height SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 806 of 2453

DI-22

Rear Differential (VA–type)

DIFFERENTIALS

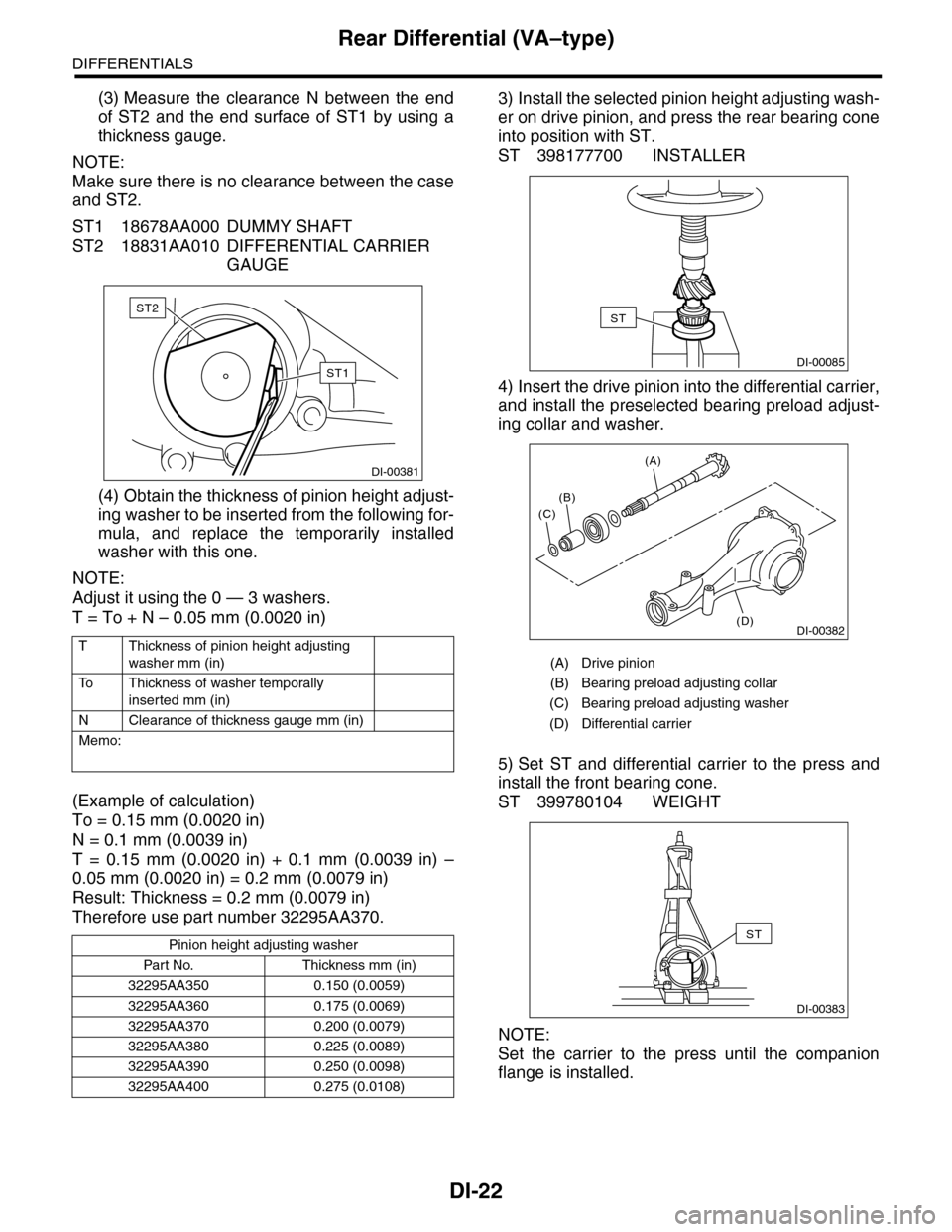

(3) Measure the clearance N between the end

of ST2 and the end surface of ST1 by using a

thickness gauge.

NOTE:

Make sure there is no clearance between the case

and ST2.

ST1 18678AA000 DUMMY SHAFT

ST2 18831AA010 DIFFERENTIAL CARRIER

GAUGE

(4) Obtain the thickness of pinion height adjust-

ing washer to be inserted from the following for-

mula, and replace the temporarily installed

washer with this one.

NOTE:

Adjust it using the 0 — 3 washers.

T = To + N – 0.05 mm (0.0020 in)

(Example of calculation)

To = 0.15 mm (0.0020 in)

N = 0.1 mm (0.0039 in)

T = 0.15 mm (0.0020 in) + 0.1 mm (0.0039 in) –

0.05 mm (0.0020 in) = 0.2 mm (0.0079 in)

Result: Thickness = 0.2 mm (0.0079 in)

Therefore use part number 32295AA370.

3) Install the selected pinion height adjusting wash-

er on drive pinion, and press the rear bearing cone

into position with ST.

ST 398177700 INSTALLER

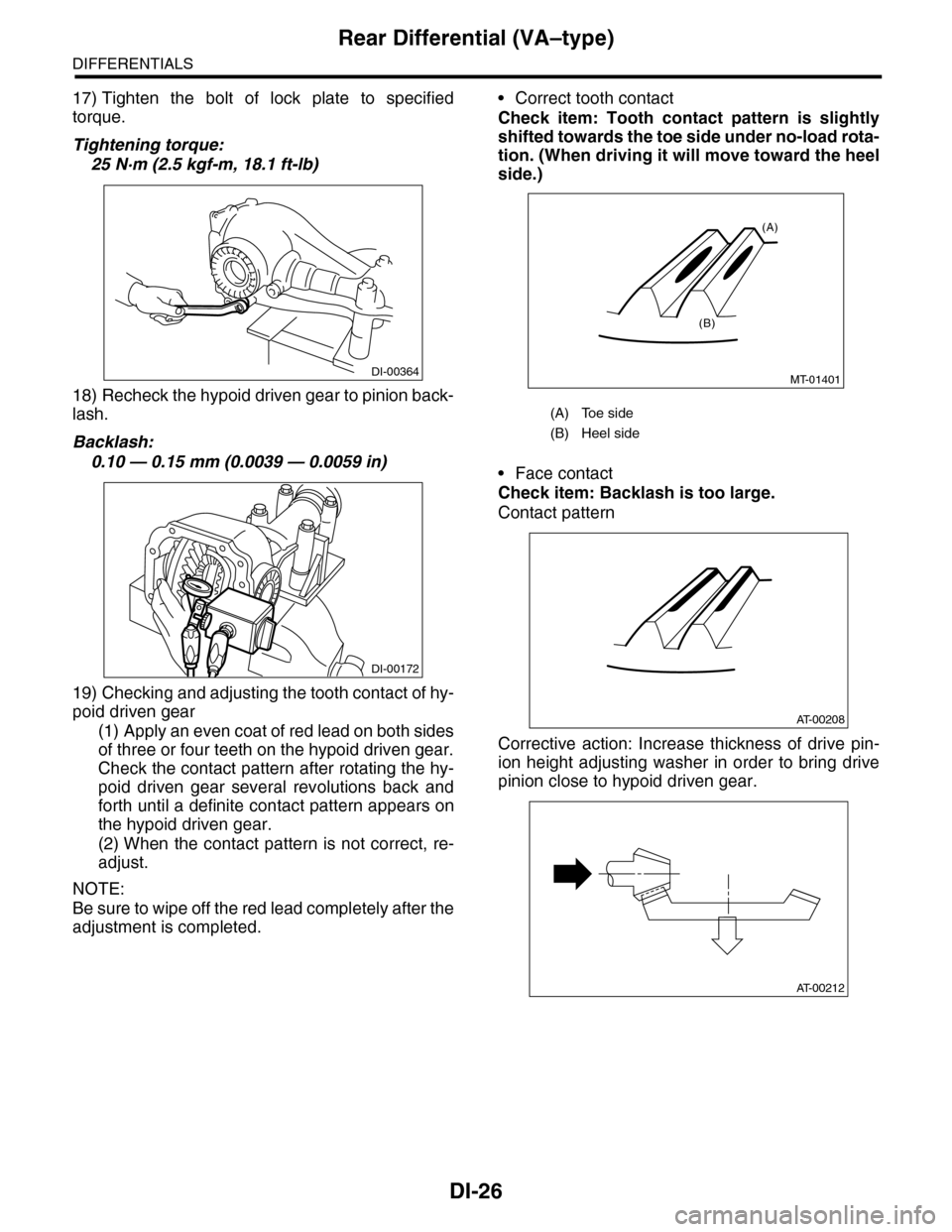

4) Insert the drive pinion into the differential carrier,

and install the preselected bearing preload adjust-

ing collar and washer.

5) Set ST and differential carrier to the press and

install the front bearing cone.

ST 399780104 WEIGHT

NOTE:

Set the carrier to the press until the companion

flange is installed.

TThickness of pinion height adjusting

washer mm (in)

To T h i c k n e s s o f w a s h e r t e m p o r a l l y

inserted mm (in)

NClearance of thickness gauge mm (in)

Memo:

Pinion height adjusting washer

Par t No. Thickness mm (in)

32295AA350 0.150 (0.0059)

32295AA360 0.175 (0.0069)

32295AA370 0.200 (0.0079)

32295AA380 0.225 (0.0089)

32295AA390 0.250 (0.0098)

32295AA400 0.275 (0.0108)

DI-00381

ST2

ST1

(A) Drive pinion

(B) Bearing preload adjusting collar

(C) Bearing preload adjusting washer

(D) Differential carrier

ST

DI-00085

(D)

(A)

(B)

(C)

DI-00382

ST

DI-00383

Page 810 of 2453

DI-26

Rear Differential (VA–type)

DIFFERENTIALS

17) Tighten the bolt of lock plate to specified

torque.

Tightening torque:

25 N·m (2.5 kgf-m, 18.1 ft-lb)

18) Recheck the hypoid driven gear to pinion back-

lash.

Backlash:

0.10 — 0.15 mm (0.0039 — 0.0059 in)

19) Checking and adjusting the tooth contact of hy-

poid driven gear

(1) Apply an even coat of red lead on both sides

of three or four teeth on the hypoid driven gear.

Check the contact pattern after rotating the hy-

poid driven gear several revolutions back and

forth until a definite contact pattern appears on

the hypoid driven gear.

(2) When the contact pattern is not correct, re-

adjust.

NOTE:

Be sure to wipe off the red lead completely after the

adjustment is completed.

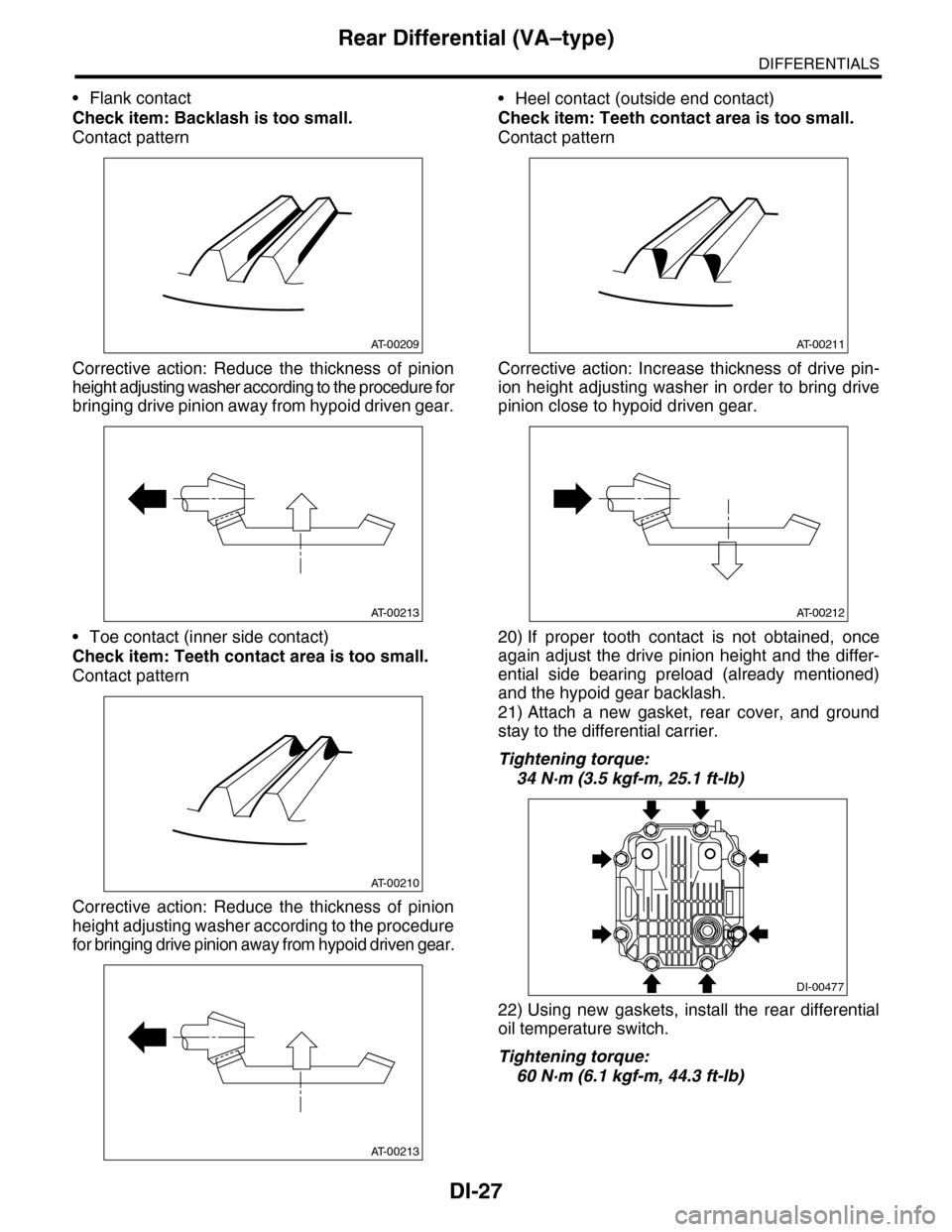

•Correct tooth contact

Check item: Tooth contact pattern is slightly

shifted towards the toe side under no-load rota-

tion. (When driving it will move toward the heel

side.)

•Face contact

Check item: Backlash is too large.

Contact pattern

Corrective action: Increase thickness of drive pin-

ion height adjusting washer in order to bring drive

pinion close to hypoid driven gear.

DI-00364

DI-00172

(A) Toe side

(B) Heel side

MT-01401

(A)

(B)

AT-00208

AT-00212

Page 811 of 2453

DI-27

Rear Differential (VA–type)

DIFFERENTIALS

•Flank contact

Check item: Backlash is too small.

Contact pattern

Corrective action: Reduce the thickness of pinion

height adjusting washer according to the procedure for

bringing drive pinion away from hypoid driven gear.

•Toe contact (inner side contact)

Check item: Teeth contact area is too small.

Contact pattern

Corrective action: Reduce the thickness of pinion

height adjusting washer according to the procedure

for bringing drive pinion away from hypoid driven gear.

•Heel contact (outside end contact)

Check item: Teeth contact area is too small.

Contact pattern

Corrective action: Increase thickness of drive pin-

ion height adjusting washer in order to bring drive

pinion close to hypoid driven gear.

20) If proper tooth contact is not obtained, once

again adjust the drive pinion height and the differ-

ential side bearing preload (already mentioned)

and the hypoid gear backlash.

21) Attach a new gasket, rear cover, and ground

stay to the differential carrier.

Tightening torque:

34 N·m (3.5 kgf-m, 25.1 ft-lb)

22) Using new gaskets, install the rear differential

oil temperature switch.

Tightening torque:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

AT-00209

AT-00213

AT-00210

AT-00213

AT-00211

AT-00212

DI-00477

Page 850 of 2453

FS-2

General Description

FRONT SUSPENSION

1. General Description

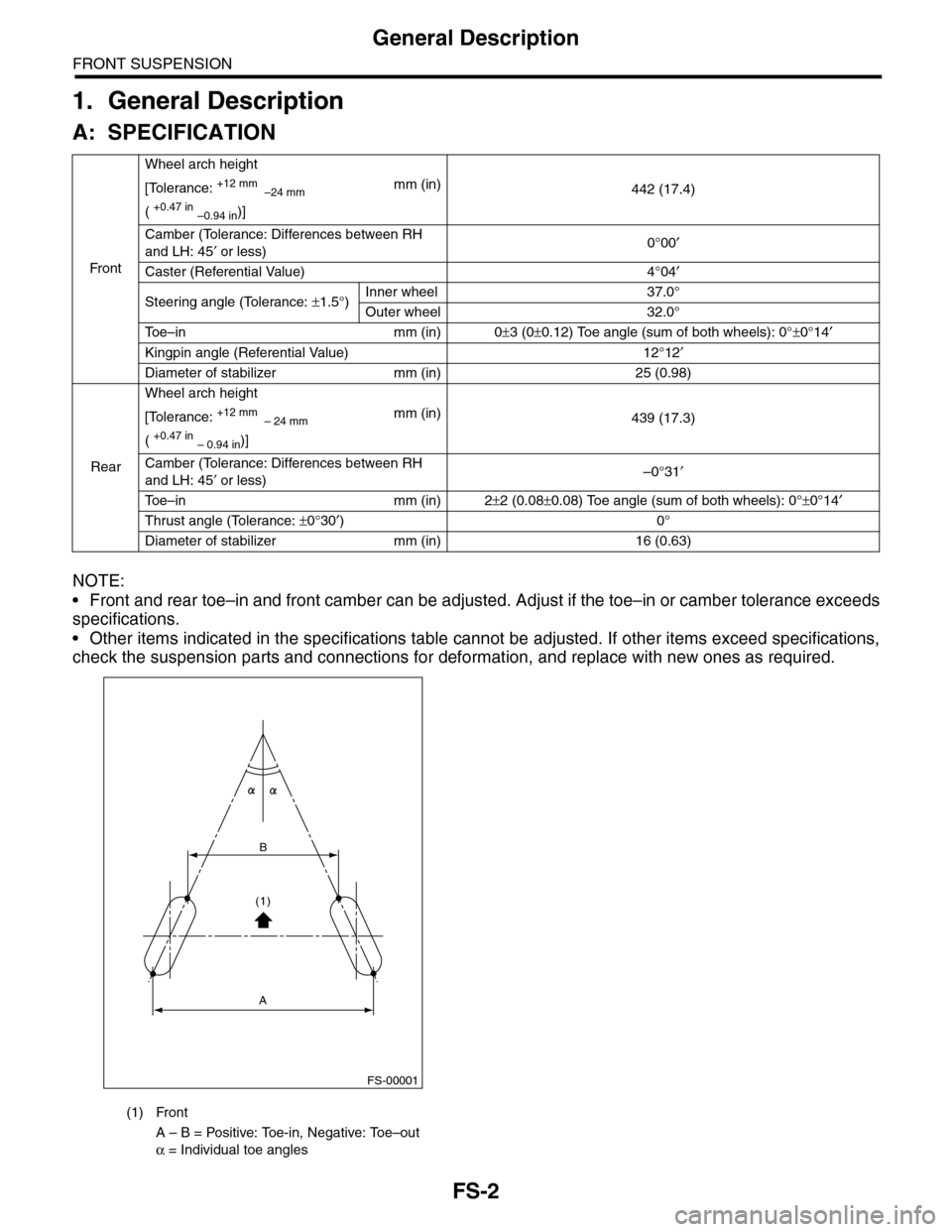

A: SPECIFICATION

NOTE:

•Front and rear toe–in and front camber can be adjusted. Adjust if the toe–in or camber tolerance exceeds

specifications.

•Other items indicated in the specifications table cannot be adjusted. If other items exceed specifications,

check the suspension parts and connections for deformation, and replace with new ones as required.

Fr o nt

Wheel arch height

442 (17.4)[Tolerance: +12 mm –24 mm

( +0.47 in –0.94 in)]

mm (in)

Camber (Tolerance: Differences between RH

and LH: 45′ or less)0°00′

Caster (Referential Value) 4°04′

Steering angle (Tolerance: ±1.5°)Inner wheel 37.0°

Outer wheel 32.0°

To e – i n m m ( i n ) 0±3 (0±0.12) Toe angle (sum of both wheels): 0°±0°14′

Kingpin angle (Referential Value) 12°12′

Diameter of stabilizer mm (in) 25 (0.98)

Rear

Wheel arch height

439 (17.3)[Tolerance: +12 mm – 24 mm

( +0.47 in – 0.94 in)]

mm (in)

Camber (Tolerance: Differences between RH

and LH: 45′ or less)–0°31′

To e – i n m m ( i n ) 2±2 (0.08±0.08) Toe angle (sum of both wheels): 0°±0°14′

Thrust angle (Tolerance: ±0°30′)0°

Diameter of stabilizer mm (in) 16 (0.63)

(1) Front

A – B = Positive: Toe-in, Negative: Toe–out

α = Individual toe angles

FS-00001

B

A

(1)

Page 854 of 2453

FS-6

Wheel Alignment

FRONT SUSPENSION

2. Wheel Alignment

A: INSPECTION

Check the following items before performing the wheel alignment measurement.

Check items before measuring wheel alignment:

•Tire inflation pressure

•Uneven wear of RH and LH tires, or difference of sizes

•Tire runout

•Excessive play and wear of ball joint

•Excessive play and wear of tie rod end

•Excessive play of wheel bearing

•Right and left wheel base imbalance

•Deformation and excessive play of steering link

•Deformation and excessive play of suspension parts

Check, adjust and measure the wheel alignment in accordance with the procedures indicated in the figure.

Wheel arch height (front and rear wheels)

↓

Camber (front and rear wheels)

↓

Caster (front wheel)

↓

Steering angle

↓

Fr o nt wh ee l to e –i n

↓

Rear wheel toe–in

↓

Thrust angle

Page 855 of 2453

FS-7

Wheel Alignment

FRONT SUSPENSION

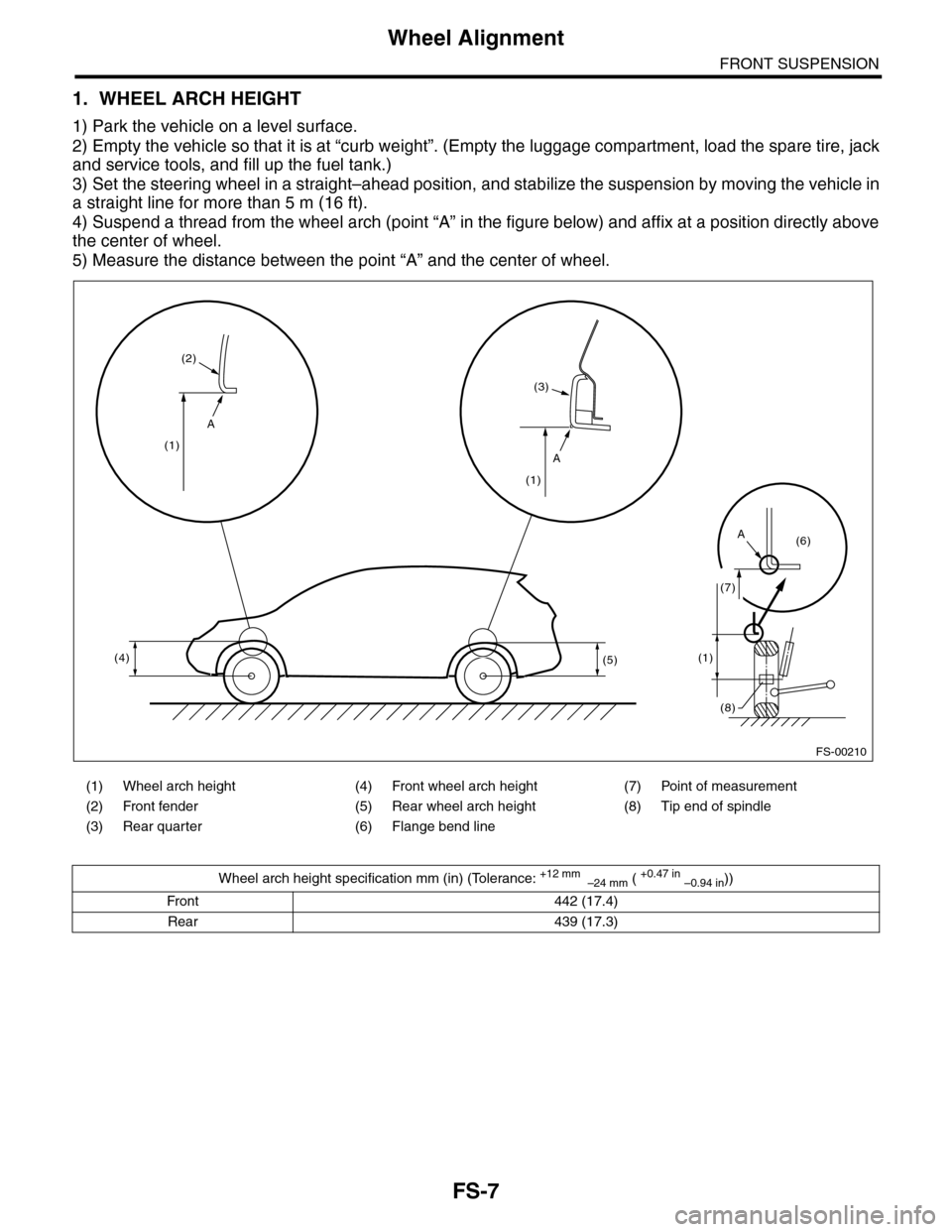

1. WHEEL ARCH HEIGHT

1) Park the vehicle on a level surface.

2) Empty the vehicle so that it is at “curb weight”. (Empty the luggage compartment, load the spare tire, jack

and service tools, and fill up the fuel tank.)

3) Set the steering wheel in a straight–ahead position, and stabilize the suspension by moving the vehicle in

a straight line for more than 5 m (16 ft).

4) Suspend a thread from the wheel arch (point “A” in the figure below) and affix at a position directly above

the center of wheel.

5) Measure the distance between the point “A” and the center of wheel.

(1) Wheel arch height (4) Front wheel arch height (7) Point of measurement

(2) Front fender (5) Rear wheel arch height (8) Tip end of spindle

(3) Rear quarter (6) Flange bend line

Wheel arch height specification mm (in) (Tolerance: +12 mm –24 mm ( +0.47 in –0.94 in))

Front 442 (17.4)

Rear 439 (17.3)

A

A

A

(4)

(1)

(2)

(3)

(1)

(5)(1)

(7)

(6)

(8)

FS-00210

Page 856 of 2453

FS-8

Wheel Alignment

FRONT SUSPENSION

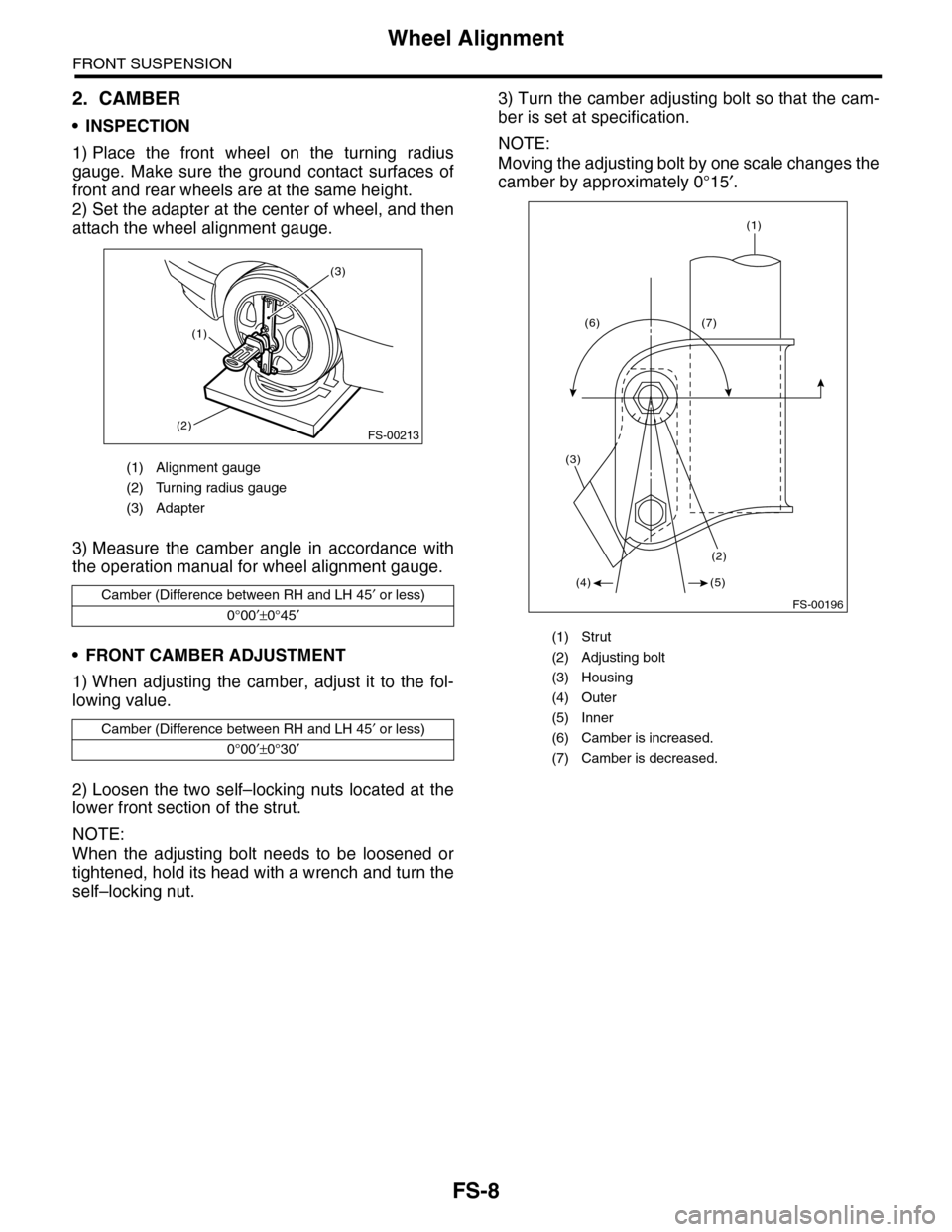

2. CAMBER

•INSPECTION

1) Place the front wheel on the turning radius

gauge. Make sure the ground contact surfaces of

front and rear wheels are at the same height.

2) Set the adapter at the center of wheel, and then

attach the wheel alignment gauge.

3) Measure the camber angle in accordance with

the operation manual for wheel alignment gauge.

•FRONT CAMBER ADJUSTMENT

1) When adjusting the camber, adjust it to the fol-

lowing value.

2) Loosen the two self–locking nuts located at the

lower front section of the strut.

NOTE:

When the adjusting bolt needs to be loosened or

tightened, hold its head with a wrench and turn the

self–locking nut.

3) Turn the camber adjusting bolt so that the cam-

ber is set at specification.

NOTE:

Moving the adjusting bolt by one scale changes the

camber by approximately 0°15′.

(1) Alignment gauge

(2) Turning radius gauge

(3) Adapter

Camber (Difference between RH and LH 45′ or less)

0°00′±0°45′

Camber (Difference between RH and LH 45′ or less)

0°00′±0°30′

FS-00213

(1)

(2)

(3)

(1) Strut

(2) Adjusting bolt

(3) Housing

(4) Outer

(5) Inner

(6) Camber is increased.

(7) Camber is decreased.

(1)

(4)

(6) (7)

(2)

(3)

(5)

FS-00196

Page 857 of 2453

FS-9

Wheel Alignment

FRONT SUSPENSION

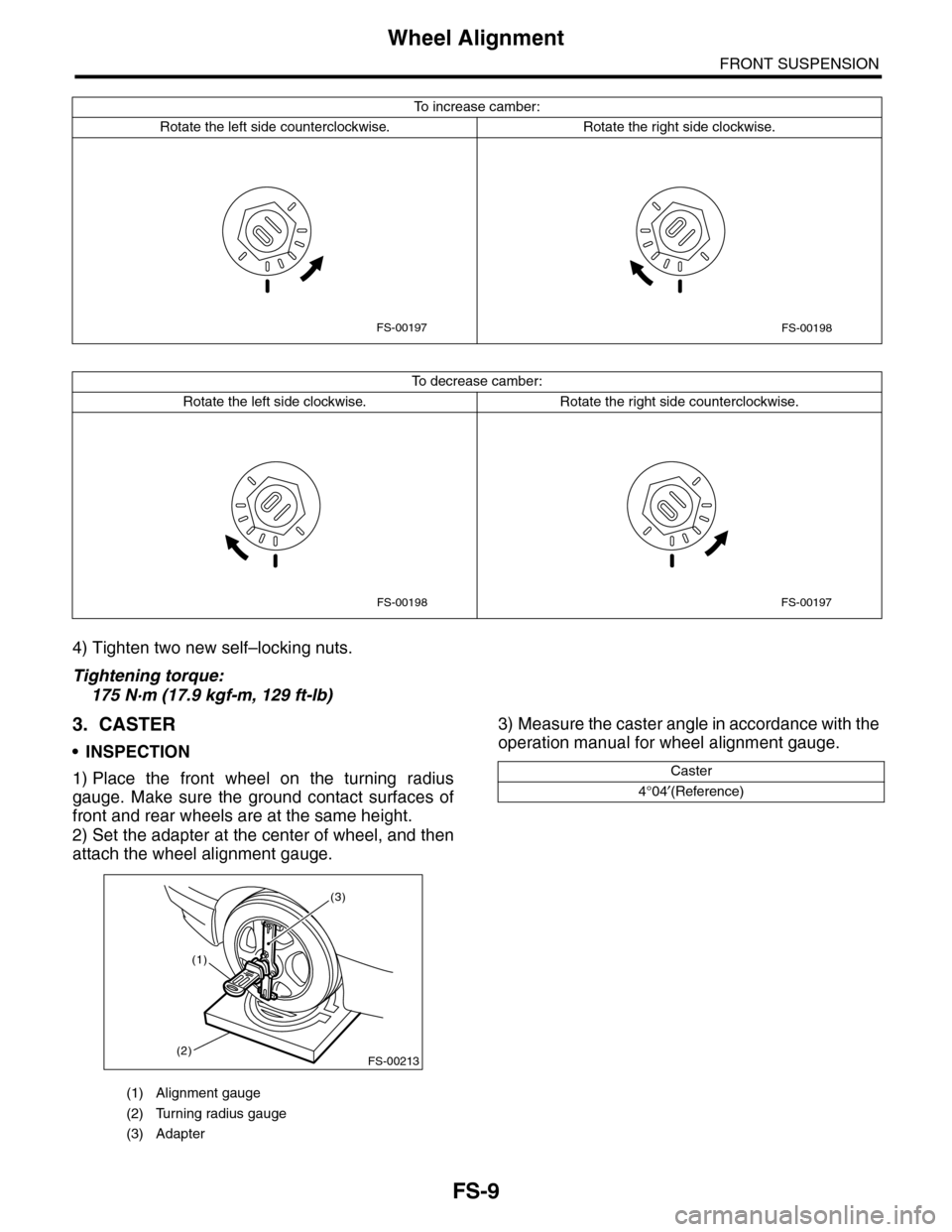

4) Tighten two new self–locking nuts.

Tightening torque:

175 N·m (17.9 kgf-m, 129 ft-lb)

3. CASTER

•INSPECTION

1) Place the front wheel on the turning radius

gauge. Make sure the ground contact surfaces of

front and rear wheels are at the same height.

2) Set the adapter at the center of wheel, and then

attach the wheel alignment gauge.

3) Measure the caster angle in accordance with the

operation manual for wheel alignment gauge.

To i n c r e a s e c a m b e r :

Rotate the left side counterclockwise. Rotate the right side clockwise.

To d e c r e a s e c a m b e r :

Rotate the left side clockwise. Rotate the right side counterclockwise.

FS-00197FS-00198

FS-00198FS-00197

(1) Alignment gauge

(2) Turning radius gauge

(3) Adapter

FS-00213

(1)

(2)

(3)

Caster

4°04′(Reference)

Page 858 of 2453

FS-10

Wheel Alignment

FRONT SUSPENSION

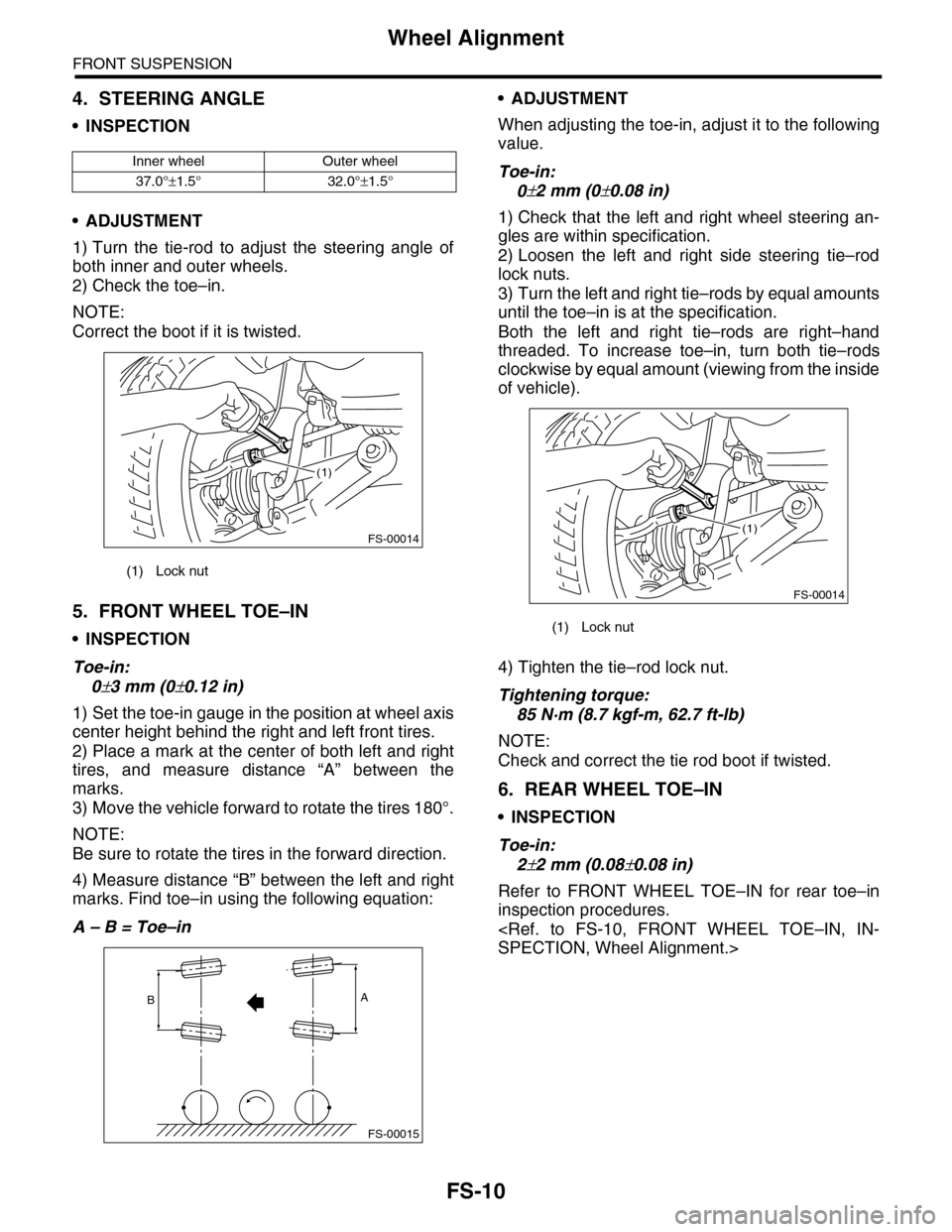

4. STEERING ANGLE

•INSPECTION

•ADJUSTMENT

1) Turn the tie-rod to adjust the steering angle of

both inner and outer wheels.

2) Check the toe–in.

NOTE:

Correct the boot if it is twisted.

5. FRONT WHEEL TOE–IN

•INSPECTION

Toe-in:

0±3 mm (0±0.12 in)

1) Set the toe-in gauge in the position at wheel axis

center height behind the right and left front tires.

2) Place a mark at the center of both left and right

tires, and measure distance “A” between the

marks.

3) Move the vehicle forward to rotate the tires 180°.

NOTE:

Be sure to rotate the tires in the forward direction.

4) Measure distance “B” between the left and right

marks. Find toe–in using the following equation:

A – B = Toe–in

•ADJUSTMENT

When adjusting the toe-in, adjust it to the following

value.

Toe-in:

0±2 mm (0±0.08 in)

1) Check that the left and right wheel steering an-

gles are within specification.

2) Loosen the left and right side steering tie–rod

lock nuts.

3) Turn the left and right tie–rods by equal amounts

until the toe–in is at the specification.

Both the left and right tie–rods are right–hand

threaded. To increase toe–in, turn both tie–rods

clockwise by equal amount (viewing from the inside

of vehicle).

4) Tighten the tie–rod lock nut.

Tightening torque:

85 N·m (8.7 kgf-m, 62.7 ft-lb)

NOTE:

Check and correct the tie rod boot if twisted.

6. REAR WHEEL TOE–IN

•INSPECTION

Toe-in:

2±2 mm (0.08±0.08 in)

Refer to FRONT WHEEL TOE–IN for rear toe–in

inspection procedures.

Inner wheel Outer wheel

37.0°±1.5° 32.0°±1.5°

(1) Lock nut

FS-00014

(1)

FS-00015

AB

(1) Lock nut

FS-00014

(1)

Page 872 of 2453

FS-24

General Diagnostic Table

FRONT SUSPENSION

9. General Diagnostic Table

A: INSPECTION

1. IMPROPER VEHICLE POSTURE OR IMPROPER WHEEL ARCH HEIGHT

2. POOR RIDE COMFORT

1) Large rebound shock

2) Rocking of the vehicle continues too long after running over bump and hump.

3) Excessive shock in bumping

3. NOISE

Po ss ibl e c a us e C o r r e ct ive ac ti o n

(1) Permanent distortion or damage of the coil spring Replace.

(2) Rough operation of damper strut or shock absorber Replace.

(3) Improper installation of strut or shock absorber Replace with appropriate parts.

(4) Installation of the wrong coil spring Replace with appropriate parts.

Po ss ibl e ca us e C or r e ct i ve a ct io n

(1) Damaged coil spring Replace.

(2) Overinflation of tires Adjust.

(3) Improper wheel arch height Adjust or replace the coil springs with new ones.

(4) Fault in operation of damper strut or shock absorber Replace.

(5) Damage or deformation of strut mount or shock absorber mount Replace.

(6) Unsuitable length (maximum or minimum) of damper strut or shock

absorber

Replace with appropriate parts.

(7) Deformation or loss of bushing Replace.

(8) Deformation or damage of helper in strut assembly or shock absorber Replace.

(9) Oil leakage from the damper strut or shock absorber Replace.

Po ss ibl e c a us e C o r r e ct ive ac ti o n

(1) Wear or damage of damper strut or shock absorber component parts Replace.

(2) Loosening of the suspension link installing bolt Tighten to the specified torque.

(3) Deformation or loss of bushing Replace.

(4) Unsuitable length (maximum or minimum) of damper strut or shock

absorber

Replace with appropriate parts.

(5) Damaged coil spring Replace.

(6) Wear or damage of the ball joint Replace.

(7) Deformation of the stabilizer clamp Replace.