Rear diff SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 935 of 2453

RS-2

General Description

REAR SUSPENSION

1. General Description

A: SPECIFICATION

NOTE:

•Front and rear toe–in and front camber can be

adjusted. Adjust if the toe–in or camber tolerance

exceeds specifications.

•Other items indicated in the specifications table

cannot be adjusted. If other items exceed specifica-

tions, check the suspension parts and connections

for deformation, and replace with new ones as re-

quired.

Wheel arch height

[Tolerance: +12 mm -24 mm ( +0.47 in -0.94 in)]mm (in) 439 (17.3)

Camber

[Tolerance: ±0°45′ Difference between RH and LH 45′ or less]–0°31′

To e – i n m m ( i n ) 2±2 (0.08±0.08) Toe angle (sum of both wheels): 0°9'±0°9'

Thrust angle [Tolerance: ±0°30′]0°

Diameter of stabilizer mm (in) 16 (0.63)

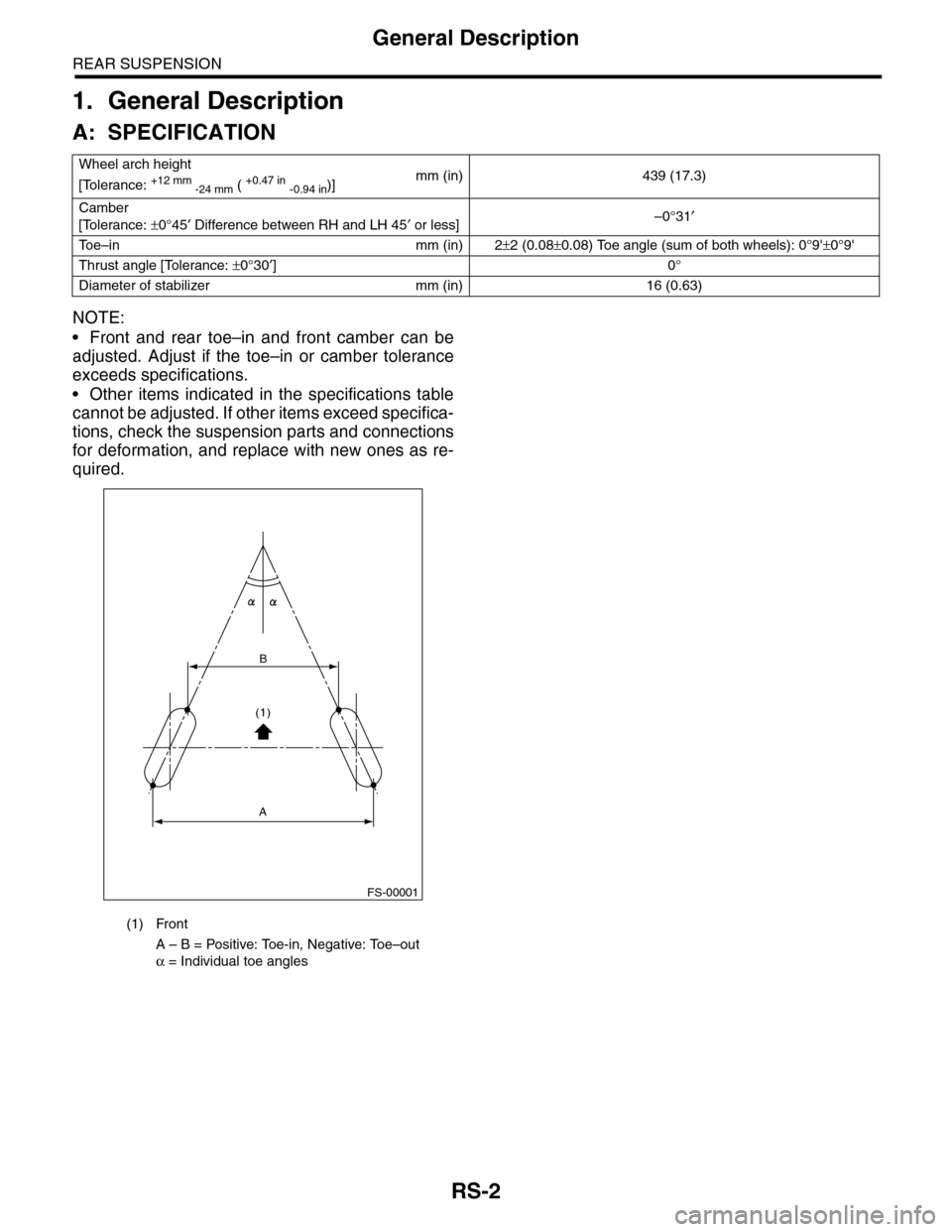

(1) Front

A – B = Positive: Toe-in, Negative: Toe–out

α = Individual toe angles

FS-00001

B

A

(1)

Page 939 of 2453

RS-6

General Description

REAR SUSPENSION

2. GENERAL TOOL

28099PA090 OIL SEAL PROTEC-

TOR

•Used for installing the rear drive shaft to the

rear differential.

•For oil seal protection

TOOL NAME REMARKS

Alignment tester Used for measuring wheel alignment.

To e – i n g a u g e U s e d f o r t o e – i n m e a s u r e m e n t .

Jack Used for removing and installing suspension.

Bearing puller Used for removing bushings.

Coil spring compressor Used for disassembling and assembling shock absorber.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST28099PA090

Page 953 of 2453

TPM(diag)-3

General Description

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

2. General Description

A: CAUTION

1. SRS AIRBAG SYSTEM

Airbag system wiring harness is routed near the

TPM control module.

CAUTION:

•Wiring harnesses of all airbag system are yel-

low. Do not use the electrical test equipment on

these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the tire pressure

monitoring control module.

2. TIRE PRESSURE MONITORING CON-

TROL MODULE

•If the alteration of tire rotation, the installation po-

sition or the replacement of transmitter is per-

formed, ID registration for the transmitter is

required.

Monitor.>

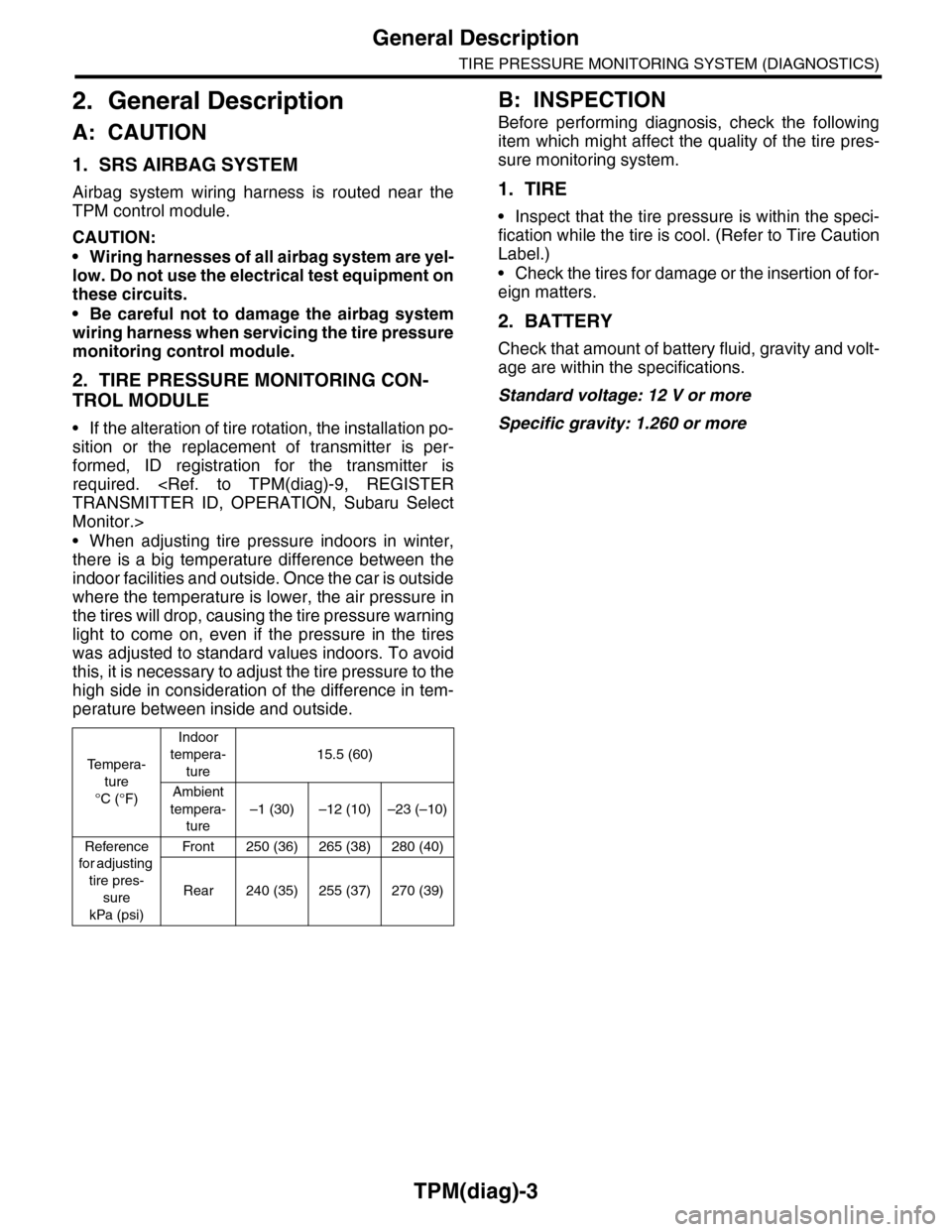

•When adjusting tire pressure indoors in winter,

there is a big temperature difference between the

indoor facilities and outside. Once the car is outside

where the temperature is lower, the air pressure in

the tires will drop, causing the tire pressure warning

light to come on, even if the pressure in the tires

was adjusted to standard values indoors. To avoid

this, it is necessary to adjust the tire pressure to the

high side in consideration of the difference in tem-

perature between inside and outside.

B: INSPECTION

Before performing diagnosis, check the following

item which might affect the quality of the tire pres-

sure monitoring system.

1. TIRE

•Inspect that the tire pressure is within the speci-

fication while the tire is cool. (Refer to Tire Caution

Label.)

•Check the tires for damage or the insertion of for-

eign matters.

2. BATTERY

Check that amount of battery fluid, gravity and volt-

age are within the specifications.

Standard voltage: 12 V or more

Specific gravity: 1.260 or more

Te m p e r a -

ture

°C (°F)

Indoor

tempera-

ture

15.5 (60)

Ambient

tempera-

ture

–1 (30) –12 (10) –23 (–10)

Reference

for adjusting

tire pres-

sure

kPa (psi)

Fr o n t 25 0 ( 36 ) 26 5 ( 3 8 ) 2 8 0 ( 4 0)

Rear 240 (35) 255 (37) 270 (39)

Page 1166 of 2453

EN(H6DO)(diag)-5

General Description

ENGINE (DIAGNOSTICS)

3. General Description

A: CAUTION

1) Airbag system wiring harness is routed near the

ECM, main relay and fuel pump relay.

CAUTION:

•All airbag system wiring harnesses and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the ECM, TCM,

main relay and fuel pump relay.

2) Never connect the battery in reverse polarity.

•The ECM will be destroyed instantly.

•The fuel injector and other parts will be dam-

aged.

3) Do not disconnect the battery terminals while the

engine is running.

A large counter electromotive force will be generat-

ed in the generator, and this voltage may damage

electronic parts such as ECM etc.

4) Before disconnecting the connectors of each

sensor and ECM, be sure to turn the ignition switch

to OFF. Perform the clear memory mode after con-

necting the connectors.

5) Poor contact has been identified as a primary

cause of this problem. Measure the voltage or re-

sistance of individual sensor or all electrical control

modules using a tapered pin with a diameter of less

than 0.64 mm (0.025 in). Do not insert the pin more

than 5 mm (0.20 in) into the part.

6) Remove the ECM from the located position after

disconnecting two cables on battery.

Otherwise, the ECM may be damaged.

CAUTION:

When replacing the ECM, be careful not to use

the wrong spec. ECM to avoid any damage on

the fuel injection system.

7) Connectors of each sensor in the engine com-

partment and the harness connectors on the en-

gine side and body side are all designed to be

waterproof. Even if the connectors are waterproof,

take care not to allow water to get into them when

washing the vehicle, or when servicing the vehicle

in rainy weather.

8) Use ECM mounting stud bolts as the grounding

point to chassis when measuring voltage and resis-

tance in the passenger compartment.

9) Use the engine ground terminal or engine as-

sembly as the grounding point to chassis when

measuring the voltage and resistance in engine

compartment.

10) Every MFI-related part is a precision part. Do

not drop them.

11) Observe the following cautions when installing

a radio in MFI equipped models.

CAUTION:

•The antenna must be kept as far apart as pos-

sible from control unit. (The ECM is located un-

der the steering column, inside of the

instrument panel lower trim panel.)

•The antenna feeder must be placed as far apart

as possible from the ECM and MFI harness.

•Carefully adjust the antenna for correct

matching.

•When mounting a large power type radio, pay

special attention to the three items mentioned

above.

•Incorrect installation of the radio may affect

the operation of ECM.

12) Release the pressure in the fuel system before

disconnecting the fuel hose. If engine starts during

this operation, run it until it stops.

13) For the model with ABS, the ABS warning light

may illuminate when performing driving test with

jacked-up or lifted-up condition, but this is not a

system malfunction. The reason for this is the

speed difference between the front and rear

wheels. After diagnosis of engine control system,

perform the ABS memory clear procedure of self-

diagnosis function.

B: INSPECTION

Before performing diagnostics, check the following

item which might affect engine problems.

1. BATTERY

1) Measure the battery voltage and specific gravity

of electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.260

2) Check the condition of the main and other fuses,

and harnesses and connectors. Also check for

proper grounding.

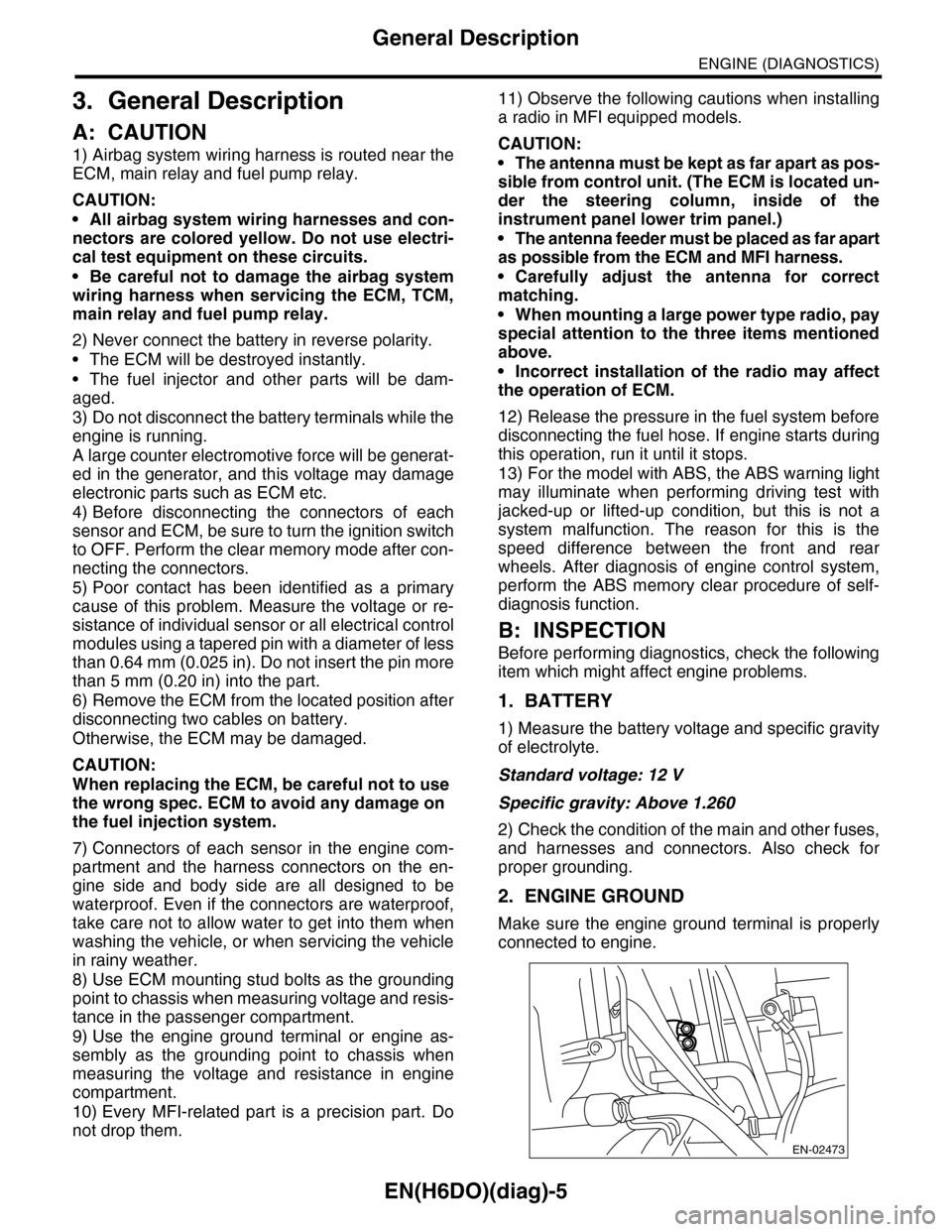

2. ENGINE GROUND

Make sure the engine ground terminal is properly

connected to engine.

EN-02473

Page 1199 of 2453

EN(H6DO)(diag)-38

Inspection Mode

ENGINE (DIAGNOSTICS)

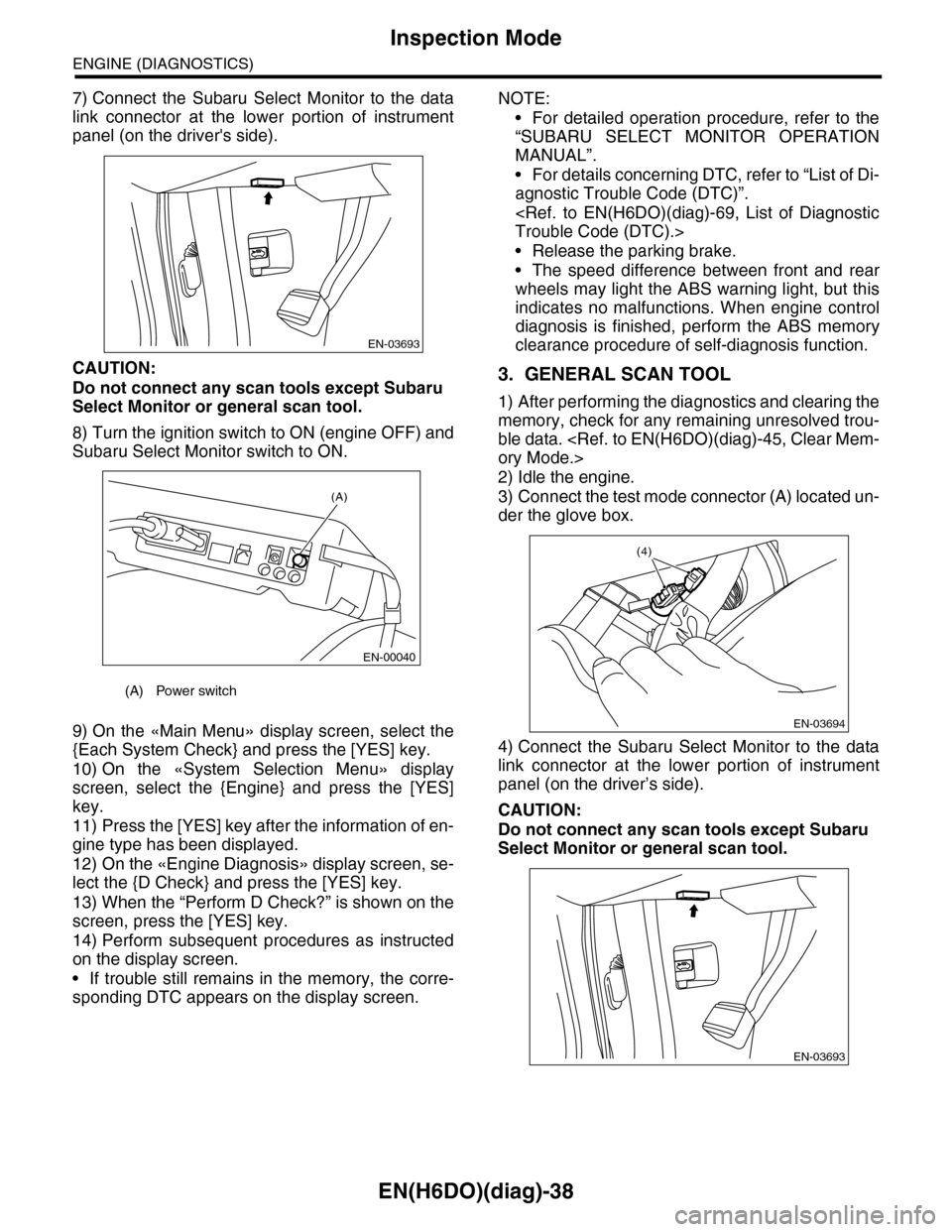

7) Connect the Subaru Select Monitor to the data

link connector at the lower portion of instrument

panel (on the driver's side).

CAUTION:

Do not connect any scan tools except Subaru

Select Monitor or general scan tool.

8) Turn the ignition switch to ON (engine OFF) and

Subaru Select Monitor switch to ON.

9) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

10) On the «System Selection Menu» display

screen, select the {Engine} and press the [YES]

key.

11) Press the [YES] key after the information of en-

gine type has been displayed.

12) On the «Engine Diagnosis» display screen, se-

lect the {D Check} and press the [YES] key.

13) When the “Perform D Check?” is shown on the

screen, press the [YES] key.

14) Perform subsequent procedures as instructed

on the display screen.

•If trouble still remains in the memory, the corre-

sponding DTC appears on the display screen.

NOTE:

•For detailed operation procedure, refer to the

“SUBARU SELECT MONITOR OPERATION

MANUAL”.

•For details concerning DTC, refer to “List of Di-

agnostic Trouble Code (DTC)”.

•Release the parking brake.

•The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunctions. When engine control

diagnosis is finished, perform the ABS memory

clearance procedure of self-diagnosis function.

3. GENERAL SCAN TOOL

1) After performing the diagnostics and clearing the

memory, check for any remaining unresolved trou-

ble data.

2) Idle the engine.

3) Connect the test mode connector (A) located un-

der the glove box.

4) Connect the Subaru Select Monitor to the data

link connector at the lower portion of instrument

panel (on the driver’s side).

CAUTION:

Do not connect any scan tools except Subaru

Select Monitor or general scan tool.

(A) Power switch

EN-03693

(A)

EN-00040

EN-03694

(4)

EN-03693

Page 1200 of 2453

EN(H6DO)(diag)-39

Inspection Mode

ENGINE (DIAGNOSTICS)

5) Start the engine.

NOTE:

Make sure the select lever is placed in “P” position

before starting.

6) Using the select lever, turn the “P” position

switch and the “N” position switch to ON.

7) Depress the brake pedal to turn brake switch

ON.

8) Keep the engine speed in 2,500 — 3,000 rpm

range for 40 seconds.

9) Shift the select lever in the “D” range and drive

the vehicle at 5 to 10 km/h (3 to 6 MPH).

NOTE:

•For AWD model, release the parking brake.

•The speed difference between front and rear

wheels may light the ABS warning light, but this in-

dicates no malfunctions. When engine control diag-

nosis is finished, perform the ABS memory

clearance procedure of self-diagnosis system.

10) Using the general scan tool, check DTC and

record the result(s).

NOTE:

•For detailed operation procedure, refer to the

general scan tool operation manual.

•For details concerning DTC, refer to “List of Diag-

nostic Trouble Code (DTC)”.

Page 1680 of 2453

GD(H6DO)-68

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

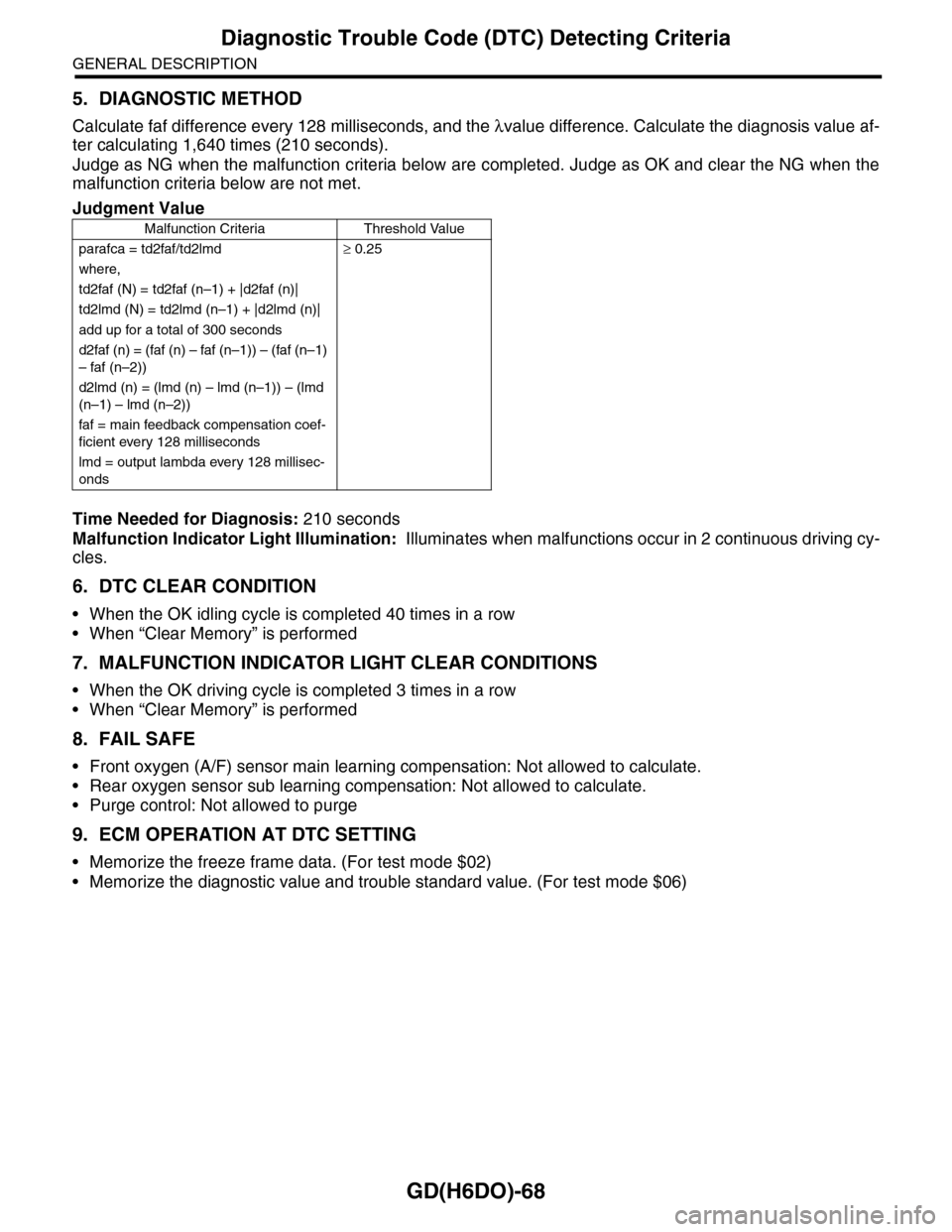

5. DIAGNOSTIC METHOD

Calculate faf difference every 128 milliseconds, and the λvalue difference. Calculate the diagnosis value af-

ter calculating 1,640 times (210 seconds).

Judge as NG when the malfunction criteria below are completed. Judge as OK and clear the NG when the

malfunction criteria below are not met.

Time Needed for Diagnosis: 210 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

•Front oxygen (A/F) sensor main learning compensation: Not allowed to calculate.

•Rear oxygen sensor sub learning compensation: Not allowed to calculate.

•Purge control: Not allowed to purge

9. ECM OPERATION AT DTC SETTING

•Memorize the freeze frame data. (For test mode $02)

•Memorize the diagnostic value and trouble standard value. (For test mode $06)

Judgment Value

Malfunction Criteria Threshold Value

parafca = td2faf/td2lmd≥ 0.25

where,

td2faf (N) = td2faf (n–1) + |d2faf (n)|

td2lmd (N) = td2lmd (n–1) + |d2lmd (n)|

add up for a total of 300 seconds

d2faf (n) = (faf (n) – faf (n–1)) – (faf (n–1)

– faf (n–2))

d2lmd (n) = (lmd (n) – lmd (n–1)) – (lmd

(n–1) – lmd (n–2))

faf = main feedback compensation coef-

ficient every 128 milliseconds

lmd = output lambda every 128 millisec-

onds

Page 1734 of 2453

GD(H6DO)-122

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

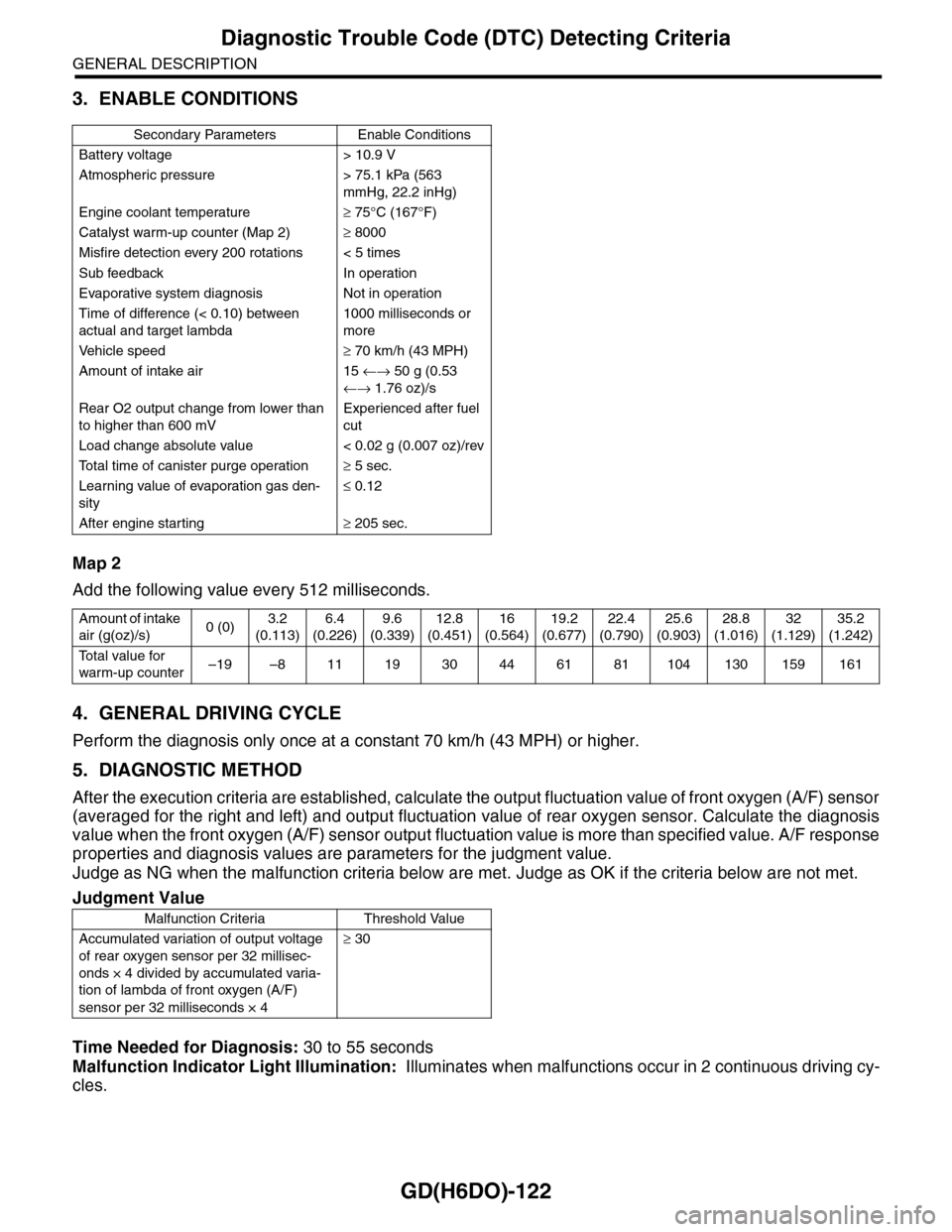

3. ENABLE CONDITIONS

Map 2

Add the following value every 512 milliseconds.

4. GENERAL DRIVING CYCLE

Perform the diagnosis only once at a constant 70 km/h (43 MPH) or higher.

5. DIAGNOSTIC METHOD

After the execution criteria are established, calculate the output fluctuation value of front oxygen (A/F) sensor

(averaged for the right and left) and output fluctuation value of rear oxygen sensor. Calculate the diagnosis

value when the front oxygen (A/F) sensor output fluctuation value is more than specified value. A/F response

properties and diagnosis values are parameters for the judgment value.

Judge as NG when the malfunction criteria below are met. Judge as OK if the criteria below are not met.

Time Needed for Diagnosis: 30 to 55 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Secondary Parameters Enable Conditions

Battery voltage > 10.9 V

Atmospheric pressure > 75.1 kPa (563

mmHg, 22.2 inHg)

Engine coolant temperature≥ 75°C (167°F)

Catalyst warm-up counter (Map 2)≥ 8000

Misfire detection every 200 rotations < 5 times

Sub feedback In operation

Evaporative system diagnosis Not in operation

Time of difference (< 0.10) between

actual and target lambda

1000 milliseconds or

more

Ve h i c l e s p e e d≥ 70 km/h (43 MPH)

Amount of intake air 15 ←→ 50 g (0.53

←→ 1.76 oz)/s

Rear O2 output change from lower than

to higher than 600 mV

Experienced after fuel

cut

Load change absolute value < 0.02 g (0.007 oz)/rev

To t a l t i m e o f c a n i s t e r p u r g e o p e r a t i o n≥ 5 sec.

Learning value of evaporation gas den-

sity

≤ 0.12

After engine starting≥ 205 sec.

Amount of intake

air (g(oz)/s)0 (0)3.2

(0.113)

6.4

(0.226)

9.6

(0.339)

12.8

(0.451)

16

(0.564)

19.2

(0.677)

22.4

(0.790)

25.6

(0.903)

28.8

(1.016)

32

(1.129)

35.2

(1.242)

To t a l v a l u e f o r

warm-up counter–19 –8 11 19 30 44 61 81 104 130 159 161

Judgment Value

Malfunction Criteria Threshold Value

Accumulated variation of output voltage

of rear oxygen sensor per 32 millisec-

onds × 4 divided by accumulated varia-

tion of lambda of front oxygen (A/F)

sensor per 32 milliseconds × 4

≥ 30

Page 1917 of 2453

ME(H6DO)-51

Rear Chain Cover

MECHANICAL

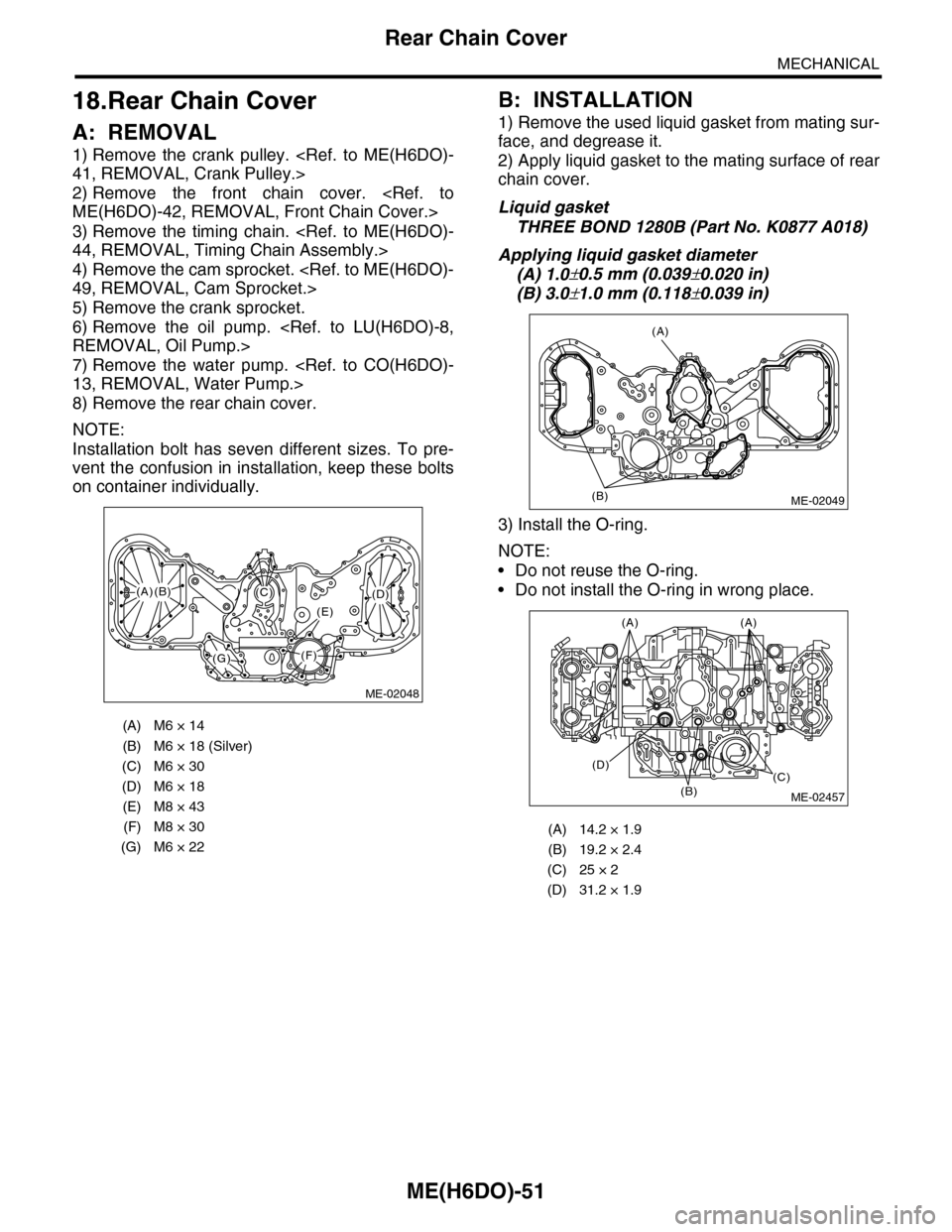

18.Rear Chain Cover

A: REMOVAL

1) Remove the crank pulley.

2) Remove the front chain cover.

3) Remove the timing chain.

4) Remove the cam sprocket.

5) Remove the crank sprocket.

6) Remove the oil pump.

7) Remove the water pump.

8) Remove the rear chain cover.

NOTE:

Installation bolt has seven different sizes. To pre-

vent the confusion in installation, keep these bolts

on container individually.

B: INSTALLATION

1) Remove the used liquid gasket from mating sur-

face, and degrease it.

2) Apply liquid gasket to the mating surface of rear

chain cover.

Liquid gasket

THREE BOND 1280B (Part No. K0877 A018)

Applying liquid gasket diameter

(A) 1.0±0.5 mm (0.039±0.020 in)

(B) 3.0±1.0 mm (0.118±0.039 in)

3) Install the O-ring.

NOTE:

•Do not reuse the O-ring.

•Do not install the O-ring in wrong place.

(A) M6 × 14

(B) M6 × 18 (Silver)

(C) M6 × 30

(D) M6 × 18

(E) M8 × 43

(F) M8 × 30

(G) M6 × 22

ME-02048

(F)

(C)(D)

(E)

(G)

(A)(B)

(A) 14.2 × 1.9

(B) 19.2 × 2.4

(C) 25 × 2

(D) 31.2 × 1.9

(A)

(B)ME-02049

(B)

(D)(C)

(A)(A)

ME-02457

Page 1929 of 2453

ME(H6DO)-63

Cylinder Block

MECHANICAL

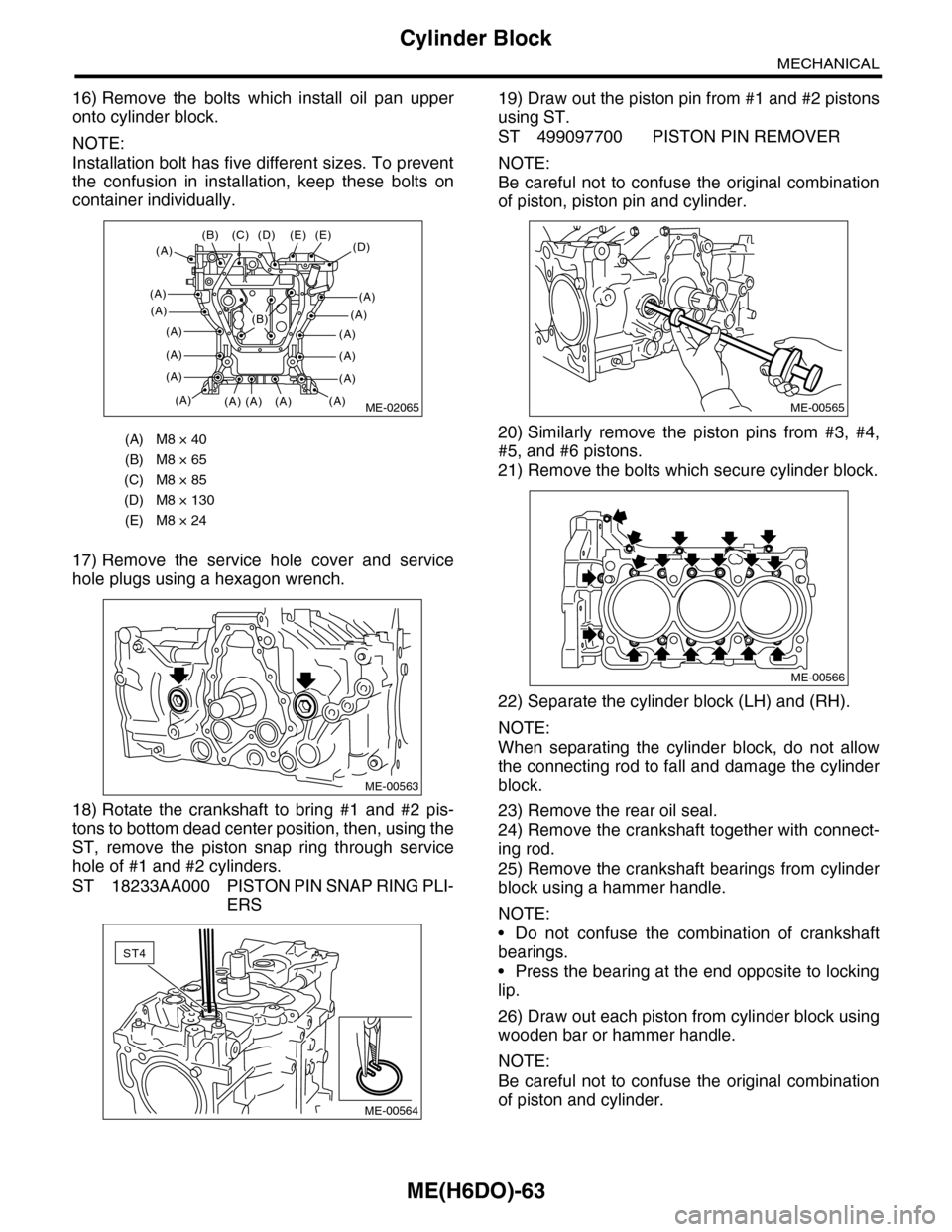

16) Remove the bolts which install oil pan upper

onto cylinder block.

NOTE:

Installation bolt has five different sizes. To prevent

the confusion in installation, keep these bolts on

container individually.

17) Remove the service hole cover and service

hole plugs using a hexagon wrench.

18) Rotate the crankshaft to bring #1 and #2 pis-

tons to bottom dead center position, then, using the

ST, remove the piston snap ring through service

hole of #1 and #2 cylinders.

ST 18233AA000 PISTON PIN SNAP RING PLI-

ERS

19) Draw out the piston pin from #1 and #2 pistons

using ST.

ST 499097700 PISTON PIN REMOVER

NOTE:

Be careful not to confuse the original combination

of piston, piston pin and cylinder.

20) Similarly remove the piston pins from #3, #4,

#5, and #6 pistons.

21) Remove the bolts which secure cylinder block.

22) Separate the cylinder block (LH) and (RH).

NOTE:

When separating the cylinder block, do not allow

the connecting rod to fall and damage the cylinder

block.

23) Remove the rear oil seal.

24) Remove the crankshaft together with connect-

ing rod.

25) Remove the crankshaft bearings from cylinder

block using a hammer handle.

NOTE:

•Do not confuse the combination of crankshaft

bearings.

•Press the bearing at the end opposite to locking

lip.

26) Draw out each piston from cylinder block using

wooden bar or hammer handle.

NOTE:

Be careful not to confuse the original combination

of piston and cylinder.

(A) M8 × 40

(B) M8 × 65

(C) M8 × 85

(D) M8 × 130

(E) M8 × 24

ME-02065

(D)(E)

(A)

(A)

(A)

(A)

(A)

(A)

(A)

(E)

(A)(A)(A)

(C)(B)

(A)

(D)

(A)

(A)

(A)

(A)

(A)

(B)

ME-00563

ST4

ME-00564

ME-00565

ME-00566