go to step 5.

5PERFORM DIAGNOSIS.

1) Correct the cause of trouble.

2) Perform the clear memory mode.

OPERATION, Subaru Select Monitor.>

3) Read the DTC.

OPERATION, Subaru Select Monitor.>

Is DTC displayed? Repeat step 5 until

DTC is not shown.

Finish the diagno-

sis.

Page 461 of 2453

LAN(diag)-5

General Description

LAN SYSTEM (DIAGNOSTICS)

3. General Description

A: CAUTION

1. SRS AIRBAG SYSTEM

Airbag system wiring harness is routed near the

body integrated unit and twisted pair line.

CAUTION:

•All airbag system wiring harness and con-

nectors are colored yellow. Do not use the elec-

trical test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the body inte-

grated unit and LAN system.

•Refer to “Airbag System” when disconnect-

ing the air bag system connector.

2. LAN SYSTEM

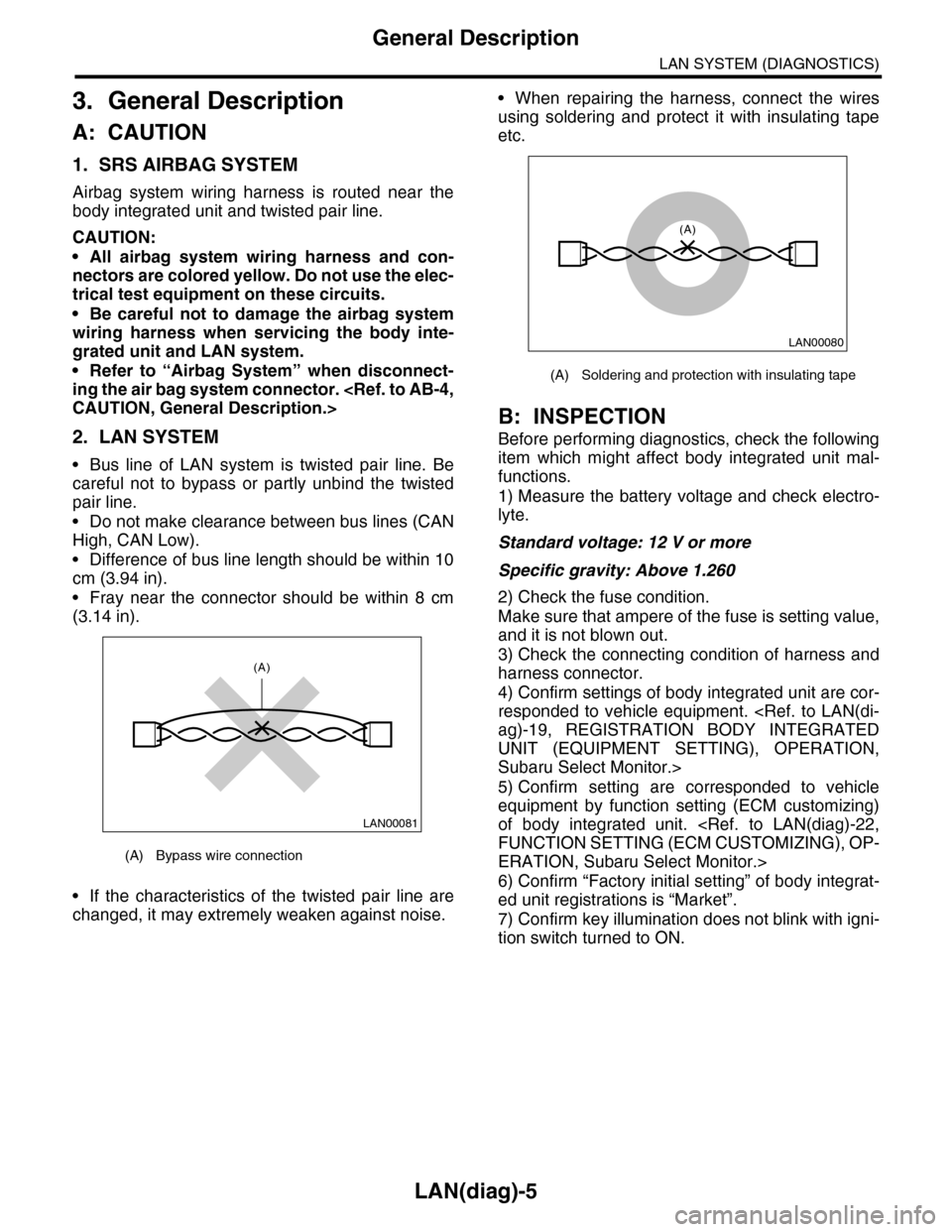

•Bus line of LAN system is twisted pair line. Be

careful not to bypass or partly unbind the twisted

pair line.

•Do not make clearance between bus lines (CAN

High, CAN Low).

•Difference of bus line length should be within 10

cm (3.94 in).

•Fray near the connector should be within 8 cm

(3.14 in).

•If the characteristics of the twisted pair line are

changed, it may extremely weaken against noise.

•When repairing the harness, connect the wires

using soldering and protect it with insulating tape

etc.

B: INSPECTION

Before performing diagnostics, check the following

item which might affect body integrated unit mal-

functions.

1) Measure the battery voltage and check electro-

lyte.

Standard voltage: 12 V or more

Specific gravity: Above 1.260

2) Check the fuse condition.

Make sure that ampere of the fuse is setting value,

and it is not blown out.

3) Check the connecting condition of harness and

harness connector.

4) Confirm settings of body integrated unit are cor-

responded to vehicle equipment.

UNIT (EQUIPMENT SETTING), OPERATION,

Subaru Select Monitor.>

5) Confirm setting are corresponded to vehicle

equipment by function setting (ECM customizing)

of body integrated unit.

ERATION, Subaru Select Monitor.>

6) Confirm “Factory initial setting” of body integrat-

ed unit registrations is “Market”.

7) Confirm key illumination does not blink with igni-

tion switch turned to ON.

(A) Bypass wire connection

LAN00081

(A)

(A) Soldering and protection with insulating tape

LAN00080

(A)

Page 489 of 2453

LAN(diag)-33

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

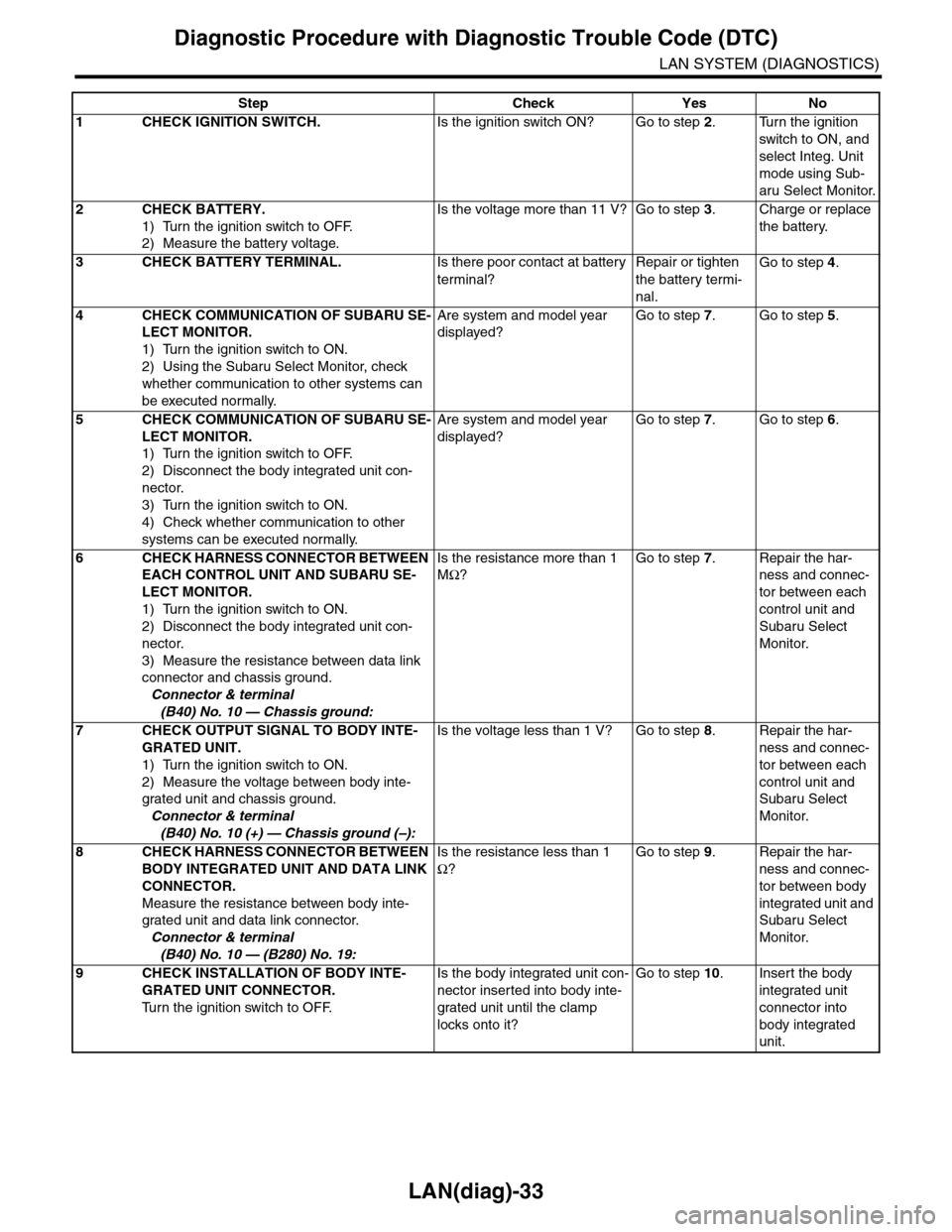

Step Check Yes No

1CHECK IGNITION SWITCH.Is the ignition switch ON? Go to step 2.Turn the ignition

switch to ON, and

select Integ. Unit

mode using Sub-

aru Select Monitor.

2CHECK BATTERY.

1) Turn the ignition switch to OFF.

2) Measure the battery voltage.

Is the voltage more than 11 V? Go to step 3.Charge or replace

the battery.

3CHECK BATTERY TERMINAL.Is there poor contact at battery

terminal?

Repair or tighten

the battery termi-

nal.

Go to step 4.

4CHECK COMMUNICATION OF SUBARU SE-

LECT MONITOR.

1) Turn the ignition switch to ON.

2) Using the Subaru Select Monitor, check

whether communication to other systems can

be executed normally.

Are system and model year

displayed?

Go to step 7.Go to step 5.

5CHECK COMMUNICATION OF SUBARU SE-

LECT MONITOR.

1) Turn the ignition switch to OFF.

2) Disconnect the body integrated unit con-

nector.

3) Turn the ignition switch to ON.

4) Check whether communication to other

systems can be executed normally.

Are system and model year

displayed?

Go to step 7.Go to step 6.

6CHECK HARNESS CONNECTOR BETWEEN

EACH CONTROL UNIT AND SUBARU SE-

LECT MONITOR.

1) Turn the ignition switch to ON.

2) Disconnect the body integrated unit con-

nector.

3) Measure the resistance between data link

connector and chassis ground.

Connector & terminal

(B40) No. 10 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 7.Repair the har-

ness and connec-

tor between each

control unit and

Subaru Select

Monitor.

7CHECK OUTPUT SIGNAL TO BODY INTE-

GRATED UNIT.

1) Turn the ignition switch to ON.

2) Measure the voltage between body inte-

grated unit and chassis ground.

Connector & terminal

(B40) No. 10 (+) — Chassis ground (–):

Is the voltage less than 1 V? Go to step 8.Repair the har-

ness and connec-

tor between each

control unit and

Subaru Select

Monitor.

8CHECK HARNESS CONNECTOR BETWEEN

BODY INTEGRATED UNIT AND DATA LINK

CONNECTOR.

Measure the resistance between body inte-

grated unit and data link connector.

Connector & terminal

(B40) No. 10 — (B280) No. 19:

Is the resistance less than 1

Ω?

Go to step 9.Repair the har-

ness and connec-

tor between body

integrated unit and

Subaru Select

Monitor.

9CHECK INSTALLATION OF BODY INTE-

GRATED UNIT CONNECTOR.

Tu r n t h e i g n i t i o n s w i t c h t o O F F.

Is the body integrated unit con-

nector inserted into body inte-

grated unit until the clamp

locks onto it?

Go to step 10.Insert the body

integrated unit

connector into

body integrated

unit.