Repair manual SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1183 of 2453

EN(H6DO)(diag)-22

General Scan Tool

ENGINE (DIAGNOSTICS)

8. General Scan Tool

A: OPERATION

1. HOW TO USE GENERAL SCAN TOOL

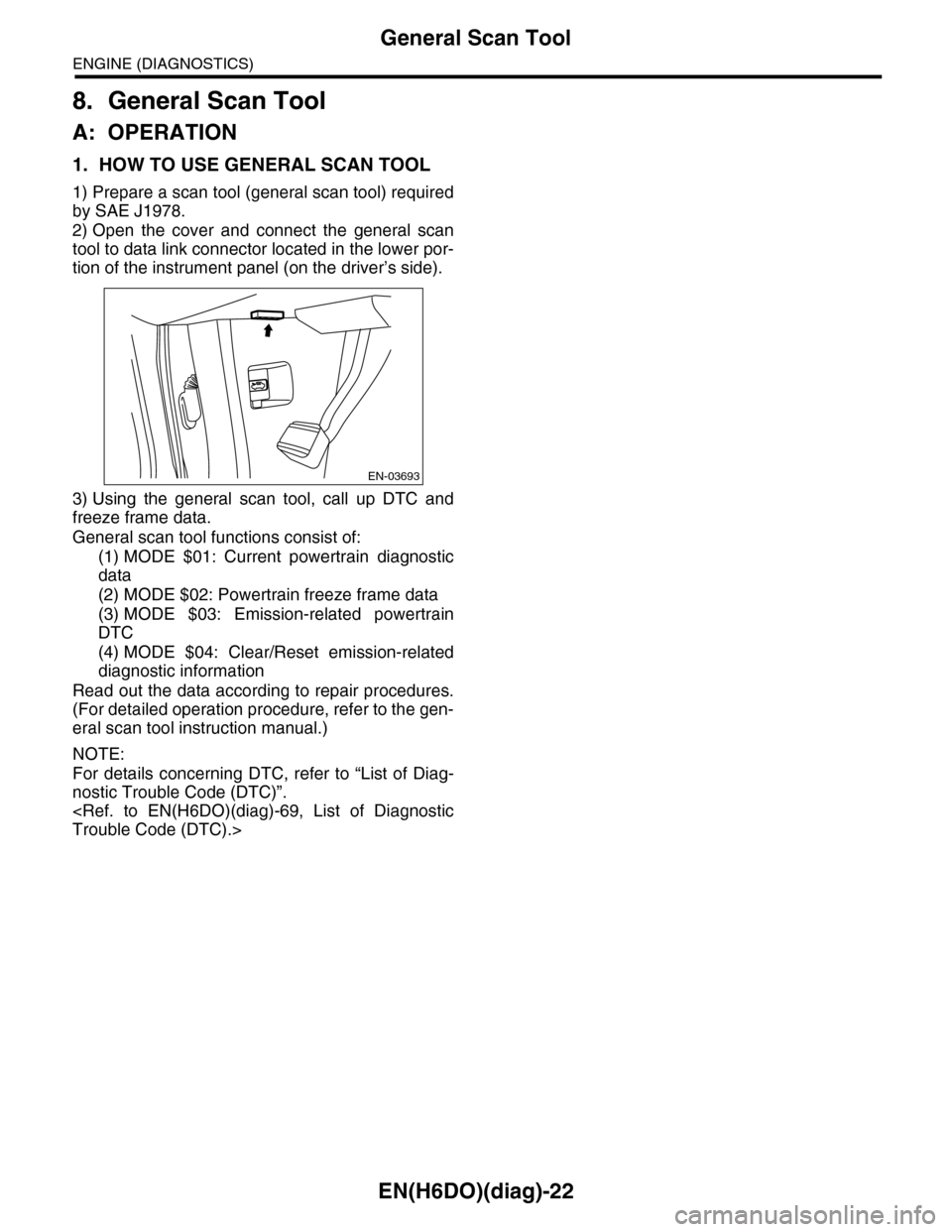

1) Prepare a scan tool (general scan tool) required

by SAE J1978.

2) Open the cover and connect the general scan

tool to data link connector located in the lower por-

tion of the instrument panel (on the driver’s side).

3) Using the general scan tool, call up DTC and

freeze frame data.

General scan tool functions consist of:

(1) MODE $01: Current powertrain diagnostic

data

(2) MODE $02: Powertrain freeze frame data

(3) MODE $03: Emission-related powertrain

DTC

(4) MODE $04: Clear/Reset emission-related

diagnostic information

Read out the data according to repair procedures.

(For detailed operation procedure, refer to the gen-

eral scan tool instruction manual.)

NOTE:

For details concerning DTC, refer to “List of Diag-

nostic Trouble Code (DTC)”.

EN-03693

Page 1238 of 2453

EN(H6DO)(diag)-77

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

18.Diagnostic Procedure with Diagnostic Trouble Code (DTC)

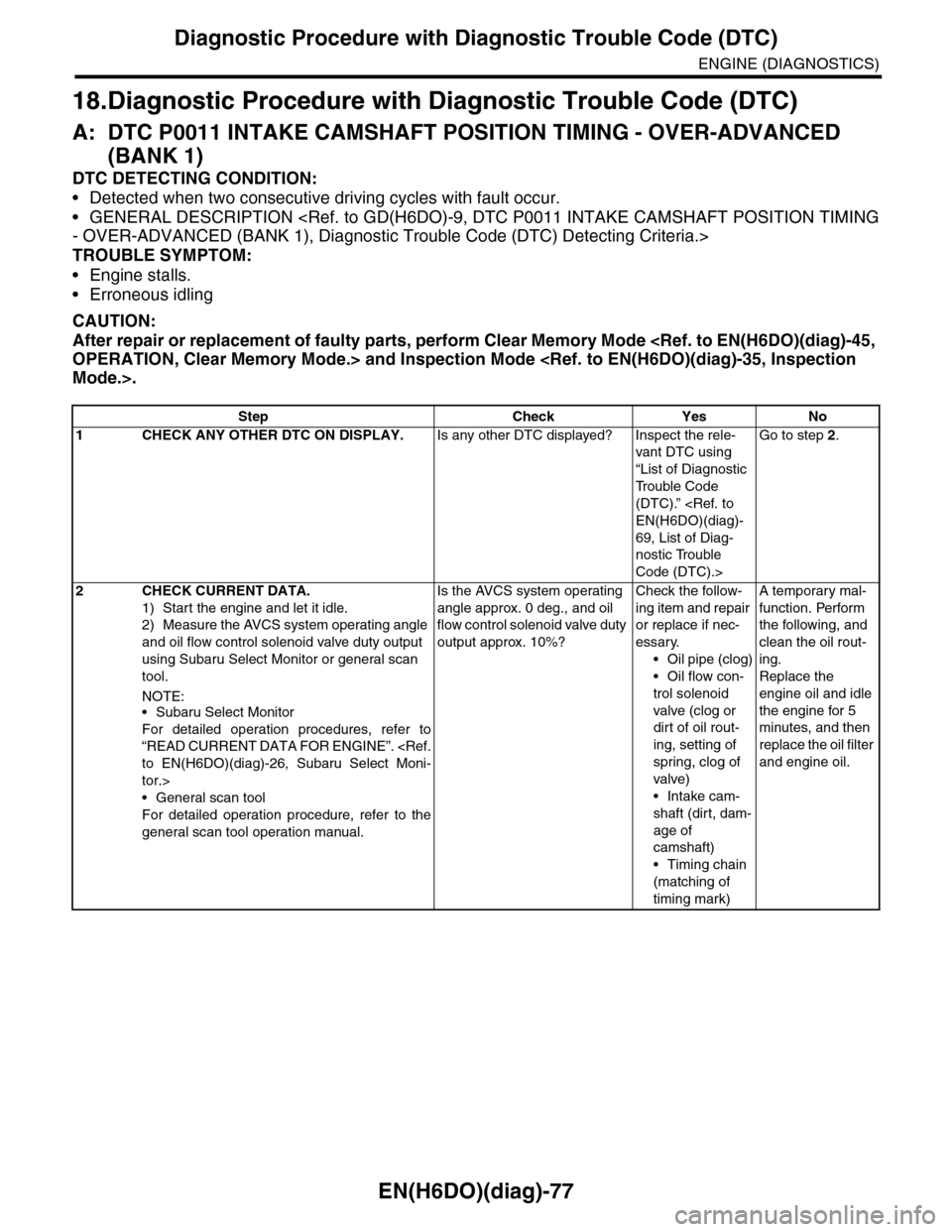

A: DTC P0011 INTAKE CAMSHAFT POSITION TIMING - OVER-ADVANCED

(BANK 1)

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Engine stalls.

•Erroneous idling

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC).”

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK CURRENT DATA.

1) Start the engine and let it idle.

2) Measure the AVCS system operating angle

and oil flow control solenoid valve duty output

using Subaru Select Monitor or general scan

tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the AVCS system operating

angle approx. 0 deg., and oil

flow control solenoid valve duty

output approx. 10%?

Check the follow-

ing item and repair

or replace if nec-

essary.

•Oil pipe (clog)

•Oil flow con-

trol solenoid

valve (clog or

dirt of oil rout-

ing, setting of

spring, clog of

valve)

•Intake cam-

shaft (dirt, dam-

age of

camshaft)

•Timing chain

(matching of

timing mark)

A temporary mal-

function. Perform

the following, and

clean the oil rout-

ing.

Replace the

engine oil and idle

the engine for 5

minutes, and then

replace the oil filter

and engine oil.

Page 1239 of 2453

EN(H6DO)(diag)-78

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

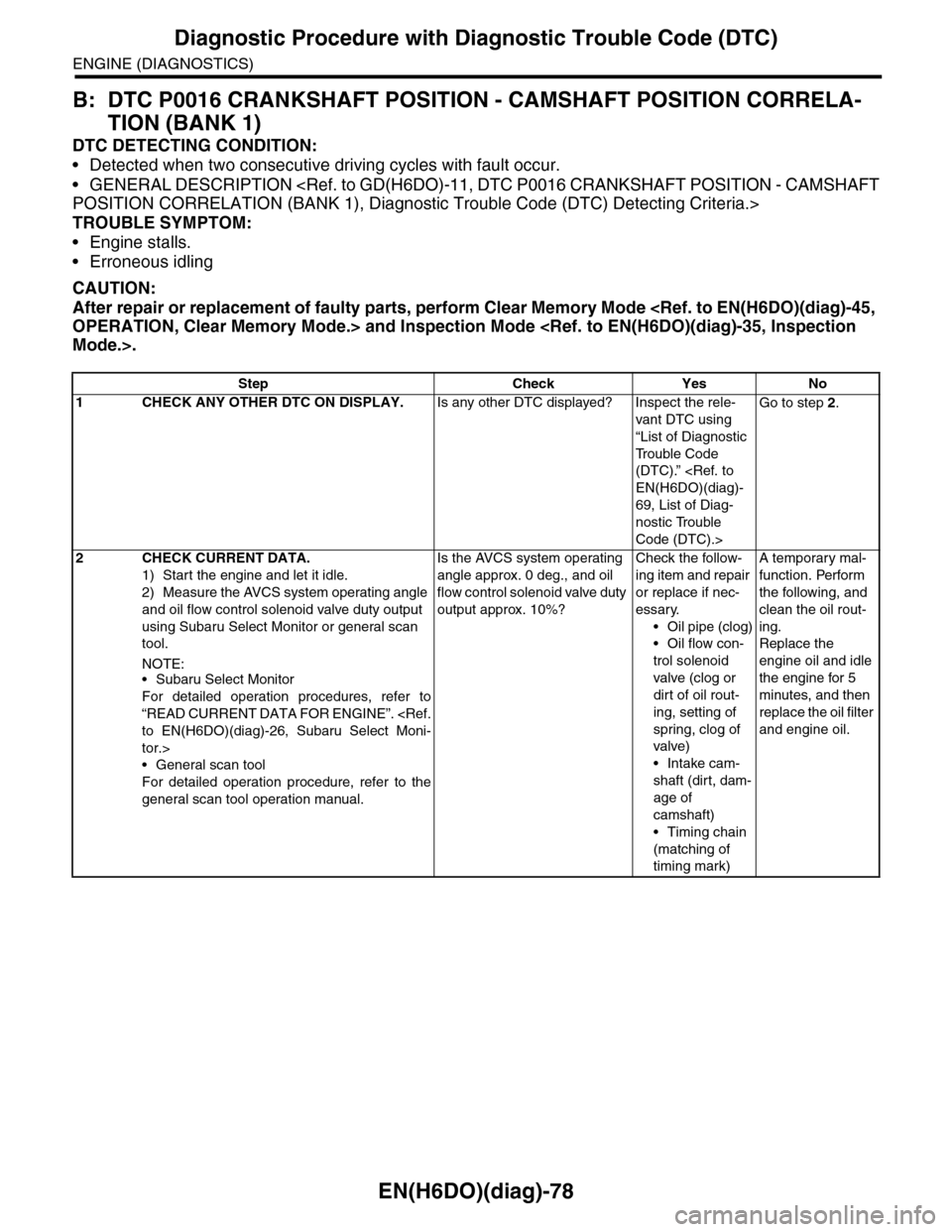

B: DTC P0016 CRANKSHAFT POSITION - CAMSHAFT POSITION CORRELA-

TION (BANK 1)

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Engine stalls.

•Erroneous idling

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC).”

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK CURRENT DATA.

1) Start the engine and let it idle.

2) Measure the AVCS system operating angle

and oil flow control solenoid valve duty output

using Subaru Select Monitor or general scan

tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the AVCS system operating

angle approx. 0 deg., and oil

flow control solenoid valve duty

output approx. 10%?

Check the follow-

ing item and repair

or replace if nec-

essary.

•Oil pipe (clog)

•Oil flow con-

trol solenoid

valve (clog or

dirt of oil rout-

ing, setting of

spring, clog of

valve)

•Intake cam-

shaft (dirt, dam-

age of

camshaft)

•Timing chain

(matching of

timing mark)

A temporary mal-

function. Perform

the following, and

clean the oil rout-

ing.

Replace the

engine oil and idle

the engine for 5

minutes, and then

replace the oil filter

and engine oil.

Page 1240 of 2453

EN(H6DO)(diag)-79

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

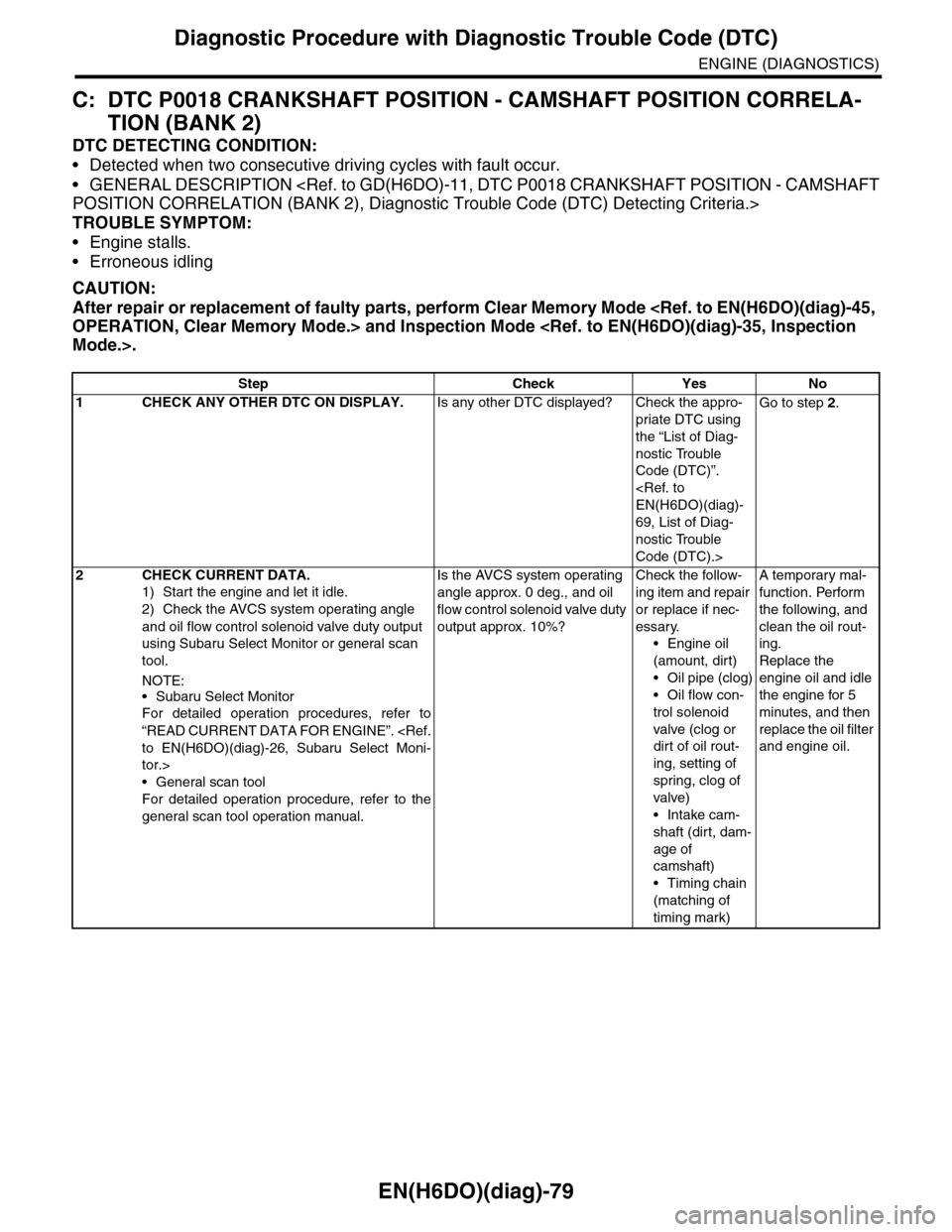

C: DTC P0018 CRANKSHAFT POSITION - CAMSHAFT POSITION CORRELA-

TION (BANK 2)

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Engine stalls.

•Erroneous idling

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK CURRENT DATA.

1) Start the engine and let it idle.

2) Check the AVCS system operating angle

and oil flow control solenoid valve duty output

using Subaru Select Monitor or general scan

tool.

NOTE:

•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the AVCS system operating

angle approx. 0 deg., and oil

flow control solenoid valve duty

output approx. 10%?

Check the follow-

ing item and repair

or replace if nec-

essary.

•Engine oil

(amount, dirt)

•Oil pipe (clog)

•Oil flow con-

trol solenoid

valve (clog or

dirt of oil rout-

ing, setting of

spring, clog of

valve)

•Intake cam-

shaft (dirt, dam-

age of

camshaft)

•Timing chain

(matching of

timing mark)

A temporary mal-

function. Perform

the following, and

clean the oil rout-

ing.

Replace the

engine oil and idle

the engine for 5

minutes, and then

replace the oil filter

and engine oil.

Page 1241 of 2453

EN(H6DO)(diag)-80

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

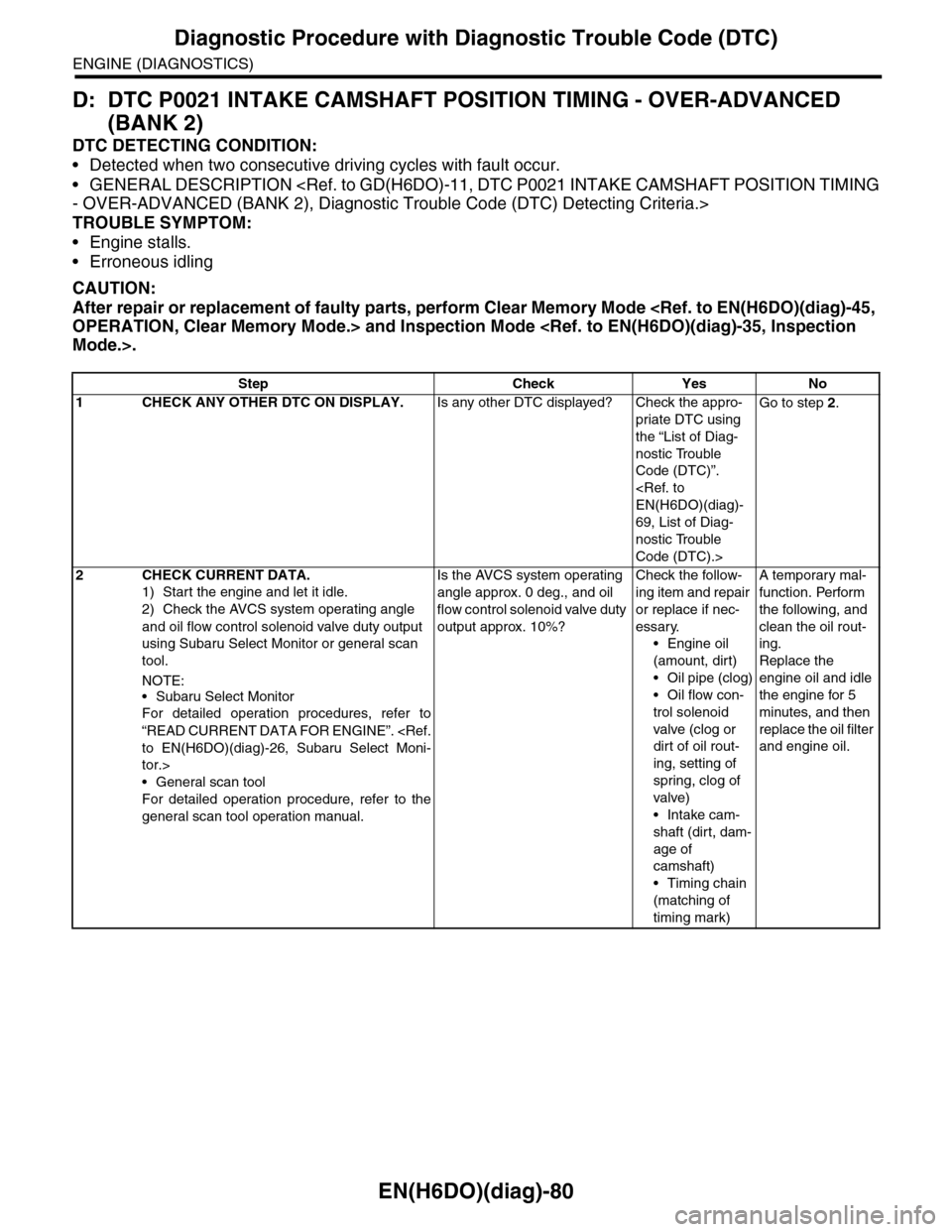

D: DTC P0021 INTAKE CAMSHAFT POSITION TIMING - OVER-ADVANCED

(BANK 2)

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Engine stalls.

•Erroneous idling

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK CURRENT DATA.

1) Start the engine and let it idle.

2) Check the AVCS system operating angle

and oil flow control solenoid valve duty output

using Subaru Select Monitor or general scan

tool.

NOTE:

•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the AVCS system operating

angle approx. 0 deg., and oil

flow control solenoid valve duty

output approx. 10%?

Check the follow-

ing item and repair

or replace if nec-

essary.

•Engine oil

(amount, dirt)

•Oil pipe (clog)

•Oil flow con-

trol solenoid

valve (clog or

dirt of oil rout-

ing, setting of

spring, clog of

valve)

•Intake cam-

shaft (dirt, dam-

age of

camshaft)

•Timing chain

(matching of

timing mark)

A temporary mal-

function. Perform

the following, and

clean the oil rout-

ing.

Replace the

engine oil and idle

the engine for 5

minutes, and then

replace the oil filter

and engine oil.

Page 1251 of 2453

EN(H6DO)(diag)-90

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

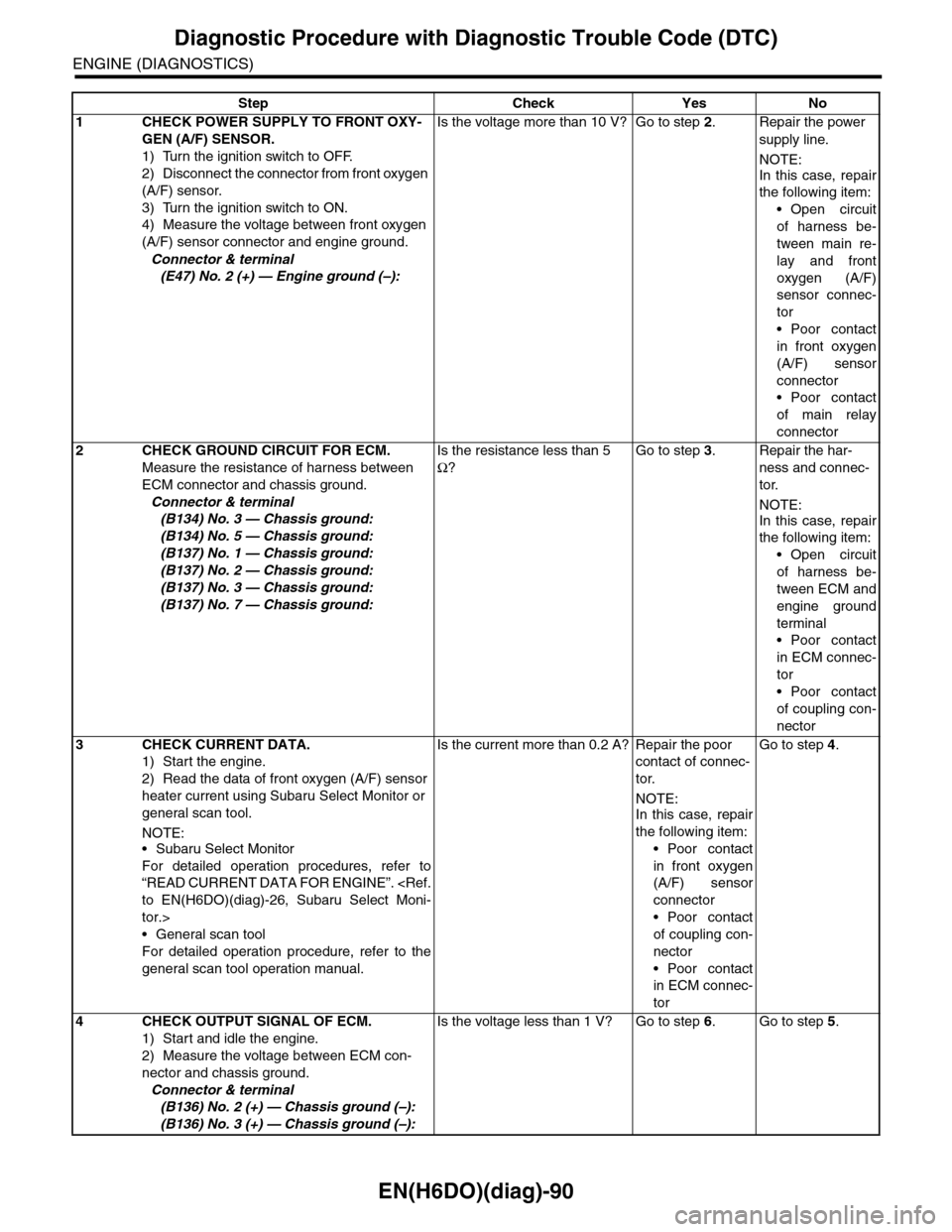

Step Check Yes No

1 CHECK POWER SUPPLY TO FRONT OXY-

GEN (A/F) SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from front oxygen

(A/F) sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between front oxygen

(A/F) sensor connector and engine ground.

Connector & terminal

(E47) No. 2 (+) — Engine ground (–):

Is the voltage more than 10 V? Go to step 2.Repair the power

supply line.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween main re-

lay and front

oxygen (A/F)

sensor connec-

tor

•Poor contact

in front oxygen

(A/F) sensor

connector

•Poor contact

of main relay

connector

2CHECK GROUND CIRCUIT FOR ECM.

Measure the resistance of harness between

ECM connector and chassis ground.

Connector & terminal

(B134) No. 3 — Chassis ground:

(B134) No. 5 — Chassis ground:

(B137) No. 1 — Chassis ground:

(B137) No. 2 — Chassis ground:

(B137) No. 3 — Chassis ground:

(B137) No. 7 — Chassis ground:

Is the resistance less than 5

Ω?

Go to step 3.Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

engine ground

terminal

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

3CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of front oxygen (A/F) sensor

heater current using Subaru Select Monitor or

general scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the current more than 0.2 A? Repair the poor

contact of connec-

tor.

NOTE:

In this case, repair

the following item:

•Poor contact

in front oxygen

(A/F) sensor

connector

•Poor contact

of coupling con-

nector

•Poor contact

in ECM connec-

tor

Go to step 4.

4CHECK OUTPUT SIGNAL OF ECM.

1) Start and idle the engine.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 2 (+) — Chassis ground (–):

(B136) No. 3 (+) — Chassis ground (–):

Is the voltage less than 1 V? Go to step 6.Go to step 5.

Page 1255 of 2453

EN(H6DO)(diag)-94

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

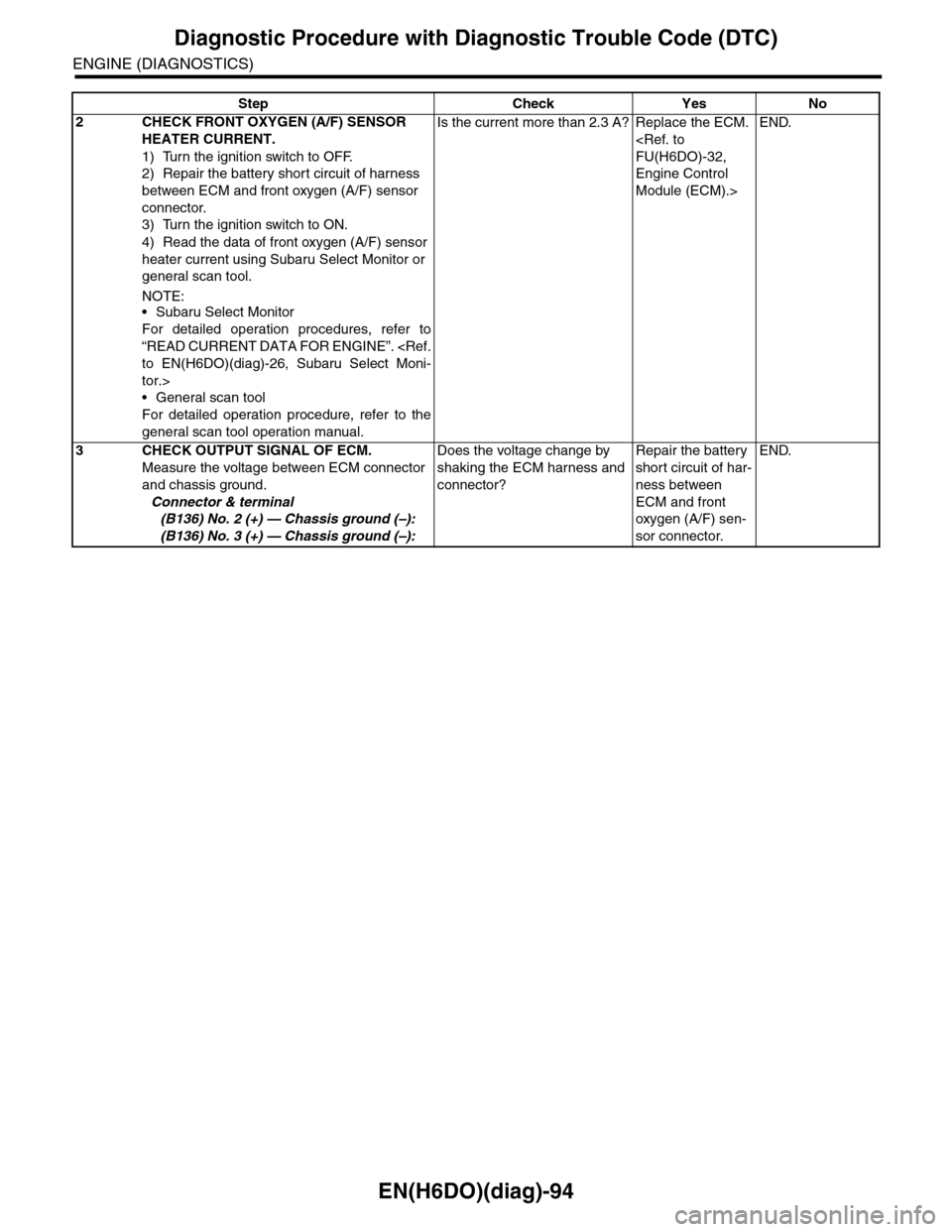

2CHECK FRONT OXYGEN (A/F) SENSOR

HEATER CURRENT.

1) Turn the ignition switch to OFF.

2) Repair the battery short circuit of harness

between ECM and front oxygen (A/F) sensor

connector.

3) Turn the ignition switch to ON.

4) Read the data of front oxygen (A/F) sensor

heater current using Subaru Select Monitor or

general scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the current more than 2.3 A? Replace the ECM.

Engine Control

Module (ECM).>

END.

3CHECK OUTPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B136) No. 2 (+) — Chassis ground (–):

(B136) No. 3 (+) — Chassis ground (–):

Does the voltage change by

shaking the ECM harness and

connector?

Repair the battery

short circuit of har-

ness between

ECM and front

oxygen (A/F) sen-

sor connector.

END.

Step Check Yes No

Page 1258 of 2453

EN(H6DO)(diag)-97

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

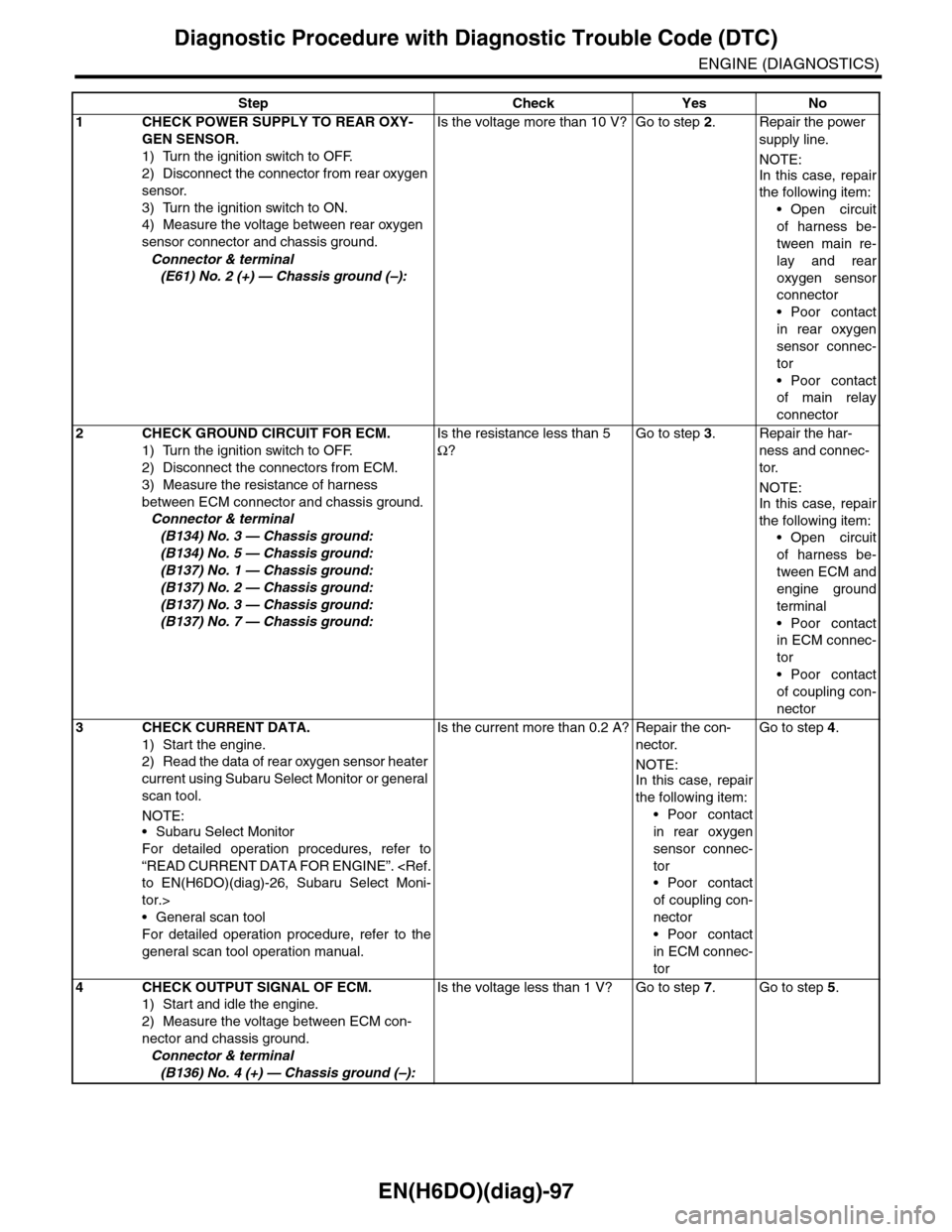

Step Check Yes No

1CHECK POWER SUPPLY TO REAR OXY-

GEN SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from rear oxygen

sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between rear oxygen

sensor connector and chassis ground.

Connector & terminal

(E61) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Repair the power

supply line.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween main re-

lay and rear

oxygen sensor

connector

•Poor contact

in rear oxygen

sensor connec-

tor

•Poor contact

of main relay

connector

2CHECK GROUND CIRCUIT FOR ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between ECM connector and chassis ground.

Connector & terminal

(B134) No. 3 — Chassis ground:

(B134) No. 5 — Chassis ground:

(B137) No. 1 — Chassis ground:

(B137) No. 2 — Chassis ground:

(B137) No. 3 — Chassis ground:

(B137) No. 7 — Chassis ground:

Is the resistance less than 5

Ω?

Go to step 3.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

engine ground

terminal

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

3CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of rear oxygen sensor heater

current using Subaru Select Monitor or general

scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the current more than 0.2 A? Repair the con-

nector.

NOTE:In this case, repair

the following item:

•Poor contact

in rear oxygen

sensor connec-

tor

•Poor contact

of coupling con-

nector

•Poor contact

in ECM connec-

tor

Go to step 4.

4CHECK OUTPUT SIGNAL OF ECM.

1) Start and idle the engine.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 4 (+) — Chassis ground (–):

Is the voltage less than 1 V? Go to step 7.Go to step 5.

Page 1262 of 2453

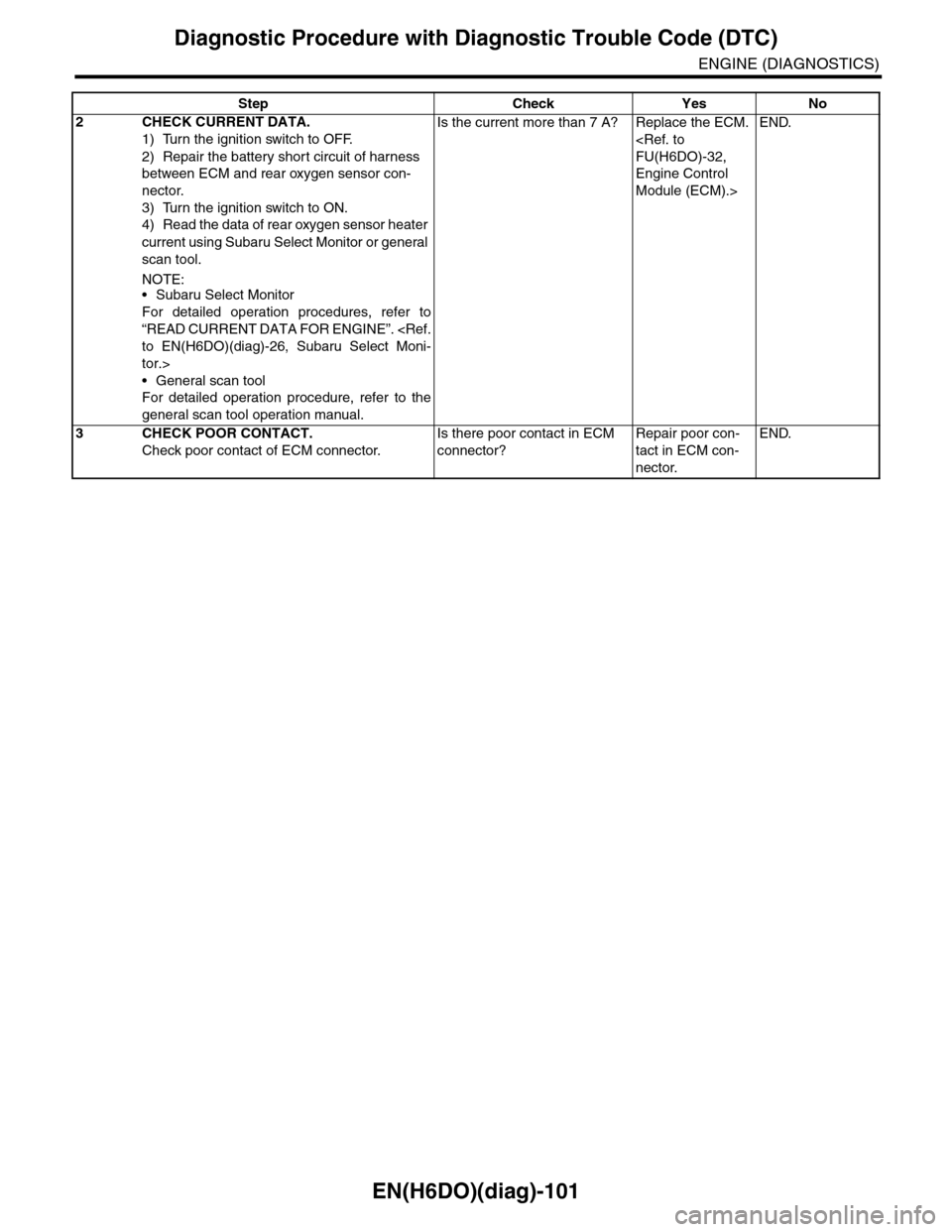

EN(H6DO)(diag)-101

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

2CHECK CURRENT DATA.

1) Turn the ignition switch to OFF.

2) Repair the battery short circuit of harness

between ECM and rear oxygen sensor con-

nector.

3) Turn the ignition switch to ON.

4) Read the data of rear oxygen sensor heater

current using Subaru Select Monitor or general

scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the current more than 7 A? Replace the ECM.

Engine Control

Module (ECM).>

END.

3CHECK POOR CONTACT.

Check poor contact of ECM connector.

Is there poor contact in ECM

connector?

Repair poor con-

tact in ECM con-

nector.

END.

Step Check Yes No

Page 1268 of 2453

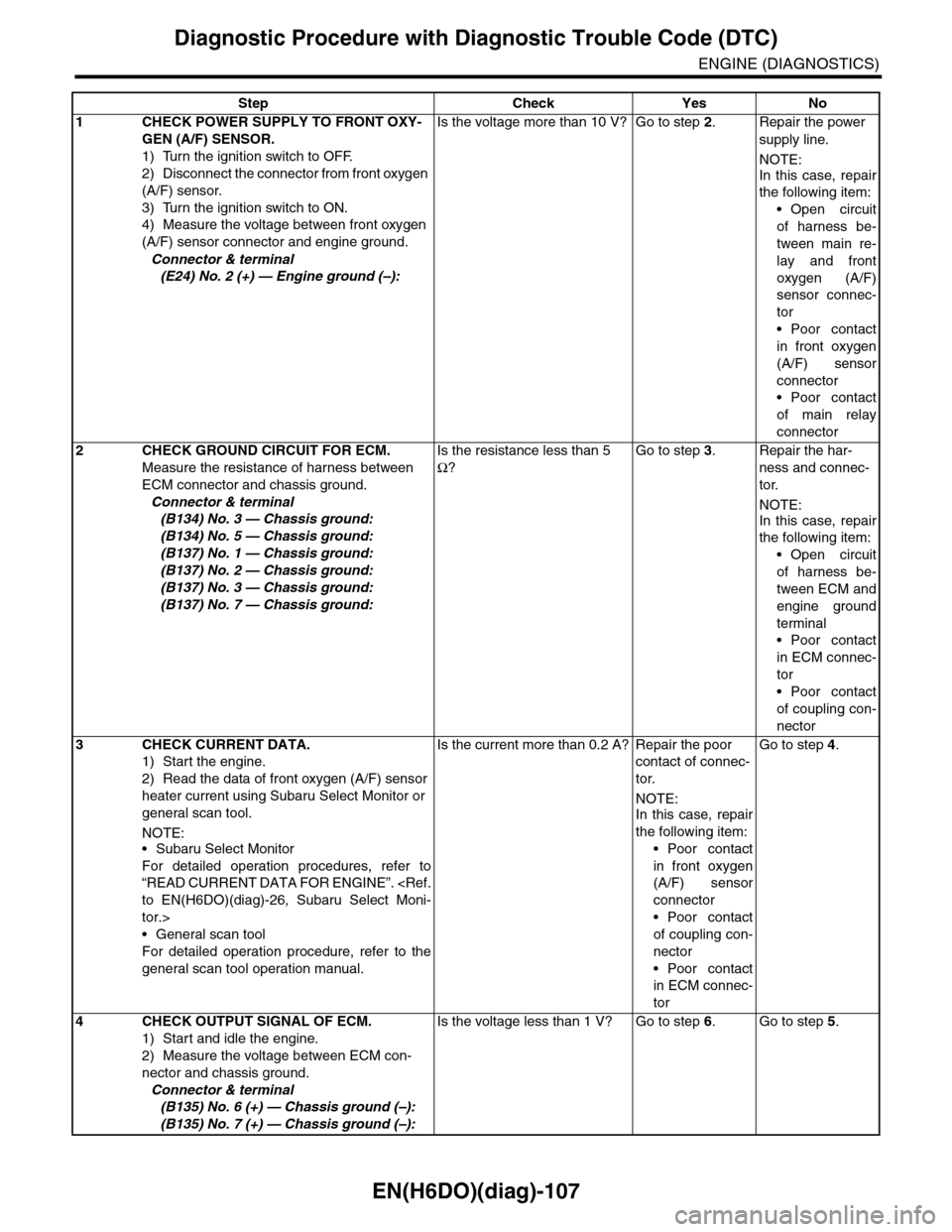

EN(H6DO)(diag)-107

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

1 CHECK POWER SUPPLY TO FRONT OXY-

GEN (A/F) SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from front oxygen

(A/F) sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between front oxygen

(A/F) sensor connector and engine ground.

Connector & terminal

(E24) No. 2 (+) — Engine ground (–):

Is the voltage more than 10 V? Go to step 2.Repair the power

supply line.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween main re-

lay and front

oxygen (A/F)

sensor connec-

tor

•Poor contact

in front oxygen

(A/F) sensor

connector

•Poor contact

of main relay

connector

2CHECK GROUND CIRCUIT FOR ECM.

Measure the resistance of harness between

ECM connector and chassis ground.

Connector & terminal

(B134) No. 3 — Chassis ground:

(B134) No. 5 — Chassis ground:

(B137) No. 1 — Chassis ground:

(B137) No. 2 — Chassis ground:

(B137) No. 3 — Chassis ground:

(B137) No. 7 — Chassis ground:

Is the resistance less than 5

Ω?

Go to step 3.Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

engine ground

terminal

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

3CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of front oxygen (A/F) sensor

heater current using Subaru Select Monitor or

general scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the current more than 0.2 A? Repair the poor

contact of connec-

tor.

NOTE:

In this case, repair

the following item:

•Poor contact

in front oxygen

(A/F) sensor

connector

•Poor contact

of coupling con-

nector

•Poor contact

in ECM connec-

tor

Go to step 4.

4CHECK OUTPUT SIGNAL OF ECM.

1) Start and idle the engine.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B135) No. 6 (+) — Chassis ground (–):

(B135) No. 7 (+) — Chassis ground (–):

Is the voltage less than 1 V? Go to step 6.Go to step 5.