Rear diff SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 734 of 2453

BR-20

Rear Disc Rotor

BRAKE

6. Rear Disc Rotor

A: REMOVAL

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Release the parking brake.

3) Remove the two mounting bolts, and remove the

rear disc brake assembly.

4) Suspend the rear disk brake assembly so that

the hose is not stretched.

5) Remove the rear disk brake rotor.

NOTE:

If the disc rotor is difficult to remove, try the follow-

ing two methods in order.

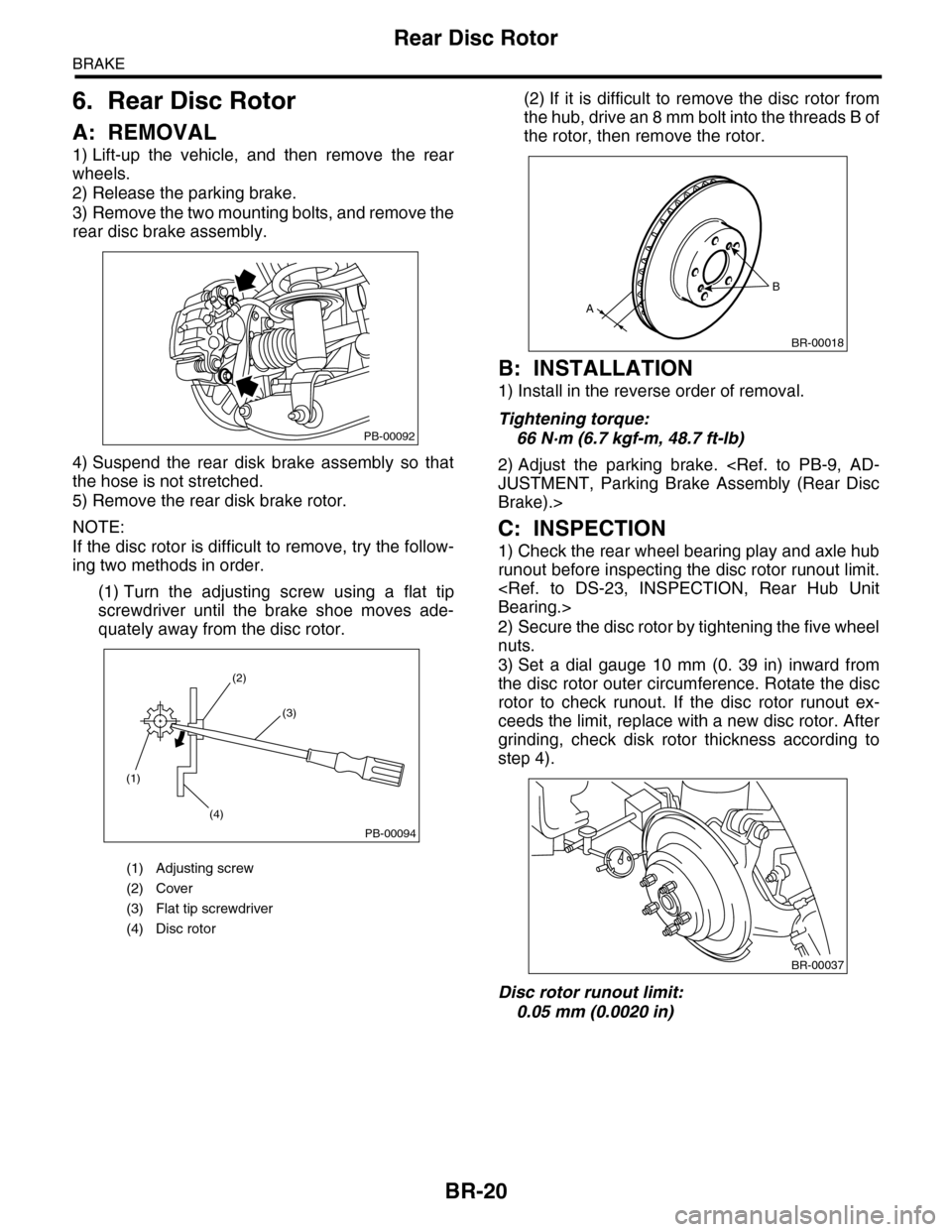

(1) Turn the adjusting screw using a flat tip

screwdriver until the brake shoe moves ade-

quately away from the disc rotor.

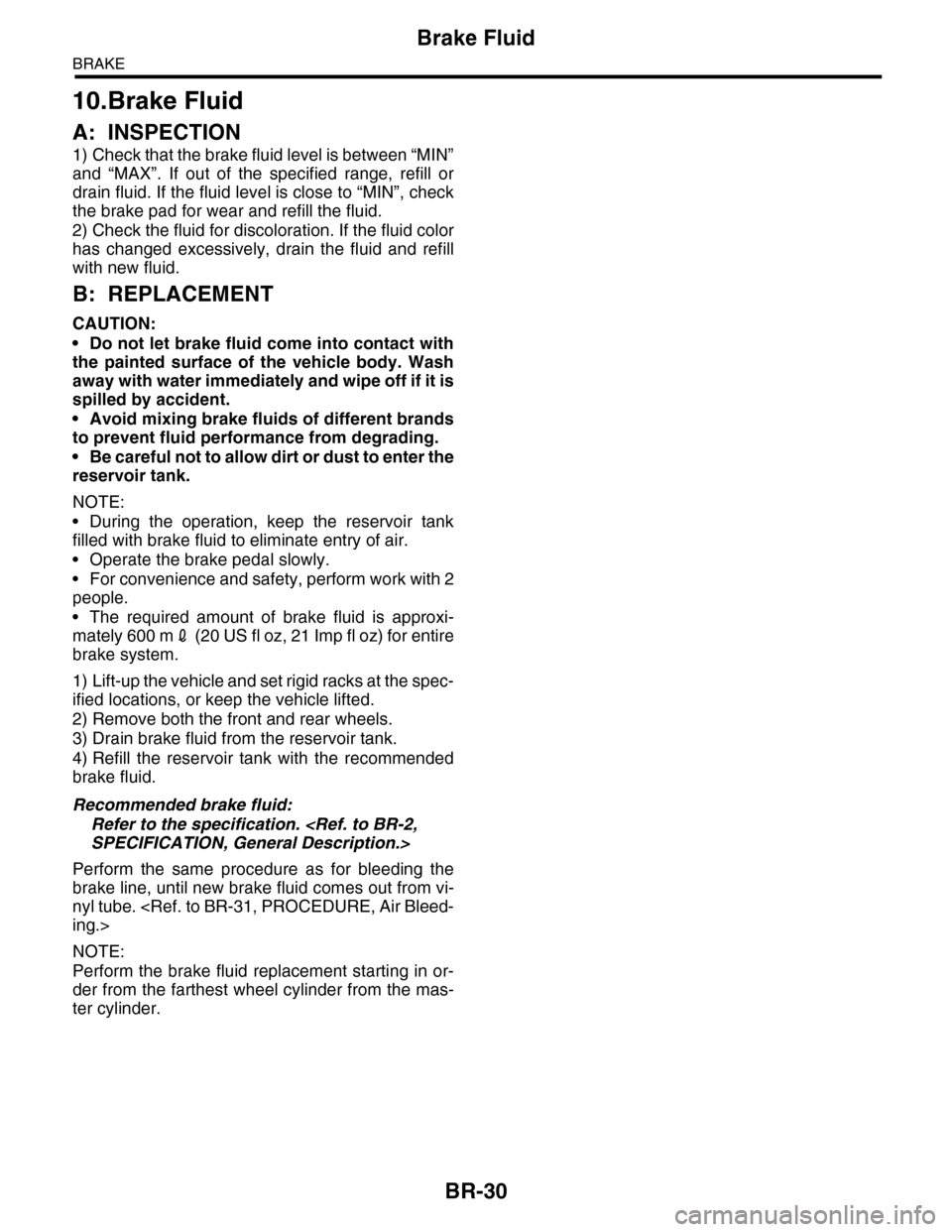

(2) If it is difficult to remove the disc rotor from

the hub, drive an 8 mm bolt into the threads B of

the rotor, then remove the rotor.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

66 N·m (6.7 kgf-m, 48.7 ft-lb)

2) Adjust the parking brake.

Brake).>

C: INSPECTION

1) Check the rear wheel bearing play and axle hub

runout before inspecting the disc rotor runout limit.

2) Secure the disc rotor by tightening the five wheel

nuts.

3) Set a dial gauge 10 mm (0. 39 in) inward from

the disc rotor outer circumference. Rotate the disc

rotor to check runout. If the disc rotor runout ex-

ceeds the limit, replace with a new disc rotor. After

grinding, check disk rotor thickness according to

step 4).

Disc rotor runout limit:

0.05 mm (0.0020 in)

(1) Adjusting screw

(2) Cover

(3) Flat tip screwdriver

(4) Disc rotor

PB-00092

(1)

(4)

(2)

(3)

PB-00094

B

A

BR-00018

BR-00037

Page 744 of 2453

BR-30

Brake Fluid

BRAKE

10.Brake Fluid

A: INSPECTION

1) Check that the brake fluid level is between “MIN”

and “MAX”. If out of the specified range, refill or

drain fluid. If the fluid level is close to “MIN”, check

the brake pad for wear and refill the fluid.

2) Check the fluid for discoloration. If the fluid color

has changed excessively, drain the fluid and refill

with new fluid.

B: REPLACEMENT

CAUTION:

•Do not let brake fluid come into contact with

the painted surface of the vehicle body. Wash

away with water immediately and wipe off if it is

spilled by accident.

•Avoid mixing brake fluids of different brands

to prevent fluid performance from degrading.

•Be careful not to allow dirt or dust to enter the

reservoir tank.

NOTE:

•During the operation, keep the reservoir tank

filled with brake fluid to eliminate entry of air.

•Operate the brake pedal slowly.

•For convenience and safety, perform work with 2

people.

•The required amount of brake fluid is approxi-

mately 600 m2 (20 US fl oz, 21 Imp fl oz) for entire

brake system.

1) Lift-up the vehicle and set rigid racks at the spec-

ified locations, or keep the vehicle lifted.

2) Remove both the front and rear wheels.

3) Drain brake fluid from the reservoir tank.

4) Refill the reservoir tank with the recommended

brake fluid.

Recommended brake fluid:

Refer to the specification.

Perform the same procedure as for bleeding the

brake line, until new brake fluid comes out from vi-

nyl tube.

NOTE:

Perform the brake fluid replacement starting in or-

der from the farthest wheel cylinder from the mas-

ter cylinder.

Page 786 of 2453

DI-2

General Description

DIFFERENTIALS

1. General Description

A: SPECIFICATION

1. REAR DIFFERENTIAL

When replacing a rear differential assembly, select the correct one according to the following table.

NOTE:

•Using a different rear differential assembly will cause the drive train and tires to drag or emit abnormal

noise.

•For option code, refer to “ID” section.

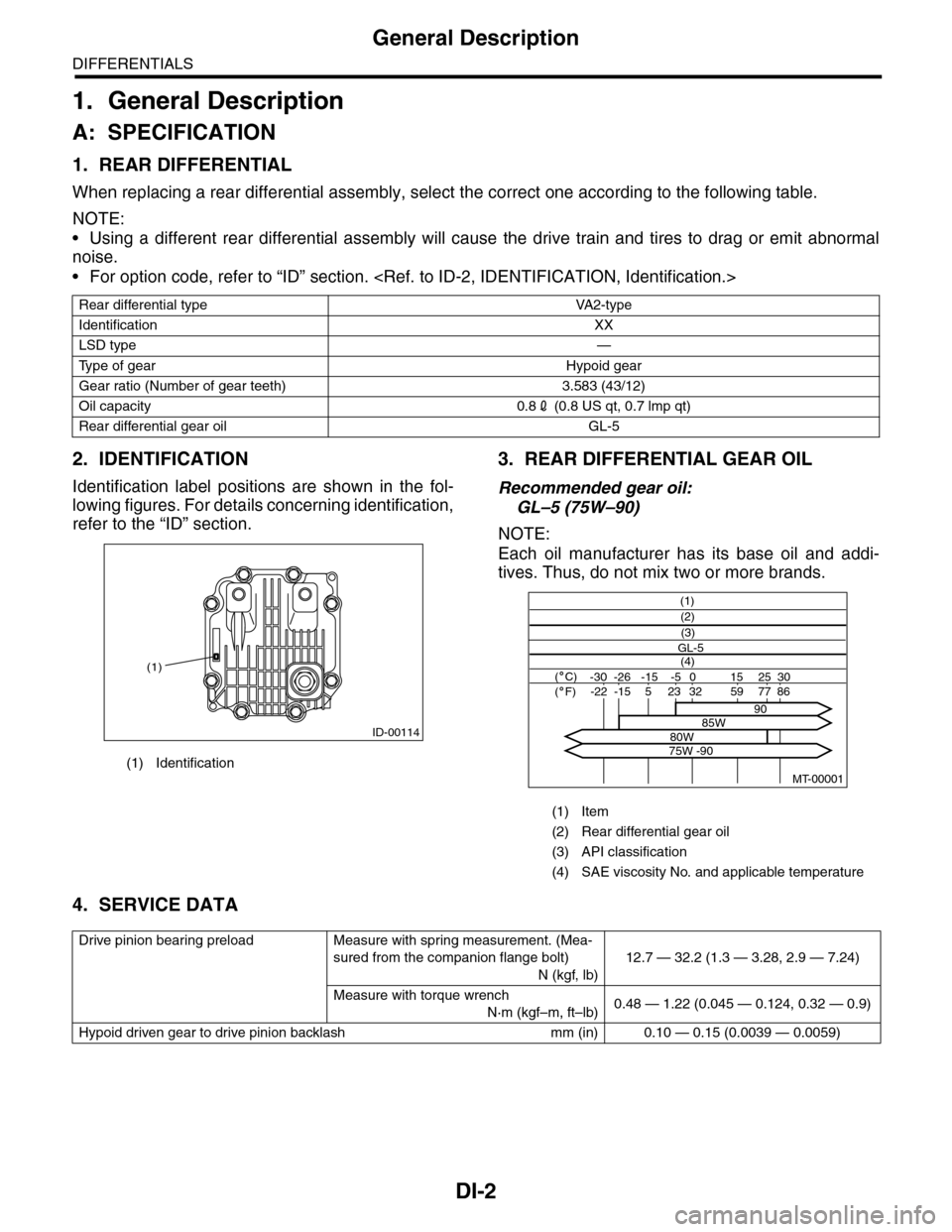

2. IDENTIFICATION

Identification label positions are shown in the fol-

lowing figures. For details concerning identification,

refer to the “ID” section.

3. REAR DIFFERENTIAL GEAR OIL

Recommended gear oil:

GL–5 (75W–90)

NOTE:

Each oil manufacturer has its base oil and addi-

tives. Thus, do not mix two or more brands.

4. SERVICE DATA

Rear differential type VA2-type

Identification XX

LSD type—

Ty p e o f g e a r H y p o i d g e a r

Gear ratio (Number of gear teeth) 3.583 (43/12)

Oil capacity 0.82 (0.8 US qt, 0.7 lmp qt)

Rear differential gear oil GL-5

(1) Identification

ID-00114

(1)

(1) Item

(2) Rear differential gear oil

(3) API classification

(4) SAE viscosity No. and applicable temperature

MT-00001

(1)

(4)GL-5(3)

(2)

( C)( F)-30 -26 -15 15

9085W80W75W -90

25 30 -5 0-22-1523328659775

Drive pinion bearing preload Measure with spring measurement. (Mea-

sured from the companion flange bolt)

N (kgf, lb)

12.7 — 32.2 (1.3 — 3.28, 2.9 — 7.24)

Measure with torque wrench

N·m (kgf–m, ft–lb)0.48 — 1.22 (0.045 — 0.124, 0.32 — 0.9)

Hypoid driven gear to drive pinion backlash mm (in) 0.10 — 0.15 (0.0039 — 0.0059)

Page 788 of 2453

DI-4

General Description

DIFFERENTIALS

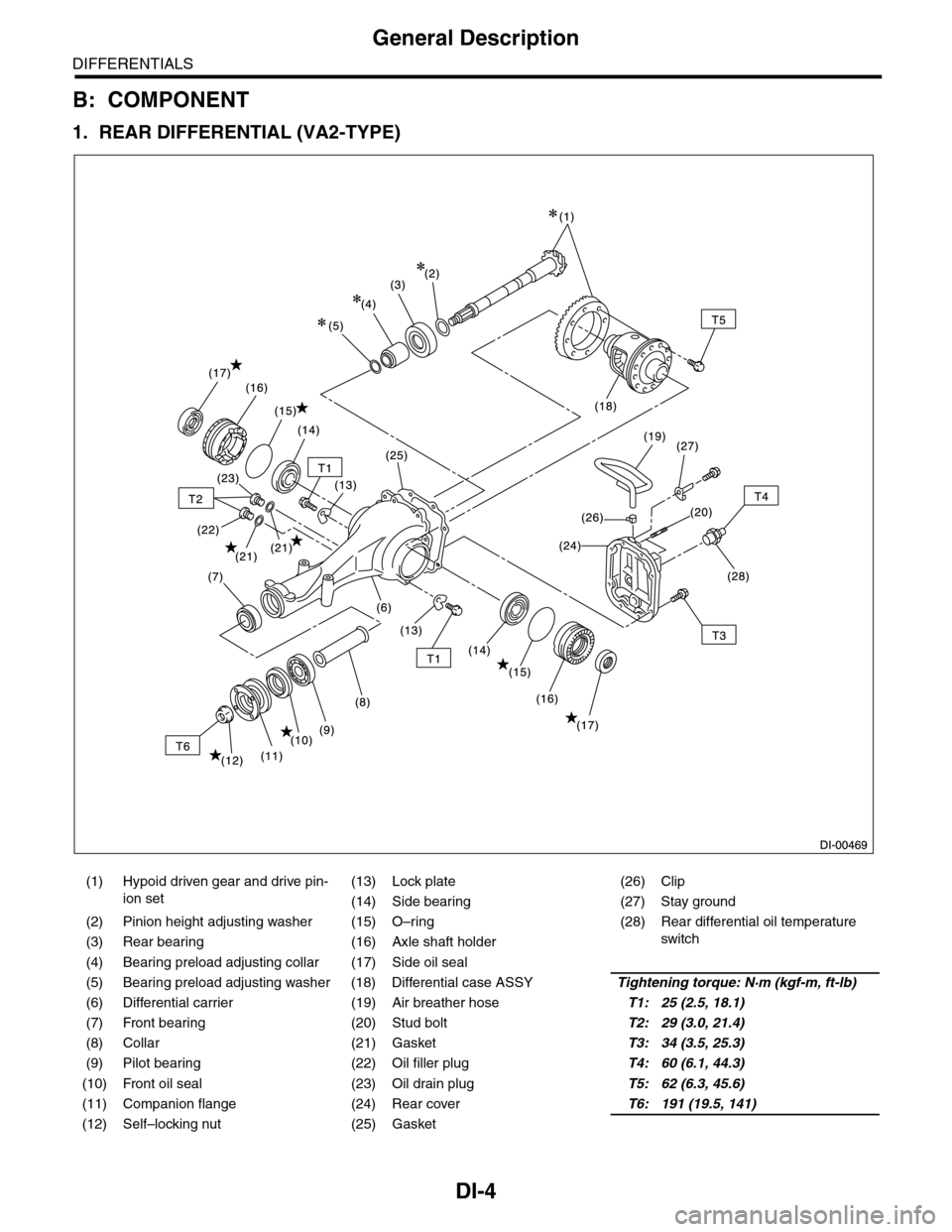

B: COMPONENT

1. REAR DIFFERENTIAL (VA2-TYPE)

(1) Hypoid driven gear and drive pin-

ion set

(13) Lock plate (26) Clip

(14) Side bearing (27) Stay ground

(2) Pinion height adjusting washer (15) O–ring (28)

Rear differential oil temperature

switch(3) Rear bearing (16) Axle shaft holder

(4) Bearing preload adjusting collar (17) Side oil seal

(5) Bearing preload adjusting washer (18) Differential case ASSYTightening torque: N·m (kgf-m, ft-lb)

(6) Differential carrier (19) Air breather hoseT1: 25 (2.5, 18.1)

(7) Front bearing (20) Stud boltT2: 29 (3.0, 21.4)

(8) Collar (21) GasketT3: 34 (3.5, 25.3)

(9) Pilot bearing (22) Oil filler plugT4: 60 (6.1, 44.3)

(10) Front oil seal (23) Oil drain plugT5: 62 (6.3, 45.6)

(11) Companion flange (24) Rear coverT6: 191 (19.5, 141)

(12) Self–locking nut (25) Gasket

Page 789 of 2453

DI-5

General Description

DIFFERENTIALS

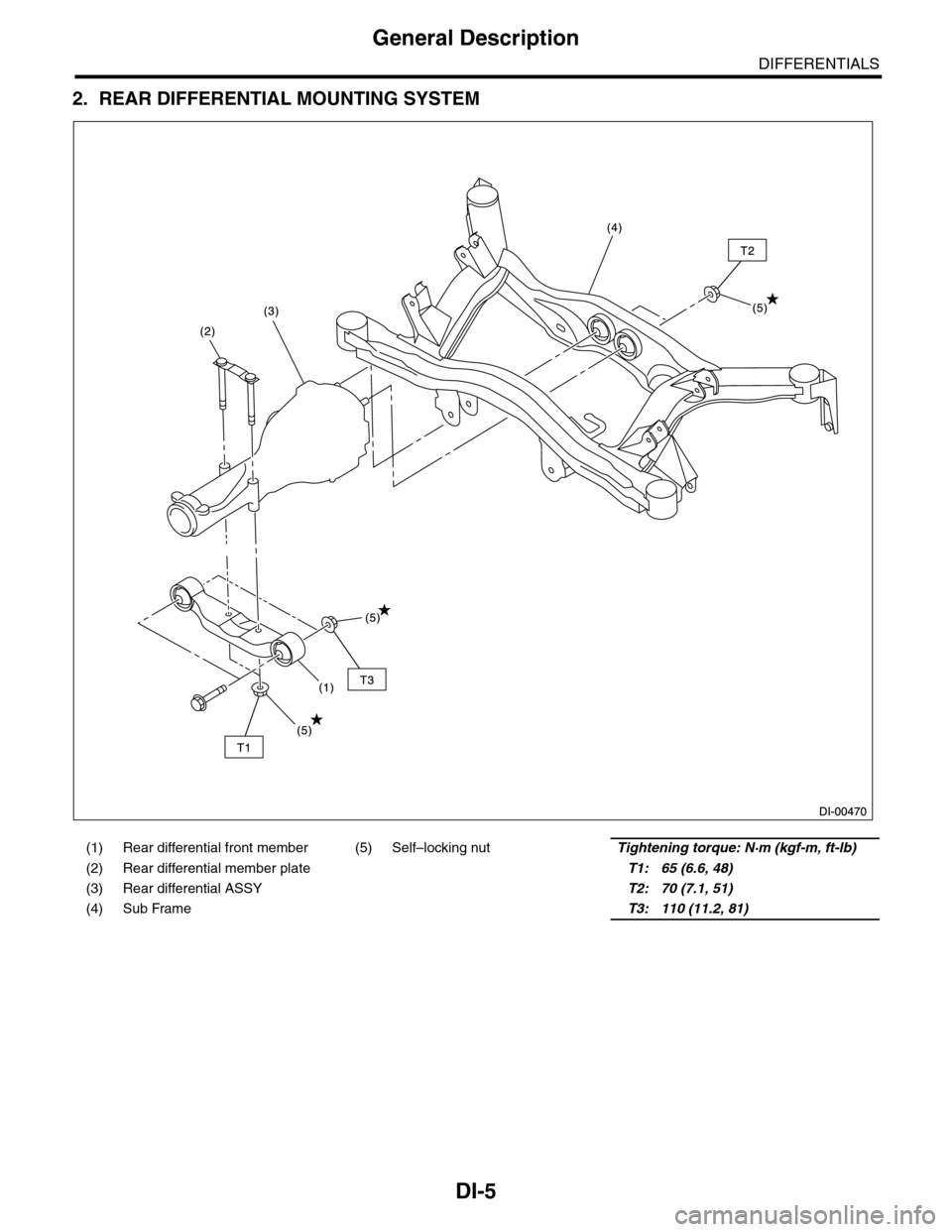

2. REAR DIFFERENTIAL MOUNTING SYSTEM

(1) Rear differential front member (5) Self–locking nutTightening torque: N·m (kgf-m, ft-lb)

(2) Rear differential member plateT1: 65 (6.6, 48)

(3) Rear differential ASSYT2: 70 (7.1, 51)

(4) Sub Frame T3: 110 (11.2, 81)

Page 790 of 2453

DI-6

General Description

DIFFERENTIALS

C: CAUTION

•Wear work clothing, including a cap, protective goggles and protective shoes during operation.

•Remove contamination including dirt and corrosion before removal, installation or disassembly.

•Keep the disassembled parts in order and protect them from dust and dirt.

•Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, in-

stallation, disassembly and replacement.

•Be careful not to burn yourself, because each part on the vehicle is hot after running.

•Use SUBARU genuine grease etc. or equivalent. Do not mix gear oil, grease, etc. with those of different

grades or from other manufacturers.

•Be sure to tighten fasteners including bolts and nuts to the specified torque.

•Place shop jacks or rigid racks at the specified points.

•Apply gear oil onto sliding or revolution surfaces before installation.

•Before installing the O-ring or snap ring, apply a sufficient amount of gear oil to avoid damage and defor-

mation.

•Before securing a part on a vise, place cushioning material such as wood blocks, aluminum plate, or cloth

between the part and the vise.

•Avoid damaging the mating surface of the case.

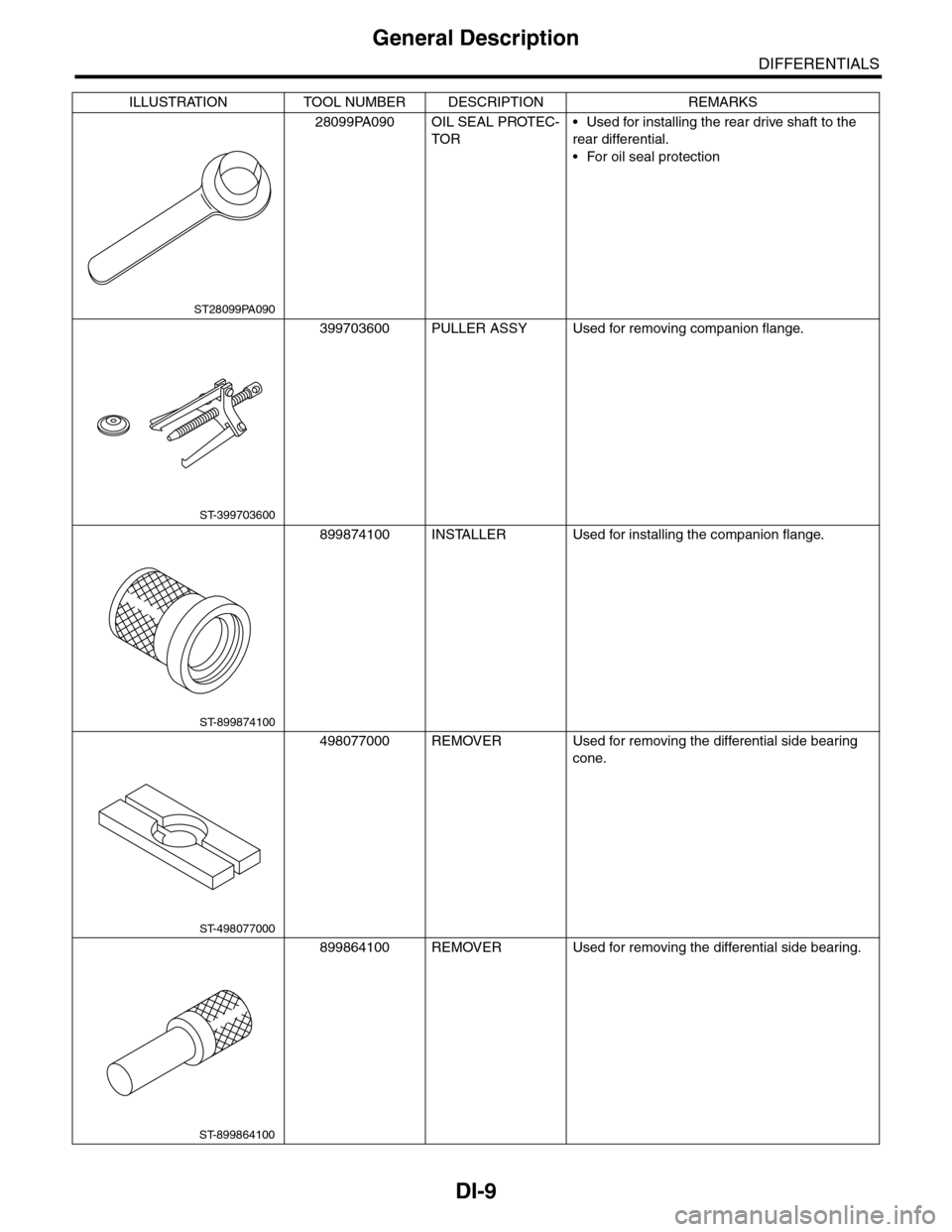

D: PREPARATION TOOL

1. SPECIAL TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

398477701 HANDLE Used for installing the front and rear bearing

cones.

398217700 ATTACHMENT SET Stand for rear differential carrier disassembly

and assembly.

498447120 INSTALLER Used for installing the front oil seal.

ST-398477701

ST-398217700

ST-498447120

Page 791 of 2453

DI-7

General Description

DIFFERENTIALS

498427200 FLANGE WRENCH Used for stopping rotation of companion flange

when removing and tightening self-lock nut.

399780104 WEIGHT Used for installing the front bearing cone and the

pilot bearing companion flange.

498247001 MAGNET BASE • Used for measuring backlash between side

gear and pinion, and hypoid gear.

•Used with DIAL GAUGE (498247100).

498247100 DIAL GAUGE • Used for measuring backlash between side

gear and pinion, and hypoid gear.

•Used with MAGNET BASE (498247001).

398177700 INSTALLER Used for installing the rear bearing cone.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-498427200

ST-399780104

ST-498247001

ST-498247100

ST-398177700

Page 792 of 2453

DI-8

General Description

DIFFERENTIALS

398477703 DRIFT 2 Used for press-fitting bearing race (rear) of differ-

ential carrier.

398437700 DRIFT Used for installing the side oil seal.

398517700 REPLACER Used for removing rear bearing cone.

398487700 DRIFT Used for press-fitting side bearing cone.

398527700 PULLER ASSY Used for removing front oil seal.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-398477703

ST-398437700

ST-398517700

ST-398487700

ST-398527700

Page 793 of 2453

DI-9

General Description

DIFFERENTIALS

28099PA090 OIL SEAL PROTEC-

TOR

•Used for installing the rear drive shaft to the

rear differential.

•For oil seal protection

399703600 PULLER ASSY Used for removing companion flange.

899874100 INSTALLER Used for installing the companion flange.

498077000 REMOVER Used for removing the differential side bearing

cone.

899864100 REMOVER Used for removing the differential side bearing.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST28099PA090

ST-399703600

ST-899874100

ST-498077000

ST-899864100

Page 798 of 2453

DI-14

Rear Differential (VA–type)

DIFFERENTIALS

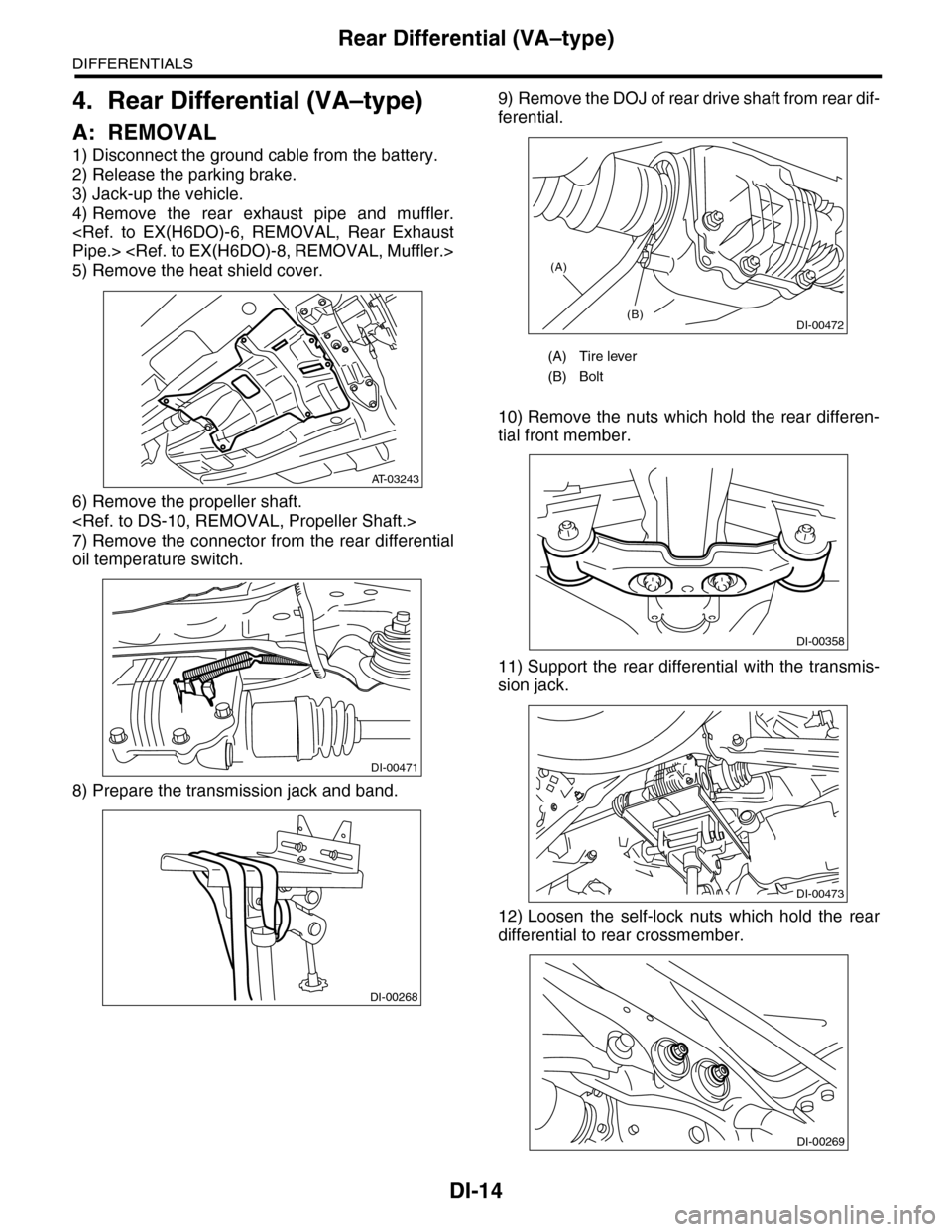

4. Rear Differential (VA–type)

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Release the parking brake.

3) Jack-up the vehicle.

4) Remove the rear exhaust pipe and muffler.

5) Remove the heat shield cover.

6) Remove the propeller shaft.

7) Remove the connector from the rear differential

oil temperature switch.

8) Prepare the transmission jack and band.

9) Remove the DOJ of rear drive shaft from rear dif-

ferential.

10) Remove the nuts which hold the rear differen-

tial front member.

11) Support the rear differential with the transmis-

sion jack.

12) Loosen the self-lock nuts which hold the rear

differential to rear crossmember.

AT-03243

DI-00471

DI-00268

(A) Tire lever

(B) Bolt

DI-00472

(A)

(B)

DI-00358

DI-00473

DI-00269