Combination meter SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 445 of 2453

IDI-6

Combination Meter System

INSTRUMENTATION/DRIVER INFO

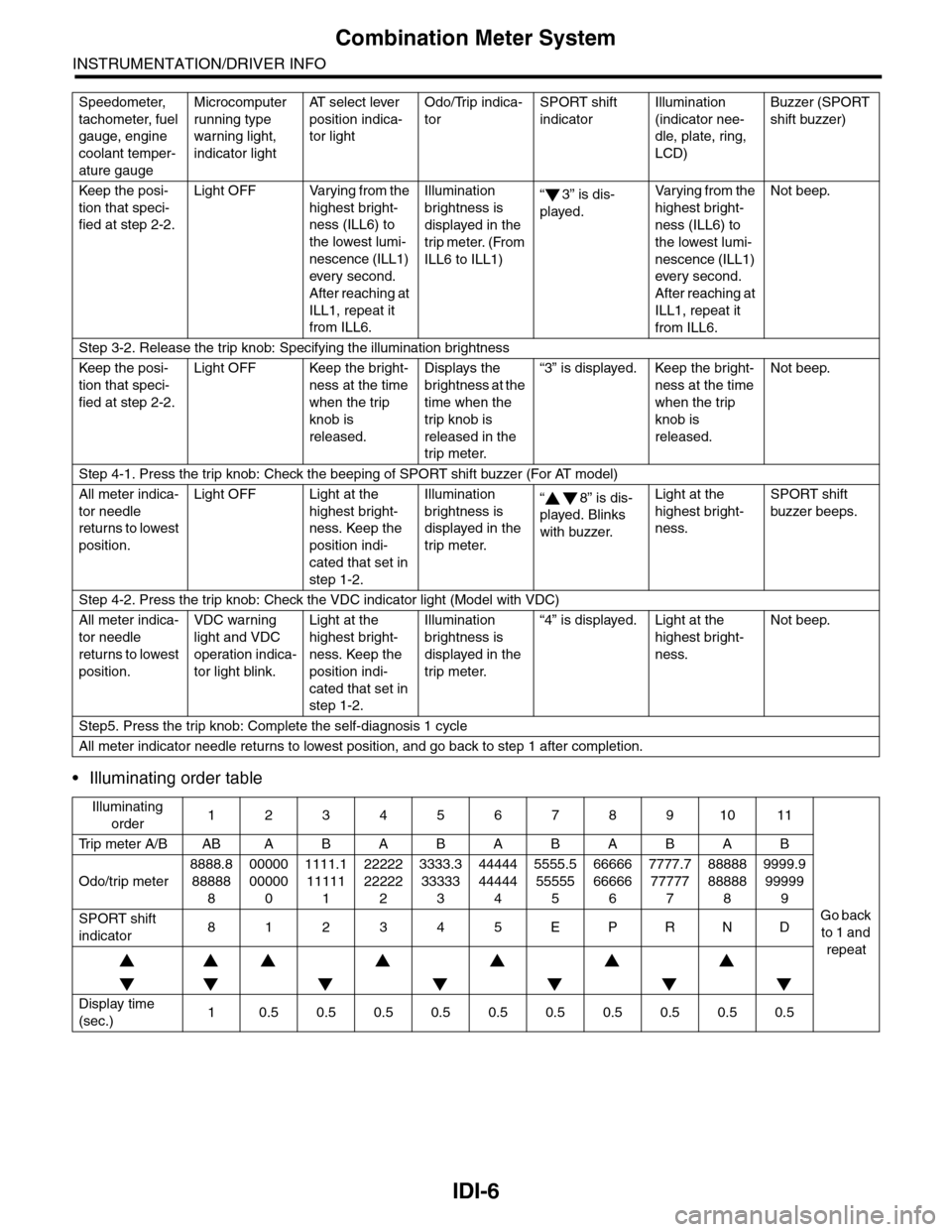

•Illuminating order table

Keep the posi-

tion that speci-

fied at step 2-2.

Light OFF Varying from the

highest bright-

ness (ILL6) to

the lowest lumi-

nescence (ILL1)

ever y second.

After reaching at

ILL1, repeat it

from ILL6.

Illumination

brightness is

displayed in the

trip meter. (From

ILL6 to ILL1)

“3” is dis-

played.

Va r y i n g f r o m t h e

highest bright-

ness (ILL6) to

the lowest lumi-

nescence (ILL1)

every second.

After reaching at

ILL1, repeat it

from ILL6.

Not beep.

Step 3-2. Release the trip knob: Specifying the illumination brightness

Keep the posi-

tion that speci-

fied at step 2-2.

Light OFF Keep the bright-

ness at the time

when the trip

knob is

released.

Displays the

brightness at the

time when the

trip knob is

released in the

trip meter.

“3” is displayed. Keep the bright-

ness at the time

when the trip

knob is

released.

Not beep.

Step 4-1. Press the trip knob: Check the beeping of SPORT shift buzzer (For AT model)

All meter indica-

tor needle

returns to lowest

position.

Light OFF Light at the

highest bright-

ness. Keep the

position indi-

cated that set in

step 1-2.

Illumination

brightness is

displayed in the

trip meter.

“8” is dis-

played. Blinks

with buzzer.

Light at the

highest bright-

ness.

SPORT shift

buzzer beeps.

Step 4-2. Press the trip knob: Check the VDC indicator light (Model with VDC)

All meter indica-

tor needle

returns to lowest

position.

VDC warning

light and VDC

operation indica-

tor light blink.

Light at the

highest bright-

ness. Keep the

position indi-

cated that set in

step 1-2.

Illumination

brightness is

displayed in the

trip meter.

“4” is displayed. Light at the

highest bright-

ness.

Not beep.

Step5. Press the trip knob: Complete the self-diagnosis 1 cycle

All meter indicator needle returns to lowest position, and go back to step 1 after completion.

Illuminating

order1234567891011

Tr i p m e t e r A / B A B A B A B A B A B A B

Go back

to 1 and

repeat

Odo/trip meter

8888.8

88888

8

00000

00000

0

1111.1

11111

1

22222

22222

2

3333.3

33333

3

44444

44444

4

5555.5

55555

5

66666

66666

6

7777.7

77777

7

88888

88888

8

9999.9

99999

9

SPORT shift

indicator812345EPRND

Display time

(sec.)10.50.50.50.50.50.50.50.50.50.5

Speedometer,

tachometer, fuel

gauge, engine

coolant temper-

ature gauge

Microcomputer

running type

warning light,

indicator light

AT s e l e c t l e v e r

position indica-

tor light

Odo/Trip indica-

tor

SPORT shift

indicator

Illumination

(indicator nee-

dle, plate, ring,

LCD)

Buzzer (SPORT

shift buzzer)

Page 446 of 2453

IDI-7

Combination Meter System

INSTRUMENTATION/DRIVER INFO

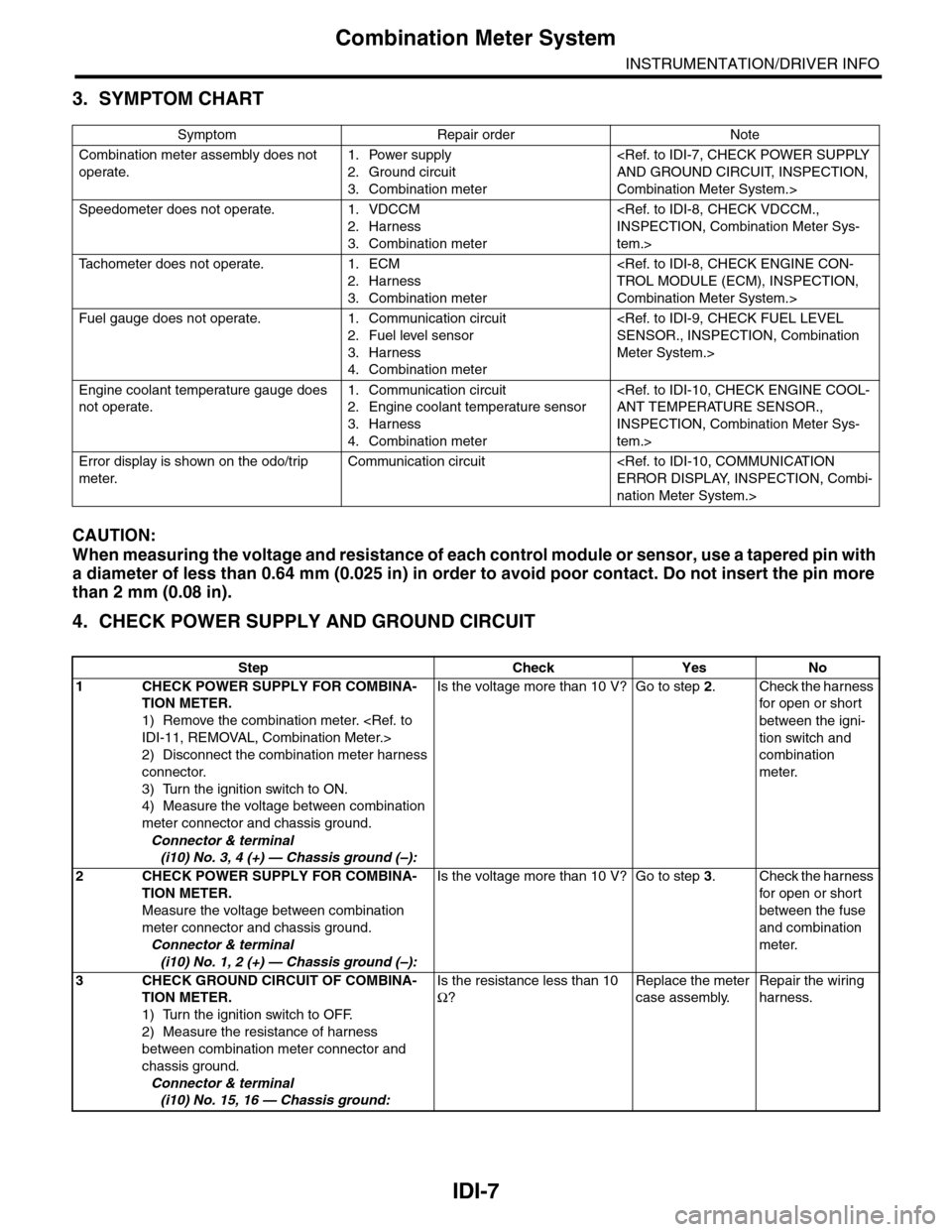

3. SYMPTOM CHART

CAUTION:

When measuring the voltage and resistance of each control module or sensor, use a tapered pin with

a diameter of less than 0.64 mm (0.025 in) in order to avoid poor contact. Do not insert the pin more

than 2 mm (0.08 in).

4. CHECK POWER SUPPLY AND GROUND CIRCUIT

Symptom Repair order Note

Combination meter assembly does not

operate.

1. Power supply

2. Ground circuit

3. Combination meter

Combination Meter System.>

Speedometer does not operate. 1. VDCCM

2. Harness

3. Combination meter

tem.>

Ta c h o m e t e r d o e s n o t o p e r a t e . 1 . E C M

2. Harness

3. Combination meter

Combination Meter System.>

Fuel gauge does not operate. 1. Communication circuit

2. Fuel level sensor

3. Harness

4. Combination meter

Meter System.>

Engine coolant temperature gauge does

not operate.

1. Communication circuit

2. Engine coolant temperature sensor

3. Harness

4. Combination meter

INSPECTION, Combination Meter Sys-

tem.>

Error display is shown on the odo/trip

meter.

Communication circuit

nation Meter System.>

Step Check Yes No

1CHECK POWER SUPPLY FOR COMBINA-

TION METER.

1) Remove the combination meter.

2) Disconnect the combination meter harness

connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 3, 4 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Check the harness

for open or shor t

between the igni-

tion switch and

combination

meter.

2CHECK POWER SUPPLY FOR COMBINA-

TION METER.

Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 1, 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.Check the harness

for open or shor t

between the fuse

and combination

meter.

3CHECK GROUND CIRCUIT OF COMBINA-

TION METER.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between combination meter connector and

chassis ground.

Connector & terminal

(i10) No. 15, 16 — Chassis ground:

Is the resistance less than 10

Ω?

Replace the meter

case assembly.

Repair the wiring

harness.

Page 447 of 2453

IDI-8

Combination Meter System

INSTRUMENTATION/DRIVER INFO

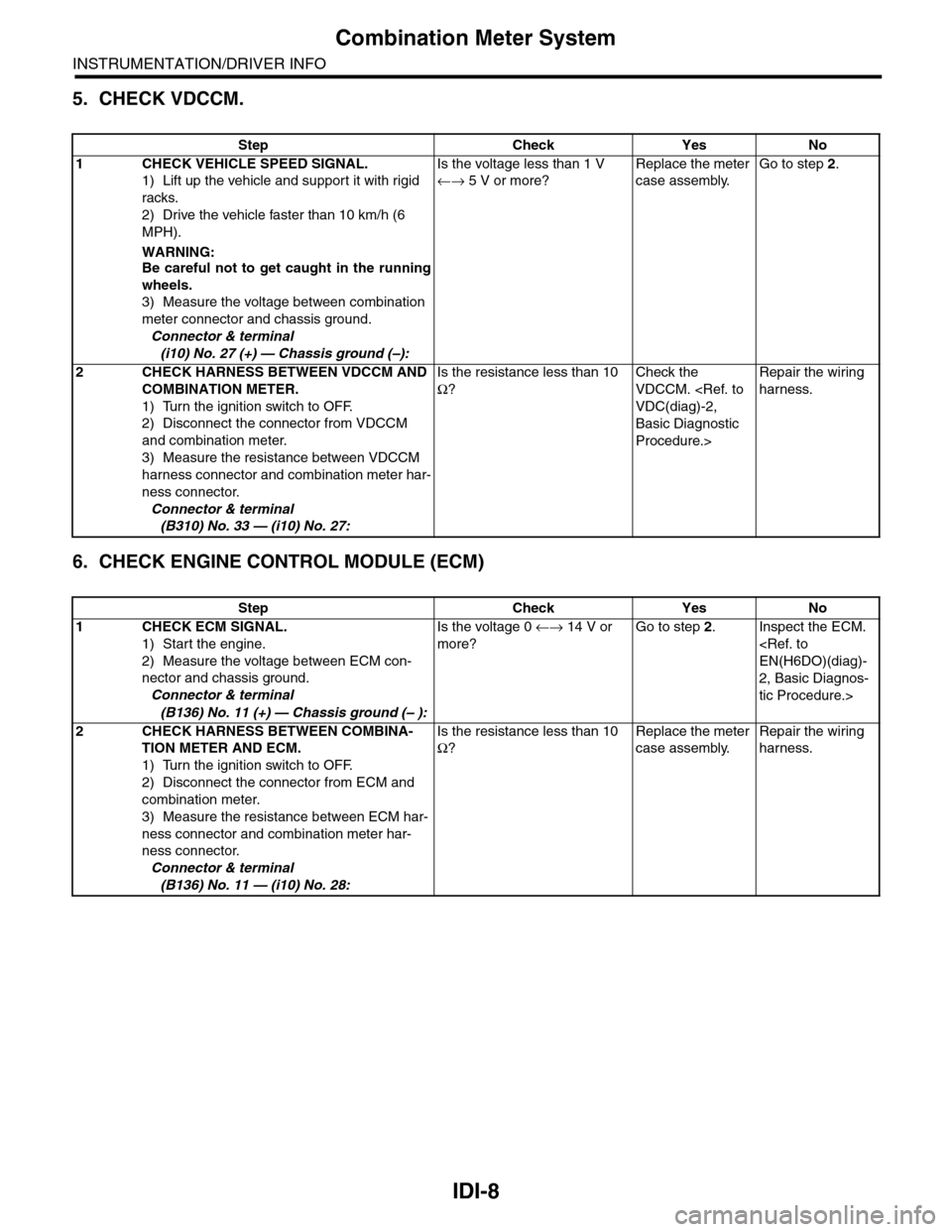

5. CHECK VDCCM.

6. CHECK ENGINE CONTROL MODULE (ECM)

Step Check Yes No

1CHECK VEHICLE SPEED SIGNAL.

1) Lift up the vehicle and support it with rigid

racks.

2) Drive the vehicle faster than 10 km/h (6

MPH).

WARNING:Be careful not to get caught in the running

wheels.

3) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 27 (+) — Chassis ground (–):

Is the voltage less than 1 V

←→ 5 V or more?

Replace the meter

case assembly.

Go to step 2.

2CHECK HARNESS BETWEEN VDCCM AND

COMBINATION METER.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from VDCCM

and combination meter.

3) Measure the resistance between VDCCM

harness connector and combination meter har-

ness connector.

Connector & terminal

(B310) No. 33 — (i10) No. 27:

Is the resistance less than 10

Ω?

Check the

VDCCM.

Basic Diagnostic

Procedure.>

Repair the wiring

harness.

Step Check Yes No

1CHECK ECM SIGNAL.

1) Start the engine.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 11 (+) — Chassis ground (– ):

Is the voltage 0 ←→ 14 V or

more?

Go to step 2.Inspect the ECM.

2, Basic Diagnos-

tic Procedure.>

2CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

combination meter.

3) Measure the resistance between ECM har-

ness connector and combination meter har-

ness connector.

Connector & terminal

(B136) No. 11 — (i10) No. 28:

Is the resistance less than 10

Ω?

Replace the meter

case assembly.

Repair the wiring

harness.

Page 448 of 2453

IDI-9

Combination Meter System

INSTRUMENTATION/DRIVER INFO

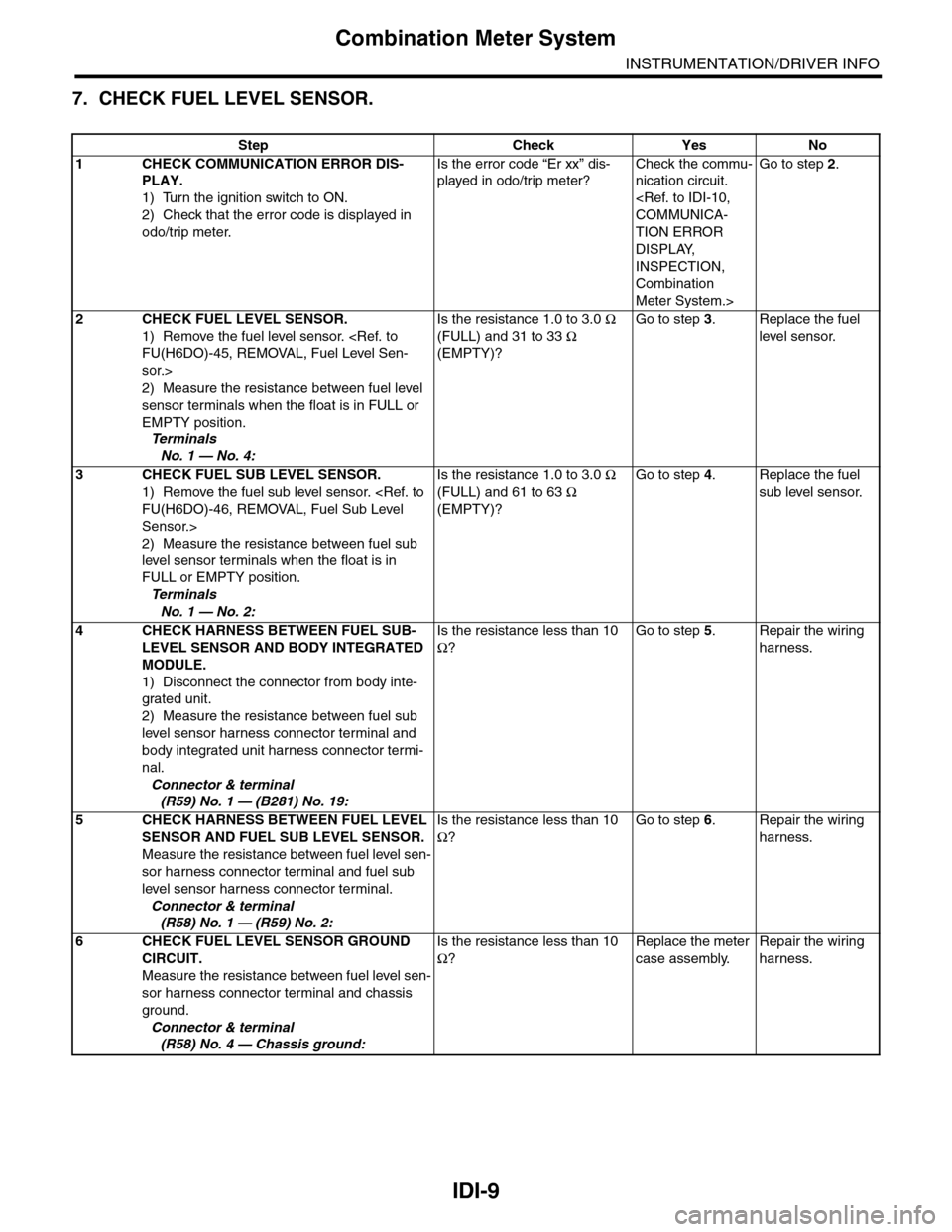

7. CHECK FUEL LEVEL SENSOR.

Step Check Yes No

1CHECK COMMUNICATION ERROR DIS-

PLAY.

1) Turn the ignition switch to ON.

2) Check that the error code is displayed in

odo/trip meter.

Is the error code “Er xx” dis-

played in odo/trip meter?

Check the commu-

nication circuit.

TION ERROR

DISPLAY,

INSPECTION,

Combination

Meter System.>

Go to step 2.

2CHECK FUEL LEVEL SENSOR.

1) Remove the fuel level sensor.

sor.>

2) Measure the resistance between fuel level

sensor terminals when the float is in FULL or

EMPTY position.

Te r m i n a l s

No. 1 — No. 4:

Is the resistance 1.0 to 3.0 Ω

(FULL) and 31 to 33 Ω

(EMPTY)?

Go to step 3.Replace the fuel

level sensor.

3CHECK FUEL SUB LEVEL SENSOR.

1) Remove the fuel sub level sensor.

Sensor.>

2) Measure the resistance between fuel sub

level sensor terminals when the float is in

FULL or EMPTY position.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance 1.0 to 3.0 Ω

(FULL) and 61 to 63 Ω

(EMPTY)?

Go to step 4.Replace the fuel

sub level sensor.

4CHECK HARNESS BETWEEN FUEL SUB-

LEVEL SENSOR AND BODY INTEGRATED

MODULE.

1) Disconnect the connector from body inte-

grated unit.

2) Measure the resistance between fuel sub

level sensor harness connector terminal and

body integrated unit harness connector termi-

nal.

Connector & terminal

(R59) No. 1 — (B281) No. 19:

Is the resistance less than 10

Ω?

Go to step 5.Repair the wiring

harness.

5CHECK HARNESS BETWEEN FUEL LEVEL

SENSOR AND FUEL SUB LEVEL SENSOR.

Measure the resistance between fuel level sen-

sor harness connector terminal and fuel sub

level sensor harness connector terminal.

Connector & terminal

(R58) No. 1 — (R59) No. 2:

Is the resistance less than 10

Ω?

Go to step 6.Repair the wiring

harness.

6CHECK FUEL LEVEL SENSOR GROUND

CIRCUIT.

Measure the resistance between fuel level sen-

sor harness connector terminal and chassis

ground.

Connector & terminal

(R58) No. 4 — Chassis ground:

Is the resistance less than 10

Ω?

Replace the meter

case assembly.

Repair the wiring

harness.

Page 449 of 2453

IDI-10

Combination Meter System

INSTRUMENTATION/DRIVER INFO

8. CHECK ENGINE COOLANT TEMPERATURE SENSOR.

9. COMMUNICATION ERROR DISPLAY

When the following error code is displayed in the

odo/trip meter, inspect the communication circuit

since the communication malfunction is generated

between each control module.

10.DTC DISPLAY MODE

When DTC display mode is operated, {ECM}, {TCM} is displayed repeatedly in this order by pressing the trip

knob. DTC is displayed in the following table according to type of control module, receiving DTC, DTC de-

tected, No DTC. If CAN communication has some trouble, “-----” is displayed.

Step Check Yes No

1CHECK COMMUNICATION ERROR DIS-

PLAY.

1) Turn the ignition switch to ON.

2) Check that the error code is displayed in

odo/trip meter.

Is the error code “Er xx” dis-

played in odo/trip meter?

Check the commu-

nication circuit.

TION ERROR

DISPLAY,

INSPECTION,

Combination

Meter System.>

Go to step 2.

2CHECK ENGINE COOLANT TEMPERATURE

SENSOR.

Check the engine coolant temperature sensor.

Is the engine coolant tempera-

ture sensor OK?

Replace the meter

case assembly.

Replace the

engine coolant

temperature sen-

sor.

IDI00188

Error code Description

Er IUMalfunction in integrated

module

Er ––

Simultaneous malfunction of

high/low speed CAN com-

munication

Er HCHigh speed CAN communi-

cation malfunction

Er LCMalfunction of low-speed

CAN communication

Er EGEGI Communication mal-

function

Er TCTCM Communication mal-

function

Er AbVDCCM communication

malfunction

Er SP

VDCCM DTC information

and vehicle speed pulse

malfunction

Er SSWheel speed data malfunc-

tion

Er bbVa c u u m p u m p s y s t e m m a l -

function

Control module Condition Display

ECM

Receiving DTC Trip “A” + “P (Blink)”

DTC detected Trip “A” + “P xxxx”

No DTC Trip “A” + “P ----”

TCM

Receiving DTC Trip “B” + “P (Blink)”

DTC detected Trip “B” + “P xxxx”

No DTC Trip “B” + “P ----”

When CAN communication error

is occurred—“-----”

Page 450 of 2453

IDI-11

Combination Meter

INSTRUMENTATION/DRIVER INFO

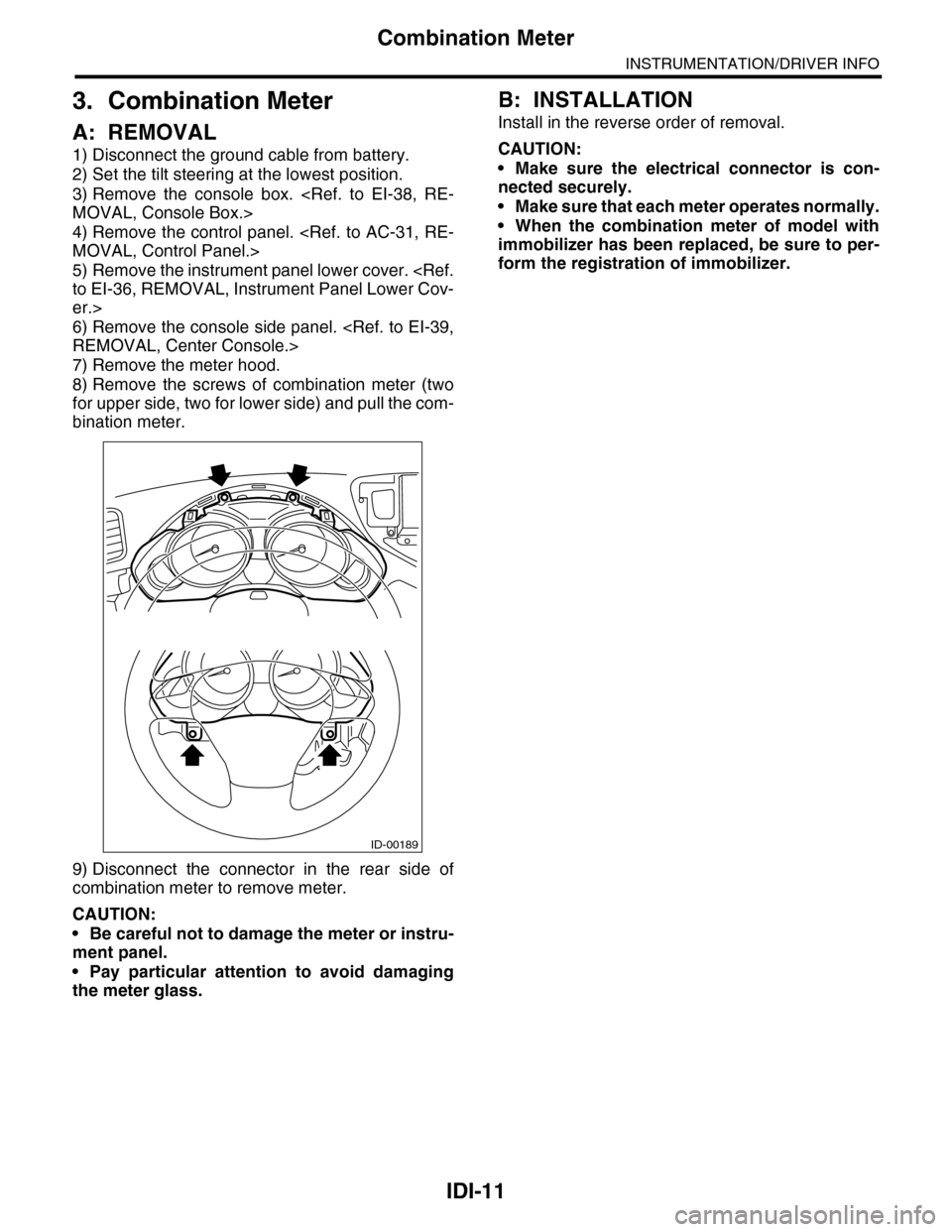

3. Combination Meter

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Set the tilt steering at the lowest position.

3) Remove the console box.

4) Remove the control panel.

5) Remove the instrument panel lower cover.

er.>

6) Remove the console side panel.

7) Remove the meter hood.

8) Remove the screws of combination meter (two

for upper side, two for lower side) and pull the com-

bination meter.

9) Disconnect the connector in the rear side of

combination meter to remove meter.

CAUTION:

•Be careful not to damage the meter or instru-

ment panel.

•Pay particular attention to avoid damaging

the meter glass.

B: INSTALLATION

Install in the reverse order of removal.

CAUTION:

•Make sure the electrical connector is con-

nected securely.

•Make sure that each meter operates normally.

•When the combination meter of model with

immobilizer has been replaced, be sure to per-

form the registration of immobilizer.

ID-00189

Page 451 of 2453

IDI-12

Combination Meter

INSTRUMENTATION/DRIVER INFO

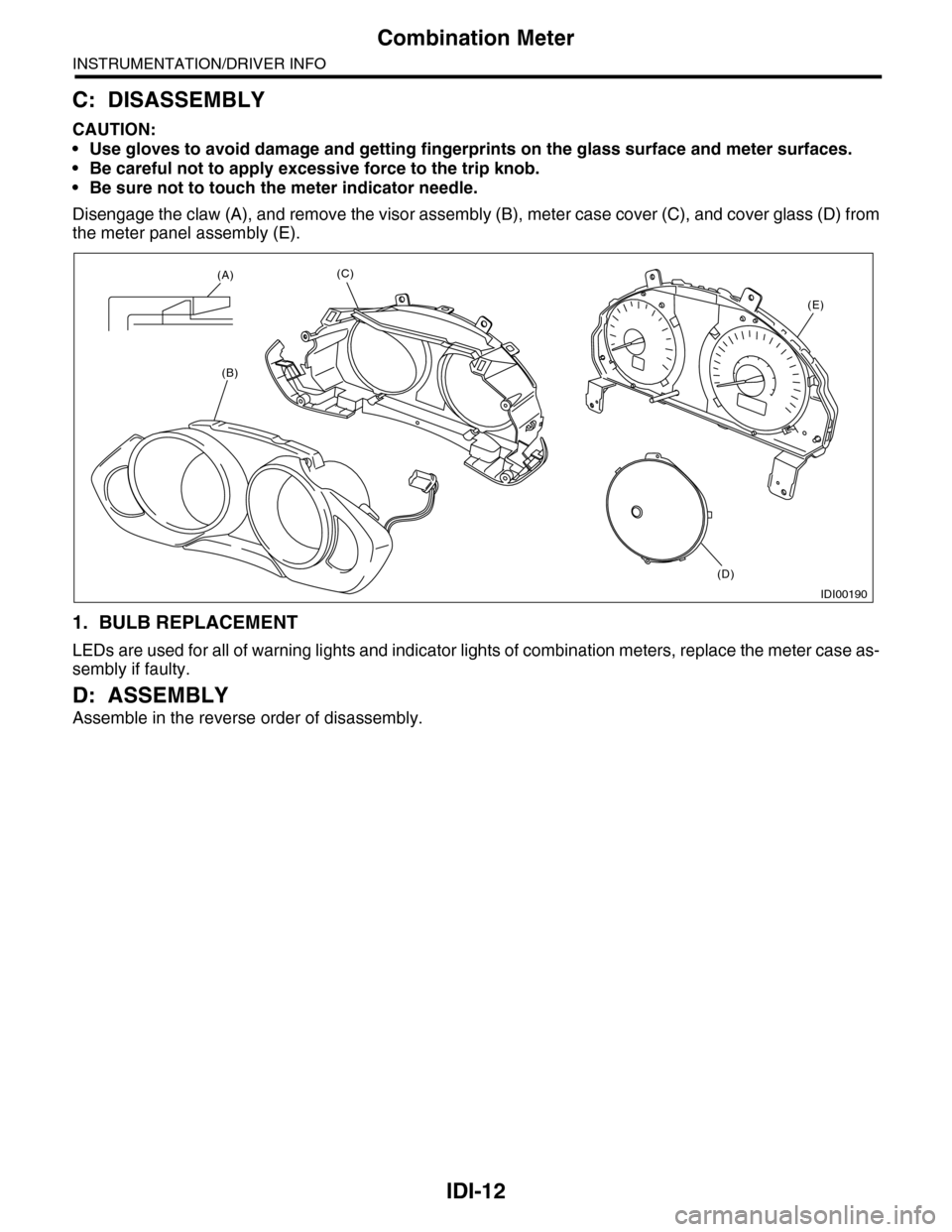

C: DISASSEMBLY

CAUTION:

•Use gloves to avoid damage and getting fingerprints on the glass surface and meter surfaces.

•Be careful not to apply excessive force to the trip knob.

•Be sure not to touch the meter indicator needle.

Disengage the claw (A), and remove the visor assembly (B), meter case cover (C), and cover glass (D) from

the meter panel assembly (E).

1. BULB REPLACEMENT

LEDs are used for all of warning lights and indicator lights of combination meters, replace the meter case as-

sembly if faulty.

D: ASSEMBLY

Assemble in the reverse order of disassembly.

IDI00190

(A)

(B)

(C)

(D)

(E)

Page 458 of 2453

LAN(diag)-2

Basic Diagnostic Procedure

LAN SYSTEM (DIAGNOSTICS)

1. Basic Diagnostic Procedure

A: PROCEDURE

1. WITH SUBARU SELECT MONITOR

CAUTION:

•Subaru Select Monitor is required for reading DTC, performing diagnosis and reading current data.

•Remove foreign matter (dust, water, oil, etc.) from the body integrated unit connector during re-

moval and installation.

•For model with immobilizer, registration of immobilizer may be needed after the replacement of

controller etc. For detailed procedure, refer to the REGISTRATION MANUAL FOR IMMOBILIZER.

NOTE:

•To check harness for broken wires or short circuits, shake trouble spot or connector.

•Check List for Interview.

Step Check Yes No

1CHECK PRE-INSPECTION.

1) Ask the customer when and how the trou-

ble occurred using interview check list.

2) Check the display of communication error

display. (Combination meter, odo/trip meter)

Is the communication error dis-

played?

Go to step 3.Go to step 2.

2BASIC INSPECTION

Check the components which might affect

body control.

Is the component that might

influence the body control

problem normal?

Go to step 3.Repair or replace

each component.

3CHECK INDICATION OF DTC.

1) Read DTC of all systems.

CODE (DTC), OPERATION, Subaru Select

Monitor.>

NOTE:•The LAN system is for the overall vehicle, so

read the DTC of all systems.

•If the communication function of the Subaru

Select Monitor cannot be executed normally,

check the communication circuit.

TIALIZING IMPOSSIBLE, Diagnostic Proce-

dure with Diagnostic Trouble Code (DTC).>

2) Record all DTC.

Is a DTC other than CAN com-

munication displayed in the

output code?

ECU: P0600 TCU: P1718 VDC

CU: C0047 or C0057, etc.

Refer to the DTC

related table.

FUNCTION

CHECK, DTC

TA B L E , L i s t o f

Diagnostic Trou-

ble Code (DTC).>

Go to step 5.

Go to step 4.

4PERFORM GENERAL DIAGNOSTICS.

Inspect using “General Diagnostics Table”.

Is result of inspection OK? LAN system is nor-

mal.

Go to step 5.

5PERFORM DIAGNOSIS.

1) Correct the cause of trouble.

2) Perform the clear memory mode.

OPERATION, Subaru Select Monitor.>

3) Read the DTC.

OPERATION, Subaru Select Monitor.>

Is DTC displayed? Repeat step 5 until

DTC is not shown.

Finish the diagno-

sis.

Page 459 of 2453

LAN(diag)-3

Check List for Interview

LAN SYSTEM (DIAGNOSTICS)

2. Check List for Interview

A: CHECK

Inspect the following item about the vehicle’s state.

1. DISPLAY OF COMMUNICATION ERROR

2. DISPLAY IN COMBINATION METER

Communication error is

displayed in odo/trip meter.

When and how often are they displayed?

Always

Sometimes

Only once

Which communication error is displayed? (Record them all)

Er IU (Fail in the body integrated unit)

Er HC (Fail of high-speed CAN)

Er LC (Fail of low-speed CAN)

Er –– (Fails of both high-speed and low-speed CAN)

Er EG (Fail of EGI communication data)

Er TC (fail of TCM communication data)

Er Ab (Fail of vehicle dynamics control (VDC)/ABS communication data)

Er bb (Fail of brake vacuum system)

Ignition key position OFF

ACC

ON (Before starting engine)

START

ON (After starting Engine, engine is running)

ON (After starting Engine, engine is at a standstill)

Timing Immediately after turning the ignition to ON.

Immediately after turning the ignition to START.

Display in combination

meter

a) Display of engine coolant temperature gauge OK / NG

b) Display of fuel gauge OK / NG

Display of other indicators c) Malfunction indicator light ON / OFF

d) SPORT indicator light (AT warning light) ON / OFF

e) ABS warning light/Vehicle dynamics control (VDC) warning

light ON / OFF

f) Security indicator light ON / Blink / OFF

g) Seat belt warning light (Driver’s seat) ON / OFF

h) Seat belt warning light (Passenger’s seat) ON / OFF

Page 463 of 2453

LAN(diag)-7

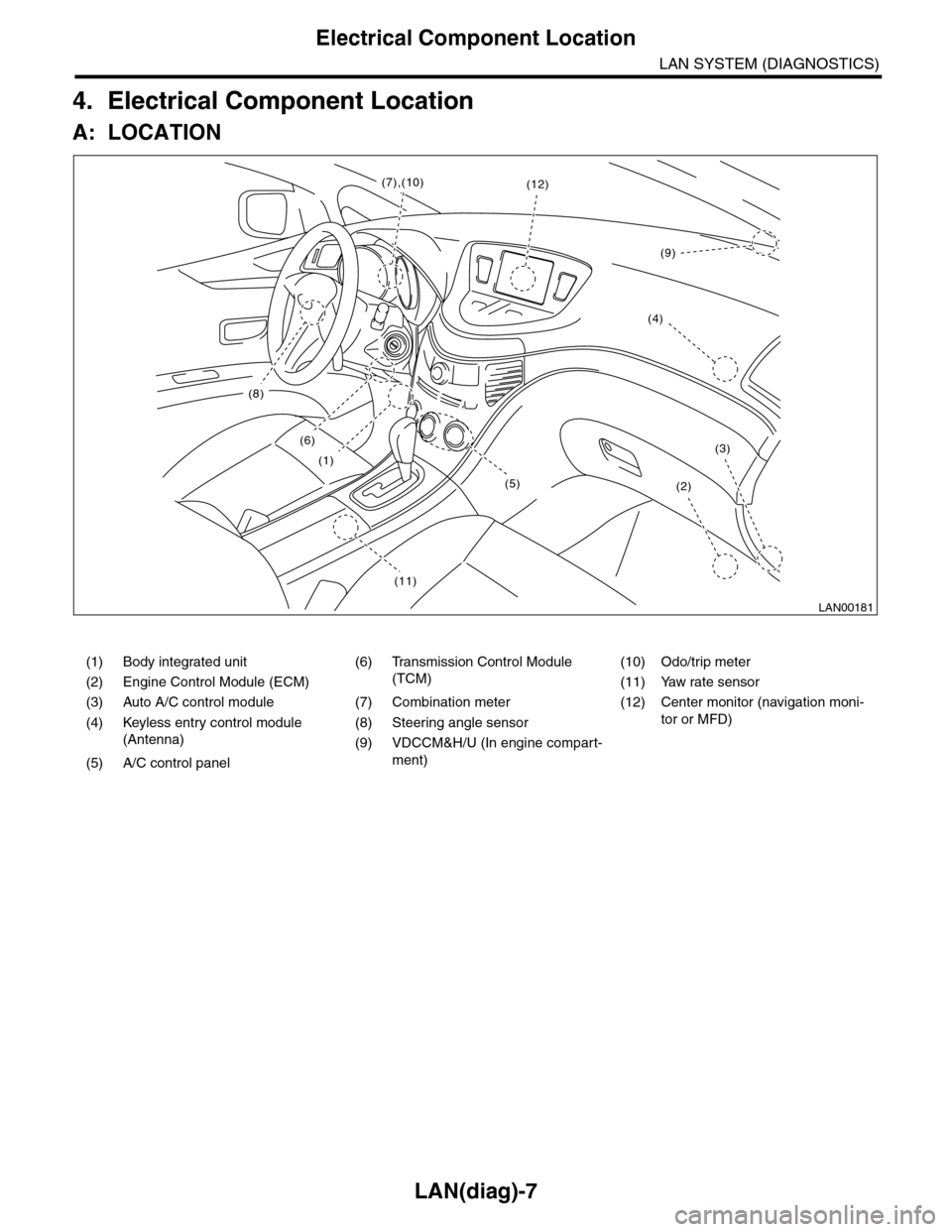

Electrical Component Location

LAN SYSTEM (DIAGNOSTICS)

4. Electrical Component Location

A: LOCATION

(1) Body integrated unit (6) Transmission Control Module

(TCM)

(10) Odo/trip meter

(2) Engine Control Module (ECM) (11) Yaw rate sensor

(3) Auto A/C control module (7) Combination meter (12) Center monitor (navigation moni-

tor or MFD)(4) Keyless entry control module

(Antenna)

(8) Steering angle sensor

(9) VDCCM&H/U (In engine compart-

ment)(5) A/C control panel

LAN00181

(8)

(6)

(1)

(11)

(2)

(3)

(12)(7),(10)

(4)

(9)

(5)